R05.1 12/02/2020 Page 3

Table of contents

1Safety instructions ................................................................................................. 4

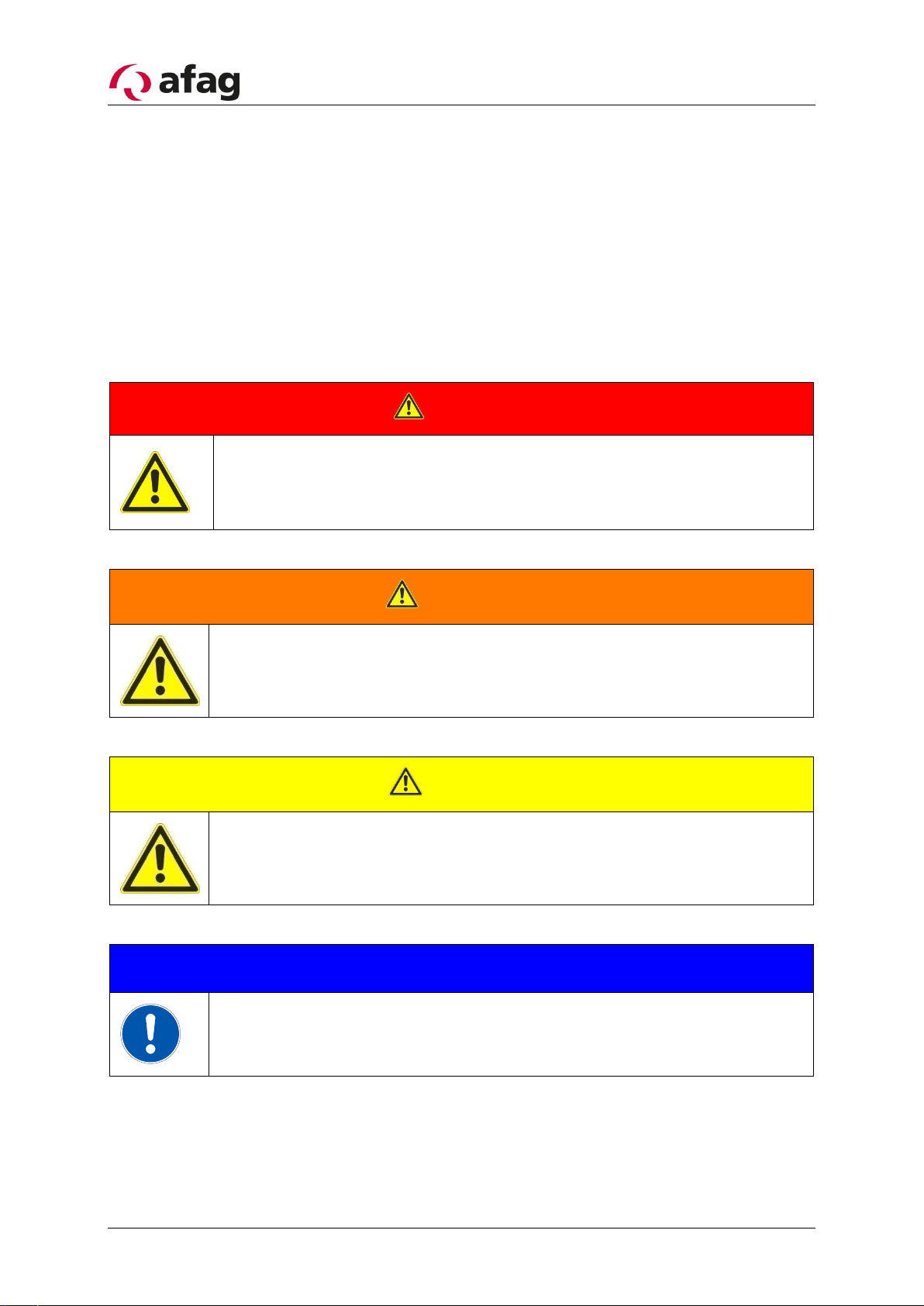

1.1 Explanation of symbols and notes ............................................................................................................ 4

1.2 Basic safety information ........................................................................................................................... 5

1.3 Intended use ............................................................................................................................................. 5

1.4 Notes for Pacemakers and Defibrillators .................................................................................................. 5

