AgLand Matador 7900 User manual

Operator’s Manual

June 2011

2011

Replacement Parts

To obtain prompt, efcient service, give your dealer the

following information.

1. Correct stock number of part.

2. Model number of the machine.

3. Serial number of the machine.

The serial number is important in identifying your ma-

chine. It contains information for ordering replacement

parts and options which may vary depending on the

serial number identication.

Measurements are given in U.S. units followed by the

equivalent in metric units. Hardware sizes are given in

inches for the U.S. hardware and millimeters for the

metric hardware.

Serial # on plate inside hitch.

Box 479 Arborg MB, R0C 0A0

Matador 7900

Made in Canada

Model #:

Serial #:

1

Contents

Warranty Registration Form ....................................................................................................................................................3

Introduction .............................................................................................................................................................................5

Safety ..................................................................................................................................................................................6–7

Transport Safety .................................................................................................................................................................................... 6

Operating Safety .................................................................................................................................................................................... 7

Hydraulic Safety ..................................................................................................................................................................................... 7

Safety Decals ...........................................................................................................................................................................8

Specications ..........................................................................................................................................................................9

Assembly ..........................................................................................................................................................................10-12

Wheel Assembly .................................................................................................................................................................................. 10

Moldboard Attachment .......................................................................................................................................................................11

Hydraulic Lift Kit ..................................................................................................................................................................................12

Operation ....................................................................................................................................................................... 13–14

Level Inverter .......................................................................................................................................................................................13

Uneven Fields - Flotation Spring Adjustment.....................................................................................................................................13

Pickup Finger Height - Gauge Wheel Adjustment..............................................................................................................................13

Setting Pickup Speed .......................................................................................................................................................................... 14

Direction of Travel ................................................................................................................................................................................14

Maintenance ................................................................................................................................................................. 15–18

Setting Drive Chain Tension ................................................................................................................................................................15

Roller Drive Chain Replacement ........................................................................................................................................................16

Bearing Replacement .........................................................................................................................................................................16

Replacing or Repacking Wheel Bearings ........................................................................................................................................... 16

Pickup Teeth, Bands, Wear Strips ...................................................................................................................................................... 17

Flotation Spring Adjustment ............................................................................................................................................................... 17

Torque Charts for Bolts and Nuts .......................................................................................................................................................18

Lubrication ............................................................................................................................................................................ 19

Hydraulics Assembly Instructions ................................................................................................................................ 20–21

Troubleshooting ............................................................................................................................................................. 22–23

Warranty ................................................................................................................................................................. Back Cover

I have instructed the buyer on the above described equipment and included a review of the Operator’s Manual, assembly,

maintenance, safety, and applicable warranty policy.

Dealer’s Signature Date

The above Equipment and Operator’s Manual have been received by me and I have been instructed as to the care, adjust-

ments, safe operation, and applicable warranty policy.

Purchaser’s Signature Date

Customer Name:

Address:

City:

Prov/State: Postal/Zip:

Phone No:

Model No:

Serial No:

Dealer:

Address:

City:

Prov/State: Postal/Zip:

Phone No:

Date Purchased:

Check One: Farm Use Commercial Use

AgLand Matador 7900™ Windrow Inverter

LIMITED WARRANTY REGISTRATION FORM

AgLand Industries Inc. warrants to the original owner of the Matador 7900 Windrow Inverter to be free of defects in workman-

ship and material for a period of one (1) year from the date of purchase for farm use (three (3) months from date of purchase

for commercial use). AgLand does not warrant any damage caused by negligence, modications, and/or lack of maintenance

(see Maintenance Schedule in Operator’s Manual).

AgLand will not be liable for the cost of shipping or any other cost incurred for replacement or repair of any parts. AgLand is

not liable for any accidents which may occur from or during the operation of the Matador 7900 Windrow Inverter, or damage

incurred due to Matador failure. The purchaser assumes all responsibility for the care, maintenance and safety.

See back of the Operator’s Manual for complete warranty details.

Failure to return completed registration to AgLand within thirty (30) days of delivery will VOID the warranty.

This form must be lled out by the dealer and signed by both dealer and customer.

Mail to:

AgLand Industries Inc.

