1. Введение

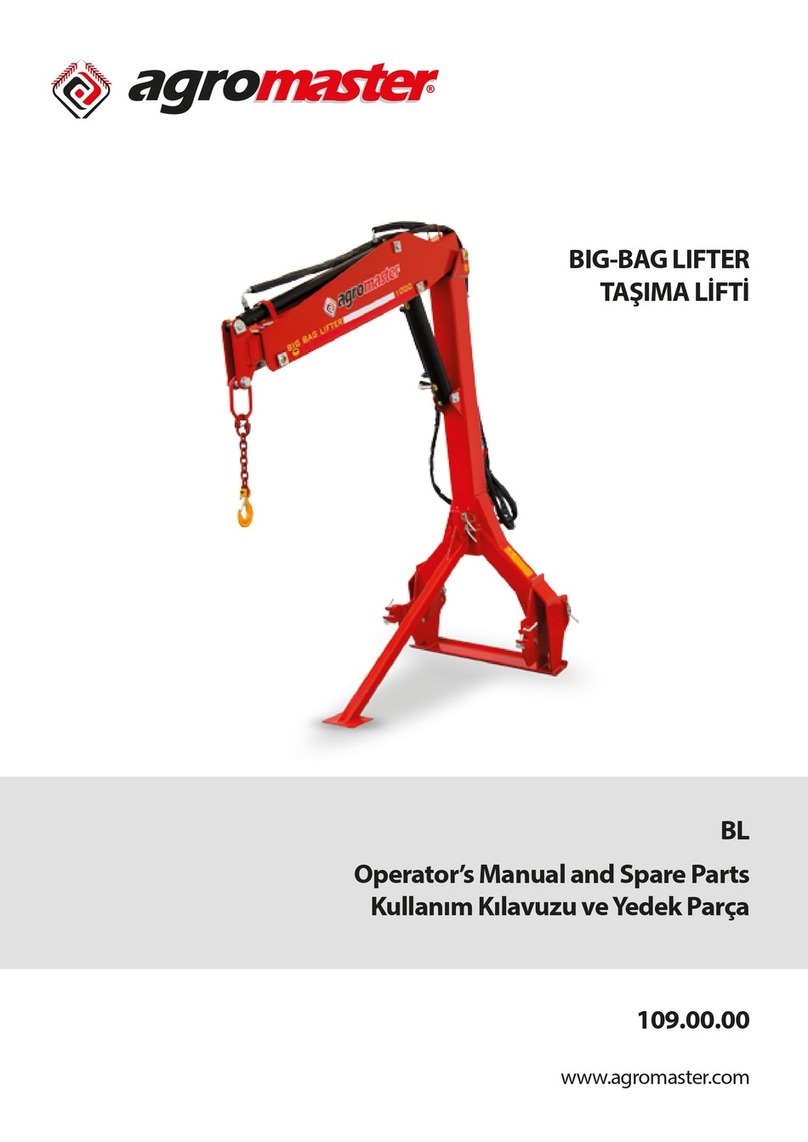

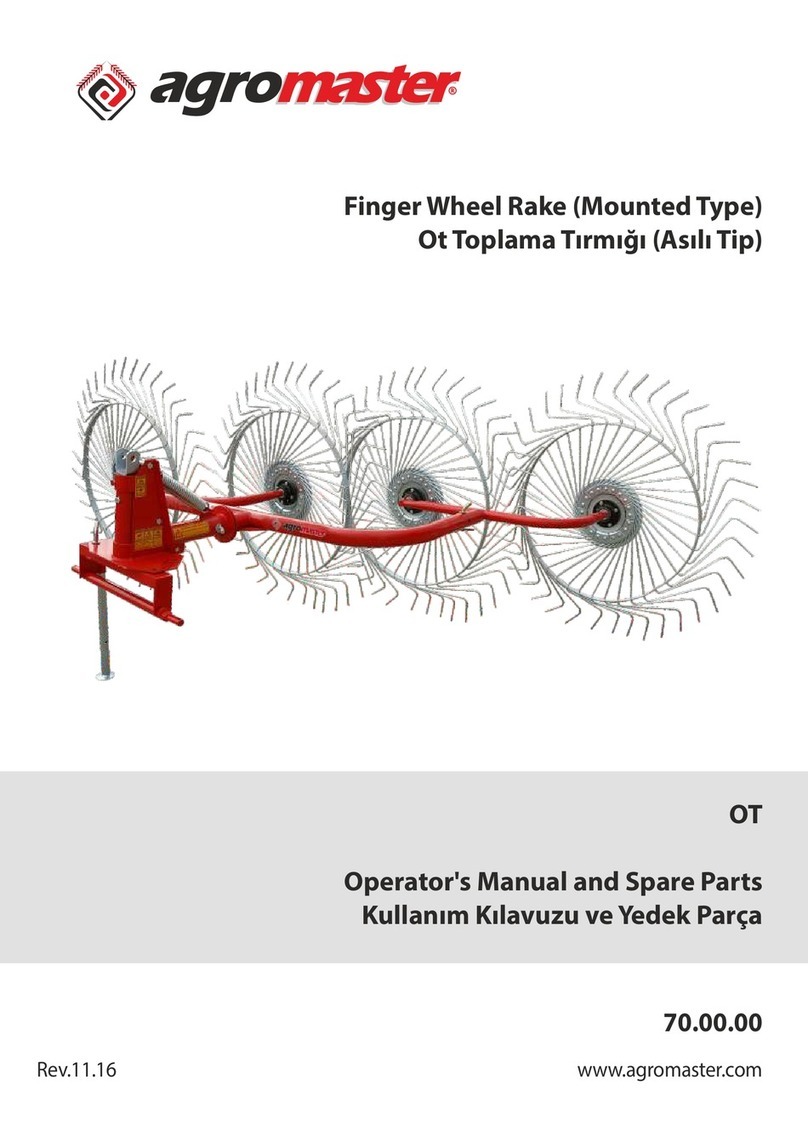

2. Описание машины

2.1. Сферы применения

3. Гарантия

3.1. Истечение срока действия гарантии

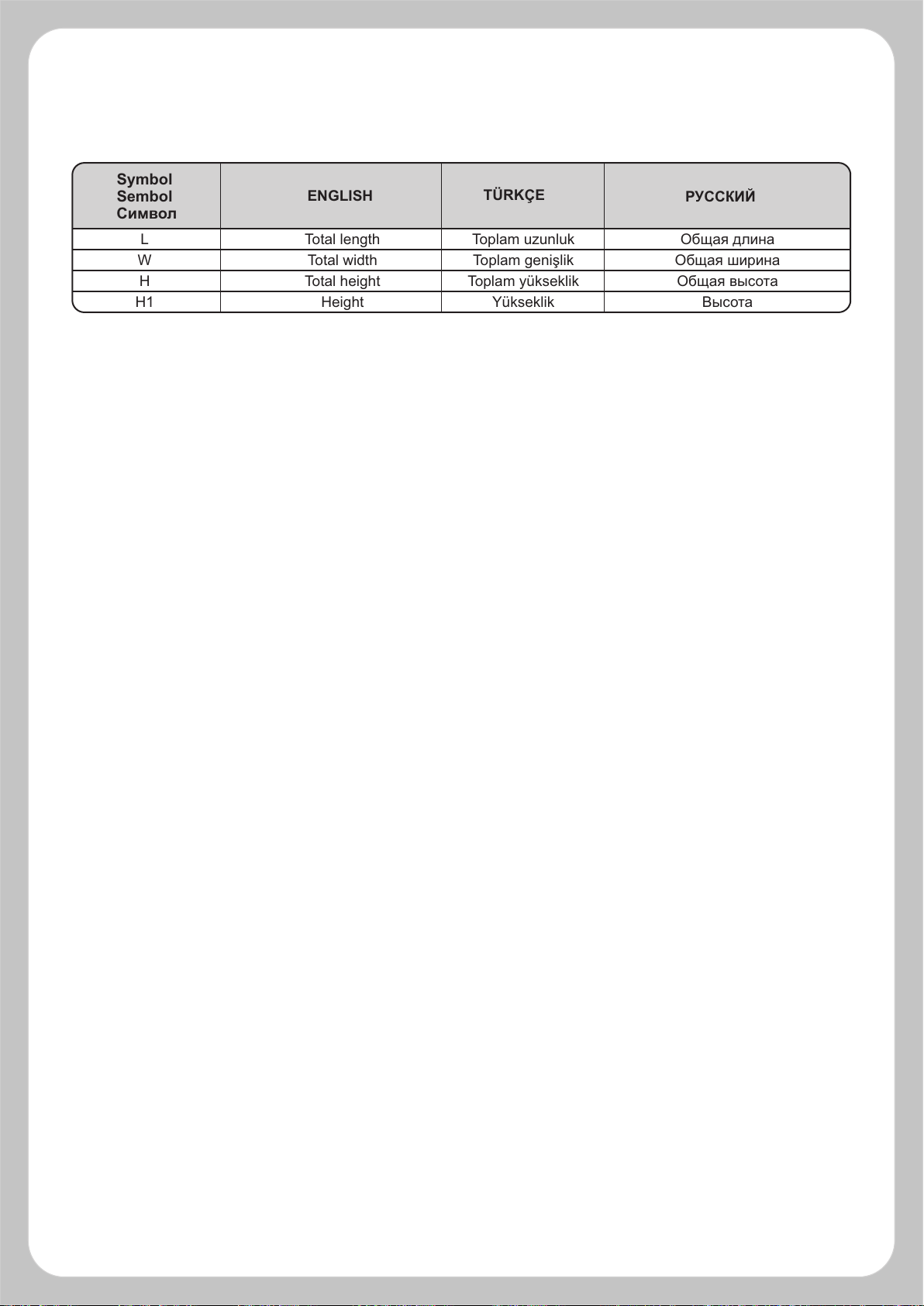

4. Технические спецификации

4.1. Размеры машины

4.2. Основные части машины

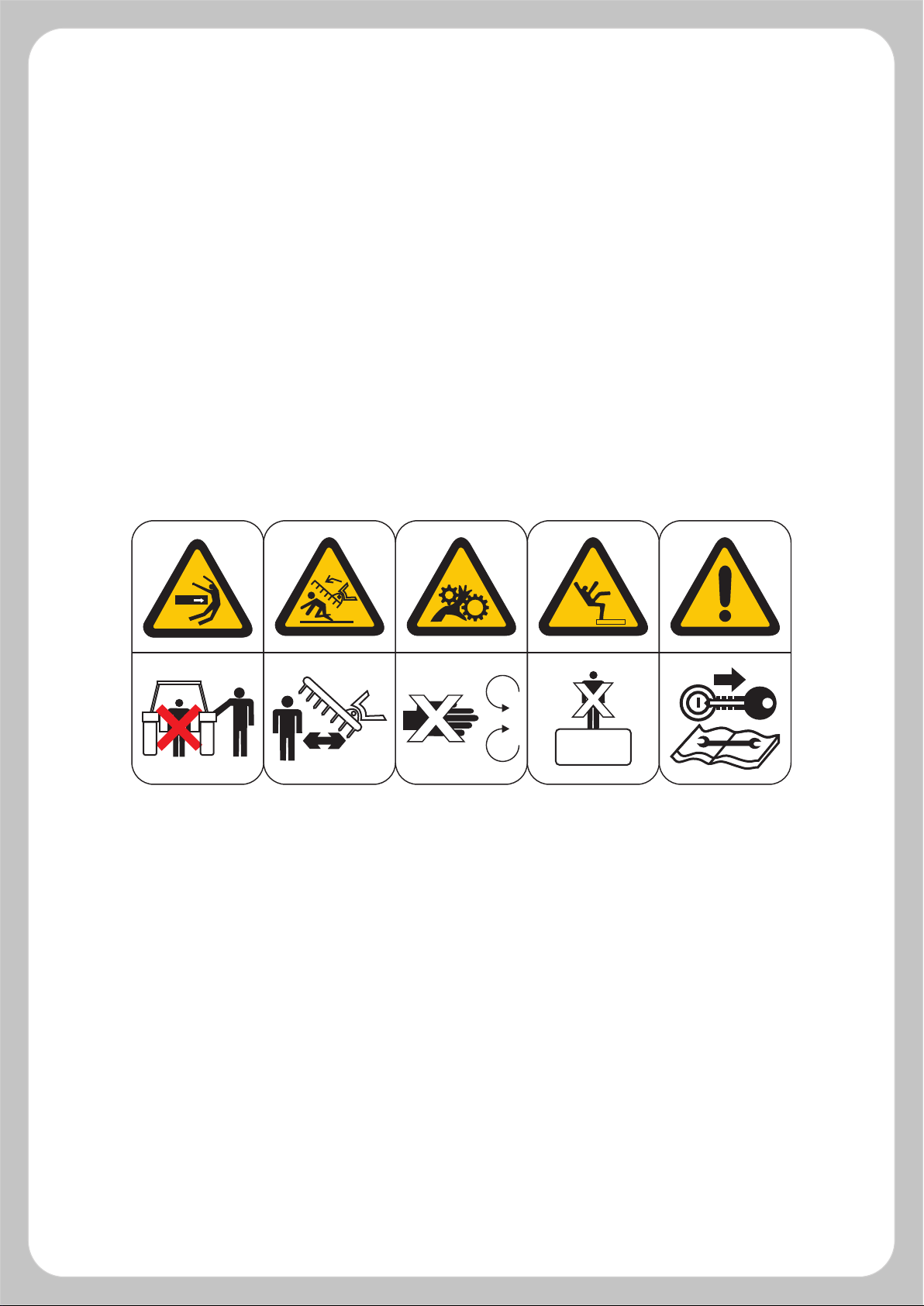

5. Меры обеспечения безопасности

5.1. Символы безопасности

5.2. Предупреждения для обеспечения безопасности

5.3. Наклейки безопасности на машине

6. Подсоединение машины к трактору

7. Эксплуатация машины

7.1. Уровень масла в насосе и антифриз

7.2. Всасывающий шланг

7.3. Регуляторклапан

7.4. Предохранительный

7.5 манометр насоса

7.6. Принцип работы насоса

7.7. Разгрузка бака

7.8. Бак для мытья рук

7.9. Заполнение бака и всасывающий шланг

7.10. Фильтр

7.11. Штанга и форсунки

7.12. Точное определение характеристик Пульверизатора

8. Отсоединение машины от трактора

9. Техобслуживание

10. Устранение неисправностей

11. Работа с каталогом запасных частей

11.1. Последовательный поиск нужной запасной части

6.1. Регулировка и подсоединение карданного вала

6.2. Транспортировка машины, а также устойчивость

трактора и машины во время транспортировки

57

57

57

58

58

59

60

61

62

62

63

64

65

65

65

67

67

67

68

68

69

69

69

69

70

70

71

72

73

73

74

75

75

ОГЛАВЛЕНИЕ

РУКОВОДСТВО ПО ЭКСПЛУАТАЦИИ