9

At power on, the factory default setting is for the output to be off. The

preset output volts and current will be determined by the present control

settings and shown in the display. The VIEW lamp is lit to indicate that it is

the preset values that are being displayed.All other settings will be the

same as they were at last power off.

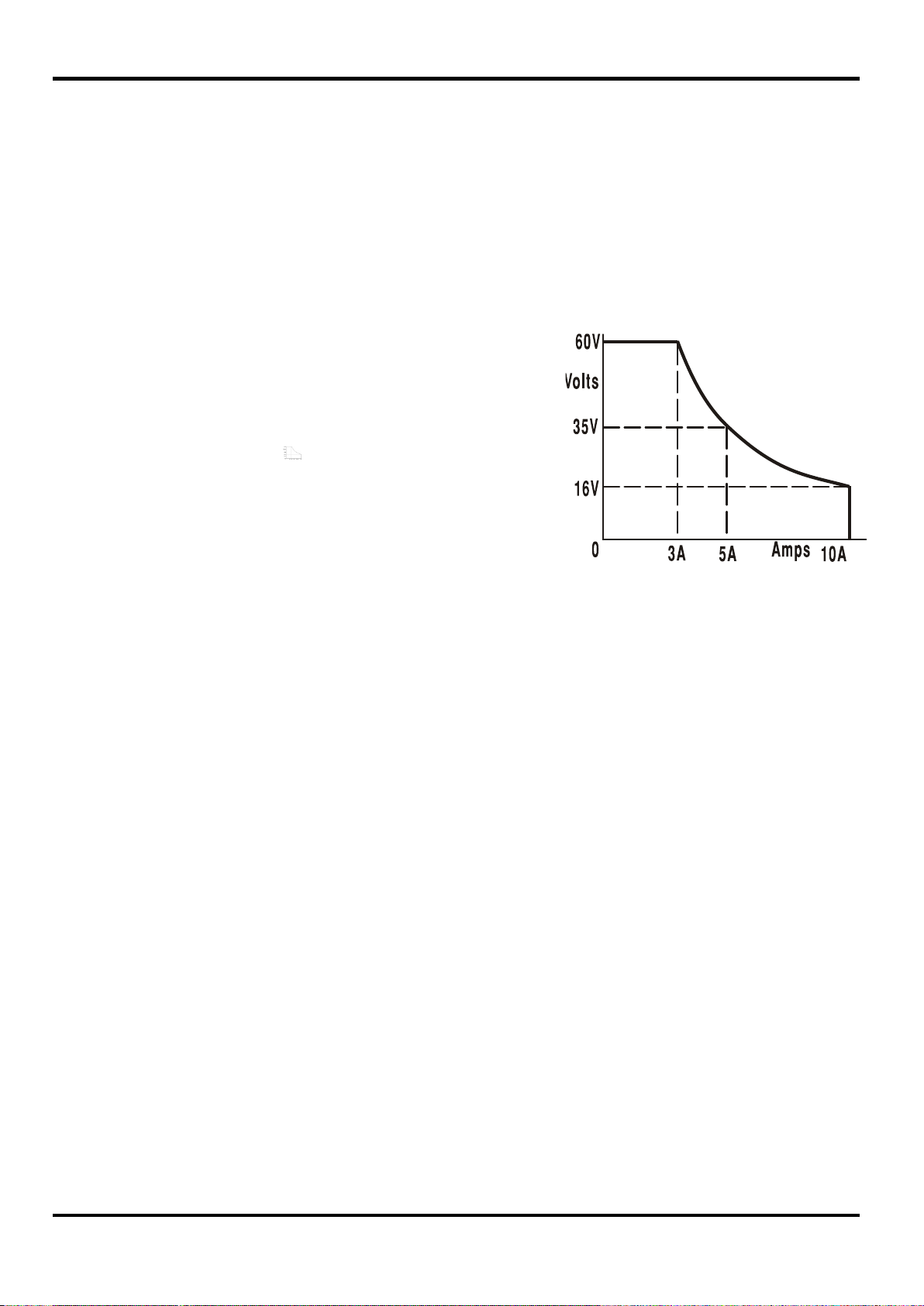

PowerFlex range which limits the maximum

current at the set voltage to that determined

by the power envelope or 10A, whichever is

the lower, see Power Limit paragraph later in

this section.

Manual Operation

The operation of both outputs is identical; the following description applies to both.

Switching On

The power switch is located at the bottom left of the front panel.

When the POWER switch is turned on ( l ), the lower meter of Output 1 briefly indicates the

instrument firmware revision; on the CPX200DP this is followed by the interface firmware revision

( IF shows in the upper meter) before the display shows Volts and Amps; the LAN lamp above

the right hand output meters will also light but will go off after ~30s if an operational LAN

connection is not found, see LAN Error paragraph in LAN Interface section.

The dc output state at power-on can be set to be ‘always off’ or ‘same as at last power-off’. The

setting can be changed as follows. With the VIEW key held down, press and hold down the

OUTPUT key; the display will first show the present setting for 1 second (OP OFF if the factory

default is still selected) before flashing the new setting for 2 seconds ( LASt Set in this

instance). After 2 seconds the new setting is shown continuously in the display and the change is

implemented; release the OUTPUT and VIEW keys. Repeating the procedure will change the

setting back to the previous state. Note that the power-on status of the two outputs needs to be set

individually.

Setting Up the Output

With the POWER switch on ( l ) and the OUTPUT switch off the output voltage and current limit

can be accurately preset using the VOLTAGE and CURRENT controls; the upper meter shows the

set voltage and the lower meter shows the set maximum current.

When the OUTPUT switch is switched on, the OUTPUT ON lamp and the CV (constant voltage)

lamp light; the upper meter continues to show the set voltage but the lower meter now shows the

actual load current.

Range Selection & Custom Limits

There are 4 possible ranges, selected by the keys immediately below the display; the associated

lamp lights to show which range is selected. Because changing ranges can change the output

voltage, range changing is only allowed if the output is off. If attempts are made to change range

with the output on, the display will briefly show the message turn oFF and the output lamp will

flash to prompt the user to turn the output off. The factory default range selection is the 60V/10A

The 60V/3A and 16V/10A ranges operate conventionally such that Constant Voltage (CV)

operation is possible over the full voltage range, provided that the load current is below the range

maximum; operation is always within the power envelope of the instrument. The VOLTAGE and

CURRENT controls are always scaled to set the range maximum when fully clockwise.

The CUSTOM LIMITS capability allows the maximum values of both the VOLTAGE and CURRENT

controls to be redefined by the user such that the controls operate over specific, lower, ranges.

This not only has the advantage of protecting against the accidental application of, for example,

excess voltages to the load, but also provides higher resolution analogue control over the specified

ranges using the full 300º rotation of the controls.