Box 479, Arborg, MB

R0C 0A0

DEALER CHECKLIST

Chain tension, checked and adjusted

Pickup, including nger height, adjusted and set

Flotation spring, checked and adjusted

Hydraulic line and ttings checked for leaks and rubbing

moving parts

All reectors in place

Wheel bolts tight

Tire air pressure (32 PSI maximum (221 kPa))

All grease ttings greased

All safety procedures have been reviewed with customer

All warning decals are in place, clean, and legible

Customer has been instructed to review safety and operat-

ing procedures with all operators annually.

I have thoroughly inspected the machine and made adjustments and corrections as needed.

Inspected By Signature Date

White - AgLand Yellow - Customer Pink - Dealer

5

Introduction

The Matador 7900 Windrow Inverter is designed to turn

and move hay swaths for a faster dry down. The Matador

utilizes a low prole, heavy duty pickup with extra width to

allow rapid operation with minimal leaf loss.

The moldboard of the Matador 7900 Windrow Inverter is

a patented design giving a 180˚ turn to the swath when

the machine is operated correctly.

These operating and maintenance instructions have been

compiled from extensive eld experience and engineering

data. Some information is general in nature due to un-

known and varying conditions. However, through experi-

ence and these instructions, you will be able to develop

operating procedures suitable to your particular situation.

Please study this manual from beginning to end BEFORE

operating your new Matador 7900. Pay special attention

to the Safety section in this manual and the safety cau-

tions on your equipment. Should anyone else operate

this equipment be sure that they understand ALL safety,

operating and maintenance information presented in

this manual.

The terms ‘right’ and ‘left’ as used throughout this manu-

al are determined by facing the direction the machine will

travel when in use.

AgLand Industries Inc. is a Canadian owned and oper-

ated company located in central Canada, in the province

of Manitoba. AgLand was founded in 2001 by a group of

innovative young men that transformed their ideas and

expertise into a leading manufacturing company of agri-

cultural crop equipment.

Box 479, Arborg, MB, Canada R0C 0A0

1.888.933.4440

Tel: 204.364.2211

Fax: 204.364.2472

Email: [email protected]

Web: www.aglandindustries.com

The photographs, illustrations, and data used in this man-

ual were current at the time of printing, but due to pos-

sible in-line production changes, your machine may vary

slightly in detail. The Manufacturer reserves the right to

redesign and change the machine as necessary without

notication.

WARNING

Some pictures in this manual show the machine with

shields removed to allow for a better view of the sub-

ject. The machine must never be operated with any of

the shields removed.

Congratulations, you have just purchased the Matador 7900 Windrow Inverter, the only true inverter on the mar-

ket today. To get the maximum benet from your Matador we suggest that you read this manual carefully.

6

Safety

Read this manual completely and understand all oper-

ating instructions and precautions BEFORE attempting

to operate or service your machine.

The safety information given in this manual does not re-

place safety codes, insurance needs, or state/province

and local laws. Make sure your machine meets all stan-

dards required by the local laws and regulations.

Understand that your safety, and the safety of others, is

measured by how you service and operate this machine.

IMPORTANT! Review and understand the positions and

functions of all machine controls before operating this

machine.

WARNING! Do NOT attempt any adjustments, mainte-

nance, troubleshooting, or repairs while machine com-

ponents are moving or activated with pressure.

▪ Lower machine to ground or onto appropriate blocks.

▪ Stop tractor engine and remove ignition key.

▪ Set tractor parking brake prior to leaving operator sta-

tion.

Safety Alert Symbol

The Safety Alert symbol identies important safety mes-

sages in the manual and on the machine.

When you see this symbol, be alert to the

possibility of personal injury or death. Fol-

low all instructions in the safety message

given. This symbol means attention, be

alert, and your safety is involved.

Three Reasons To Follow Safety Instructions:

1. Accidents disable and kill.

2. Accidents cost.

3. Accidents can be avoided.

Slow Moving Vehicle Emblem

The Slow Moving Vehicle (SMV) emblem must be placed on

the rear of the machine and be visible to trafc approach-

ing the machine from the rear while trav-

eling on public roads. Keep the SMV em-

blem clean and replace when damaged

or when emblem materials have faded.

The SMV should only be displayed on the

machine at road speeds less than 25 MPH (40 km/h).

▪ The operator is responsible for complying with all

local regulations regarding transporting agricultural

equipment on public roads and highways.

▪ Ensure all lights and reectors, as required by local

law, are in place, intact, and clean before transport-

ing machine on public roads and highways.