2Description of the LF linear feeder........................................................................ 6

2.1 General ..................................................................................................................................................... 6

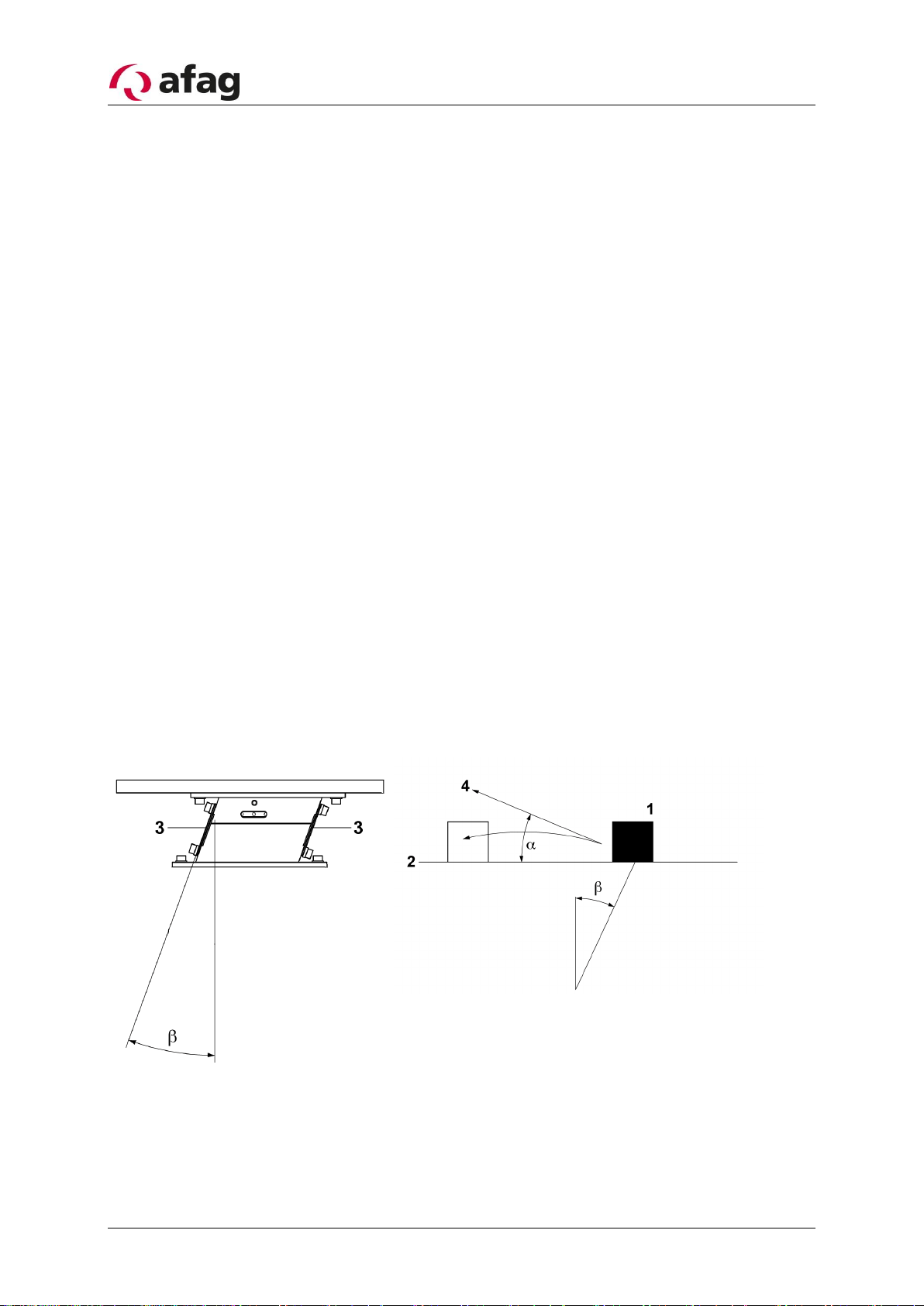

2.2 Functional description............................................................................................................................... 6

