AgLand Macerator 6600 Operation and maintenance manual

Macerator 6600™

Assembly Instructions

Operators Manual

Parts Catalog

INTRODUCTION PAGE 3

SAFETY PRECAUTIONS PAGE 4

SPECIFICATIONS PAGE 5

ASSEMBLY PAGE 6 - 8

TRANSPORT PAGE 9

OPERATION PAGE 10 -13

MAINTENANCE PAGE 14 -16

LUBRICATION PAGE 17

AIR SYSTEM PAGE 18

HYDRAULIC SYSTEM PAGE 18

TROUBLE SHOOTING PAGE 19 - 20

PARTS LISTS - MAIN UNIT PAGE 22 - 32

ATTACHMENTS PAGE 33 - 35

WARRANTY BACK COVER

Replacement Parts

To obtain prompt, efficient service, always

remember to give the dealer the following

information:

1. Correct part description

2. Model number of the machine

3. Serial number of the machine

The serial number is important in identifying your

machine. It contains information for ordering

replacement parts and options, which may vary,

depending on the serial number identification.

(Serial # plate inside right side cover)

Measurements are given in U.S. units, followed

by the equivalent in metric units. Hardware sizes

are given in inches for the U.S. hardware and mil-

limeter for metric hardware.

INDEX

2

MODEL

SERIAL #

Made in Canada

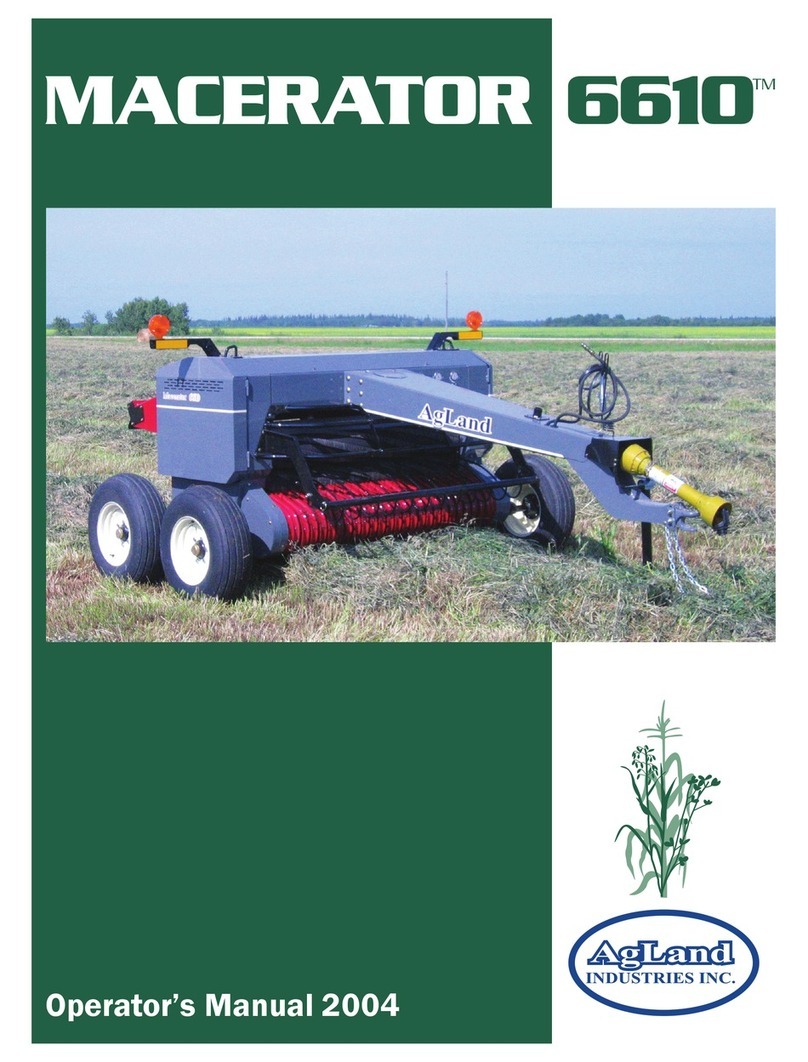

Macerator 6600

Box 112, Arborg, MB R0C 0A0

INTRODUCTION

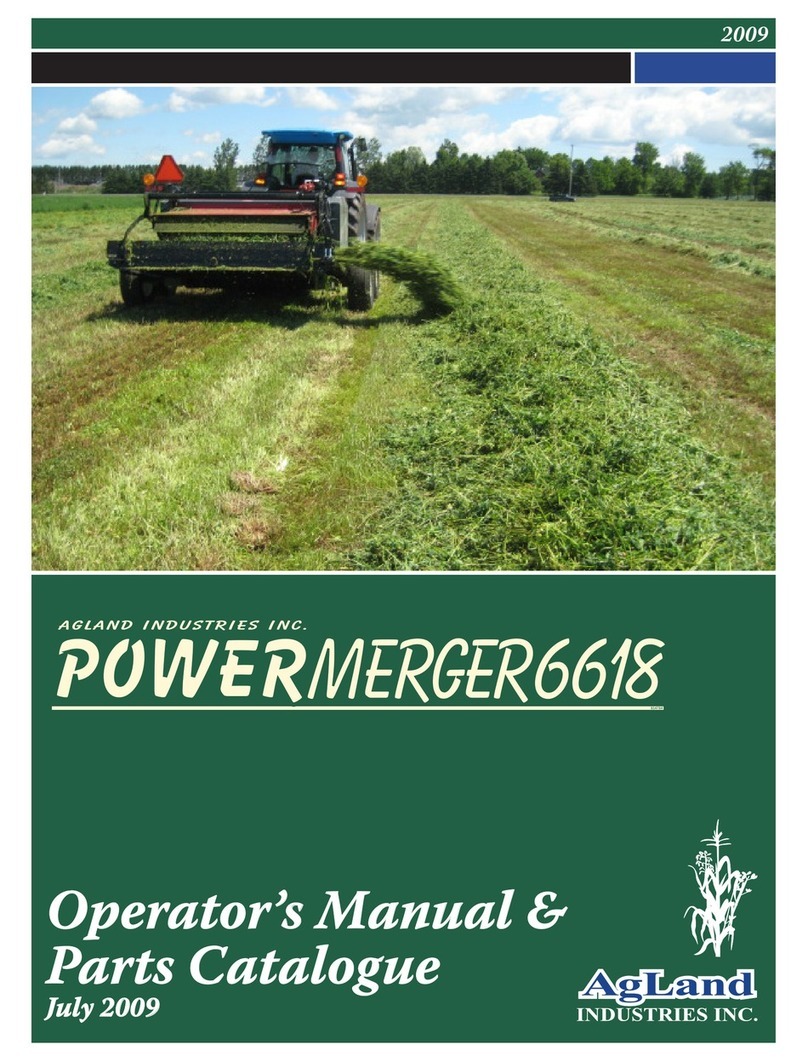

Congratulations, you have just purchased the AgLand

Macerator 6600

To get the maximum benefit from your Macerator we

suggest that you read the owners manual carefully.

The Macerator is designed to condition the hay for a

super fast dry down while maintaining the maximum

amount of nutrients and colour. Dry down time is

reduced from up to 100 hours to as little as 32 hours

or less. The Macerator utilizes special steel macera-

tor rollers each running at a different speed allowing

for a measured nicking or cutting of the top half of the

stem or leaf for greater air exposure. The low profile,

heavy-duty pickup, with extra width rollers allow for

rapid operation with minimal leaf loss.

The roller system of the Macerator is a patented

design, to allow for the right amount of maceration

without cutting up the hay.

These operating and maintenance instructions have

been compiled from extensive field experience and

engineering data. Some information is general in

nature due to unknown and varying conditions.

However, through experience and these instructions,

you will be able to develop operating procedures suit-

able to your particular situation.

Please study this manual from the beginning to end

BEFORE operating your new Macerator 6600. Pay

special attention to the safety cautions in this book

and on your equipment. Should anyone else operate

this equipment be sure that they understand All Safety,

Operating and Maintenance information presented in

this manual.

“Right” and “Left”, as used throughout this manual,

are determined by facing the direction the machine

will travel when in use.