▪ Ensure SMV emblem is clean and properly displayed,

where required by law, before transporting machine

on public roads and highways.

▪ Do NOT allow riders on machine at any time includ-

ing transport of machine on public roads and high-

ways.

▪ Maximum transport speed is 20 MPH (32 km/h).

Reduce speed on rough roads and surfaces.

▪ Use proper retainer on drawbar hitch pin and attach

safety tow chain to tractor prior to transporting ma-

chine on public roads and highways.

▪ When using a ball and socket, make sure the lock-

ing jaws are pinned securely in position.

▪ Do not rely on the pickup lift hydraulic cylinder to

keep the pickup raised. Be sure pickup reel is in

raised position and lever is secured with the pick-

up travel lock pin provided.

Transport Safety

DANGER

DANGER: Indicates an imminently hazardous situation

that, if not avoided, WILL result in death or serious injury

if proper precautions are not taken.

Signal Words

WARNING: Indicates a potentially hazardous situation

that, if not avoided, COULD result in death or serious in-

jury if proper precautions are not taken.

CAUTION: Indicates a potentially hazardous situation that,

if not avoided, MAY result in minor or moderate injury if

proper practices are not taken, or serves as a reminder to

follow appropriate safety practices.

CAUTION

WARNING

7

Operating Safety

▪ Ensure that all components in the hydraulic system

are kept in good condition.

▪ Replace any worn, cut, abraded, attened, or

crimped hoses and/or metal lines.

▪ Do not attempt any poorly executed repairs to hy-

draulic lines, ttings, or hoses by using tape, clamps,

or cements. The hydraulic system operates under

extremely high pressure: 1600 to 2300 PSI (11,033

to 15,859 kPa). Such repair will fail suddenly and

create unsafe conditions.

▪ Wear proper hand and face protection (e.g. face

shield) when searching for a high pressure hydraulic

leak. Use a piece of wood or cardboard as a back-

drop instead of hands. A high pressure concentrated

stream of hydraulic uid can pierce the skin. If this

should happen, seek immediate medical attention

as infection and toxic reaction could develop.

▪ Before applying hydraulic pressure to the system,

ensure all connections are tight and that lines, hos-

es, and couplings are not damaged.

Think Safety,

Work Safely!

▪ REVIEW ALL SAFETY INSTRUCTIONS with all opera-

tors before allowing them to operate the equipment.

Review instructions at least once each year.

▪ All shields and guards must be intact and in po-

sition and securely fastened before operating the

Windrow Inverter.

▪ Only use a tractor equipped with ROPS cab and seat

belt. Be careful when operating close to a road or

building, the machine can throw stones and other

objects during operation.

▪ Emphasize the importance of safety when working

around and operating the machine.

▪ Do NOT allow riders on any part of the equipment at

any time.

▪ Always keep hands, feet, and clothing away from

moving parts.

▪ Always lower the pickup to the ground when parking.

▪ Use a retainer or draw pin to secure the lifting lever

of the pickup before transporting equipment.

▪ Use safety tow chain at all times.

▪ NEVER attempt to unplug the machine when the trac-

tor is running and hydraulic system is pressurized.

▪ Keep hands, feet, and clothing away from the pickup

area when in operation to avoid entanglement haz-

ards. Do not open or remove shields or guards while

machine is running.

▪ Relieve all pressure from hydraulic lines before dis-

connecting them. Before applying pressure to the

system, make sure all connections are tight and

that hoses and lines have not been damaged.

Hydraulic Safety

Hitch and safety chain. Pickup lift with travel lock pin.

Safety

8

Safety Decals

Moving Parts Hazard High Pressure Fluid Hazard

Keep Shields and Guards in Place

9

Specications

AgLand Matador

Model 7900

Dimensions

Overall Width 102” to 104” (259 cm to 264 cm)

Length with rear hitch extended 187” (475 cm)

with rear hitch removed 175” (444 cm)

Height with pickup lowered 46” (117 cm)

with pickup raised 48” (122 cm)

Weight 1,350 lbs. (613 kg)

Tires (4)

Main Tire Size 5.90 x 15

Pressure 30 PSI (207 kPa)

Wheel Hub 4 bolt

Wheel Torque 85 ft-lbs. (115.2 Nm)

Gauge Wheel Tire Size 4.8 x 8.50

Pressure 50 PSI (345 kPa)

Pickup

Width 77” (196 cm)

Clearance* 15” to 17” (38 cm to 43 cm)

Tooth Clearance** 13.5” to 15” (34 cm to 38 cm)

Pickup Tooth Spacing 2.75” (7 cm)

RPM of Pickup Shaft 10 to 400 RPM

Drive System Hydraulic motor,

Roller chain driving two full

width roller drums.