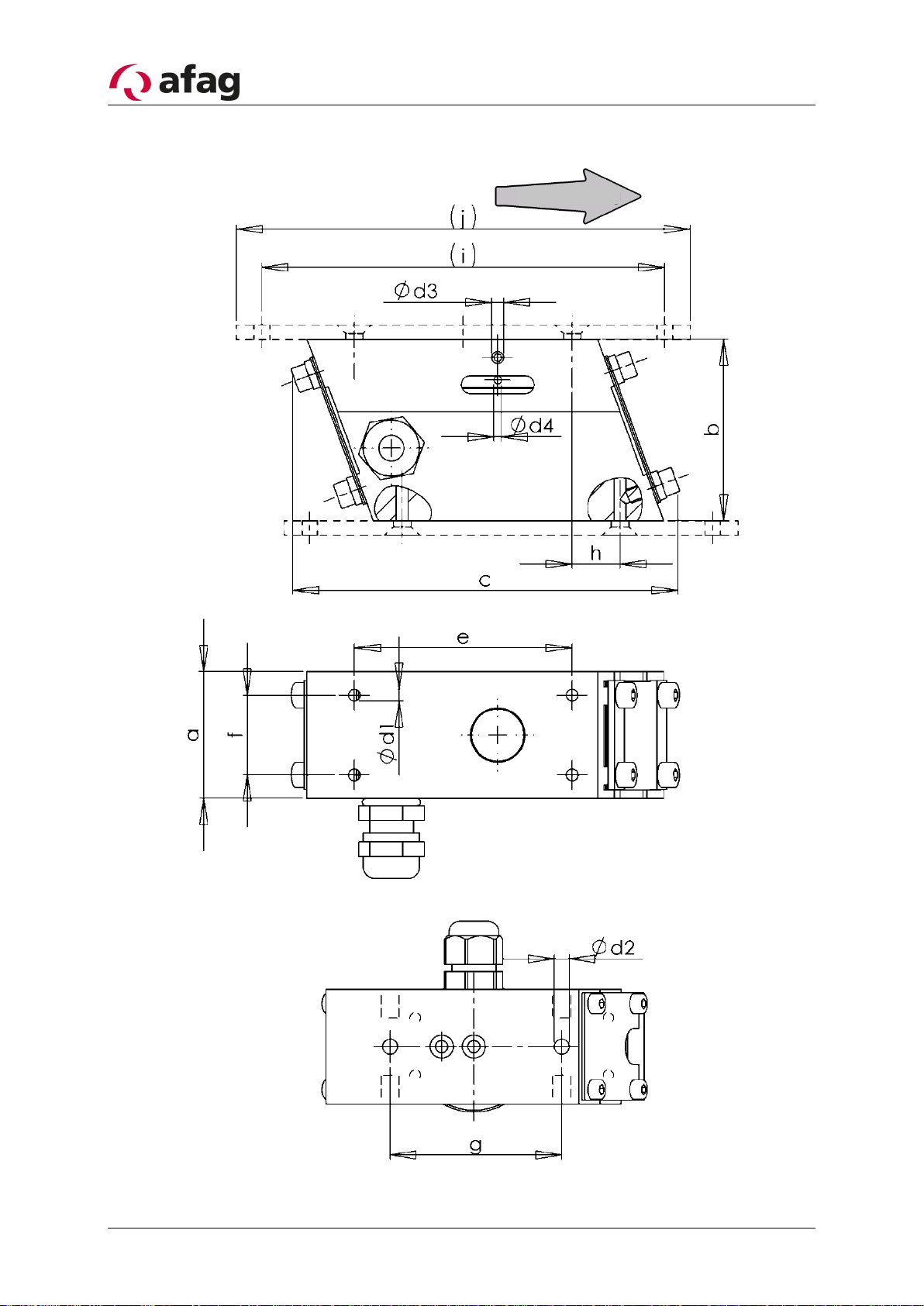

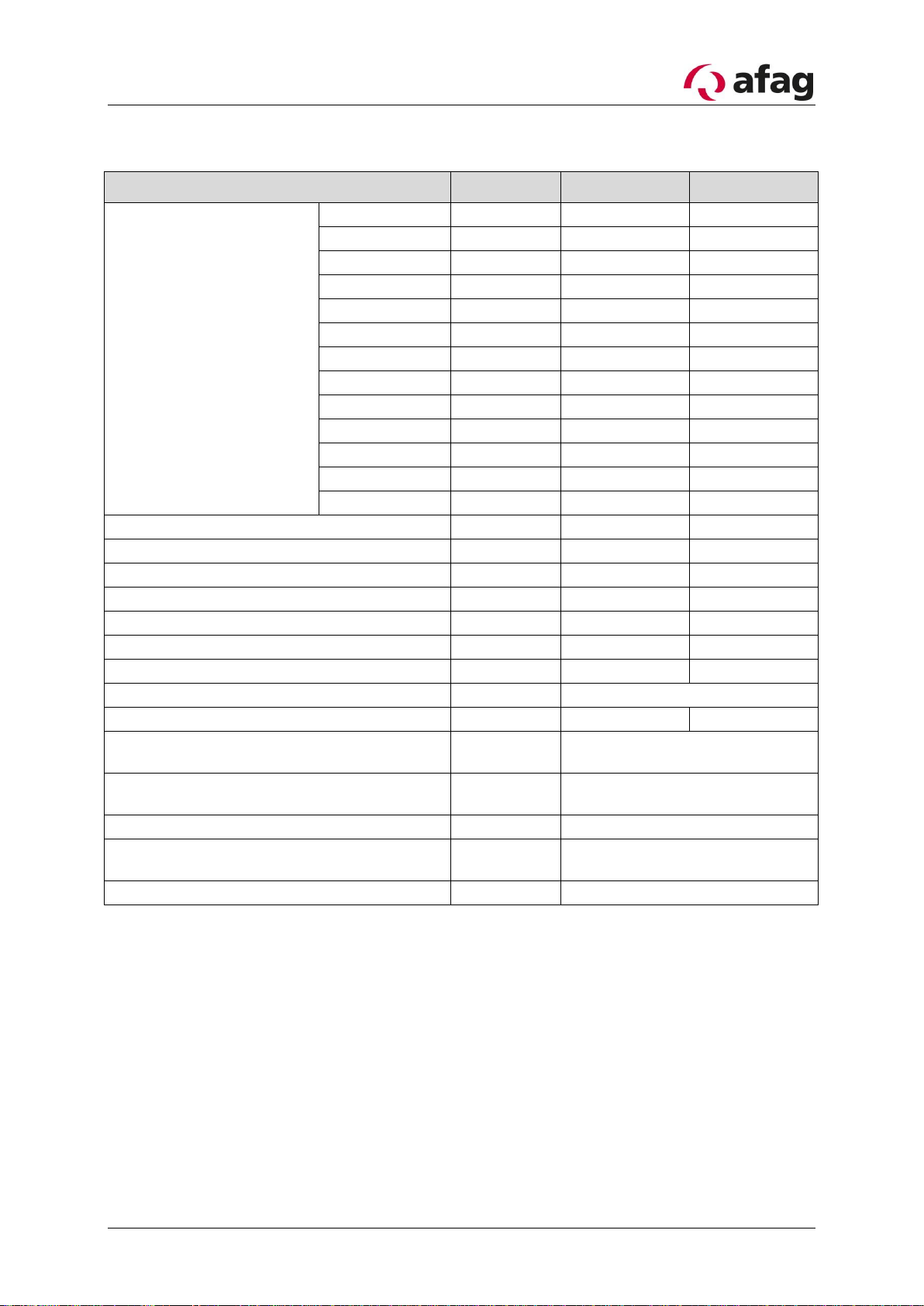

2.3 Technical data........................................................................................................................................... 8

3Assembly instructions......................................................................................... 10

3.1 Transport ................................................................................................................................................ 10

