AgLand MACERATOR 6610 User manual

TM

Operator’s Manual 2004

MACERATOR 6610

Replacement Parts

To obtain prompt, effi cient service, always remember to

give the dealer the following information.

1. Correct part description.

2. Model number of the machine.

3. Serial number of the machine.

The serial number is important in identifying your ma-

chine. It contains information for ordering replacement

parts and options which may vary depending on the serial

number identifi cation.

Measurements are given in U.S. units followed by the

equivalent in metric units. Hardware sizes are given in

inches for the U.S. hardware and millimeters for the met-

ric hardware.

Contents

Warranty Registration Form

..............................................................................................................................................

2

Introduction

..........................................................................................................................................................................

4

Safety

................................................................................................................................................................................

Safety ................................................................................................................................................................................Safety

5

–

6

Transport Safety

....................................................................................................................................................................................

Transport Safety ....................................................................................................................................................................................Transport Safety

5

Operating Safety

....................................................................................................................................................................................

6

Hydraulic Safety

.....................................................................................................................................................................................

Hydraulic Safety ..................................................................................................................................................................................... Hydraulic Safety

6

Air Safety

................................................................................................................................................................................................

6

Sp

ecifi cations

.......................................................................................................................................................................

7

Assembly

...............................................................................................................................................................................

Assembly ...............................................................................................................................................................................Assembly

8

Assembly (attachments)

.............................................................................................................................................

9

–11

Swath Inverter

.......................................................................................................................................................................................

9

Spreader

..............................................................................................................................................................................................

10

Windrower

............................................................................................................................................................................................

1

1

Field Setup

..................................................................................................................................................................

1

2

–13

PTO Speed

...........................................................................................................................................................................................

1

2

Pickup Height and Adjustment

...........................................................................................................................................................

12

Steel Roll Adjustment

..........................................................................................................................................................................

12

Pr

eparation (Air System)

.....................................................................................................................................................................

13

Rubber Roll Press

ure Adjustment

......................................................................................................................................................

13

Steel Roll P

ressure Adjustment

..........................................................................................................................................................

1

3

Maintenance

...............................................................................................................................................................

14–16

Checklist

..............................................................................................................................................................................................

14

Roll Drive Belt Replacement

...............................................................................................................................................................

15

Bearing Replacement

.........................................................................................................................................................................

16

Replacing or Repacking Wheel Bearings

...........................................................................................................................................

16

Pickup Teeth, Wrappers, and Wear Strips

.........................................................................................................................................

1

6

Lubrication

.........................................................................................................................................................................

1

7

Trouble Shooting

...............................................................................................................................................................

1

8

Warranty

.............................................................................................................................................................

Warranty .............................................................................................................................................................Warranty

Back Cover

Serial # on plate inside right side cover.

Box 479 Arborg MB, R0C 0A0

Macerator 6610

Made in Canada

Model #:

Serial #:

1

I have instructed the buyer on the above described equipment and included a review of the Operator’s Manual, assembly,

maintenance, safety, and applicable warranty policy.

Dealer’s Signature Date

The above Equipment and Operator’s Manual have been received by me and I have been instructed as to the care, adjust-

ments, safe operation, and applicable warranty policy.

Purchaser’s Signature Date

Customer Name:

Address:

City:

Prov/State: Postal/Zip:

Phone No:

Model No:

Serial No:

D

ealer:

Address:

City:

Prov/State: Postal/Zip:

Date P

urc

hased:

Check One: Commercial Use Farm Use

Prov/State: Postal/Zip:

Prov/State: Postal/Zip:

AgLand Macerator 6610

™

LIMITED

WARRANTY REGISTRATION FORM

The Macerator 6610 is warranted by AgLand to the original purchaser, to be free of defects in workmanship and material for a

period of one (1) year from date of purchase for farm use (three (3) months from date of purchase for commercial use). AgLand

does not warrant any damage caused by negligence, modifi cations, and/or lack of maintenance. (See Maintenance Schedule in

Operator’s Manual.)

AgLand will not be liable for the cost of shipping or any other cost incurred for replacement or repair of any parts. AgLand is not

liable for any accidents which may occur from or during the operation of the Macerator 6610, or damage incurred due to Mac-

erator failure. The purchaser assumes all responsibility for the care, maintenance, and safety.

Failure to return completed registration to AgLand within 30 days of delivery will VOID warranty.

This form must be fi lled out by the dealer and signed.

Mail to:

AgLand Industries Inc.

Box 479 Arborg, MB

R0C 0A0

Check One: Commercial Use Farm Use

Check One: Commercial Use Farm Use

DEALER CHECKLIST

Belt

tension

P

ickup including fi nger height

Air lines, gauges, and airbag

Hydraulic lines and fi

t

tings

Drive shafts and gear box

All refl ectors in place

Wheel bolts tight

Tire air pressure (20 PSI)

All grease fi ttings greased

All safety procedu

res have been reviewed with customer

Rubber and steel rolls

, in

cluding spac

ing

All warning de

cals are in place

, clean

, and legible

Customer has been instructed to review safety and operat-

ing procedures with all operators annually

.

Belt

P

Air lines, gauges, and airbag

Wheel bolts tight

All refl ectors in place

Drive shafts and gear box

Customer has been instructed to review safety and operat-

All grease fi ttings greased

All safety procedu

Rubber and steel rolls

All warning de

I have thoroughly inspected the machine and made adjustments and corrections as needed.

Inspected By Signature Date

Hydraulic lines and fi

White - AgLand Yellow - Customer Pink - Dealer

AgLand Industries Inc.

is a Canadian owned and oper-

ated company located in central Canada, in the province

of Manitoba. AgLand was founded in 2001 by a group of

innovative entrepreneurs that transformed their ideas

and expertise into a leading manufacturing company of

agricultural crop equipment.

Box 479 Arborg MB, Canada R0C 0A0

1.888.933.4440

Tel: 204.364.2211

Fax: 204.364.2472

Email: [email protected]

Web: www.aglandindustries.com

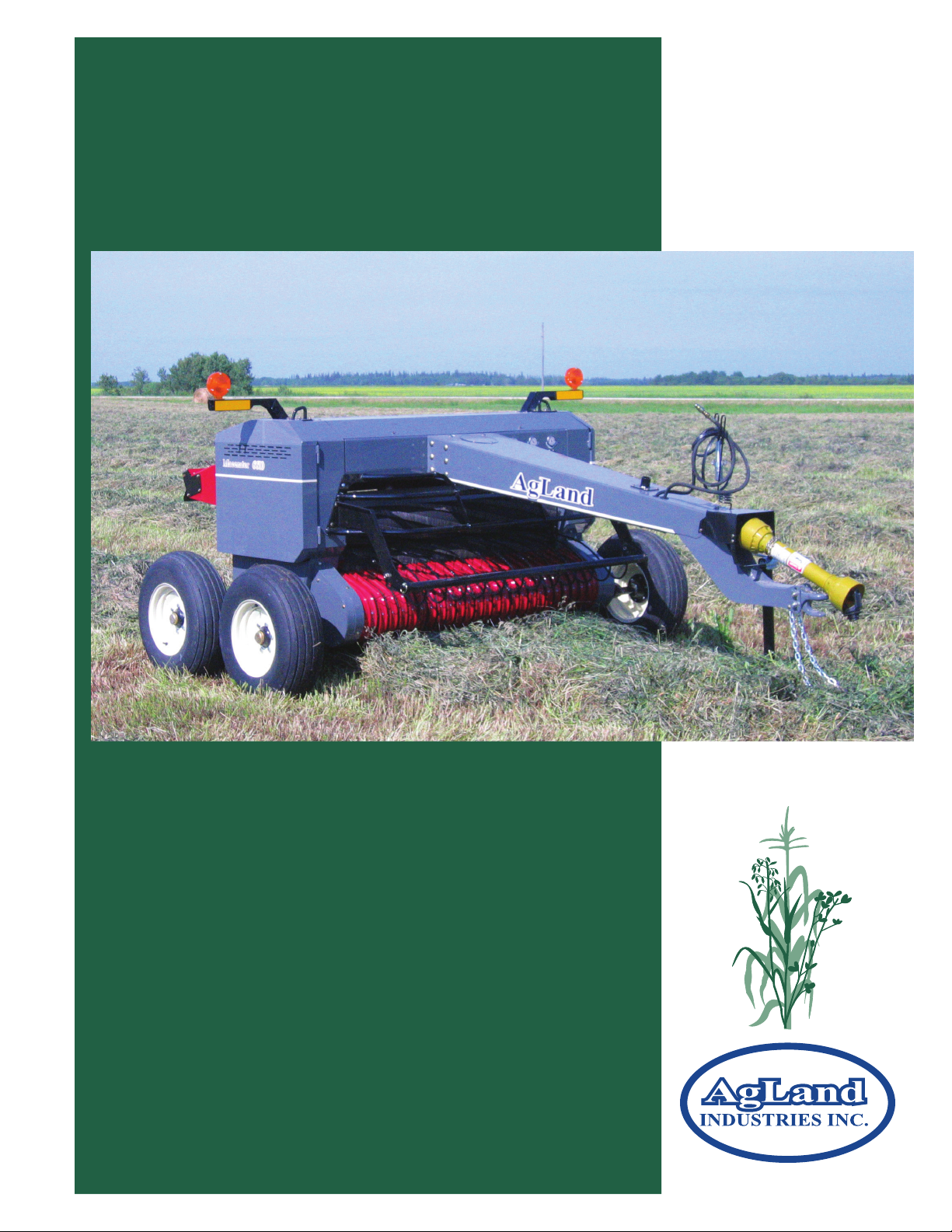

Introduction

Congratulations, you have just purchased the new and

improved AgLand Macerator 6610. To get the maximum

benefi t from your Macerator we suggest that you read the

Operator’s Manual carefully.