The photographs, illustrations, and data used in this

manual were current at the time of printing; but due to

possible inline production changes, your machine can

vary slightly in detail. the Manufacturer reserves the

right to redesign and change the machine as neces-

sary without notification.

3

WARNING

Some pictures in this manual show the machine

with shields removed to allow for a better view of

the subject of the picture. The machine must never

be operated with any of the shields removed!

SAFETY PRECAUTIONS

4

Read this manual completely and understand all

operating instructions and precautions before

attempting to operate or service your machine.

Understand that your safety and the safety of other

persons is measured by how you service and operate

this machine. Know the positions and operations of all

controls before you try to operate this machine. MAKE

SURE YOU CHECK ALL CONTROLS IN A SAFE

AREA BEFORE STARTING YOUR WORK.

The Safety Alert symbol identifies important safety

messages on the machine and in the manual. When

you see this symbol, be alert to the possibility of per-

sonal injury or death. Follow the instructions in the

safety message.

Three Big Reasons

1. Accidents disable and kill.

2. Accidents cost.

3. Accidents can be avoided.

The safety information given in this manual does not

replace safety codes, insurance needs, or state and

local laws. Make sure your machine has the correct

equipment needed as specified by the local laws and

regulations!

SAFETY ALERT SYMBOL

This Safety Alert symbol means -

ATTENTION!

BE ALERT!

YOUR SAFETY IS INVOLVED!

WATCH OUT FOR THIS SYMBOL ON

YOUR MACERATOR 6600 AND

THROUGHOUT THE MANUAL.

SIGNAL WORDS:

DANGER - An immediate and specific hazard

which WILL result in severe personal injury or

death if the proper precautions are not taken.

WARNING - A specific hazard or unsafe

practice which COULD result in severe

personal injury or death if proper precautions

are not taken.

CAUTION - Unsafe practices COULD result

in personal injury if proper practices are not

taken, or as a reminder of good safety prac-

tices.

Dimensions

Width - 10’6” (320 cm)

Length - 11’4” (345 cm)

Height - operation 3’6” (107 cm)

transport 4’10” (147 cm)

Weight - 3600 lbs (1633 Kg)

Tires (4)

Tire size - 26 x 12 x 12

Pressure - 20 psi (138 kPa)

Wheel hub - 6 bolt

Wheel torque - 85 ft. lbs. (115.2 NM)

Pickup

Width (inside flare) - 5’11” (180 cm)

Clearance under pickup when raised -

14” to 16” (35.5 to 40.5 cm)

Tooth clearance when raised -

10” to 12” (25 to 30 cm)

Rollers

Width of rubber feed rollers 5’6” (168 cm)

RPM of rubber feed rollers 428 @ 540 pto

Width of steel Macerator rollers 5’6” (168 cm)

RPM of top steel Macerator roller 540 @ 540 pto

RPM of bottom steel roller 810 @ 540 pto

Spacing between bottom and top Macerator

roller 1/32” (1 mm)

Pickup tooth spacing - 2 3/4” (7 cm)

Height when working - 19” (48 cm)

Some weights and measurements in this

column are approximate.

Tractor Requirement

Suggested minimum tractor size -

80 HP( 60 KW)

* Note : Tractor should be of sufficient size to

maintain operator control in all situations.

Air System

Size of Air Pressure tank 10 gallon (38 l)

Maximum Air Pressure in tank 120 psi

Hydraulic outlets required - 1

Suggested minimum underframe clearance -

15” (38 cm) to allow swath to flow freely under tractor

Operating speed

Approximate range - 5 to 10 mph (8 to 16 k/h),

depending on crop conditions

Swath Size

Width up to - 5’ (1.5m)

Cut Width

Maximum 14’ (427”)

Capacity

Up to - 2 1/2 ton/acre

Model 6600 AgLand Macerator

SPECIFICATIONS

NOTE: All specifications, statements and information shown in this manual

are believed to be accurate at the time of printing. Specifications are subject

to change without notice

5

ASSEMBLY

6

1. Install right and left mounting brackets (1) to macer-

ator frame with 3/8” x 1” flange bolts

2. Install right side adjustment bar (2) to mounting

bracket, using 1/2” x 1 1/2” hex bolts with bushing,

washer and hex nut.

