ATF2000 Operation Manual OP2000.1.2.3ENG

3

1. Introduction

ATF2000 Series thermal mass flow meter is designed on the basis of thermal dispersion. It adopts method of constant

differential temperature to measuring gas flow. It has the advantages of small size, high digitization, easy installation and

high accuracy.

The sensor consists of two platinum resistance temperature sensors. Using bridge circuit, one sensor is used as a

temperature sensor to monitor the actual process values while the other is used as a heater which is maintained at a

constant differential temperature above this by varying the power consumed by the sensor. It is possible to measure flow

at high temperature and high pressure.

ALIA ATF2000 thermal gas mass flowmeter has the following technical advantages:

●No need for temperature and pressure compensation. It can measure the mass flow rate or standard volume flow rate

of gas conveniently and accurately.

●Large range ratio. Gases with flow rates up to 120 m/s and down to 0.1 m/s can be measured. It can be used for gas

leak detection.

●Good anti-seismic performance and long service life. The sensor has no moving parts and pressure sensitive parts.

The measurement accuracy will not be affected by vibration.

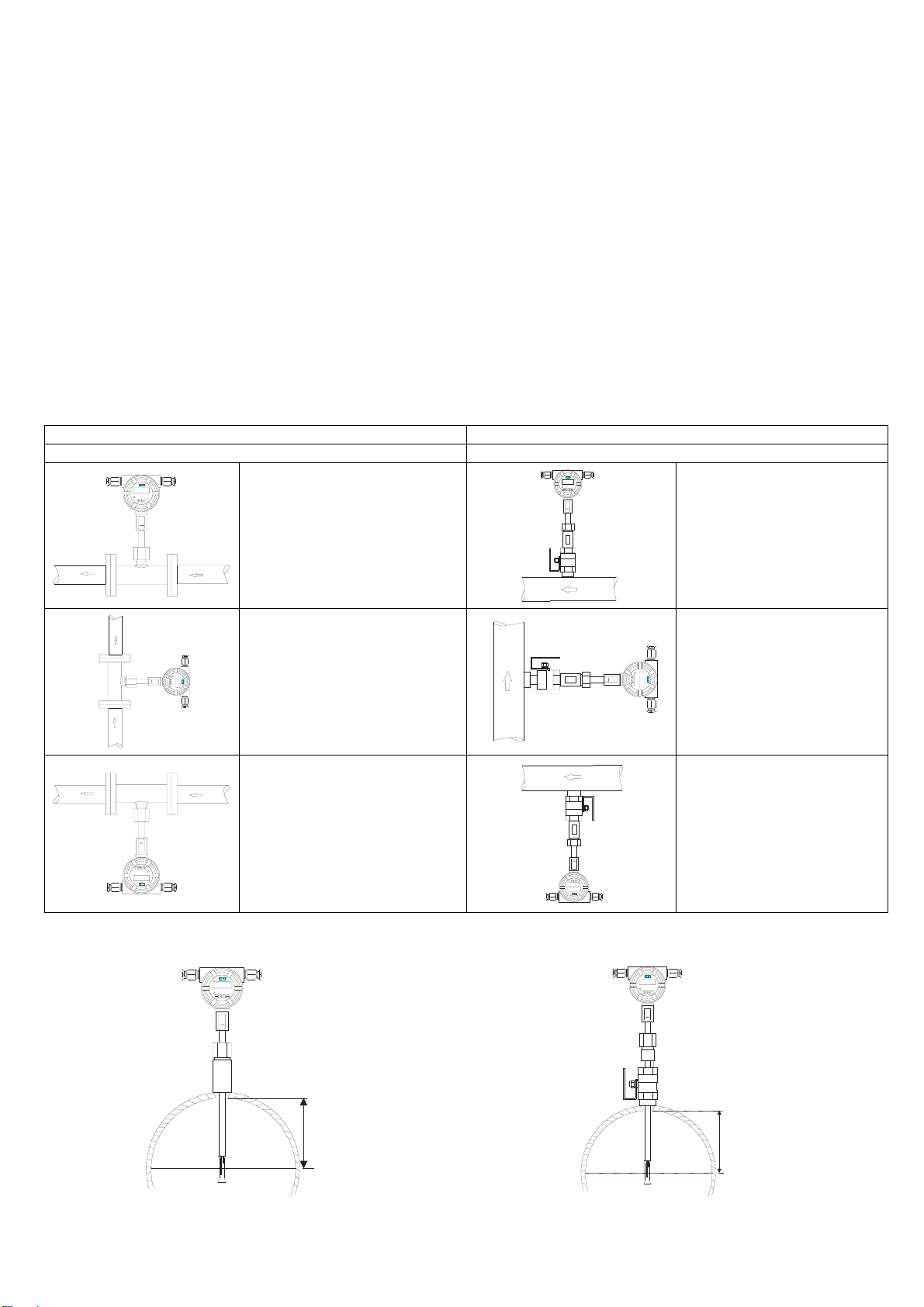

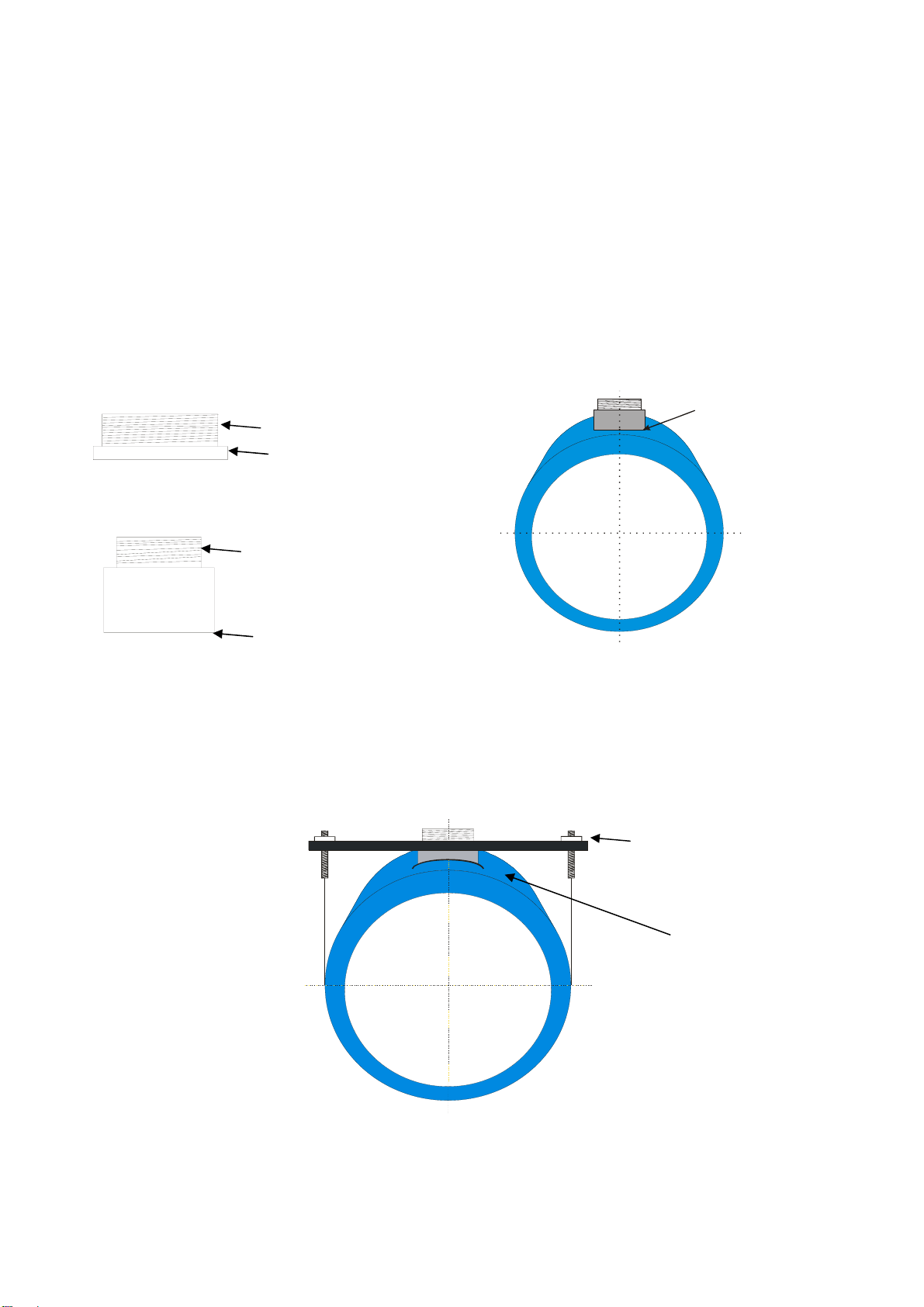

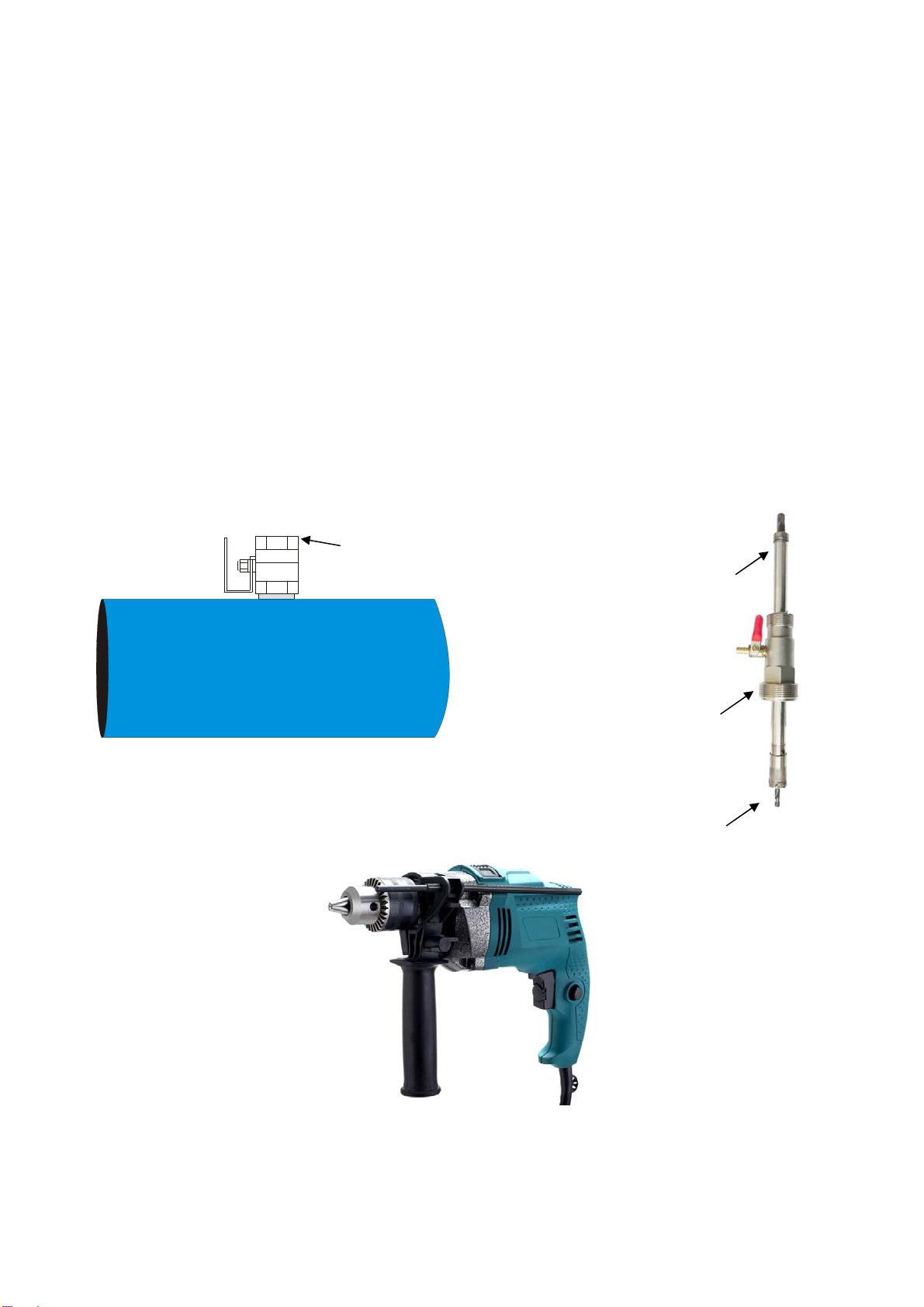

●Easy installation and maintenance. Non-stop production installation and maintenance is possible if site conditions

permit.

●Digital design. The whole instrument adopts a digital circuit which realizes accurate measurement and easy

maintenance.

2. Technical Parameters and Functions

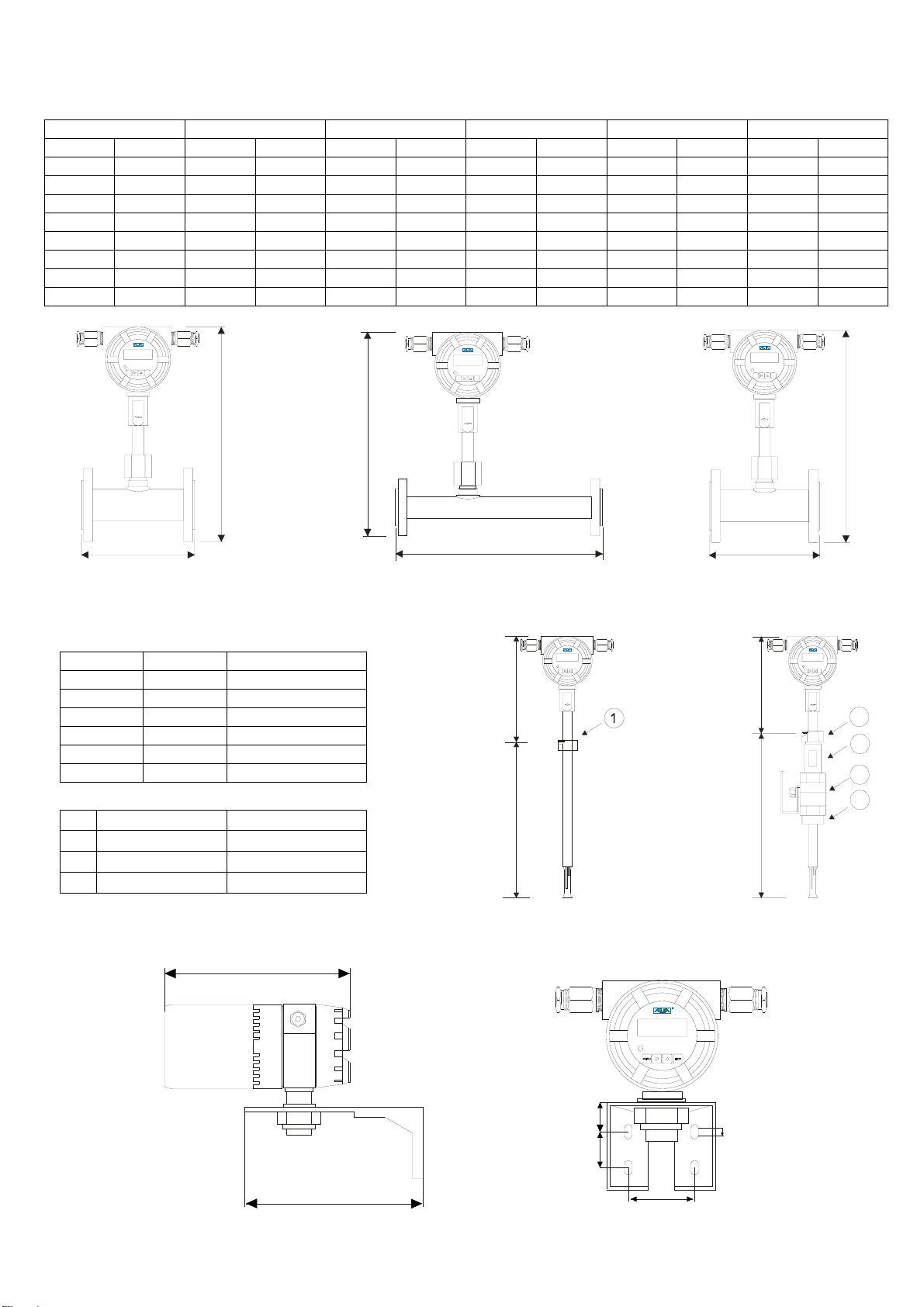

Insertion type Pipe-type

Measuring Medium Single component gas and multi-component gas

Pipe Size Circular pipe: DN80-7000 mm or

square pipe Circular pipe: DN10-1000 mm

Flow Rate 0.1-120 m/s

Accuracy +/-1%, of reading +/-0.5% FS

Working temperature Normal temperature type: -40-200 °C

High temperature type: -40-350 °C

Working Pressure Max. pressure: 63 kg/cm2(Please specify for special case)

Power Supply DC24V and AC90-260V Power ≤10W

Response Speed 1s

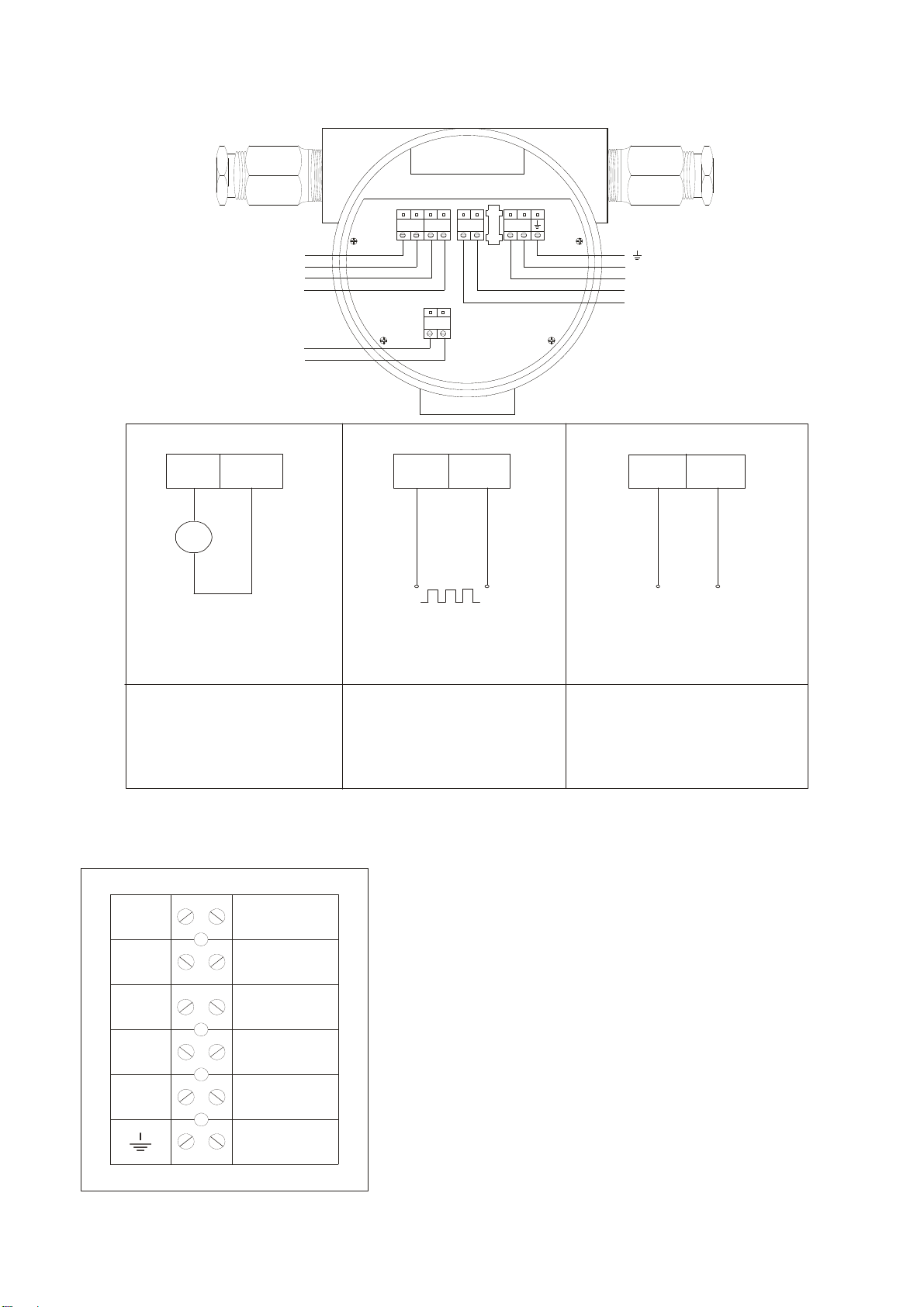

Current Output 4-20 mA (photoelectric isolation, up to 800 load), 2-channel 4-20 mA

photoelectric isolation (optional: 2-channel 4-20 mA).

Pulse Output

Cumulative pulse: Optical isolated OD output, max. current is 120 mA, optional,

0.1-5999.9 ms of Pulse width adjustable (0.1 ms of resolution), the Min. Pulse

interval time is 0.1-5999.9 ms (0.1 ms of resolution), the flow corresponding to

a single pulse is 0.001-59999. (Optional)

Communication

Output RS-485 (MODBUS-RTU) (photoelectric isolation)

Output

Signal

Alarm Output

No.2 circuit alarm limit can be DC30V/5A or AC250V/5A, which can be

programmable to be normally open or normally closed state, as well as other

alarm modes, such as flow and temperature limit alarm (optional function).

Pipe Material Metal or non-metallic

Display 16 * 2, English, flow rate, total flow, medium temperature, alarm status, total

running time, current date and time.

IP Grade Transmitter: IP67 Sensor: IP68

Explosion-proof Exd CTⅡ4