The Macerator is designed to condition the hay for a super

fast dry down while maintaining the maximum amount of

nutrients and color. The Macerator utilizes special steel

rolls, each running at a different speed allowing for a mea-

sured nicking of the stem for greater air exposure. The low

profi le, heavy duty pickup allows for rapid operation with

minimal leaf loss.

The roll system of the Macerator is designed to allow for the

right amount of maceration without cutting up the hay.

These operating and maintenance instructions have been

compiled from extensive fi eld experience and engineering

data. Some information is general in nature due to un-

known and varying conditions. However, through experi-

ence and these instructions, you will be able to develop

operating procedures suitable to your particular situation.

Please study this manual from the beginning to end BE-

FORE operating your new Macerator 6610. Pay special

attention to the Safety section in this manual and the

safety cautions on your equipment. Should anyone else

operate this equipment be sure that they understand

ALL safety, operating, and maintenance information pre-

sented in this manual.

The terms ‘right’ and ‘left’, as used throughout this manu-

al, are determined by facing the direction the machine will

travel when in use.

The photographs, illustrations, and data used in this man-

ual were current at the time of printing, but due to pos-

sible inline production changes, your machine can vary

slightly in detail. The Manufacturer reserves the right to

redesign and change the machine as necessary without

notifi cation.

WARNING

Some pictures in this manual show the machine with

shields removed to allow for a better view of the sub-

ject. The machine must never be operated with any of

the shields removed.

4

Read this manual completely and understand all oper-

ating instructions and precautions

BEFORE

attempting

to operate or service your machine.

The safety information given in this manual does not re-

place safety codes, insurance needs, or state/province

and local laws. Make sure your machine has the correct

equipment needed as specifi ed by the local laws and reg-

ulations.

Understand that your safety and the safety of other per-

sons is measured by how you service and operate this

machine.

IMPORTANT!

Review and understand the positions and

functions of all machine controls before operating this

machine.

WARNING! Do

NOT attempt any adjustments

, mai

nte-

nance, trouble

shooting, or repairs while machine com-

ponents are moving or activated with pressure.

▪ Lower machine to ground or onto appropriate blocks.

▪ Stop tractor engine and remove ignition key.

▪ Set tractor parking brake prior to leaving operator sta-

tion.

Safety Alert Symbol

The Safety Alert symbol identifi es impor-

tant safety messages in the manual and

on the machine. When you see this sym-

bol, be alert to the possibility of personal

injury or death. Follow all the instructions

in the safety message given. This symbol means atten-

tion, be alert, and your safety is involved.

Three Reasons To Follow Safety Instructions:

1. Accidents disable and kill.

2. Accidents cost.

3. Accidents can be avoided.

Slow Moving Vehicle E

mblem

The Slow Moving Vehicle (SMV) emblem

must be placed on the rear of the ma-

chine and be visible to traffi c approaching

the machine from the rear while traveling

on public roads. Keep the SMV emblem

clean and replace when damaged or emblem materials

have faded. The SMV should only be displayed on the ma-

chine at road speeds less than 40 km/hr (25 MPH).

Safety

▪ The operator is responsible for complying with all

local regulations regarding transporting agricultural

equipment on public roads.

▪ Ensure all lights and refl ectors, as required by local

law, are in place, intact, and clean before transport-

ing machine on public roads.

▪ Connect electrical socket on machine wiring har-

ness to tractor receptacle.

▪ Ensure SMV emblem is clean and properly displayed,

where required by law, before transporting machine

on public roads.

▪ Do NOT allow riders on machine at any time includ-

ing transport of machine on public roads.

▪ Maximum transport speed is 32 km/hr (20 MPH).

Reduce speed on rough roads and surfaces.

▪ Use proper retainer on drawbar hitch pin and attach

safety tow chain to tractor prior to transporting ma-

chine on public roads.

▪ Ensure that transport lock pin is installed and se-

cured in the hole provided for transport.

▪ Tractor light switches should be set for road trans-

port. Refer to tractor operator’s manual for infor-

mation.

Tra

nsport

Safety

DANGER

DANGER:

Indicates an imminently hazardous situation

that, if not avoided, WILL result in death or serious injury

if proper precautions are not taken.

Signal Words

WARNING

:

Indicates a potentially hazardous situation

that, if not avoided, COULD result in death or serious in-

jury if proper precautions are not taken.

CAUTION

:

Indicates a potentially hazardous situation that,

if not avoided, MAY result in minor or moderate injury if

proper practices are not taken, or serves as a reminder to

follow appropriate safety practices.

CAUTION

WARNING

5

Safety

Operating Safety

▪ Ensure that all components in the hydraulic system

are kept in good condition.

▪ Replace any worn, cut, abraded, fl attened, or

crimped hoses and/or metal lines.

▪ Do not attempt any poorly executed repairs to hy-

draulic lines, fi ttings, or hoses by using tape, clamps,

or cements. The hydraulic system operates under

extremely high pressure: 11,033 to 15,859 kPa

(1600 to 2300 PSI). Such repair will fail suddenly

and create unsafe conditions.

▪ Wear proper hand and face protection (e.g. face

shield) when searching for a high pressure hydraulic

leak. Use a piece of wood or cardboard as a back-

drop instead of hands. A high pressure concentrated

stream of hydraulic fl uid can pierce the skin. If such

happens, seek immediate medical attention as in-

fection and toxic reaction could develop.

▪ Before applying hydraulic pressure to the system,

make sure all connections are tight and that lines,

hoses, and couplings are not damaged.

Think Safety,

Work Safely!

▪ REVIEW ALL SAFETY INSTRUCTIONS with all opera-

tors before allowing them to operate the equipment.

Review instructions at least once each year.

▪ All shields and guards must be intact and in po-

sition and securely fastened before operating the

Macerator.

▪ Only use a tractor equipped with ROPS cab and seat

belt. Be careful when operating close to a road or

building, the machine can throw stones and other

objects during operation.

▪ Emphasize the importance of safety when working

around and operating the machine.

▪ Do NOT allow riders on any part of the equipment at

any time.

▪ Always keep hands, feet, and clothing away from

moving parts.

▪ Always lower the Macerator to the ground when

parking.

▪ Use transport lock pin and retainer to secure the

lift linkage of the Macerator before transporting

equipment.

▪ Use safety tow chain at all times.

▪ NEVER attempt to unplug the machine when the trac-

tor is running and hydraulic system is pressurized.

▪ Keep hands, feet, and clothing away from the pickup

area when in operation to avoid entanglement haz-

ards. Do not open or remove shields or guards while

machine is running.

▪ Relieve all pressure from hydraulic lines before dis-

connecting them. Before applying pressure to the

system, make sure all connections are tight and

that hoses and lines have not been damaged.

Hydraulic

Safety

▪ Make sure all hoses and bellows are kept in good

condition and are clean.

▪ Replace any damaged lines or bellows.

▪ Do not exceed 827 kPa (120 PSI) air pressure in

tank and 689 kPa (100 PSI) in air bags.

