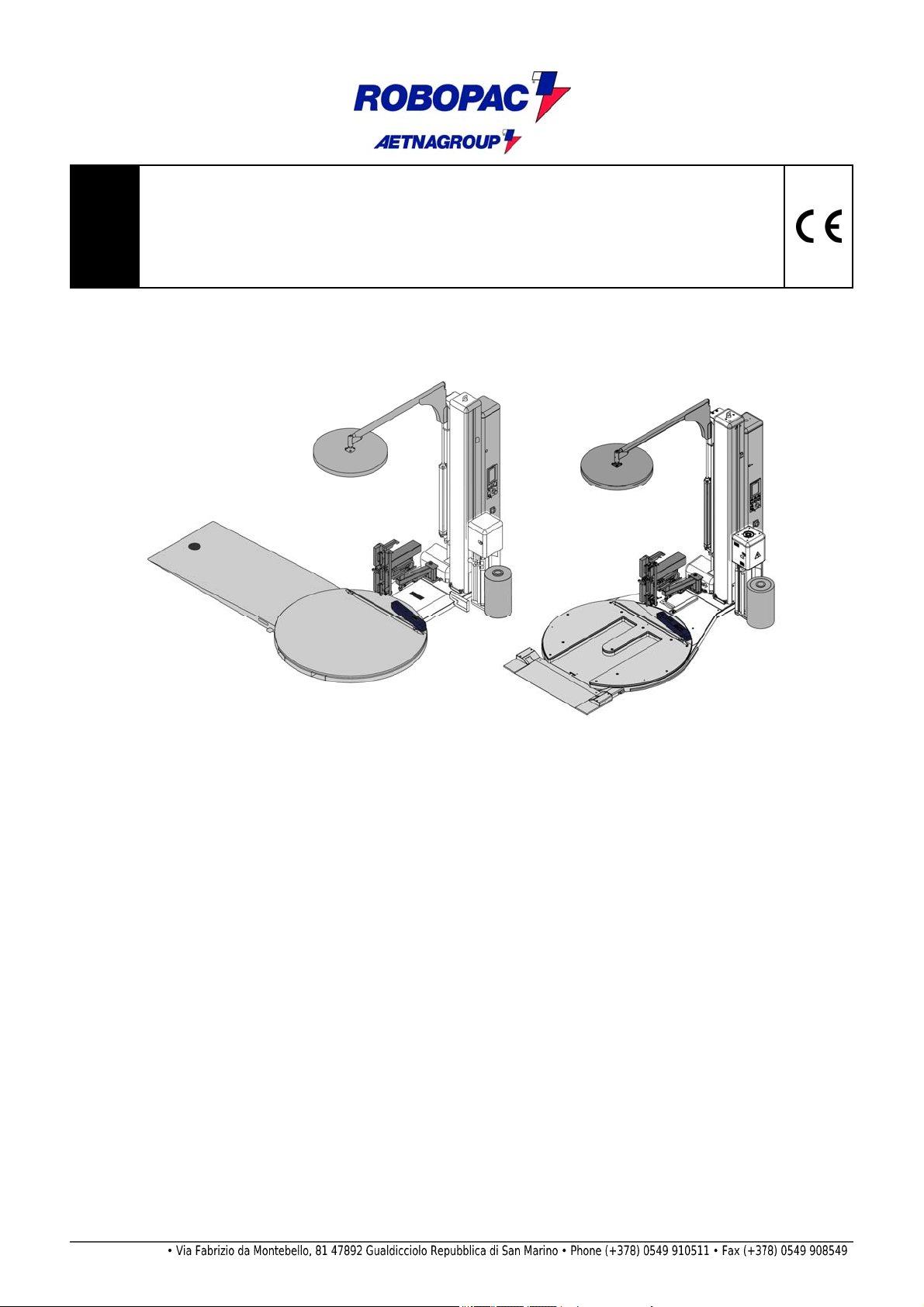

TECHNOPLAT CS/CW

TECHNOPLAT CS/CW TP

2.4.1.INCORRECT USE THAT CAN BE REASONABLY EXPECTED

‒The predictable incorrect use consists of: “the use of the machine different from the indications given in

the manual, that may stem from the easily predictable human behaviour”.

he machine must be used ONLY for wrapping and stabilising products with regular shap

or with a shape that ensure a stable wrapping.

he packs that contain liquids or insubstantial materials must be suitable for the produc

and must be perfectly closed and tight in order to prevent any leaks of the content.

DO NOT wrap or palletize products in packaging (boxes, containers for liquids, etc…) with an irregular

form or one that does NOT guarantee their stability.

‒The machine must be used ONLY for the uses intended by the manufacturer.

‒DO NOT allow the machine to be used by operators that are not properly trained, informed and

unauthorised.

‒Packages that contain liquid or inconsistent products must ensure that they do not leak.

‒DO NOT wrap products that are loose, that have an irregular shape or that are not suitably collected, to

prevent inadequate palletisation.

‒Do not use the machine to wrap and stabilise living beings (animals and humans).

‒DO NOT use the machine with wrapping material different from that provided by the manufacturer.

‒Do not use the machine as a lifting device or as a rest surface for work activities (for example, a

workbench).

‒Do not over stretch or pre-stretch the film and do not wrap with an excessive number of bindings in

order to prevent damaging the packages and products contained inside.

‒DO NOT use or let the machine be used for purposes or in ways not provided by the manufacturer.

‒DO NOT use or make use of machines with defective, deactivated and/or not perfectly installed safety

devices.

‒DO NOT continue to use the machine if malfunctions have been detected.

Stop the machine immediately and restart it only after the normal conditions of use have been restored.

‒NEVER carry out an intervention with the machine enabled but ONLY after having stopped it properly,

under safety conditions.

‒NEVER use the machine without wearing the Personal Protective Devices indicated by the manufacturer

and required by current workplace laws.

‒NEVER use the machine if the scheduled maintenance interventions have not been carried out

accordingly.

‒DO NOT clean or wash the machine with aggressive products to avoid damaging the components.

‒DO NOT replace the components with non-original spare parts or with different design and constructive

features.

‒DO NOT leave the machine unattended at the end of the work without shutting it down first in safety

conditions.

2.4.2.EMPLOYER OBLIGATIONS

‒The operator must be trained to acquire the skills required for the packaging machine or an equivalent

machine.

Upon completion of training, make sure the operator has understood the contents in the use manual,

especially the information regarding safety.

‒The operator must possess the required training and meet the suitable conditions for carrying out the

activities in safety conditions.

‒The employer must inform the operator on the INCORRECT USES predictable and on the persistent

Residual risks

‒The operator must be capable of reading and understanding the user manual and must easily identify

the safety signs.

‒Make sure the machine is ONLY used by adequately trained, documented and authorized operators.

The employer must draw up the documentation of the specific training carried out by the operators in

order to exhibit it in case of litigation.