2 (20)

Table of Contents

1 Introduction ______________________________________________ 3

2 Scope ___________________________________________________ 3

3 Service __________________________________________________ 3

4 Maintenance ______________________________________________ 3

5 TechnicalSpecications ____________________________________ 4

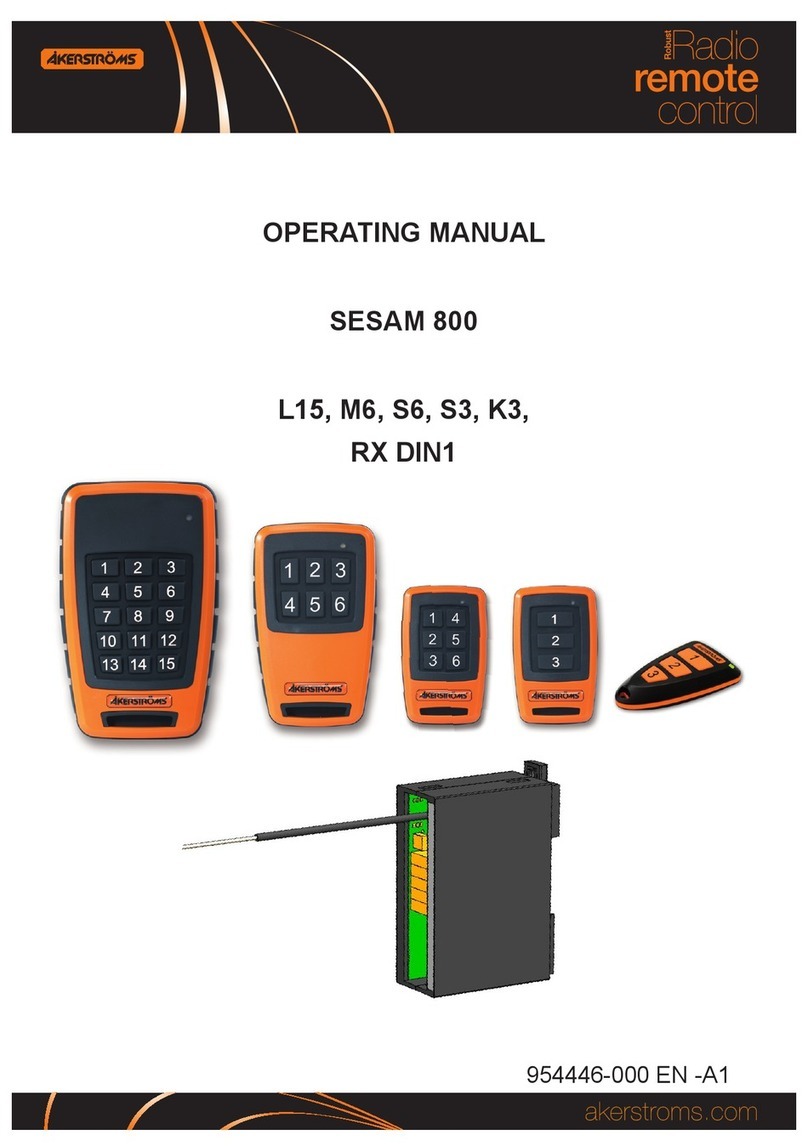

6 Short Description of the System _____________________________ 5

6.1 Receiver __________________________________________________ 5

6.2 Transmitters _______________________________________________ 5

7 Description of the Receiver__________________________________ 6

7.1 Indications on the Receiver ___________________________________ 7

8 Installation of the Receiver __________________________________ 8

8.1 Mounting Steps ____________________________________________ 8

9 Description of the Transmitter ______________________________ 10

9.1 Control buttons____________________________________________ 10

9.2 Indicator LED Indications on the Transmitter _____________________ 11

10 Pairing Receiver and Transmitter ____________________________ 11

11 L99TransmitterConguration______________________________ 12

11.1 Group ID_________________________________________________ 12

11.2 CongurationoftheDisplayWindowIllumination _________________ 13

12 Operation _______________________________________________ 13

13 Replacing Batteries in the Transmitter _______________________ 14

13.1 Replacing Batteries in the M6 Transmitter _______________________ 14

13.2 Replacing Batteries in the L99 Transmitter ______________________ 15

14 OutputConguration______________________________________ 16

14.1 4 Channel digital input module (optional)________________________ 16

14.2 RS232 Serial output module (optional) _________________________ 18

15 Receiver Drill Measures____________________________________ 19

Listofgures

Figure 1. Sesam 800 RXM model indicators, connections and jumper ____________ 6

Figure2. OutputLEDnumberingandrelationshipwithoutputterminals ___________ 7

Figure3. Conguringinternalsupplyofoutputpower _________________________ 9

Figure4. Numberingofoutputs __________________________________________ 9

Figure 5. The transmitter indicator and buttons _____________________________ 10

Figure 6. Transmitter control buttons _____________________________________ 10

Figure7. Batterycoverandthescrewsholdingthecover _____________________ 14

Figure 8. Batteries inserted in the transmitter _______________________________ 14

Figure9. Backsideofthecoverinsertedinitsposition________________________ 14

Figure10. Batterycoverandthescrewsholdingthecover _____________________ 15

Figure 11. Batteries in the transmitter______________________________________ 15

Figure12. Backsideofthecoverinsertedinitsposition _______________________ 15

Figure13. Jumpersetfornoexpansioncardorserialcard,Default(Position1) _____ 16

Figure14. Jumpersetfordigitalinputcard__________________________________ 16

Figure15. Positionoftheinputcard _______________________________________ 16

Figure16. ExternalDigitalInputcard ______________________________________ 17

Figure17. Positionofthe6pinboardconnectorforoutputmodule _______________ 18

Figure 18. RS232 card _________________________________________________ 18

Figure 19. Receiver drill measure _________________________________________ 19