Air

Safety

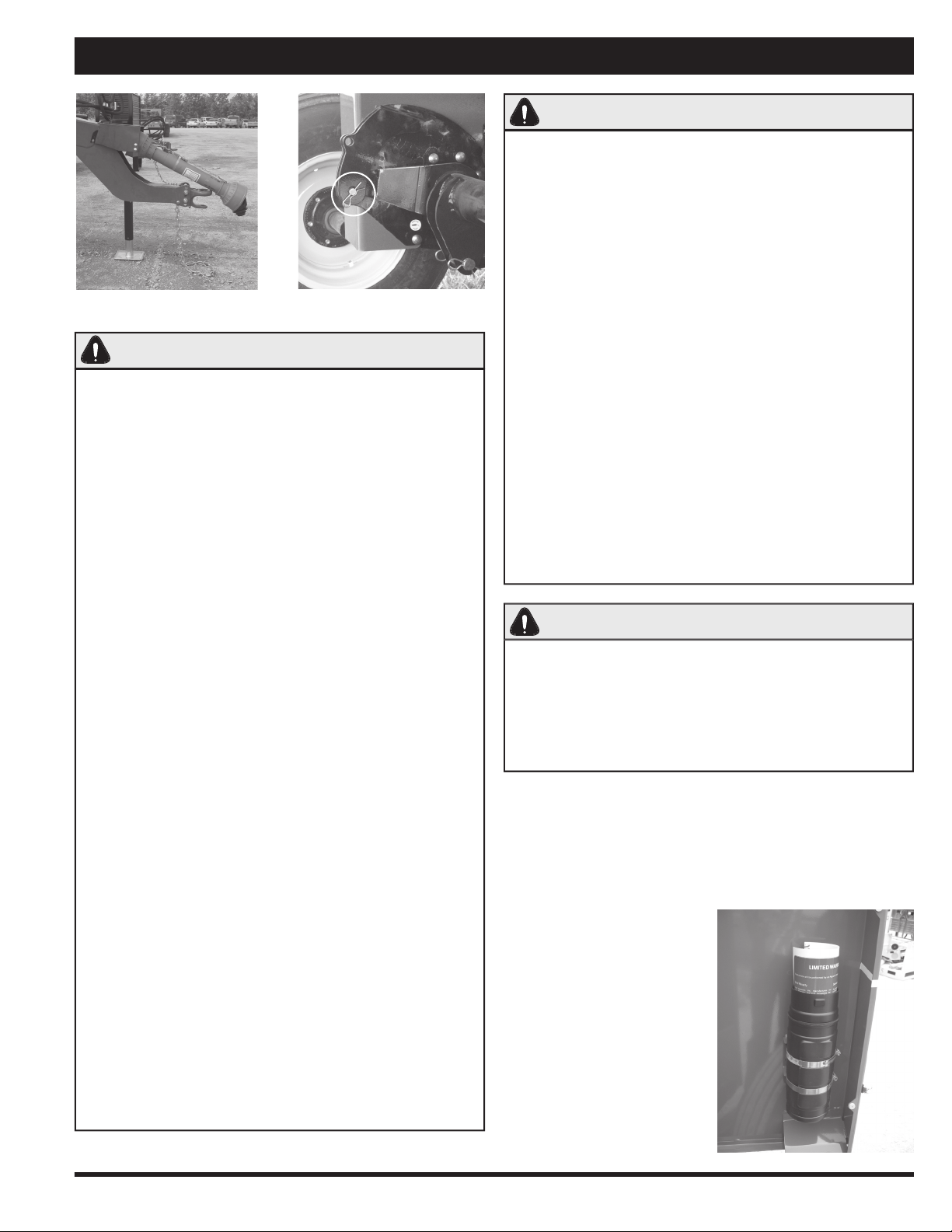

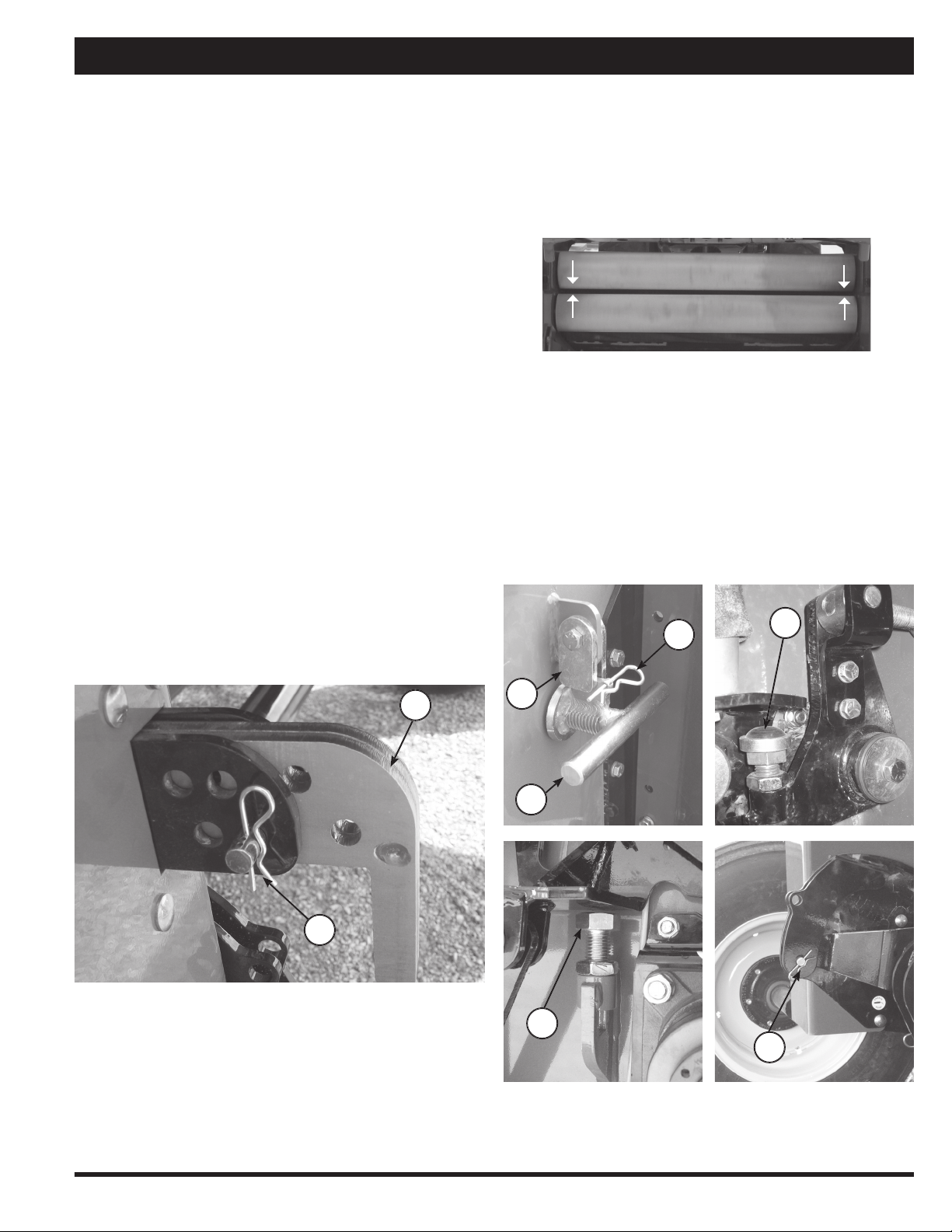

Hitch and safety chain.

Lock travel pin in place.

Keep the Operator’s Manual

in the storage container pro-

vided on the Macerator. The

Operator’s Manual must be

available for use by all op-

erators.

Manual Storage Container

6

Specifi cations

Dimensions

Overall Width 10’6” (315 cm)

Length 11’4” (345 cm)

Height operation 3’6” (105 cm)

transport 5’6” (165 cm)

Weight 3,800 lbs. (1,633 kg)

Tires (4)

Tire Size 11 L - 15 SL

Pressure 138 kPa (20 PSI)

Wheel Hub 6 bolt

Wheel Torque 85 ft. lbs. (115.2 NM)

Pickup

Width 5’6” (165 cm)

Clearance* 14” to 16” (35.5 cm to 40.5 cm)

Tooth Clearance** 10” to 12” (25 cm to 30 cm)

Pickup Tooth Spacing 2.75” (7 cm)

*Under pickup when raised.

**When raised.

Rolls

Width of rubber feed rolls 5’6” (165 cm)

RPM of rubber feed rolls 645 RPM

Min. space between rubber rolls 1/16” (1.6 mm)

Width of steel rolls 5’6” (165 cm)

RPM of top steel roll 1372 RPM

RPM of bottom steel roll 1514 RPM

Min. space between steel rolls 1/32” (.8 mm)

Tractor Requirements

Sug

gested min. tractor size* 80 HP (60 KW)

Suggested min. under frame clearance** 15”

(38 cm)

*Tractor shoul

d be of suffi cient size to maintain operator co

n-

trol in all situations.

**To allow swath to fl ow freely under tractor.

AgLand Macerator

M

odel 6610

Air System

Size of air pressure tank 12 Gallon (46 L)

Max. air pressure in tank 120 PSI

Hydraulic outlets required 1

Operating

Speed

Approximate range* 8 to 16 km/hr (5 to 10 MPH)

*Dep

ending on crop conditions.

Swath Size

Width up to 5’ (150 cm)

Cut Width

Recommended Width 14’ to 16’ (480 cm)

Capacity

Up to 50 ton/hr

Some weights and measurements are approximate.

All specifi cations, statements, and information shown in

this manual are believed to be accurate at the time of print-

ing. Specifi cations are subject to change without notice.

7

Assembly

Attaching Hitch

Sometimes the hitch will be shipped detached from the

unit to allow for a more compact shipping package.

1. Bolt hitch to main frame, Figure 1, using fourteen

5/8” x 1 1/2” carriage bolts. Be sure bolts are se-

curely tightened all around.

2. Remove bearing on front of hitch (C), slide drive

shaft (B) onto override clutch (A) through front bear-

ing hole and reinstall bearing and tighten shaft bolts

on override clutch (A).

3. Install the long hydraulic hose (G) securely with the

3. Install the long hydraulic hose (G) securely with the

clamps (F) provided, as shown in Figure 2.

clamps (F) provided, as shown in Figure 2.

