目录

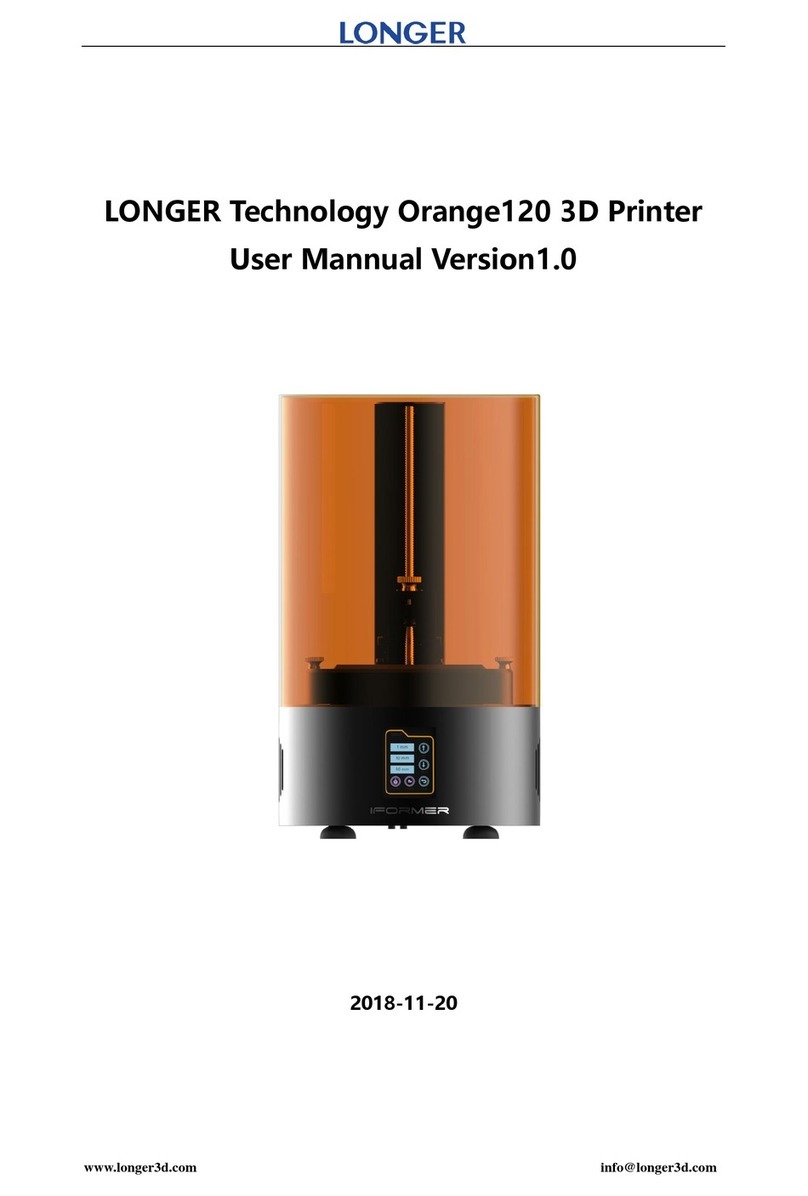

A. Product information........................................................................................................................3

(1) Model parameter...................................................................................................................3

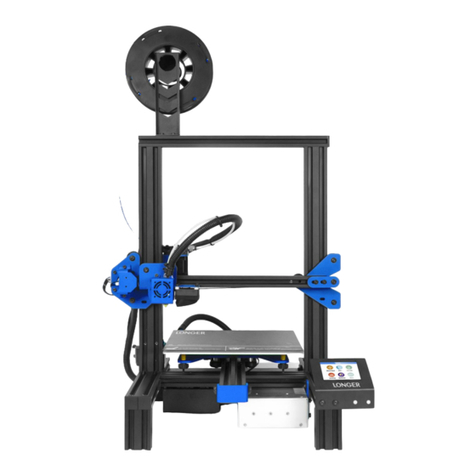

(2) Machine introduction............................................................................................................ 4

(3) Nozzle module exploded view...............................................................................................4

(4) Install filament bracket.......................................................................................................... 5

(5)leveling method...................................................................................................................... 6

B.Machine operation......................................................................................................................7

(1)Machine control................................................................................................................ 7

(2)Main interface................................................................................................................... 8

C.Cura installation and operation software................................................................................... 9

(1)Slice software offline printing instructions.....................................................................12

(2)Software parameter setting............................................................................................ 15

D.Operation for online printing....................................................................................................18

E.Resume printing and filament run-out detection function......................................................21

(1)Power outage recovery................................................................................................... 21

(2)Filament run-out detection.............................................................................................21

F.FAQ manual............................................................................................................................... 23

Question1: How to update the firmware?...........................................................................23

Question 2:What if the filament does not discharge from the machine?...................... 23

Question 3: When the machine returns the filament, it can't be returned. What should

I do when stuck in the pneumatic joint?............................................................................. 24

Question 4: What should I do if I cannot resume printing after power shutdown?..... 24

Question 5:After the machine heats up, the filament is discharged normally. However,

when the printing is performed for the first time, the curling occurs on the platform.

After printing several layers, the filaments get out of the platform. What can I do?.25