3. Install left side main frame (3) to the left side mount-

ing bracket, using 1/2” x 1 1/2” hex bolts with bushing,

washer and hex nut.

4. Attach right side main frame (4) to left side main

frame (3) with using 1/2” x 1 1/2” hex bolts with

bushing, washer and hex nut.

Do not tighten adjustment bolts (8)

5. Slide main frame adjustment bracket ( 2) through the

adjustment bar (5) and insert 1/2” x 3” pin

Mold board sheet installation

6. Install short mold board (6) to outside portion of main

frame (3) using 3/8” x 3” carriage bolts and flange nuts.

DO NOT tighten bolts at this time.

7. Install longer mold board sheet (7) on to the left side

of the main frame (3) using 5/16” x 3/4” carriage bolts,

overlapping the short mold board sheet.

8. All bolts holding the moldboard sheets can now be

fully tightened.

9. Adjust angle of moldboard by moving adjustment

bracket (2) in or out of adjustment bar 5 to preferred

moldboard angle and insert 1/2” x 3” pin

The tighter angle will result in less inversion, The

wider angle will give you a greater inversion.

1

7

25

6

4

3

7 6

5

SWATH INVERTER (MOLD BOARD)

ASSEMBLY

7

SPREADER ATTACHMENT

The Spreader attachment allows the

Macerator to spread a wider swath and

leave a thinner layer on the field for

greater sun and wind exposure.

The Spreader attachment consist of

only three pieces and easily bolts on to

the rear main frame.

1. Insert 3/8” x 1” flange bolts through

side panels and attach to main frame

(1). Do not tighten bolts.

2. Mount top plate(3) to brackets (2)

with 5/16” x 3/4” flange bolts.

3. Insert 5/16” x 3/4” bolts through top

lip of bracket and attach to top cover

of main frame (1)

3. Tighten all bolts evenly.

WINDROWER ATTACHMENT

The windrower attachment allows you

to direct the cut hay down to keep a

tighter windrow, or out for a wider

swath width.

1. Insert 3/8” x 1” flange bolts through

side panels (1) and attach to main

frame (7) Do not tighten bolts.

2. Mount top plate (2) to brackets (1)

with 5/16” x 3/4” flange bolts.

3. Attach top plate (2) to main frame (7)

with 5/16” x 3/4” flange bolts.

4. Mount one side brackets (3) to

bracket (1) with 3/8” x 3/4” flange

bolts.

5. Insert windrow baffle (5) into hole of

side brackets (3)

6. Mount the other side bracket (6) to

side panel with 3/8” x 3/4” flange bolts.

3

2

1

Spreader attachment

Windrower attachment

7. Mount adjustment bracket (8) using 5/16 x 1 1/2 socket head

cap screw and insert wing bolt (4)

8. Install left & right side width adjusters (9) using 3/8” x 1” bolt &

bushing (11) through top plate (2).

9. Insert wing bolt (10) through slot into width adjuster (9).

8 3 9 5

2

6

1

4

7

11

10

ASSEMBLY

8

ATTACHING HITCH

Sometimes the hitch will be shipped detached from

the unit to allow for a more compact shipping pack-

age.

1. Bolt Hitch to main frame using fourteen 5/8 x 1

1/2” carriage bolts. Be sure bolts are securely tight-

ened all around

2. Remove bearing on front of hitch, slide drive shaft

into friction clutch through front bearing hole and rein-

stall bearing and tighen shaft bolts on friction clutch.

3.Install the long hydraulic hose securely as shown

above.

this T goes to

first cylinder

goes to

second cylinder

friction clutch

long hose

drive shaft here

front hitch bearing

The Macerator can easily be moved from location to

location. When transporting follow this procedure.

TRANSPORT

1. Make sure you are in compliance with all

local regulations regarding transporting equip-

ment on public roads and highways.

2. Make sure the SMV(Slow Moving Vehicle)

emblem and all the lights and reflectors that are

required by the local highway and transport

authorities are in place, are clean and can be seen

clearly by all overtaking and oncoming traffic.