A. Override Clutch

B. Drive Shaft

C. Front Hitch Bearing

D. A Frame Cover (Back)

E. A Frame Cover (Front)

F. Hose Clamp

G. Long Hydraulic Hose

Figure 1

Figure 2

B

C

D

E

A

F

G

8

A. Mold Board Attachment Bracket L/H

A. Mold Board Attachment Bracket L/H

B. Mold Board Main Frame

B. Mold Board Main Frame

C. Main Frame Adjustment Bracket

C. Main Frame Adjustment Bracket

D. Mold Board Attachment Bracket R/H

D. Mold Board Attachment Bracket R/H

E. Quick Attach Bracket

E. Quick Attach Bracket

F. Small Frame

F. Small Frame

G. Extension Adjustment Bar

H. Adjustment Pin

J. Adjustment Bar

K. Short Mold Board Sheet

L. Long Mold Board Sheet

M. Lynch Pin

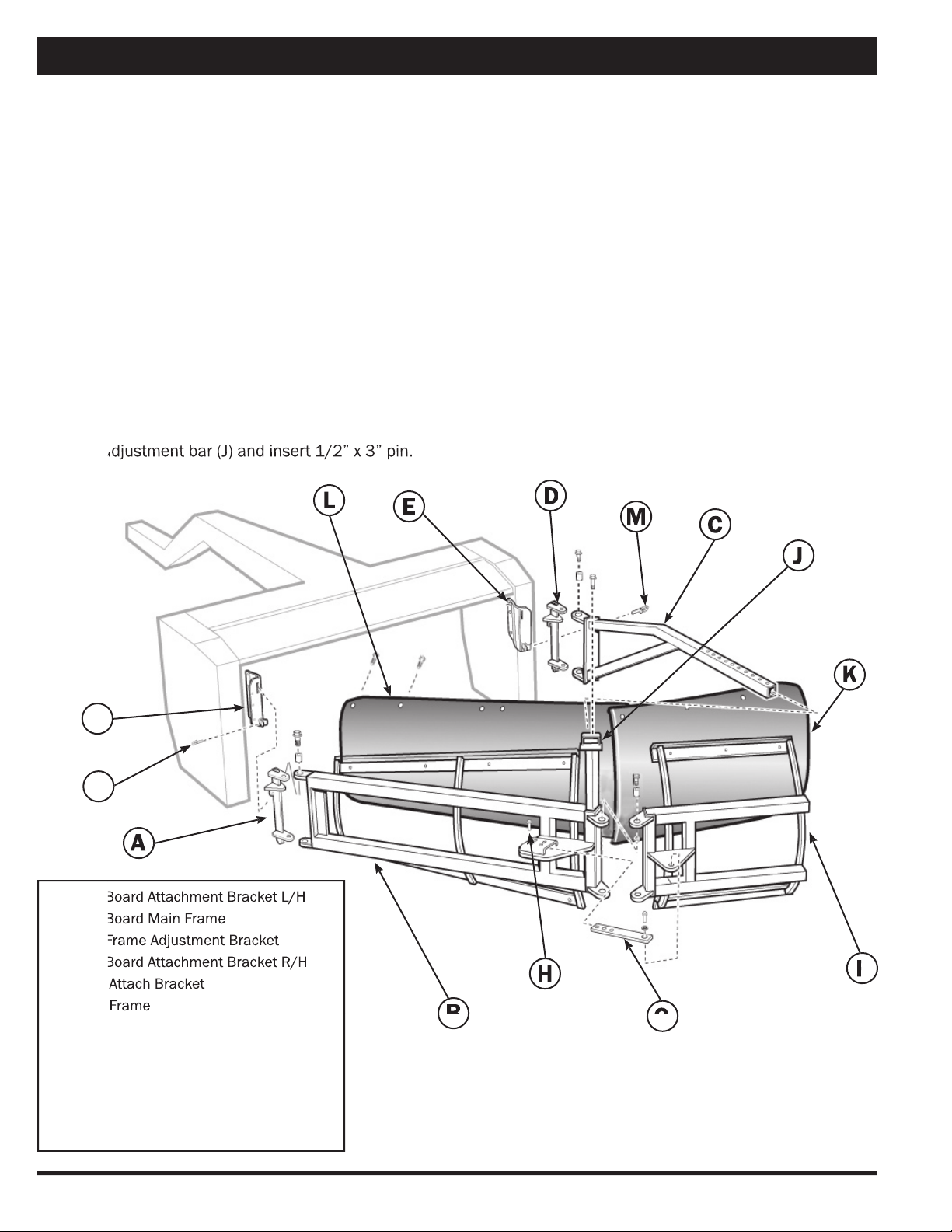

Assembly (Attachments)

1. Attach mold board attachment bracket L/H (A) to the

mold board main frame (B) and attach main frame

to quick attach bracket (E - already installed) and in-

sert lynch pin.

2. Attach mold board attachment bracket R/H (D) to

the adjustment bar (C) and attach bar to bracket (E

- already installed) and insert lynch pin (M).

3. Attach small frame (F) to the main frame (B), using

1/2” x 1 1/2” hex bolts with bushing, washer, lock

washer, and hex nut.

4. Attach extension adjustment bar (G) to frame (F)

using 1/2” x 1 1/2” std bolt, bushing, washer, lock

washer and std nut and insert adjuster pin (H).

5. Slide main frame adjustment bracket (C) through

the adjustment bar (J) and insert 1/2” x 3” pin.

the adjustment bar (J) and insert 1/2” x 3” pin.

Mold

B

oard Sheet Installation

6. Install short mold board (K) to outside portion of

main frame (F) using 5/16” x 3/4” carriage bolts

and hex nuts.

7. Install longer mold board sheet (L) on to the main

frame (B) using 5/16” x 3/4” carriage bolts, overlap-

ping the short mold board sheet.

8. All bolts holding the mold board sheets can now be

fully tightened.

9. Adjust angle of mold board by moving adjustment

bracket (C) in or out of adjustment bar (J) to pre-

ferred mold board angle and insert 1/2” x 3” pin.

The tighter angle will result in less inversion. The

wider angle will give you a greater inversion.

Swath Inverter (Mold Board)

A

F

F

E

D

C

B

B

G

G

H

K

L

J

E

M

Mold Board Attachment

M

9

A

B

C

D

E

E

A

G

H

F

Assembly (Attachments)

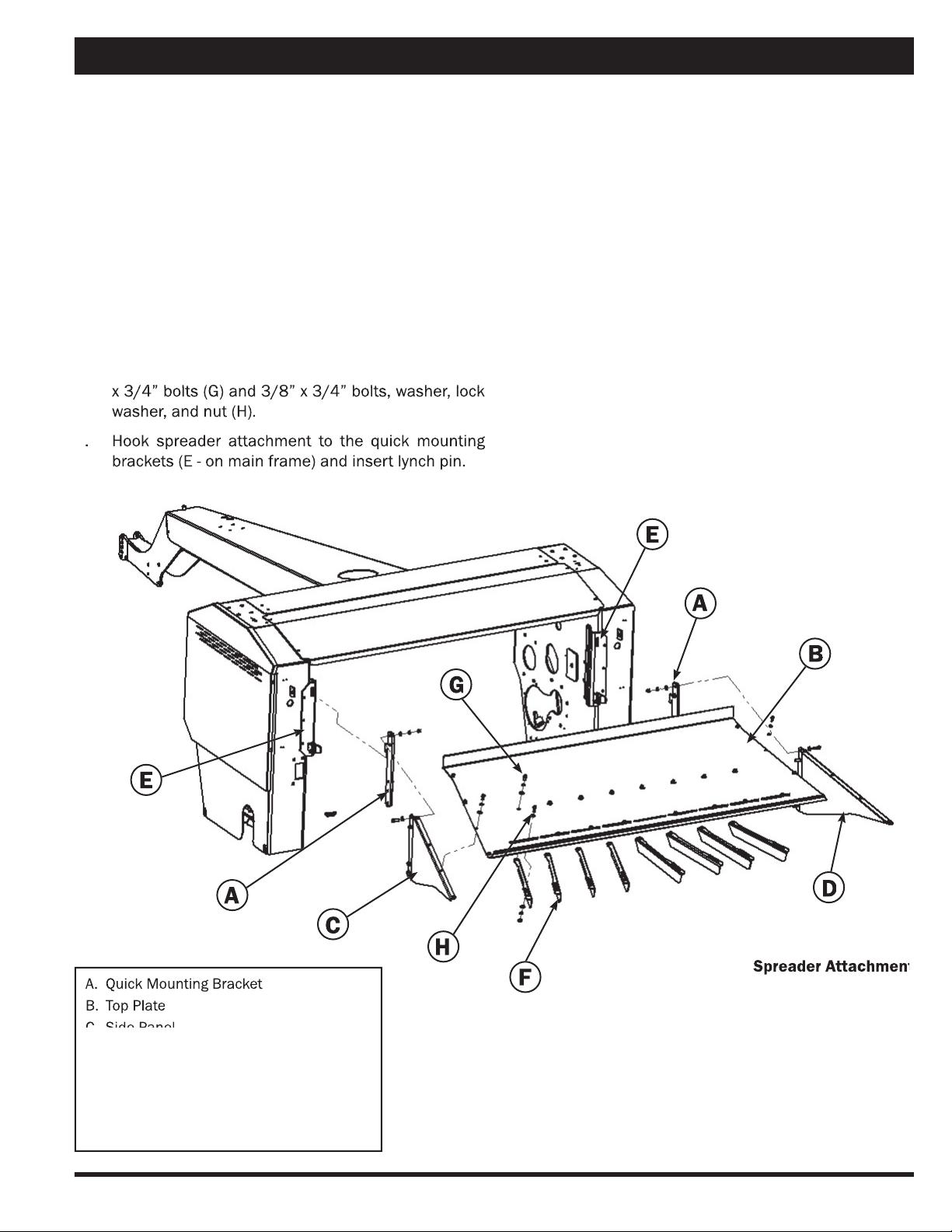

Spreader Attachment

The spreader attachment allows the Macerator to spread

a wider swath and leave a thinner layer on the fi eld for

greater sun and wind exposure.

