R01.0 2/20/2018 Page 3

Table of Contents:

1Safety Instructions..............................................................................................5

1.1 Explanation of symbols and notes ............................................................................................................5

1.2 Basic safety instructions ...........................................................................................................................6

1.3 Safety Instructions ....................................................................................................................................6

1.3.1 Danger areas ....................................................................................................................................7

1.4 Intended Use.............................................................................................................................................8

1.5 Improper use.............................................................................................................................................9

2Description of the Device .................................................................................10

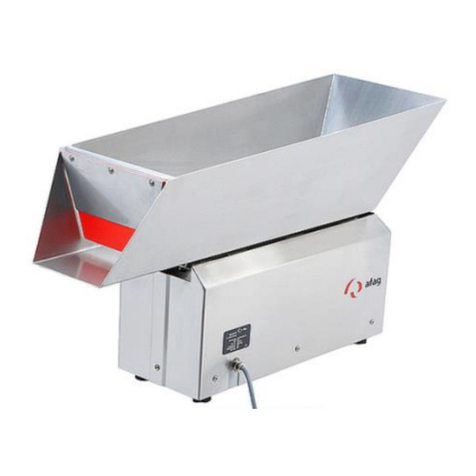

2.1 General ...................................................................................................................................................10

2.2 Functional description ............................................................................................................................10

2.3 Technical data ........................................................................................................................................10

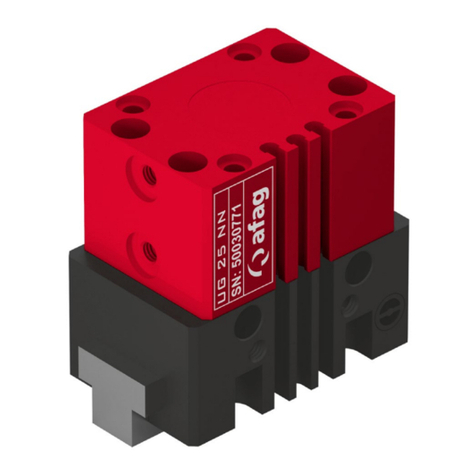

2.3.1 IBB3.5 –IBB6..................................................................................................................................10

2.3.2 IBB12 - IBB50..................................................................................................................................11

3Installation Instructions....................................................................................12

3.1 Transport ................................................................................................................................................13

3.2 Unit assembly .........................................................................................................................................13

3.2.1 Notes on safe installation ..............................................................................................................13

3.2.2 Electrical connection......................................................................................................................13

3.3 Power supply ..........................................................................................................................................14

4Operating Instructions...................................................................................... 15

4.1 Commissioning........................................................................................................................................15

4.1.1 Checking the belt run:....................................................................................................................15

4.1.2 Checking the lateral guides............................................................................................................15

4.2 Filling the system ....................................................................................................................................15

4.3 Adjustment options ................................................................................................................................15

4.3.1 Lateral guides.................................................................................................................................15

4.3.2 Parts chute .....................................................................................................................................15

4.3.3 Adjustable front panel ...................................................................................................................15

4.3.4 Belt tensioning ...............................................................................................................................15

5Maintenance Instructions .................................................................................17

5.1 Cleaning ..................................................................................................................................................17

5.2 Conveyor belt..........................................................................................................................................17

5.2.1 Replacing the conveyor belt ..........................................................................................................17

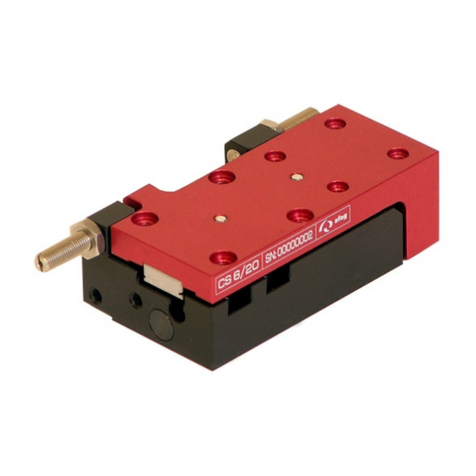

5.3 Drive........................................................................................................................................................19

5.4 Other components ..................................................................................................................................19

5.5 Spare parts..............................................................................................................................................19

6Accessories .......................................................................................................20