4-TRACK RECORDING/PLAYBACK SYSTEM

This model employs a 4-track 2-channel stereo recording

and

play~ack

system.

STEREO RECORDING & PLAYBACK

STEREO

1 1

Track

1 1

Stereo

L

1-

Track

1

Ll-

2

R2-

2 1

1'12-

3 1

Stereo

R1-

3

R1-

4

L2-

4 1

L2-

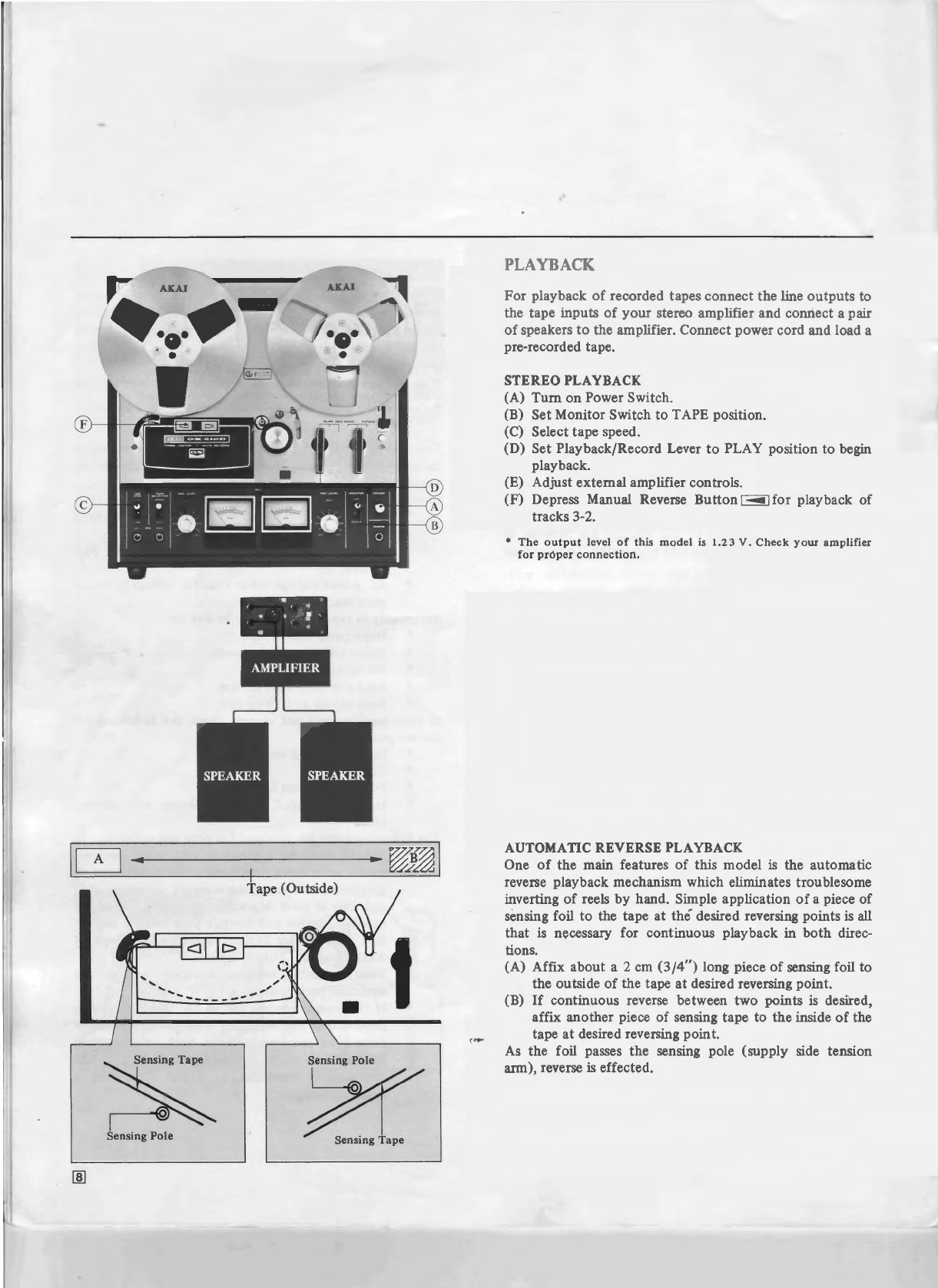

Stereo recording and playback requires the simultaneous

use

of

two tracks. The first stereo playback and recording

takes place on tracks 1 and 3. The second playback takes

place on tracks 2 and

4,

after

the

machine has been set to

reverse mode

or

the reels have been inverted.

To

record on

tracks 2 and 4, invert reels.

This model does

not

record in reverse direction.

For

reverse

playback, use sensing tape for automatic reverse

or

the

Reverse Button provided on

the

front panel for manual

reverse,

or

invert reels.

•

Front

panel

manu

al reverse

buttons

will

not

function

if

the

tape

is

not

threaded

through

the

take·up

side

tension

arm.

OPERATING PRECAUTIONS

Y

our

machine

is

constructed

of

the very finest materials

and with proper care will bring you many years

of

musical

enjoyment.

We

therefore urge you

to

read the following

instructions carefully prior

to

operation.

•

The

use

of

new

tapes will result in

the

best

recordings.

• As

tape

which

has

not

been

used

for

a

period

of

time

may

have

become

sticky,

run

tape

once

bef

ore

using.

•

Operate

machine

on

a

flat

horizontal

surface

in

either

horizontal

or

vertical

position.

The conditions listed below do

not

indicate mechanical

failure

of

your

unit.

If

any

of

these conditions are

exhibited, check for trouble as indicated.

Loss

of

sensitivity and tone quality maybe due to;

•

D?st

on combination recording/erase

or

playback

head. See Head Cleaning procedure.

• Magnetized head. See Head Demagnetizing pro-

cedure.

•

AC

power voltage lower than the voltage

to

which

your

machine

is

set.

lrregularity in tape transport may be due to:

• Improperly loaded tape.

• Grime adhering to the heads.

• Oil on capstan.

• Sticky

or

dirty tape surface.

• Bent supply

or

take-up reel.

If

your

machine will

not

record, check the following for

correct position:

•

Input

plugs and connections.

• Controls.

• Position

of

Pause Lever.

• Is tape threaded through take-up side tension

arm?

The following notes are provided for

your

convenience.

• Should there be a problem with your machine,

please write down model and seriai number and ail

pertinent data regarding waranty coverage, etc.,

and also

as

clear a description as possible

of

the

existing trouble and contact

your

nearest author-

ized Akai Service Station or the Service Dept.

of

Akai Company, Tokyo, Japan.

• Your machine requires constant voltage for

optimum performance.

•

If

the sound sources are so far from

the

micro-

phones

that

the recording level controls must be

turned

to

maximum, sorne hum

or

noise will

inevitably be recorded. In such an instance, a test

recording

is

recommended before attempting a

final recordiÎI.g.