The spreader attachment quick attaches onto the rear of

the main frame.

1. Attach bracket (A) to the side panels (C and D) using

3/8” x 1 1/4” bolts with washer, lock washer, and

nut.

2. Mount side panels (C and D) to top plate (B) with

5/16” x 3/4” bolts, washer, and lock washer.

3. Mount defl ector fi ns (F) to top plate (B) using 3/8”

x 3/4” bolts (G) and 3/8” x 3/4” bolts, washer, lock

x 3/4” bolts (G) and 3/8” x 3/4” bolts, washer, lock

washer, and nut (H).

4. Hook spreader attachment to the quick mounting

4. Hook spreader attachment to the quick mounting

brackets (E - on main frame) and insert lynch pin.

Spreader Attachment

Spreader Attachment

A. Quick Mounting Bracket

B. Top Plate

C. Side Panel

C. Side Panel

D. Side Panel

E. Quick Mounting Bracket (on main frame)

F. Defl ector Fin

G. Bolt

H. Bolt

10

Assembly (Attachments)

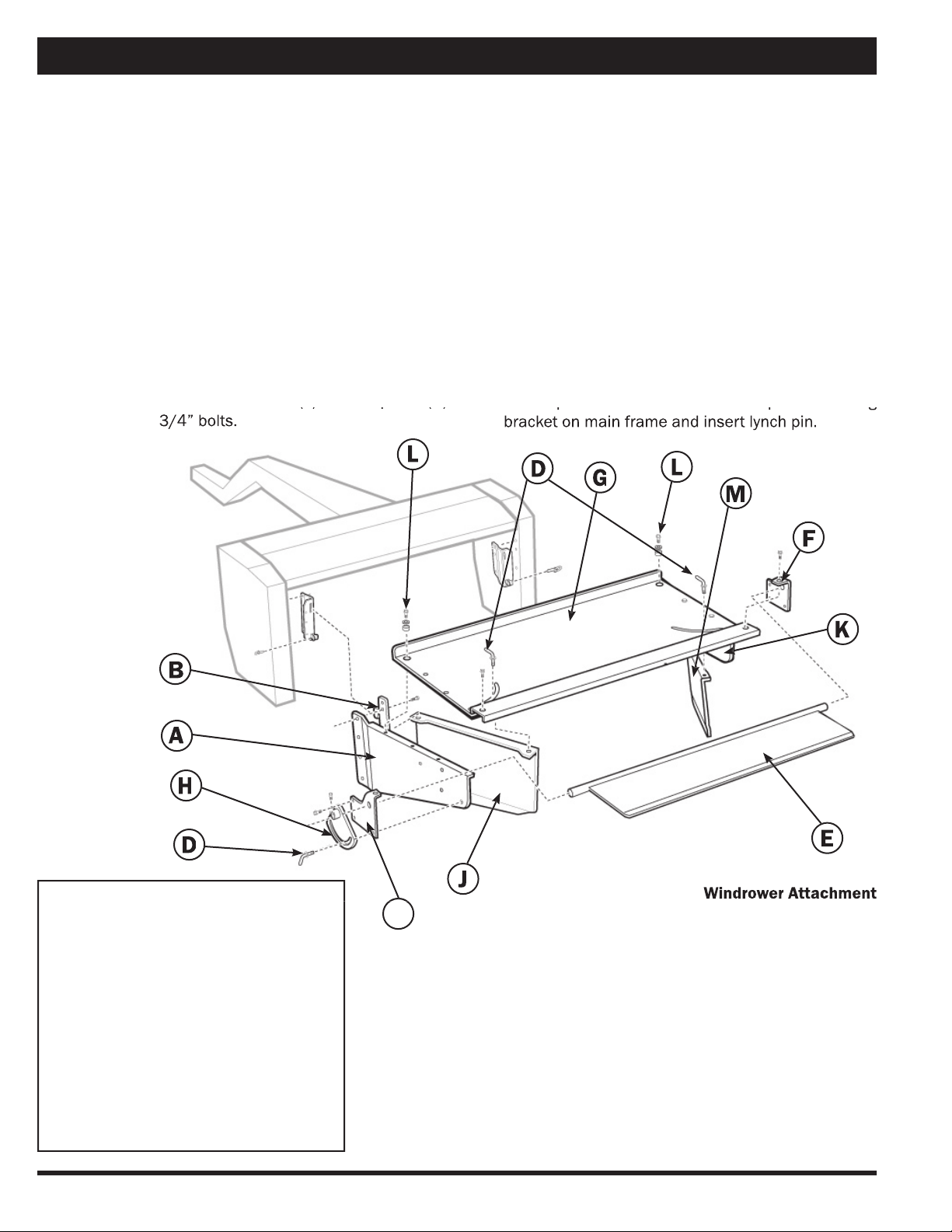

Windrower Attachment

The windrower attachment allows you to direct the cut hay

down to keep a tighter windrow, or out for a wider swath

width.

1. Insert 3/8” x 1 1/4” bolts through side panel (A) and

attach quick mounting bracket (B).

2. Mount side panels (A and K) to top plate (G) with

5/16” x 3/4” bolts. Do not tighten bolts.

3. Mount side bracket (C) to panel (A) with 3/8” x 3/4”

bolts. Only two bolts.

4. Insert windrow baffl e (E) into hole of side bracket

(C).

5. Mount the other side bracket (F) to side panel (K)

5. Mount the other side bracket (F) to side panel (K)

with 3/8” x 3/4” bolts.

with 3/8” x 3/4” bolts.

6. Mount adjustment bracket (H) using 5/16” x 1 1/2”

socket head cap screw and wing bolt (D).

7. Install left and right side width adjusters (J and M)

using 3/8” x 1” bolt and bushing (L) through top

plate (G).

8. Insert wing bolt with washer (D) through slot into

width adjusters (J and M).

9. Tighten all bolts evenly.

10. Hook spreader attachment to the quick mounting

10. Hook spreader attachment to the quick mounting

bracket on main frame and insert lynch pin.

A. Side Panel

B. Quick Mounting Bracket

C. Left Side Bracket

D. Wing Bolt

E. Windrow Baffl e

F. Right Side Bracket

G. Top Plate

H. Adjustment Bracket

J. Width Adjuster

K. Side Panel

L. Bushing

M. Width Adjuster

Note:

Use supplied washers and nuts with described bolts

above.

Windrower Attachment

A

B

C

D

E

F

G

H

K

M

D

L

J

L

11

1. Raise the Macerator using the hydraulics.

2. Turn crank (A) clockwise to widen the gap or counter-

clockwise to narrow the gap. 1 turn = .04” (1 mm).

For a better fi ne tune, adjust bolt (D).

3. Be sure to set the gap exactly the same on both

sides, use gauge.

4. Put crank lock (B) in place and secure with pin (C).

5. To assure that the rolls do not touch, the safety stop

is set by the factory at 1/32” or .8 mm.

6. If safety stop (E) needs adjusting put travel pin (F) in

place while unit is raised.

7. Adjust the safety stop bolt (E) as needed. Be sure the

rolls don’t touch during operation.

8. Repeat steps 1–7 to fi ne tune if necessary.

Field Setup

A

Use with a tractor having a minimum of 80 HP (60 KW).

Tractor should have suffi cient ground clearance for

swath to pass cleanly under it.

PTO Speed

Unless otherwise specifi ed, units are shipped with 1000

PTO speed. Units with 540 RPM PTO are also available,

contact dealer.

The PTO should be run at approximately 1000 RPM. The

front rubber rolls run at 645 RPM and the bottom steel

roll runs at 1514 RPM at a tractor PTO speed of 1000.

The upper steel roll runs at 1372 RPM at 1000 tractor

PTO speed.

Pickup

Height & Adjustment

The Macerator 6610 pickup should be adjusted so that

it will cleanly pick up all material off of the fi eld without

gouging the soil. You may have to reset the height a few

times to arrive at the best working height.

1. If your pickup is too low to the ground use your trac-

tor hydraulic cylinder control to raise the pickup.

2. Remove pin (A) and slide adjuster bar (B) to desired

height. Pushing bar in raises machine and pulling

the bar out lowers the machine.

3. Reinsert pin and lock in place.

Gap Gap

B

A

Steel Roll Adjustment

For best results adjust the Macerator 6610 for your specif-

ic fi eld conditions. The smaller the gap between the steel

serrated rolls the more aggressive will be the maceration

of the hay. Both the space between the rolls and the air

pressure need to be adjusted for maximum effi ciency.

B

C

E

F

D

12

Field Setup

Preparation (Air System)

The purpose of the air system on the Mac-

erator 6610 is to keep continuous pres-

sure on the rolls.

The pressure can make a difference on

how well the machine performs on the

fi eld. While the pressure on the rubber rolls may not be

as crucial, too much pressure on the steel rolls will result

in considerable leaf loss and some plugging may result in

short wet hay.

Before heading out to t

he fi eld, make sure the air pres-

sure tank has a minimum of 100 PS

I pressure

. This sho

uld

give the operator suffi cient

air supply for the day.

Rubber Roll Pressure Adjustment

The rubber rolls are designed to take the

material from the pickup and feed it into

the steel rolls. The rubber rolls do not crush

or crimp the hay.

As a standard setting, we recommend 20–

30 PSI pressure on the rubber rolls. Regulate the pressure

by pulling out the knob on the regulator marked ‘rubber

rolls’ and turning it clockwise or counter-clockwise. When

turning the knob counter-clockwise you should hear the

air escaping from the regulator.

In extreme conditions, increase or decrease the pressure.

For example, very heavy swaths may require more pres-

sure.

Steel Roll Pressure Adjustment

The steel serrated rolls (rear) take the ma-

terial from the rubber rolls and crack the

stems. To achieve the right setting, some

fi eld testing may be necessary.

1. Pull out the knob on the air regulator

marked ‘steel rolls’ and turn the knob clockwise or

counter-clockwise to set the pressure to the steel

rolls at approximately 5-35 PSI in alfalfa, 40–80 in

grasses

2. If you experience too much leaf loss or the plants are

crushed too intensely, lower the air pressure.

3. If there is not enough maceration, increase pressure

to the rolls by increasing the air pressure. Make sure

the gap is adjusted (see page 12).

Field Notes:

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

13

Maintenance

Use Good Safety Practices When

Working On This Machine

Before doing any maintenance or service on the ma-

chine you must:

□

Park machine on a solid level surface.

□

Lower the machine fully to the ground or onto

blocks.

□

Disengage all power.

□

Put the tractor transmission in PARK or apply the

tractor parking brake.

□

Stop the tractor engine and remove key from the

ignition.

□

Look and listen. Make sure all moving parts have

stopped.

First Time Use

□

Tighten hub bolts A–E* after the fi rst 1 hour of oper-

ation and repeat procedure after 10 hours and 50

hours.

*

Importa

nt

Hubs A - tighten to 60 ft. lbs.

Hubs B - tighten to 30 ft. lbs.

Hubs C - tighten to 9 ft. lbs.

Hubs D - tighten to 6 ft. lbs.

Hub E - tighten to 15 ft. lbs.

Daily

□

Check and tighten all hub bolts.

□

Remove all dirt and crop deposits from machine.

After The First 25 Hours Of Use

□

Check bearing and set screw tightness.

At The Beginning Of Each Season

□

Review all safety instructions.

□

Carefully inspect all components for excessive wear

or hazardous con-

ditions.

□

Lubricate the ma-

chine at all lubrica-

tion points.*

□

Check tires for cor-

rect infl ation pres-

sure.

□

Tighten bolts.

*See lubrication sched-

ule and procedures on

page 1

7.

Checklist

A

B

C

E

C

A

B

CAUTION

D

D

14

Maintenance

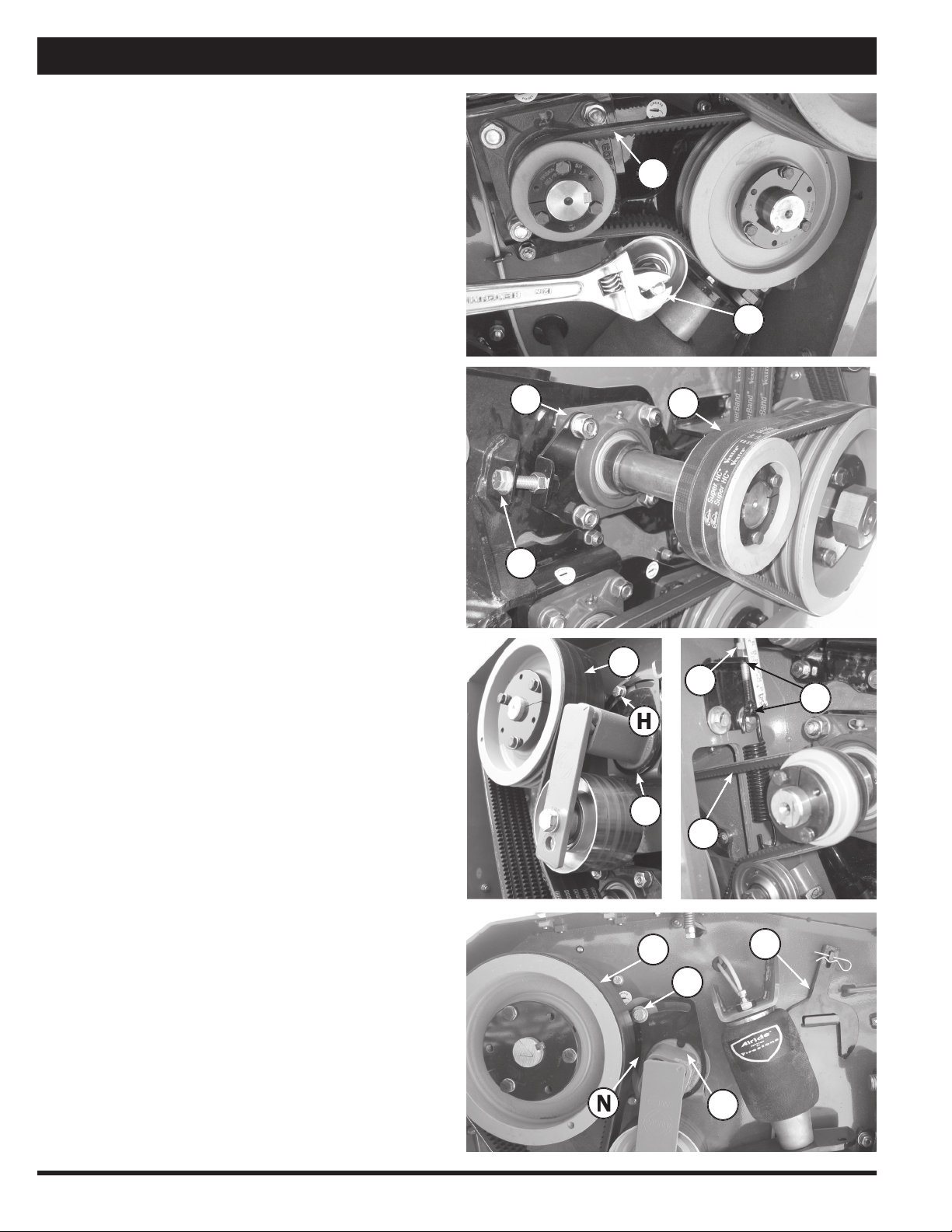

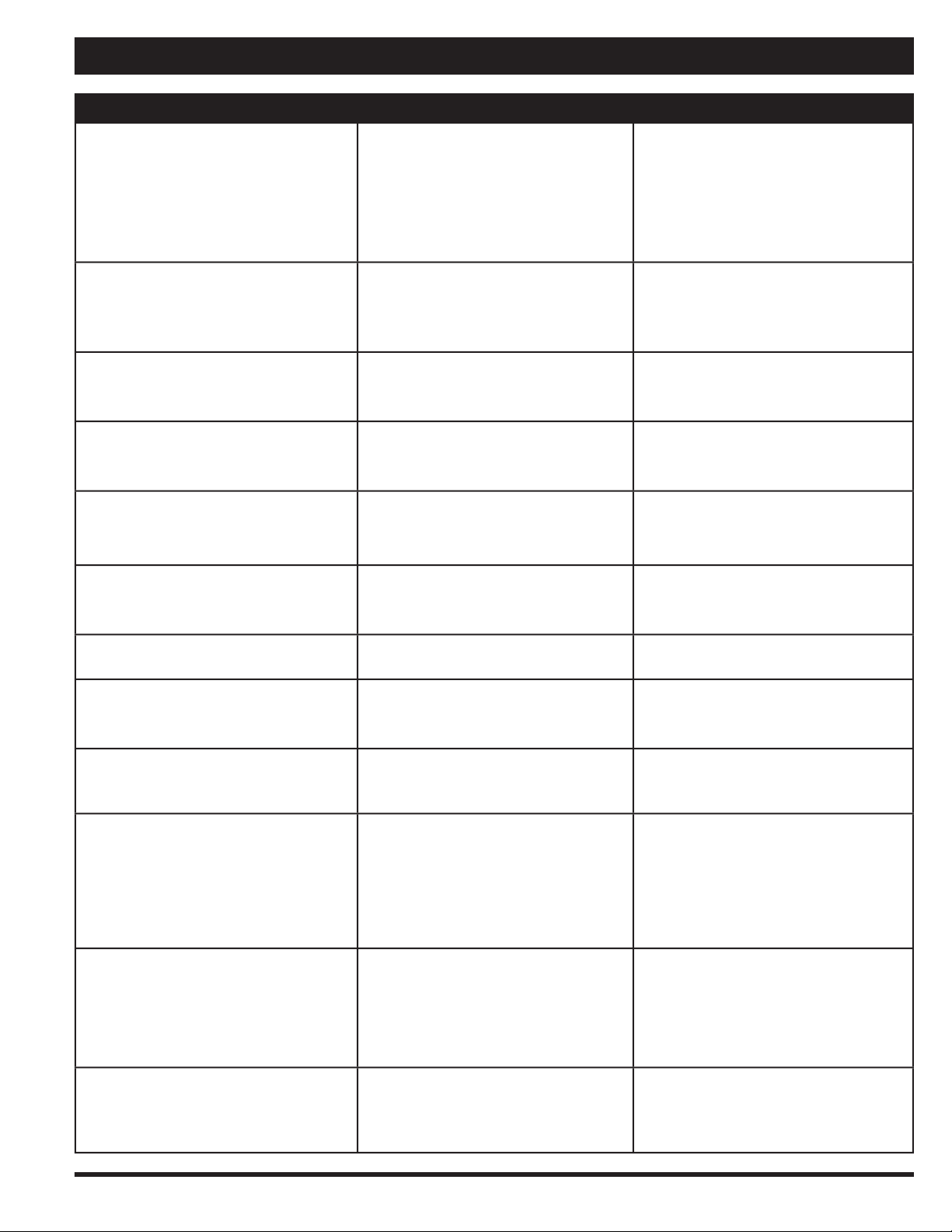

Roll Drive Belt Replacement

Replace worn or damaged belts as follows:

1. Raise Macerator and secure travel safety pin, see

page 6.

2. To remove belts (A) loosen and turn fl attened bolt (B)

counter-clockwise.

3. To remove belts (C) loosen 4 bolts (D) then loosen

bolt (E) and slide roll forward.*

4. To remove belt (F) loosen bolt (G) behind tightener,

then loosen bolt (H) and slide tightener forward.

5. To remove belt (M) loosen bolt (N) on the other side

of the panel behind tightener. Take tightening wrench

(O) (use a pipe for leverage) and hold spring loaded

tightener (P) fi rmly in place while loosening bolt (Q),

then release tension slowly with wrench.

6. Replace all belts and tighten bolts (reverse sequence

of steps 2–5).

7. To remove belt (J) loosen spring tension by turning

off nut (K) counter-clockwise. To tighten the belt,

tighten nuts (K) until you measure approximately 2

inches (L) or proper tension on the belt.

8. Reinstall all covers.

* To maintain proper roll alignment be sure to adjust the

oppo

site tightener on the other side of the machine.

M

N

Q

P

O

E

D

C

B

A

F

H

G

L

K

J

15

Figure 1

Figure 1

A

Locking Collar

Bearing

Maintenance

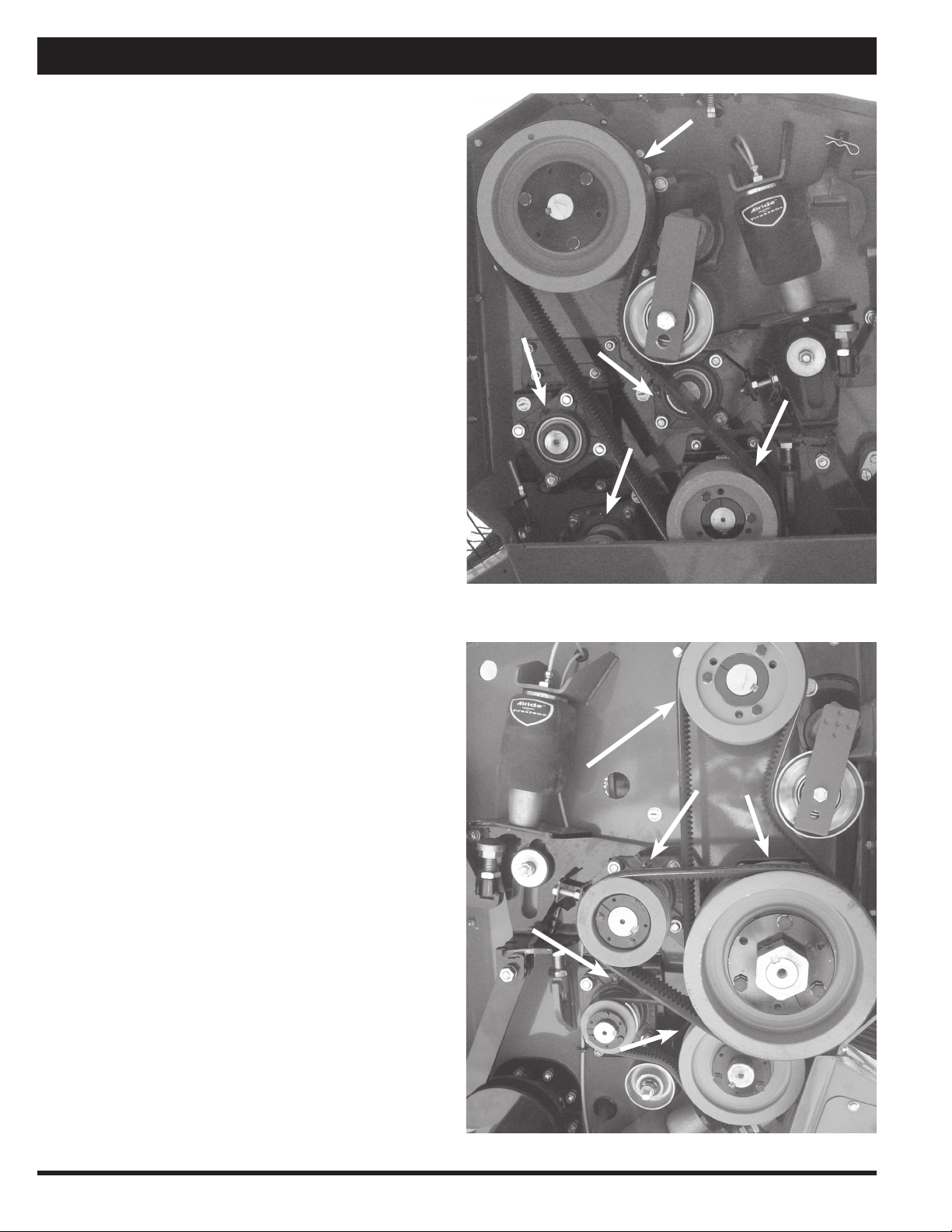

Bearing Replacement

Sealed ball bearings are held in position on the shaft by

a locking collar, Figure 1, which is rotated to lock the as-

sembly on the shaft and secured by a set screw. To re-

move bearing:

1. Loosen set screw.

2. Use a drift punch inserted in the drift pin hole to

rotate and loosen the locking collar (A). Rotate the

locking collar counter-shaft rotation

3. Remove the locking collar.

4. Support the shaft, for easier assembly later.

5. Remove the bolts for the bearing fl anges.

6. Slide the bearing and the fl anges from the shaft.

Note: Cleaning paint and corrosion from the shaft

will make removal easier.

7. Put on the new bearing and fl anges.

8. Replace locking collar on the shaft. Rotate the lock-

ing collar in the direction of the shaft rotation until

lightly engaged. Tighten the collar by hitting it with a

drift pin punch inserted in the drift pin hole rotating

it further until fully tightened

9. Tighten set screw.

9. Tighten set screw.

Figure 2

Figure 2

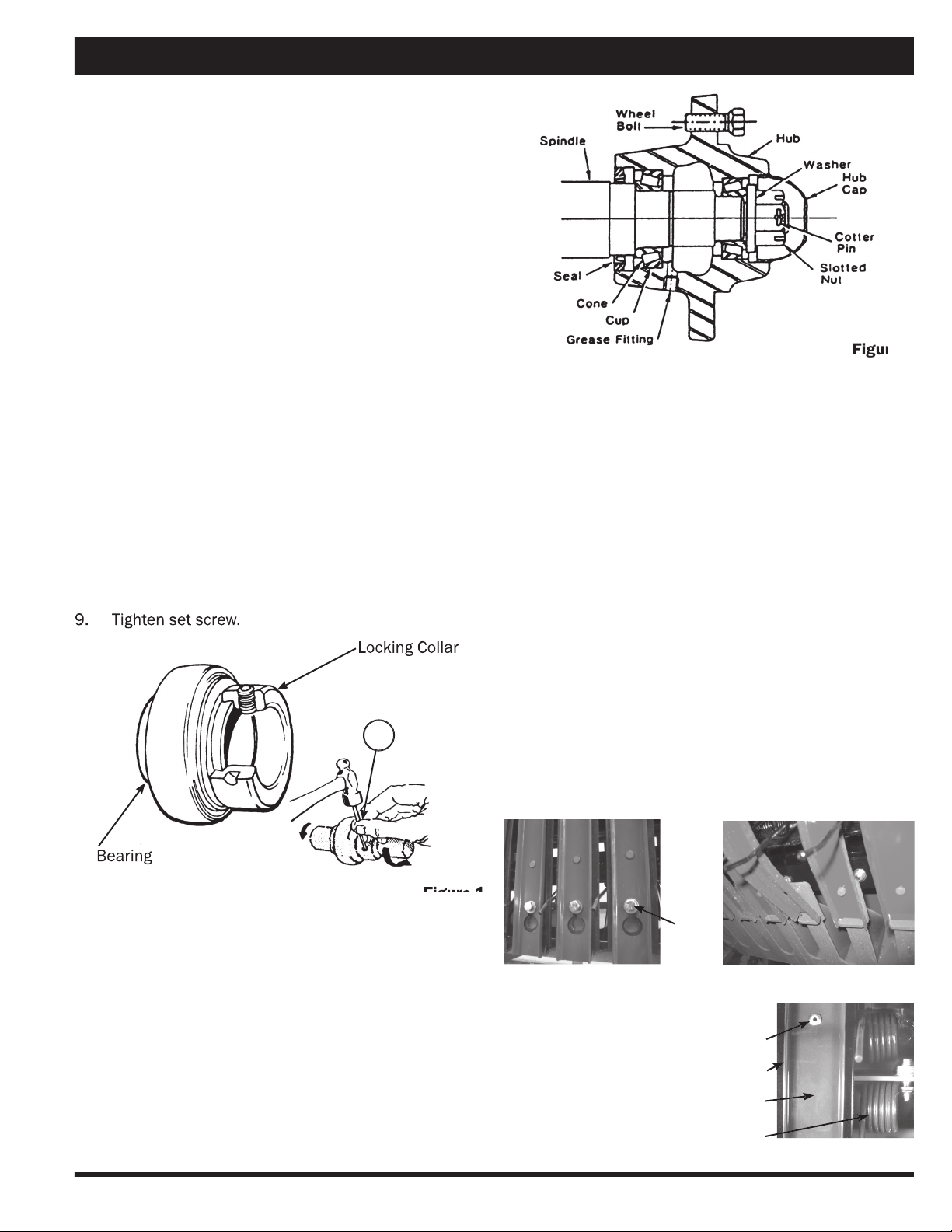

Replacing or Repacking Wheel Bearings

1. Remove wheel hubs and disassemble.

2. Clean bearings, seals, caps, washers, nuts, and hubs

with kerosene or other solvent.

3. Replace bearings or seals if worn or damaged.

4. Pack bearing cones and seals with No. 2 multipur-

pose lithium grease or equivalent.

5. Reassemble hub and bearings, Figure 2.

6. Press cups against the shoulder in the hub.

7. Press seal fl ush into hub after bearing.

8. Place hub on shaft taking care not to damage the

seal.

9. Tighten the wheel bearing nut. Do not overtighten.

10. Secure nut with a cotter pin.

11. Be sure to replace hub cap.

Pickup Teeth, Wrappers, and Wear Strips

Check for bent, broken or loose parts. If it is necessary to

replace teeth or related parts, proceed as follows.

1. Ensure that your Macerator is blocked securely.

Loosen the bolt holding the wrapper(s) on pickup,

Figure 3. Lift the wrapper on top and slide forward to

remove.

2. Should the plastic wear strip require removal and

replacement, drill out or carefully grind off the ‘pop’

rivets. Replace strip with new rivets, Figure 5.

3. Install new teeth or wrapper(s).

Figure 3

‘Pop’ Rivets

Figure 5

Plastic Wear Strips

Wrapper

Teeth

Figure 4

Bolt

16

Lubrication

General Information

A NLGI No. 2 multi-purpose high temperature lithium base

grease is recommended.

Use a manual grease gun for all greasing. Air powered

grease guns may damage the seal on the bearings.

Wipe all grease fi ttings with a clean cloth before greasing

to avoid injecting dirt or grit in the bearings.

At The Beginning Of The Season

Grease all the sealed bearings, front rolls (two places),

rear rolls (two places) and drive shaft (one place), Figures

1 and 2.

Figure 1

Figure 2

17

Trouble Shooting

Problem Possible Cause Solution

Pickup is skipping swath or not

picking cleanly.

▪ Missing or broken pickup teeth.

▪ Pickup too high.

▪ Driving too fast for pickup speed.

▪ Not following the same direction as

swath was cut.

▪ Replace missing teeth.

▪ Adjust pickup height.

▪ Use lower tractor gear with higher

RPM.

▪ Follow same direction as swath cut.

Material wrapping in pickup.

▪ Nylon wear plates are missing or

worn.

▪ Pickup and travel speeds are not

matched.

▪ Replace missing or worn nylon

plates.

▪ Match pickup and ground speed as

close as possible.

Breakage or bending of pickup teeth.

▪ Running pickup too low.

▪ Excessive pickup rotation speed in

rough or rocky conditions.

▪ Adjust pickup height.

▪ Reduce pickup or ground speed.

Excessive noise or heat from gear

box.

▪ Insuffi cient oil in gear box.

▪ Worn or broken parts inside gear

box.

▪ Top up gear oil as needed.

▪ Replace parts as needed.

Air pressure does not hold in air tank

and air bags.

▪ Broken air line.

▪ Torn or punctured air bag.

▪ Air regulator not working.

▪ Repair or replace line as needed.

▪ Replace air bag as needed.

▪ Clean or replace regulator.

Pickup does not rise or lower.

▪ Worn or punctured hydraulic cylin-

der or hydraulic oil line.

▪ Bushings too tight.

▪ Replace hydraulic lines and cylin-

ders as needed.

▪ Replace or clean bushings.

Pickup height adjustment does not

hold.

▪ Broken or worn parts on adjuster.

▪ Replace worn parts as needed.

Rubber rolls not feeding properly.

▪ Air pressure too high or low.

▪ Gap between rolls too tight or too

wide.

▪ Adjust air pressure using regulator.

▪ Adjust gap width.

Wax build up on steel rolls.

▪ Temperature and hay conditions

cause the wax to come off of the

plant and stick to the rolls.

▪ The wax will come off after the rolls

cool down. A thin layer of wax/

leaves will build up on the rolls.

Excessive leaf loss.

▪ Too much air pressure on steel

rolls.

▪ Hay conditions too dry.

▪ The gap between steel rolls is too

narrow or the rolls are going too

fast.

▪ Release air pressure.

▪ Condition hay early in the morning.

▪ Adjust gap between steel rolls.

Hay is not being macerated.

▪ Not enough air pressure on steel

rolls.

▪ Gap between rolls is too wide.

▪ Windrow is too thick.

▪ Steel rolls not running fast enough.

▪ Adjust air pressure as required.

▪ Narrow the gap between steel rolls.

▪ Cut wider or thinner windrows.

▪ Increase tractor RPM.

Swath not being inverted completely.

▪ Mold board is not adjusted properly.

▪ Adjust mold board angle. The

tighter angle will result in less inver-

sion. The wider angle will result in a

greater inversion.

18

LIMITED WARRANTY

Warranty service will be performed by AgLand Dealer authorized to sell the Macerator.

AGLAND WARRANTY

AgLand Industries Inc. manufactures the AgLand

Macerator. AgLand Industries Inc. (Manufacturer)

warrants each Macerator sold by it to be free of de-

fects in material or workmanship under normal use

and service. The sole obligation of the Manufacturer

is limited to repairing or replacing, as the Manufac-

turer may elect, any part or parts that prove, in the

Manufacturer’s judgement, to be defective in mate-

rial or workmanship within one year* after delivery

to the original Retail Purchaser under normal farm

use. The defective part or parts will be replaced or

repaired only to the original Retail Purchaser. War-

ranty repair or replacement will be done at the loca-

tion of the AgLand dealer who sold the Macerator.

Defective parts must be returned to the Manufactur-

er or Dealer who sold the Macerator at the expense

of the Retail Purchaser to be inspected by the Manu-

facturer. Purchaser must give written notice to the

Dealer from whom the Macerator was purchased of

any claimed defect and the Dealer will repair or re-

place the part or parts found to be defective.

*3 months after delivery when purchased by a com-

mercial operator.

Note: The sole remedy of the Purchaser for claim

under this warranty is the repair or replacement of

defective parts.

This warranty does not extend to the drive compo-

nents or tires, which are made by other manufactur-

ers and carry warranties from said manufacturers.

There are no representations, warranties, or condi-

tions, express or implied, statutory or otherwise, ex-

cept those herein contained and no agreement col-

lateral otherwise except those herein contained, and

no agreement collateral hereto shall be binding upon

either party unless in writing hereon or attached

hereto, signed by the Purchaser and accepted by the

Manufacturer at its head offi ce.

SERVICE AND WARRANTY

INFORMATION

The Manufacturer’s liability under this warranty is

limited to the repairing or replacing of parts only, and

the Manufacturer shall in no event be liable to the

Retail Purchaser for consequential damage or loss

of profi ts sustained by it as a result of any defect in

material or workmanship on any of the equipment

covered by this warranty.

The Macerator is warranted for agricultural use only.

This warranty does not cover claims resulting from

any use for other than agricultural applications.

Altering, modifying or adding additional equipment

which is not approved for installation on the Macera-

tor by the Manufacturer will void this warranty.

All warranties are subject to legislation of the state

or province in which the Macerator is sold.

Note: There are no warranties, express or implied,

by the Manufacturer or its Dealer regarding the

Macerator except the warranty against defects in

the material or workmanship expressed herein. No

person is authorized to bind the Manufacturer to

any other warranty whatsoever.

The Manufacturer reserves the right at any time

to make changes in the design, material, parts, or

specifi cations of the Macerator without thereby be-

coming liable to make similar changes in equipment,

machinery or parts previously manufactured.

AgLand Industries Inc.

Issue Date July 2004 Part No. 808321

Cost $14.00 plus $2.50 postage and handling (prices CDN)

Printed in Canada JZ 0305

Table of contents

Other AgLand Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions