5

Safety

This power supply is a Safety Class I instrument according to IEC classification and has been

designed to meet the requirements of EN61010-1 (Safety Requirements for Electrical Equipment

for Measurement, Control and Laboratory Use). It is an Installation Category II instrument intended

for operation from a normal single phase supply.

This instrument has been tested in accordance with EN61010-1 and has been supplied in a safe

condition. This instruction manual contains some information and warnings which have to be

followed by the user to ensure safe operation and to retain the instrument in a safe condition.

This instrument has been designed for indoor use in a Pollution Degree 2 environment in the

temperature range 5°C to 40°C, 20% - 80% RH (non-condensing). It may occasionally be

subjected to temperatures between +5°C and –10°C without degradation of its safety. Do not

operate while condensation is present.

Use of this instrument in a manner not specified by these instructions may impair the safety

protection provided. Do not operate the instrument outside its rated supply voltages or

environmental range.

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

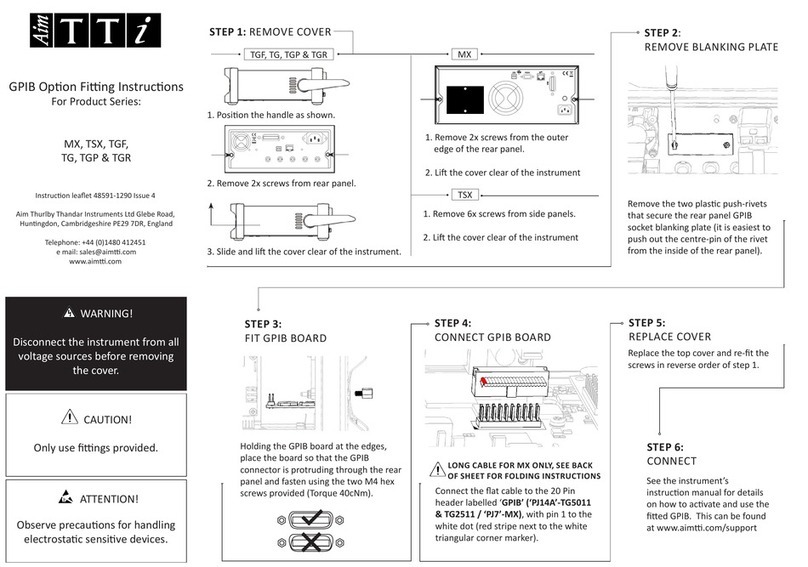

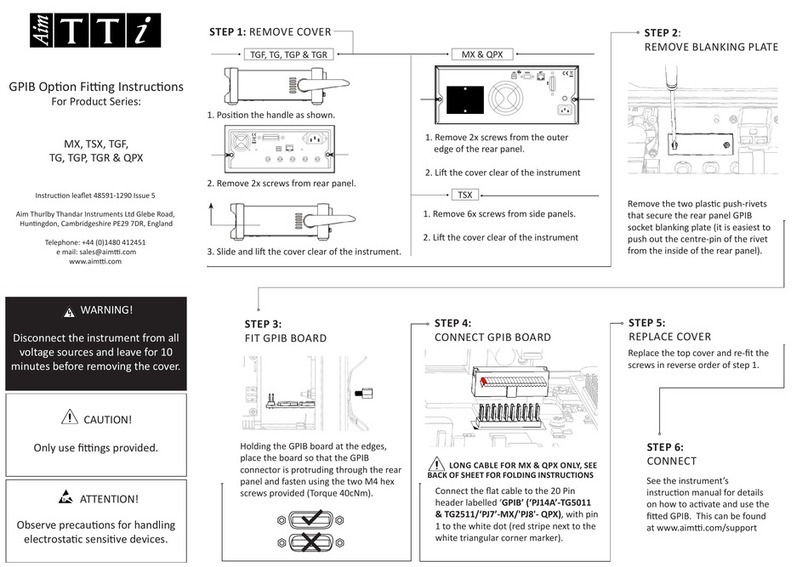

When the instrument is connected to its supply, terminals may be live and opening the covers or

removal of parts (except those to which access can be gained by hand) is likely to expose live

parts. The apparatus shall be disconnected from all voltage sources before it is opened for any

adjustment, replacement, maintenance or repair. Capacitors inside the power supply may still be

charged even if the power supply has been disconnected from all voltage sources but will be safely

discharged about 10 minutes after switching off power.

Any adjustment, maintenance and repair of the opened instrument under voltage shall be avoided

as far as possible and, if inevitable, shall be carried out only by a skilled person who is aware of

the hazard involved.

If the instrument is clearly defective, has been subject to mechanical damage, excessive moisture

or chemical corrosion the safety protection may be impaired and the apparatus should be

withdrawn from use and returned for checking and repair.

Make sure that only fuses with the required rated current and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuse holders is prohibited.

Do not wet the instrument when cleaning it.

The following symbols are used on the instrument and in this manual:-

Caution - refer to the accompanying documentation, incorrect operation