3. Do not allow anyone to ride on the

Macerator or tractor during transport.

4. Do not exceed 32 km/h (20 mph). Reduce

speed on rough roads and surfaces.

5. Use a retainer on the drawbar pin and

install a safety chain before transporting.

6. Always use proper lighting on the tractor

when transporting.

7. Stay away from overhead electrical wires.

Electrocution can occur without direct contact.

8. When using a ball and socket, make sure

the locking jaws are pinned securely in position.

9. Do not rely on the pickup lift hydraulic

cylinder to keep the pickup raised! Be sure pick-

up reel is in raised position and lever is secured

with the pick up lock-up pin provided.

TRANSPORT SAFETY Slow moving vehicle emblem

Hitch and safety chain

Lock travel pin in place

9

OPERATION

Operating Safety

10

1. REVIEW ALL SAFETY INSTRUCTIONS

with all operators before allowing them to oper-

ate the equipment . Follow up at least once a

year!

2. All shields and guards must be in position

and securely fastened before operating the

Swath Inverter.

3. Only use a tractor with ROPS cab and seat

belt. Be careful when operating close to a

road or building, the machine can throw stones

and other debris during operation.

4. Emphasize the importance of safety when

working around and operating the machine.

5. Do not allow or carry riders on any part of the

equipment or tractor at any time.

6. Always keep hands, feet, and clothing away

from moving parts.

7. Always lower the pickup to the ground when

parking.

8. Use a retainer or draw pin to secure the lift-

ing lever of the pickup before transporting

equipment.

9. Use safety chain at all times.

10. NEVER attempt to unclog the machine

when the tractor is running and hydraulic sys-

tem is operating.

11. Before servicing, adjusting, repairing, or

unplugging, stop the tractor engine, remove the

ignition key, set the park brake, disengage

hydraulics, and wait for all moving parts to stop.

12. Keep hands, feet, and clothing away from

the pickup area when adjusting the pickup

speed to avoid entanglement hazard. Never

check drive chains while machine is running.

13. Be sure to relieve all pressure from

hydraulic lines before disconnecting them.

Before applying pressure to the system, make

sure all connections are tight and that hoses

and lines have not been damaged.

14. Always use adequate safety warnings and

lights when transporting the machine on public

roads.

15. Be sure the Slow Moving Vehicle emblem

is installed at the rear of the machine. Check

with local law enforcement regarding any spe-

cific requirements.

PTO SPEED

Unless otherwise specified, units are shipped

with 1000 PTO speed. Conversion kits from 540 to

1000 or from 1000 to 540 are available from your

dealer. See page 9 for installation instructions.

The PTO should be run at approximately 1000 rpm.

The front rubber rolls run at 792 rpm and the rear

upper steel roller runs at 1000 rpm at a tractor pto

speed of 1000. The bottom rear steel roller runs at

1500 rpm at 1000 tractor pto speed.

PICKUP HEIGHT & ADJUSTMENT

The Macerator 6600 pickup should be adjusted so

that it will cleanly pick up all material of the field with-

out gouging the soil. You may have to reset the height

a few times to arrive at the best working height.

RAISING OR LOWERING THE PICKUP

1. If your pickup is to low to the ground, use your trac-

tor hydraulic cylinder control to raise the pickup

approximately 1/2” - 1” off the ground.

2. Remove pin (1) and slide adjuster bar (2) to desired

height (pushing bar in raises machine, pushing bar

out lowers the unit).

3. Reinsert pin and lock in place.

OPERATION

2

11

Use with a tractor having a minimum of 80hp (59kw). Tractor should have sufficient ground clear-

ance for swath to pass cleanly under it.

macerator

rollers

rubber intake

rollers

pick up reel

1 2

STEEL ROLLER ADJUSTMENT

For best results adjust the Macerator 6600 for

your specific field conditions. The smaller the gap

between the steel serrated rollers the more aggres-

sive will be the maceration of the hay. Both the space

between the rollers and the air pressure need to be

adjusted for maximum efficiency.

ADJUSTING GAP BETWEEN STEEL ROLLS

1. Raise the pickup, using your hydraulic cylinders, to

the full upward position and put the “travelling” safety

pin in place.

2. Open the right and left panels.

3. The roller stop, shown under the top air bag, in

figure1, consists of a 5/8” bolt with a 5/8” nut. Loosen

the nut and turn the bolt in to narrow the gap or out

to widen the gap. Use a spark plug gauge to mea-

sure the gap and set at no less than 1/32” or 1 mm

4. Be sure to set the gap exactly the same on

both sides! Tighten the locking nuts and close

cover.

PREPARATION - AIR SYSTEM

The purpose of the air system on the Macerator 6600

is to act as a shock absorber as well as keeping con-

tinuous pressure on the rolls.

Before heading

out to the field

make sure the

air pressure

tank has a mini-

mum of 100 psi

pressure. This

should give the

operator suffi-

cient air supply

for the day.

The pressure can make a difference on how well the

machine performs on the field. While the pressure on

the rubber rolls may not be as crucial too much pres-

sure on the steel rolls will result in considerable leaf

loss and some plugging may result in short wet hay.

RUBBER ROLLER ADJUSTMENT

The rubber rollers are designed to take the material

off the pick-up and feed it into the steel rollers. The

rubber rollers do not crush or crimp the hay and the

pressure on these rollers is not as crucial as on the

steel rollers.

OPERATION

figure 1

air fill

12

OPERATION

13

Rubber Rollers continued...

As a standard setting, we rec-

ommend 30-40 psi pressure on

the rubber rollers. Regulate the

pressure by pulling out the

knob on the regulator marked

rubber rollers and turning the

knob clockwise or counter

clockwise. When turning the

knob counter clockwise you

should hear the air escaping

from the regulator.

In extreme conditions, increase or decrease the pres-

sure. For example very heavy swaths may require

less pressure.

STEEL ROLLERS

The steel serrated rollers (rear) take the material from

the rubber rollers and kink or bend the stem approx-

imately every 1/8”.

To achieve the right setting

some field testing may be

necessary.

1. Pull out knob on air regula-

tor marked steel rollers and

turn knob clock/ counter clock

wise to set pressure to the

steel rollers at approximately

30 psi.

FIELD TEST.

2. If you experience too much leaf loss or the plants

are crushed too intensely, lower the air pressure.

3. If there is not enough maceration - increase pres-

sure to the rollers by increasing the air pressure.

rubber rollers

steel rollers

check list

FIRST TIME USE

❑ Tighten hub bolts 1-4* after the first 1/2 hour

of operation and repeat procedure after 1 1/2

hours and 3 hours.

*IMPORTANT

Hub 1 - tighten to 348”/ lbs

Hubs 2-4 - tighten to 192”/ lbs

DAILY

❑ Check and tighten all hub bolts.

❑ Lubricate all items as required*.

❑ Remove all dirt and crop deposits from machine.

EVERY 8 HOURS OF USE

❑ Grease all points. All grease point are identified

with a yellow label, replace labels when missing*.

AFTER THE FIRST 25 HOURS OF USE

❑ Check sprockets for set screw tightness

EVERY 100 HOURS OF USE

❑ Clean, repack and adjust wheel bearings.

AT THE BEGINNING OF EACH SEASON

❑ Review all safety instructions.

❑ Carefully inspect all components for

excessive wear or hazardous conditions.

❑ Lubricate the machine at all lubrication

points*.

❑ Clean, repack and adjust wheel bearings**.

❑ Check tires for correct inflation pressure.

❑ Tighten bolts.

* SEE LUBRICATION SCHEDULE AND

PROCEDURES ON PAGE 17

** SEE REPLACING OR REPACKING WHEEL

BEARINGS ON PAGE 16

MAINTENANCE

Before doing any maintenance or service

work on the machine, you must:

❑Park machine on a solid level surface.

❑ Disengage all power

❑ Put the tractor transmission in PARK or

apply the tractor parking brake.

❑ Stop the tractor engine and take the key

with you.

❑ LOOK AND LISTEN! Make sure all

moving parts have stopped.

❑ Install the cylinder safety stops, if

applicable.