Height When Working 19” (48 cm)

* under pickup when raised

** when raised

Operating Speed

Approximate range* 5 to 10 MPH (8 to 16 km/hr)

* depending on crop conditions

Swath Size

Width up to 36” to 42” (91 cm to 107 cm)

Tractor Requirements

Suggested min. tractor size* 50 HP (37 KW)

Hydraulic Outlets Required

two double acting outlets

1,500 to 2,000 PSI range (10,343 kPa to 13,790 kPa)

Suggested minimum hydraulic ow rate

10 US GPM (38 L/min)

Suggested minimum underframe clearance**

15” (38 cm)

Suggested minimum front and rear wheel tread***

66” (168 cm)

* tractor should be of sufcient size to maintain operator

control in all situations.

** toallowswathtoowfreelyundertractor

*** adjusted to avoid contact with inverter during sharp corners

Some weights and measurements are approximate.

All specications, statements and information shown in

this manual are believed to be accurate at the time of print-

ing. Specications are subject to change without notice.

10

Depending on shipment desti-

nation, the Matador 7900 may

be shipped assembled and

ready for use; or some periph-

erals may be shipped separate-

ly as follows:

1. Wheel Kit

2. Moldboard Attachment

3. Lift Kit (Optional)

Wheel Assembly

If the main frame is standing in a vertical position with

the hitch pointing upward, lower machine to a horizontal

position and secure with blocks. If you have a block and

tackle, you may wish to lift the entire unit off the ground

to assemble and install the wheels.

Assembly

Rear Wheel Installation

Install left and right hand brack-

ets with slotted holes to the bot-

tom (with pipe extended outward

as shown). Move bracket in from

back of frame and attach with

5/8” x 5” bolt and spring wash-

ers (A). Flat washers for slotted

holes only (B).

Install rear wheel hub/axle as-

semblies in axle tubes, leaving

a gap sufcient to clear guards,

hoses, etc. Tighten 1/2” x 1-1/2” set screw and lock nut

(C).

Gauge Wheel Installation

(Small Wheels)

Install gauge wheels with 3/4” x 7” grade 8 bolts in sec-

ond hole from top of adjustment plate. Tighten nuts se-

curely ensuring the wheel turns freely. Install with a nut on

either side of mount bracket. Grease gauge wheels before

use.

Gauge Wheel

Installed

Rear Wheel

Installed

A

BC

11

Moldboard Attachment

Moldboard kit (moldboard sheet not shown)

Moldboard Frame Assembly

1. Install right hand moldboard frame assembly (A)

with 1/2” x 1” bolts, lock washers and nuts; do not

tighten.

2. Install top left long square tube (front tab to outside

of front main frame tab). Use 1/2” x 3-1/2” bolts

from outside of plate at rear (B).

3. Loosely install angles and brackets (C, D & E), DO

NOT tighten at this time.

4. Install lower curved angle (F) on centre, single tab on

main frame (behind pickup), with the tab under the

angle iron. Tighten in the fully forward position.

5. All bolts in the moldboard frame can now be fully

tightened in the following sequence:

a. 1/2” x 1” bolt to the main frame

b. Lower curved angle bolts.

c. All remaining bolts.

6. Install hold down clamp on hoses at lower right.

Moldboard Sheet Installation

1. Install sheet inside moldboard frame shown. Start-

ing with the top right hand front (A), use 3/8” x 3”

carriage bolts, then the top rear (B), use 3/8” x 1”

bolts and nuts.

2. Install the bolts in the lower, curved angle (C) and

tighten all bolts. DO NOT OVER TIGHTEN. Three bolts

are required at the front edge of the moldboard (D).

Some sheets are not predrilled. If this is the case,

drill these holes from the bottom to 3/8” and install

remaining bolts.

Assembly

D

C

AB

A

B

C

D

E

F

12

Assembly

Hydraulic Lift Kit

The pickup lift kit is an optional attachment available for

all Matador Windrow Inverter models.

Installation

1. Attach brackets (A) and (B) to main frame using 3/4”

x 2” bolt (C), do not tighten.

2. Insert bushing (D) into 3/4” hole on horizontal arm

(E). Slide arm (E) between brackets (A) and (B) so

that holes line up. The at washer goes in between

(A) and (E). Tighten to main frame using 3/4” x 3”

bolt.

3. Insert bushing (F) into bottom hole on guide arm (G)

and tighten guide arm to pickup using 1/2” x 1-1/2”

bolt, nut and spring washer.

4. Insert bushing (H) into oval hole on guide arm (G).

From back of arm insert 1/2” x 1-3/4” bolt, using

large at washer (J) to hold bushing in horizontal arm

(E) and tighten with nut and spring washer.

5. Attach hydraulic cylinder to lift kit using pin provided.

6. Install hose connectors (K).

7. If hoses are not already installed, install as shown

above.

8. Tighten all bolts and check to make sure hydraulic

hoses are not rubbing.

9. Attach hoses to cylinder, pressure from tractor to

bottom of cylinder, return hose to the top of the cyl-

inder.

A

B

J

H

G

E

C

D

K

F

pressure

return

13

Operation

Use with a tractor having a minimum of 50 HP (37 KW).

Tractor should have sufcient ground clearance for swath

to pass cleanly under it.

Level Inverter

When hooked up to the tractor the windrow inverter rear

frame should be parallel to the ground when measured

across upper cross tube and rear corner of moldboard

frame (A). If necessary level by changing the hitch tongue

mounting bolt locations in the main frame and/or by in-

verting the tongue in the main frame brackets (B).

The axles can also be pivoted up or down on the main

frame, in their slotted mounting holes (C).

Adjust tractor hitch if further adjustment is required.

Uneven Fields

Flotation Spring Adjustment

If pickup bounces too much due to uneven elds, release

the spring tension. First loosen off top nut (A), then turn

bottom nut (B) counter clockwise. This will put more weight

on the pickup and should help minimize the bouncing ac-

tion.

Pickup Finger Height

Gauge Wheel Adjustment

(Small Wheels)

Check pickup height when in eld position, crop should be

picked up cleanly without gouging the soil. Should adjust-

ment be required:

a. Raise or lower pickup, Figure 1.

b. Remove the nut on the bolt which holds the gauge

wheel on the pickup and place bolt in the desired lo-

cation, Figure 1. Tighten all nuts securely, ensuring

that the wheel turns freely.

Ensure both left and right hand wheels are set at the

same height.

B

A

A

C

B

Figure 1

14

Operation

Setting Pickup Speed

(Hydraulic Motor)

Lower the pickup to the ground. Engage the hydraulic le-

ver on the tractor, which controls the hydraulic motor on

the windrow inverter. The windrow inverter has a valve

that prevents accidentally turning the pickup backward.

The hydraulic system for operating the windrow inverter

consists of two basic components:

1. The hydraulic motor.

2. The adjustable ow control valve.

Adjustable Flow Control Valve

If your tractor has a:

CLOSED CENTRE TRACTOR HYDRAULIC SYSTEM WITH

ADJUSTABLE VALVE:

1. Set the windrow inverter ow control at maximum

setting of 10.

2. Engage the tractor hydraulic system lever.

3. Adjust the tractor ow control valve. If the oil surges

through the system, close the windrow inverter ow

control valve slowly until the surging stops.

4. Further windrow inverter valve adjustments may be

necessary to ensure smooth and complete pickup at

speed travelled.

If your tractor has an:

OPEN CENTRE HYDRAULIC SYSTEM WITHOUT AN AD-

JUSTABLE VALVE:

1. Set the windrow inverter ow control valve in the 0

position.

2. Engage the tractor hydraulic system lever.

3. Set the pickup speed with the windrow inverter ow

control valve to approximately 4 or 5.

4. Further adjustments may be necessary once you are

inverting to ensure smooth and complete pickup at

speed travelled.

Direction of Travel

Start inverting at the same location and direction as mow-

ing started, although the Matador Windrow Inverter will

generally pickup “against the grain” as well. Centre the

tractor and windrow inverter on the swath. Start gradu-

ally, and gear up smoothly, until you are operating at the

desired eld speed.

Adjust the hydraulic ow control on the tractor and/or the

windrow inverter to change the pickup speed as required.

Pickup speed should be sufcient to pickup crop cleanly.

Excessive leaf loss will occur if pickup speed is too fast.

In cereal crops or crops with an “in line” orientation, it will

be necessary to pick up the swath “head rst.”

The hydraulic pickup lift kit makes it easy to raise the

pickup over obstacles in the eld or to skip a swath which

does not need inverting.

With innite variety of crop and eld conditions, only op-

erator experience will indicate best driving, cornering and

adjustment techniques for maximizing the use of your

Matador Windrow Inverter.

15

Maintenance

Use Good Safety Practices When

Working On This Machine

Before doing any maintenance or service on the ma-

chine you must:

□ Park machine on a solid level surface.

□ Disengage all power.

□ Put the tractor transmission in PARK or apply the

tractor parking brake.

□ Stop the tractor engine and remove key from the

ignition.

□ Look and listen. Make sure all moving parts have

stopped.

□ Install the cylinder safety stops, if applicable.

□ Block the inverter securely before working.

Checklist

CAUTION

Daily

□ Lubricate all items as required.

□ Remove all dirt and crop deposits from machine.

After Every 8 Hours Of Use

□ Grease gauge wheel bushings.

After The First 25 Hours Of Use

□ Check sprockets for set screw tightness.

After Every 100 Hours Of Use

□ Grease the sealed bearings on the pickup shaft

(two locations, front roll (two places) and rear roll

(four places).

At The Beginning Of Each Season

□ Review all safety instructions.

□ Carefully inspect all components for excessive wear

or hazardous conditions.

□ Lubricate the machine at all lubrication points to

force out any collected moisture.

□ Check drive chain for correct tension, replace if worn

or damaged.

□ Clean and repack or replace the wheel bearings, if

required.

□ Check tires for correct ination pressure.

□ Tighten bolts.

Setting Drive Chain Tension

1. Adjust tension with pickup pinned in raised position

(A).

2. Inspect and adjust through the access hole provided

in chain cover (B). The correct tension of the chain

should allow for approximately 1/2” (1.3 cm) of de-

ection when slight pressure is applied to the lon-

gest span of chain (C). If required move sprocket (D)

to increase or decrease tension on chain.

3. Check that the chain is not riding up on the sprocket

teeth (especially the large sprocket) as this would in-

dicate a worn out chain which requires replacement.

Regular lubrication with chain lubricant, proper ad-

justment, and replacement of worn chains will en-

sure proper function of the Matador and prolong the

life of the sprockets.

A

B

16

Roller Drive Chain Replacement

Replace worn or damaged chains as follows:

1. Lower pickup completely.

2. Remove chain cover.

3. Raise pickup and secure with pin.

4. Remove the connector link from the chain and re-

move chain from the sprockets.

5. Replace worn sprockets and bearings. (Ensure all

sprockets are securely tightened.)

6. Install new chain.

7. Move sprocket (A) to allow for approximately 1/2”

(13 mm) deection when slight pressure is applied

to the longest span of the chain (B).

8. Reinstall chain cover.

Bearing Replacement

Sealed ball bearings are held in position on the shaft by a

locking collar which is rotated to lock the assembly on the

Maintenance

B

A

shaft and secured by a set screw. To remove bearing:

1. Loosen set screw.

2. Use a drift punch inserted in the drift pin hole to

rotate and loosen the locking collar (A). Rotate the

locking collar counter clockwise.

3. Remove the locking collar.

4. Support the shaft, for easier assembly later.

5. Remove the bolts for the bearing anges.

6. Slide the bearing and the anges from the shaft.

Note: Cleaning paint and corrosion from the shaft

will make removal easier.

7. Put on the new bearings and anges ensuring the

bearing inner race is turned in a counter clockwise

direction.

8. Install bolts ensuring the bearing is straight.

9. Replace locking collar on the shaft. Rotate the lock-

ing collar in direction of shaft rotation until lightly en-

gaged. Tighten the collar by tapping it with a drift pin

punch inserted in the drift pin hole rotating it further

clockwise.

10. Tighten set screw.

Replacing or Repacking Wheel Bearings

1. Remove wheel hub and disassemble.

2. Clean bearings, seals, caps, washers, nuts and hubs

with kerosene or other solvent.

3. Replace bearings or seals if worn or damaged.

4. Pack bearing cones and seals with No. 2 multipur-

pose lithium grease or equivalent.

5. Reassemble hub and bearings.

a. Press oil seal very lightly against the shoulder on

A

Bearing

Locking Collar

Spindle

Cone

Cup

Grease Fitting

Wheel

Bolt Hub

Washer

Cotter Pin

Hub Cap

Slotted Nut

Seal

17

the spindle.

b. Press cups against the shoulder in the hub.

c. Press sleeve to the shoulder in the hub.

d. Place hub on shaft taking care not to damage the

seal.

e. Adjust the wheel bearing nut until there is a no-

ticeable drag while turning the wheel. Do not back

the nut off.

f. Secure nut with a cotter pin.

Pickup Teeth, Bands and Wear Strips

Check for bent, broken, or loose parts. If it is necessary to

replace teeth or related parts, proceed as follows:

1. Ensure that pickup is blocked securely. Loosen the

bolts, holding the band(s) on pickup. Slide band for-

ward and remove the band from the bolts.

2. Should the plastic wear strips require removal and

replacement, drill out or carefully grind off the “pop”

rivets. Replace strip with new rivets.

3. Install new teeth or band(s). Use only the hardened

washers supplied as original equipment from the

manufacturer.

two bottom bolts

Flotation Spring Adjustment

Set spring tension as follows:

Lower pickup to ground, attach a pull scale with a capacity

of up to 100 lbs. (45 kg) to the wind guard crosstube. Cor-

rect tension on the scale should be approximately 50 lbs.

(23 kg) in order to just begin to raise pickup. To lighten

tension, loosen top nut (A) then turn bottom nut (B) coun-

ter clockwise until desired tension is reached. Turn nut (B)

clockwise if more tension is needed.

Maintenance

Band

“Pop” Rivets

Teeth

Plastic Wear Strips

Hardened Washer

B

A

18

Inch Torque Chart for Bolts and Nuts

Standard Torque Requirements Foot-Pounds

Use this chart as a guide when tightening bolts/nuts

which do not have special torque requirements.

Bolts Locknuts

Bolt

Diameter

(inches)

SAE

Grade 5

Plated

W/ZnCr

SAE

Grade 8

Plated

W/ZnCr

Grade B

with GR5

Bolt

Grade C

with GR8

Bolt

1/4 112* 157* 61* 86*

5/16 229* 324* 125* 176*

3/8 34 48 19 26

7/16 54 77 30 42

1/2 83 117 45 64

9/16 120 169 65 92

5/8 165 233 90 127

3/4 293 413 160 226

7/8 473 667 258 364

1708 1000 386 545

SAE Grade 5 SAE Grade 8

*Torque values are inch-pounds.

Metric Torque Chart for Bolts and Nuts

Standard Torque Requirements Foot-Pounds

Use this chart as a guide when tightening bolts/nuts

which do not have special torque requirements.

Metric Bolt Markings & Torque Values

Metric bolts are identied by the grade number stamped

on the head of the bolt or on the surface of metric nuts.

The higher the number, the greater the strength of the

bolt.

Bolt

Diameter

Grade

8.8

Grade

10.9

6mm 60* 108*

7mm 108* 168*

8mm 18 23

10mm 30 45

12mm 55 75

14mm 85 120

16mm 130 175

18mm 170 240

*Torque values are inch-pounds.

8.8 10.9

Maintenance

Note: For inch and metric bolts and nuts:

▪ These values are based on clean, dry threads. Reduce the value by 10% when a lubricant is used. Reduce

the value by 20% if new plated bolts are used.

▪ Bolts threaded into aluminum must have two diameters of thread engagement and may require 30% more

reduction in the torque.

Table of contents

Other AgLand Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Accles & Shelvoke

Accles & Shelvoke CASH Cowpuncher .22R Original instruction manual

Cumberland

Cumberland 6500 Series Operation and installation manual

Smithco

Smithco TCV 5000 Parts & Service operators

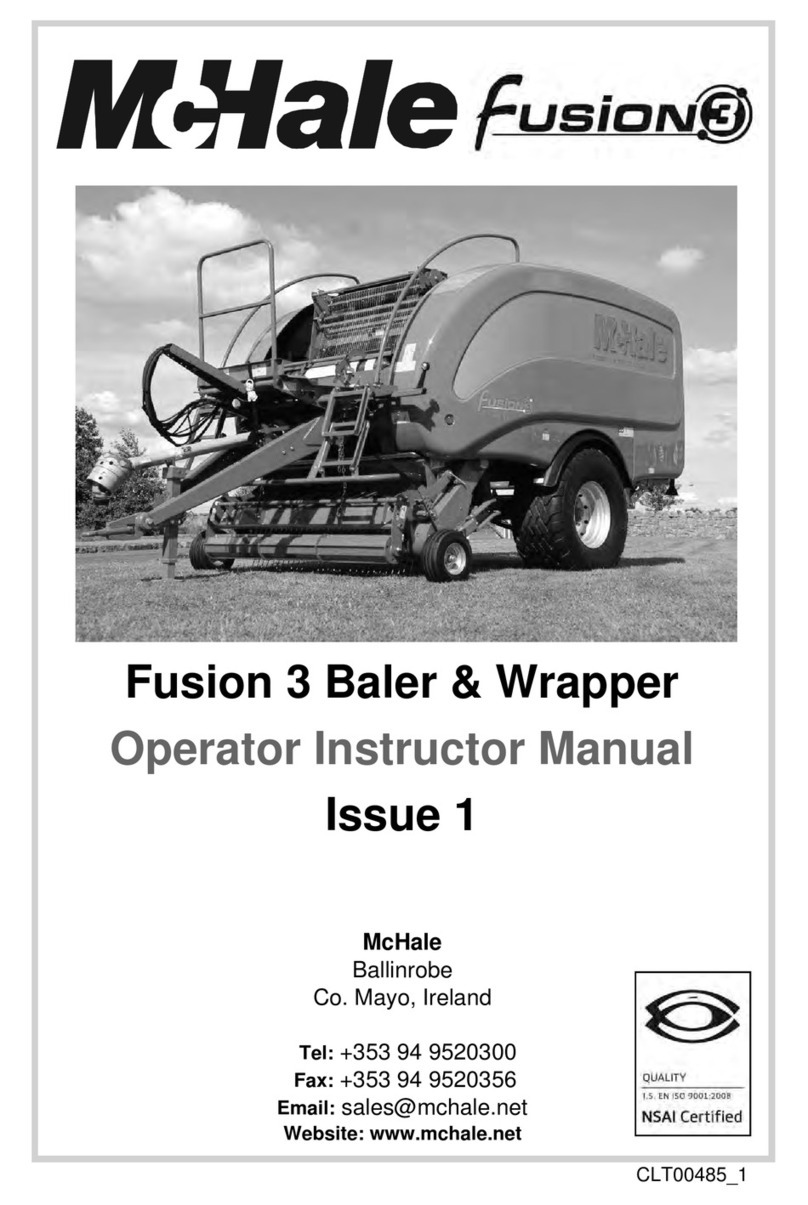

McHale

McHale Fusion 3 Operator Instructor Manual

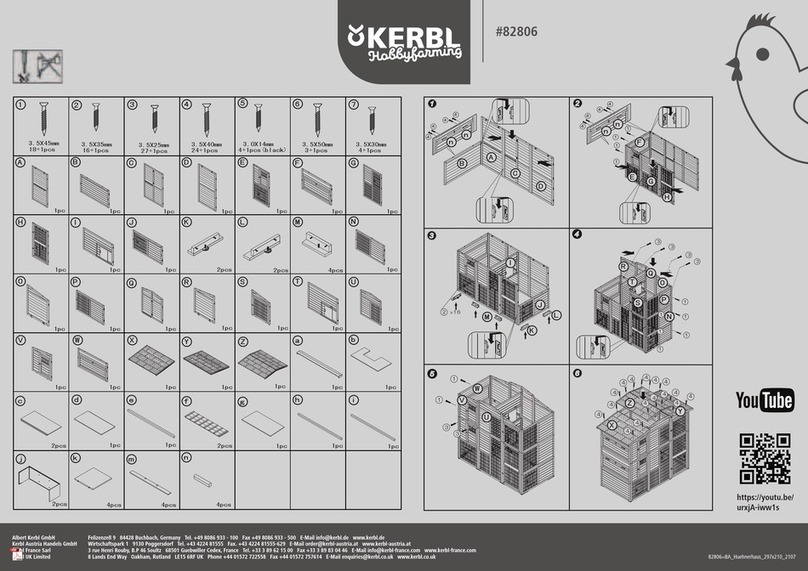

Kerbl

Kerbl 82806 instruction manual

Checchi & Magli

Checchi & Magli TEXDRIVE BEST Use and maintenance manual