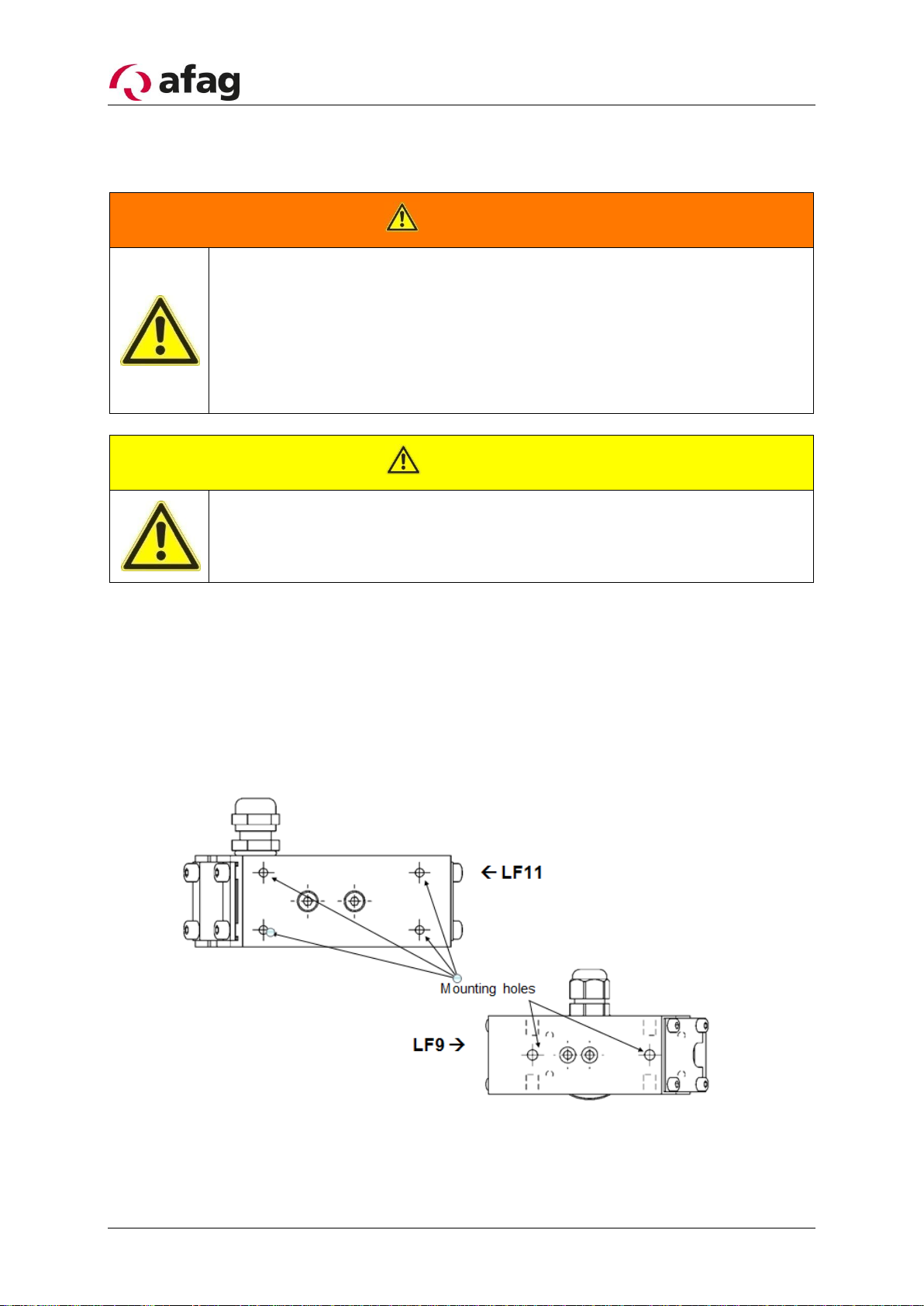

3.2 Installing the unit.................................................................................................................................... 10

3.3 Mounting of the linear track................................................................................................................... 11

3.4 Power supply........................................................................................................................................... 12

4Operating instructions......................................................................................... 13

4.1 Correlations between the transport speed and the LF spring package .................................................. 13

4.2 Setting the distance between the rail and the support surface .............................................................. 14

4.3 Standard operation................................................................................................................................. 14

4.4 Torques ................................................................................................................................................... 15

5Maintenance instructions .................................................................................... 16

5.1 Troubleshooting and fault repair ............................................................................................................ 16

5.2Replacing springs or spring packages ..................................................................................................... 18

5.3 Replacing the magnetic coil.................................................................................................................... 20

5.4 Setting the air gap between magnetic coil and anchor bolt................................................................... 22

5.5 Spare and wearing parts......................................................................................................................... 23

6Accessories .......................................................................................................... 24

6.1 Mounting parts ....................................................................................................................................... 24

6.2 Control device ......................................................................................................................................... 24

6.3 Address for orders................................................................................................................................... 25

7Disposal ................................................................................................................ 25