2 LDKPT-1608SYCK Liquid-emitting Diode Yellow SMD 0603 19

LED1~7,9~20

angle 120°

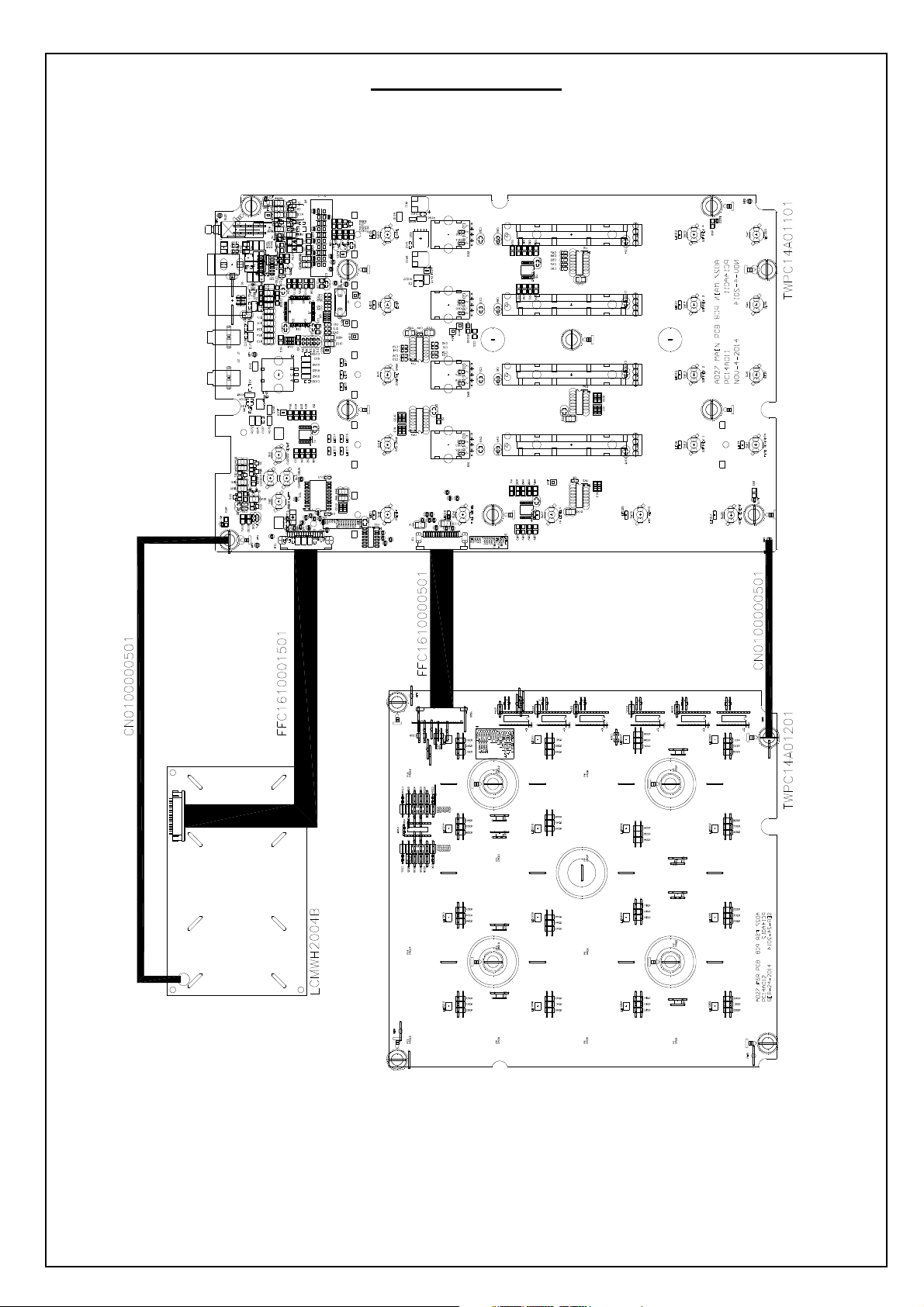

2 PC14A011 TOP PCB 2Layer FR-4 1.6T 255*165MM 1

-

2 RS000008J05 RES 0Ω5% SMD 0805 15

R10,27,60,61,63,66,99,101,127,132,133

R139,142,148,162

2 RS001508F05 RES 15Ω1% SMD 0805 1

R153

2 RS001K08F05 RES 1K 1% SMD 0805 3

R128~130

2 RS001K10F03 RES 1K 1% SMD 0603 1

R165

2 RS002208F05 RES 22Ω1% SMD 0805 2

R72,73

2 RS004708F05 RES 47Ω1% SMD 0805 9

R1,7,74,76,77,163,167,173,176

2 RS010008F05 RES 100Ω1% SMD 0805 10

R2,15~17,21~25,172

2 RS010K08F05 RES 10K 1% SMD 0805 57

R3~5,8,9,14,18~20,26,35,62,64,67,70,71

R79~90,94,95,97,102,105,115,117,119,123

R126,134,138,140,141,143~145,149~151

R156,159~161,164,171,501~503

2 RS012K08F05 RES 12K 1% SMD 0805 1

R146

2 RS01K108F05 RES 1.1K 1% SMD 0805 1

R137

2 RS01K508F05 RES 1.5K 1% SMD 0805 1

R147

2 RS022008F05 RES 220Ω1% SMD 0805 3

R168~170

2 RS027010F03 RES 270Ω1% SMD 0603 1

R75

2 RS047008F05 RES 470Ω1% SMD 0805 1

R152

2 RS047508F05 RES 475Ω1% SMD 0805 1

R136

2 RS068008F05 RES 680Ω1% SMD 0805 1

R157

2 RS080608F05 RES 806Ω1% SMD 0805 1

R135

2 RS100K08F05 RES 100K 1% SMD 0805 2

R69,155

2 RS220K08F05 RES 220K 1% SMD 0805 3

R68,124,125

2 RS2K1508F05 RES 2.15K 1% SMD 0805 1

R166

2 RS4K7508F05 RES 4.75K 1% SMD 0805 1

R158

2 RS820K08F05 RES 820K 1% SMD 0805 1

R131

2 RS8K0608F05 RES 8.06K 1% SMD 0805 1

R154

2 SWDC11B20214A8 Switch Rotatiomal 20 pulse 20mm push-on 1

E1

switch

2 SWEVQ11L04M Switch Tact 4.3mm 160g Horizontal DIP 21

SW0~20

2 SWSPPJ22ME04 Switch Push 2P2T Dual Row Lock 1

SW21

2 UHBLM18AG102SN1 BEAD 1000Ω100MHZ 1

L7

2 UHCBC3225T100MR INDUCTOR 10UH 0.9A 0.133OHM 20% 1210 2

L1,2

2 VRR12302501 Potentiometer Rotary 12.5k 2B*2 25mm 4

R32,44,65,91

2 VRS10304533 Potentiometer Slide 10K 2B 45mm 15mm 4

R107,109,116,118

Dual Unit

2 XTM08000X6F1 Crystal 8MHZ 49US SMD Fundamental 1

X1

1 TWPC14A01201 FSR PCB Assembly 1

6

2 AL2-49-0070 Diode BAV70 8

D200~207

2 AL2-71-1324 IC LMV324 SOP-14 1

U200

2 CS103K5003X7R CCAP SMD 0.01uF/50V 10% 0603 X7R 4

C204~207

2 CS104K5003X7R CCAP SMD 0.1uF/50V 10% 0603 X7R 7

C208,211~216

2 CS106K0605X5R CCAP SMD 10uF/6.3V 10% 0805 X5R 4

C209,210,217,218

2 CS561J5005NPO CCAP SMD 560pF/50V 5% 0805 NPO 4

C200~203

2 FCN1T1001602 FCN Down Touch ZIF SMD Pitch=1.0mm 16P 1

J200

2 IC74HC595 Integrated Circuit 6

U201~206

2 LDG1F1A1BB8S3S3 Liquid-emitting Diode Red/Green/Blue SMD 16

LED200~215

2.0*2.0MM angle 110°

2 PC14A012 FSR PCB 2Layer FR-4 1.6T 162*162MM 1

-