❑ Block the Macerator up securely before

working

14

USE GOOD SAFETY

PRACTICES WHEN

WORKING ON THIS

MACHINE

1

2

4

3

Check that the chain is not riding up on sprocket teeth

(especially the large sprocket) as this would indicate

a worn out chain and requires replacement of chain.

Regular lubrication with chain lubricant, proper adjust-

ment, and replacement of worn chains will ensure

proper function of the Macerator and prolong the life of

the sprockets.

ROLLER DRIVE CHAIN REPLACEMENT

Replace worn or damaged chain as follows:

1. Raise pick-up

2. Remove side covers.

3. Remove the connector link from the chain and

remove chain from sprockets.

4. Replace worn sprockets and bearings. (Be sure

all sprockets are securely tightened).

5. Install new chain.

6. Move sprocket (1) to allow for approximately

1/2” (13mm) deflection when slight pressure is

applied to the longest span of the chain (2)

7. Short chains require non adjustment.

8. Reinstall covers!!

BEARING REPLACEMENT

Sealed ball bearings are held in position on the shaft

by a locking collar which is rotated to lock the assem-

bly on the shaft and secured by a set screw. To

remove Bearing:

1. Loosen set screw

2. Use a drift punch inserted in the drift pin hole to

rotate and loosen the locking collar (1). Rotate the

locking collar counter clock wise.

3. Remove the locking collar.

4. Support the shaft, for easier assembly later.

5. Remove the bolts for the bearing flanges.

6. Slide the bearing and the flanges from the shaft.

Note: Cleaning paint and corrosion from the shaft will

make removal easier.

7. Put on the new bearings and flanges.

8. Install bolts making sure the bearing is straight

within the flanges.

9. Replace locking collar on the shaft. Rotate the lock-

ing collar clockwise until lightly engaged. Tighten the

collar by hitting it with a drift pin punch inserted in the

drift pin hole rotating it further clockwise.

10. Tighten set screw.

After lubricating, servicing, or adjusting the

Macerator, make sure all tools and equipment are

removed from Macerator to prevent damage.

MAINTENANCE

1

locking collar

bearing

1

3

2

2

3

1

15

REPLACING OR REPACKING

WHEEL BEARINGS

1. Remove wheel hubs and disassemble.

2. Clean bearings, seals, caps, washers, nuts and

hubs with kerosene or other solvent.

3. Replace bearings or seals if worn or damaged.

4. Pack bearing cones and seals with No. 2 multi-pur-

pose lithium grease or equivalent.

5. Reassemble hub and bearings. ( fig 1)

a. Press oil seal very lightly against the

shoulder on the spindle.

b. Press cups against the shoulder in the hub.

c. Press sleeve to the shoulder in the hub.

d. Place hub on shaft taking care not to

damage the seal!

d. Adjust the wheel bearing nut until there is a

noticeable drag while turning the wheel.

Do Not back the nut off.

e. Secure nut with a cotter pin.

PICKUP TEETH, WRAPPERS, WEAR STRIPS

Check for bent, broken or loose parts. If it is nec-

essary to replace teeth or related parts, proceed

as follows.

1. Ensure that pickup is blocked securely.

Loosen the bolts, holding the wrapper(s) on pick-

up. (see fig. 2) Slide wrapper forward, and

remove the wrapper from the bolts.

“Pop” Rivets

Plastic Wear Strips

Wrapper

Teeth

2. Should the plastic wear strip require removal

and replacement, drill out or carefully grind off the

“pop” rivets. Replace strip with new rivets(fig.3).

3. Install new teeth or wrapper(s).

MAINTENANCE

Figure 3

Figure 2

16

two top bolts

two bottom bolts

We recommend a good grade SAE multi-pur-

pose high temperature grease.

Use a manual grease gun for all greasing. Air

powered grease guns may damage the seal

on the bearings.

Wipe all grease fittings with a clean cloth

before greasing to avoid injecting dirt or grit

in the bearings.

Every 8 hours of use

Coat chain with chain lubricant to prevent rust

and seizing , figure 1 and 2.

Every 100 hours of use

or at the beginning of the season

Grease all the sealed bearings, front rollers (two

places) rear rollers ( two places) and drive shaft

two places, figure 1 and 2.

Clean, repack and adjust wheel bearings. Grease

wheel bearings (nipples in hub), just enough to

force out moisture, figure 3.

.

LUBRICATION

17

Figure 1

Figure 2

Figure 3

AIR & HYDRAULIC SYSTEM

18

HYDRAULIC AND AIR SAFETY

AIR SYSTEM HYDRAULIC SYSTEM

HYDRAULIC SAFETY

Make sure that all components in the hydraulic

system are kept in good condition and are

clean.

Replace any worn, cut, abraded, flattened or

crimped hoses and metal lines.

Do not attempt any makeshift repairs to

hydraulic lines, fittings, or hoses by using tape,

clamps, or cements. The hydraulic system

operates under extremely high pressure:

1600to 2300 PSI (11 033 to 15 859 kPa). Such

repair will fail suddenly and create unsafe con-

ditions.

A high pressure concentrated stream of

hydraulic fluid can pierce the skin. If such hap-

pens, seek immediate medical attention as

infection and toxic reaction could develop.

Wear proper hand and face protection (eg. face

shield) when searching for a high pressure

hydraulic leak. Use a piece of wood or card-

board as a backdrop instead of hands.

Before applying pressure to the system, make

sure all connections are tight and that line,

hoses, and couplings are not damaged.

AIR SAFETY

Make sure all hoses and bellows are kept in

good condition and are clean.

Replace any damaged lines or bellows.

Do not exceed 110 lbs air pressure in tank and

90 lbs. in air bags.

Think SAFETY!

Work SAFELY!

TROUBLE SHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

Pickup is skipping swath Missing or broken pickup teeth Replace missing teeth

or not picking cleanly Pickup to high Adjust pickup height

Driving to fast for pickup speed Use lower tractor gear with higher rpm

Not following the same direction as Follow the same direction as swath

swath was cut. was cut

Material wrapping in pickup Nylon wear plates missing or worn Replace missing or worn nylon pads

Pickup & travel speed not matched Match pickup & ground speed as

close as possible

Breakage or bending of Running pickup to low Adjust pickup height

pickup teeth Excessive pickup rotation speed in Reduce pickup or ground speed

rough or rocky conditions

Excessive noise from Chain or sprockets worn Replace parts as needed

chains or sprockets Incorrect tension chain Adjust as per “servicing” section

Chain dry or rusted Use proper lubrication on chains

Excessive noise or Insufficient oil in gear box Top up gear oil as needed

heat from gear box Worn or broken parts inside gear box Replace parts as needed

Air pressure does not hold Broken air line Repair or replace line as needed

in air tank and air bags Torn or punctured air bag Replace air bag as needed

Air regulator not working clean or replace air regulator

Pickup does not rise Worn or punctured hydraulic cylinder Replace hydraulic lines & cylinders

or hydraulic oil line as needed

Pickup height adjustment

does not hold Broken or worn parts on adjuster Replace worn parts as needed

Rubber rolls not feeding properly Air pressure to high or to low Adjust air pressure using the regulator

Gap between rollers to tight or to wide Adjust gap width

Wax build up on steel rolls Temperature & hay conditions cause The wax will come off after the rollers

the wax to come off the plant and cool down. A thin layer of wax/leaves

stick to the rollers will build up on the rollers

Excessive leaf loss Too much air pressure on steel rollers Release air pressure

Hay conditions to dry Condition hay early in the morning

The gap between steel rollers is to narrow Adjust gap between steel rollers

or the rolls going to fast

19

TROUBLE SHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

Hay is not being macerated Not enough air pressure on steel rolls Adjust air pressure as required

Gap between rollers is to wide Narrow the gap between steel rollers

Windrow is to thick Cut wider or thinner windows

Steel rolls not running fast enough Increase tractor rpm

Swath not being Moldboard not adjusted Adjust moldboard angle.

inverted completely properly The tighter angle will result

in less inversion, The wider

angle will give you a greater

inversion.

20

Other manuals for Macerator 6600

1

Table of contents

Other AgLand Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions