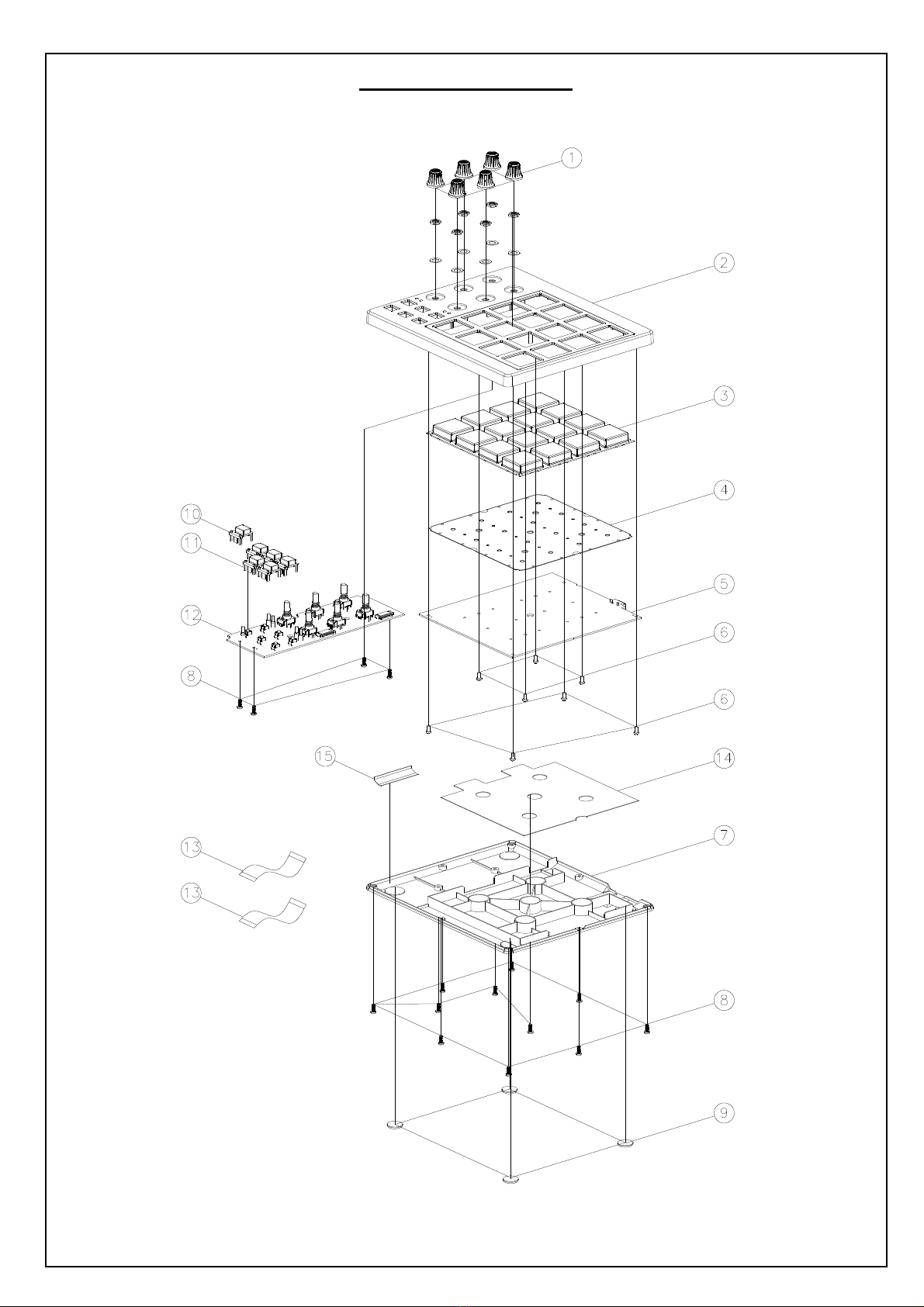

AD18AKA21 BOM

LEVEL

P/N DESCRIPTION QTY

REF

0 AD18AKA21 AD18 USB5V USA 0

1 AA821535X USB 2.0 Cable 1m A/B Type Black 1

1 EVA1504476 EVA(50x15mm) 1 15

1 EVA1504479 EVA 1 14

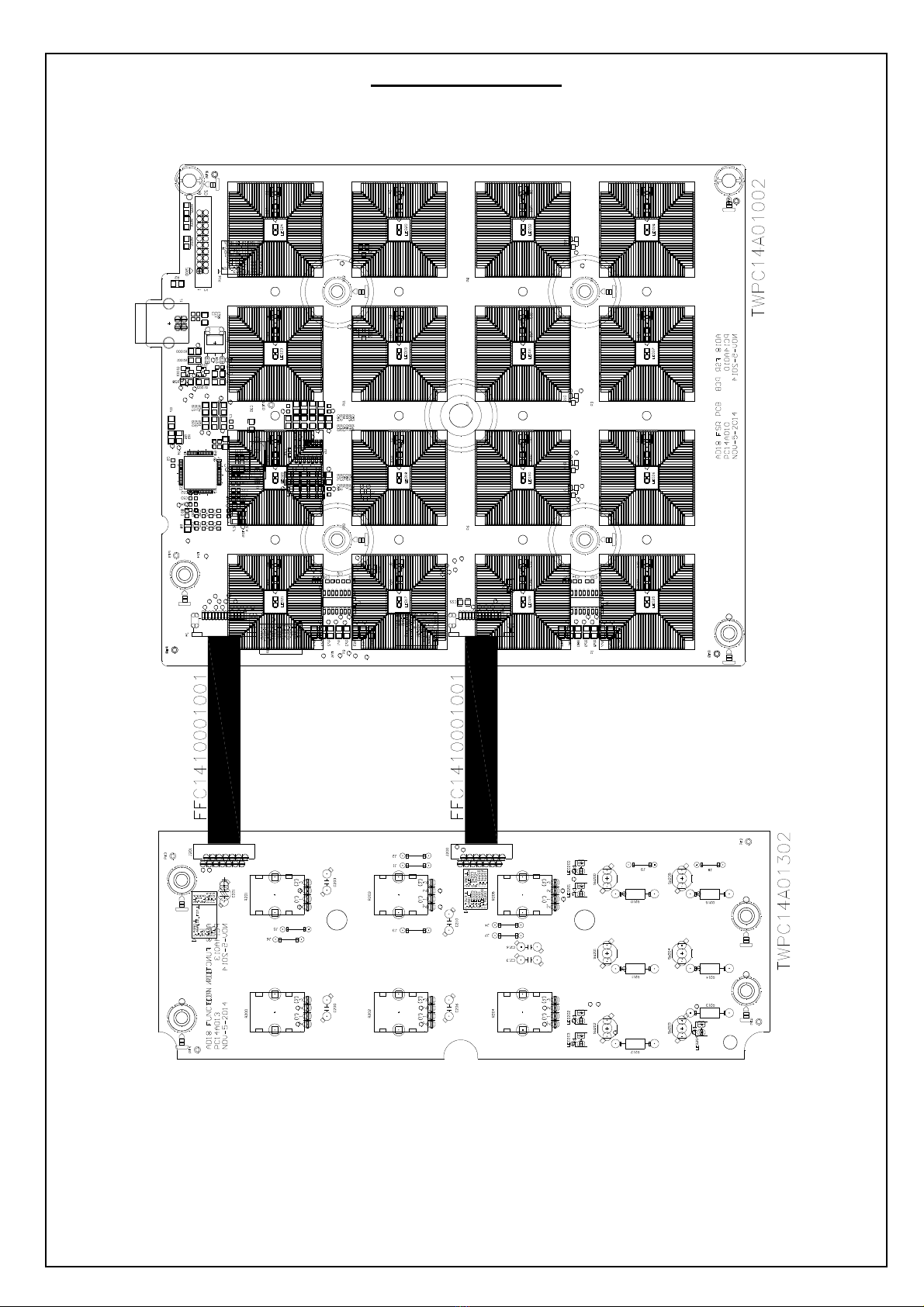

1 FFC1410001001 FFC 14P Pitch:1.0mm Length:100mm 2 13

1 GEAKA17 Ableton Card 1

1 LAC22AKA370 Serial Number Label 1

1 LAC22AKA42 Sticker S/N Ableton 1

1 LAC46AKA393 Istruction Label(IOS MODE) 1

1 LAC57AKA398 Safety Label 1

1 LAC62AKA369 Bar Code Label(CODE39) 0.1

1 LAC62AKA371 Bar Code Label(GTIN14) 0.1

1 LAC67YAH261 Label φ8mm Green 0.1

1 OTFSR16KEY-AD33 FSR 16KEY 1 4

1 PAD18AKA21 Packing Assembly 1

2 AL7-51-0226-M Safety Manual 1

2 CGAD18310AKA01 Gift Box 1

2 CTAD18513AKA01 Shipping Carton 0.1

2 GEAKA20 Generic Card 1

2 OPAD18AKA01 Instruction Book 1

2 PE230190402B07 Pe Bag 1

2 PLAD1801 Poly Foam(Left) 1

2 PLAD1802 Poly Foam(Right) 1

2 SD30026010 Soft Sheet Bag 1

1 PT15106125 Button(B;clear) 1 10

1 PT15106150 Knob 6 1

1 PT15106191 Button(Black) 5 11

1 PT153004401 Top Panel(Print/Paint) 1 2

2 PT1530044 Top Panel 1

1 PT1530336 Bottom Panel 1 7

1 RU1110670 Rubber Foot 4 9

1 RU1510638 Rubber Knob 1 3

1 SC0308PBBI Screw M3X8 PBB Tapping 15

8

1 SC2605PBBI Screw M2.6x5 PBB Tapping 8 6

1 TWPC14A01002 FSR PCB Assembly 1 5

2 AL2-49-0070 Diode BAV70 8 D13~20

2 AL2-51-4403 Transistor 2N4403 PNP SOT-23 16

Q1~16

2 AL2-61-7223 IC NJU7223DL1-33 3.3V TO-252 1 U2

2 AL2-71-1324 IC LMV324 SOP-14 1 U5

2 AL4-08-0402 Con USB 4-Pin Female PC-MNT Horizontal 1 J1

2 CS102J5003NPO CCAP SMD 1nF/50V 5% 0603 NPO 4 C31~34

2 CS103K5003X7R CCAP SMD 0.01uF/50V 10% 0603 X7R 21

C8,15~20,42,43,50~57,82,84,86,88

2 CS104K5003X7R CCAP SMD 0.1uF/50V 10% 0603 X7R 12

C1,3,4,5,7,10~12,26,29,30,58

2 CS106K0605X5R CCAP SMD 10uF/6.3V 10% 0805 X5R 6 C9,13,14,22,35,36

2 CS180J5003NPO CCAP SMD 18pF/50V 5% 0603 NPO 2 C2,6

2 CS561J5005NPO CCAP SMD 560pF/50V 5% 0805 NPO 4 C81,83,85,87

2 FCN1T1001402 FCN DOWN Touch ZIF SMD Pitch=1.0mm 14P 2 J3,4

2 IC74HC595 Integrated Circuit 2 U1,3