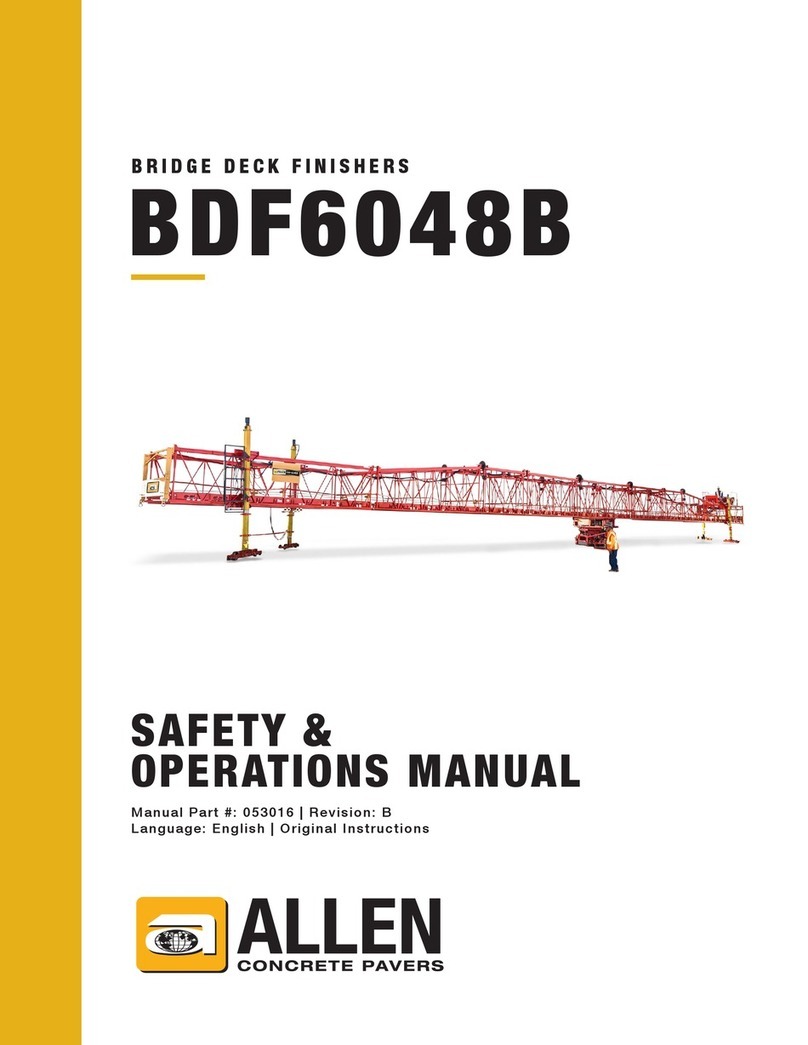

BRIDGE DECK FINISHER SET-UP GUIDE - 069596Page 8

BDF Assembly & Set-up

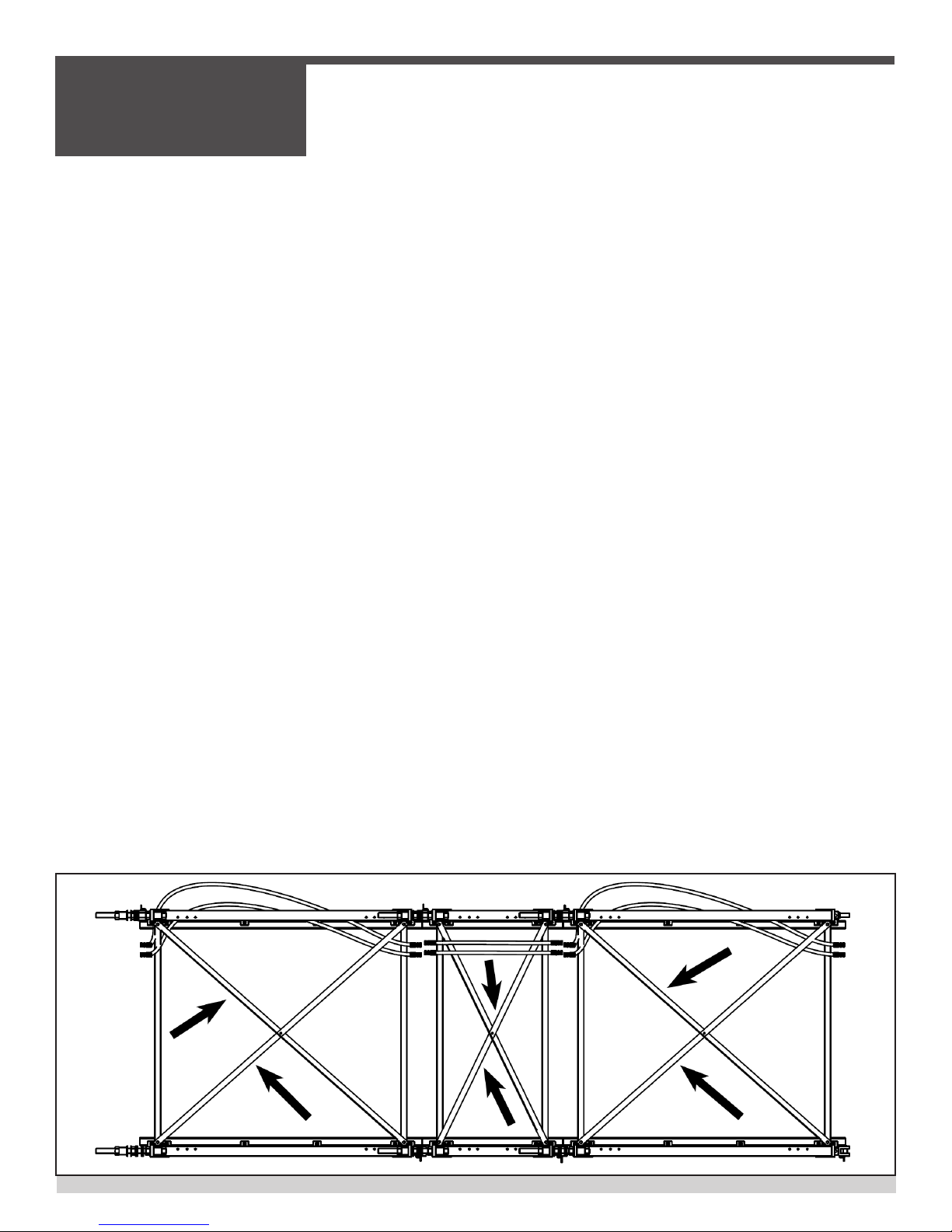

STRAIGHTENING CARRIAGE RAIL

• For string-lining the carriage rail, use nylon masonry line.

DANGER: USE ONLY STRING-LINE PROVIDED WITH BDF

• Attached the string-line from eye bolt to eye bolt on each

end of the BDF. These are located at the base of each end

panel. DO this step for both sides of the frame.

• Tighten the string-line by pulling it taut with no sag. It may

be necessary turn the eye-bolts to gain additional tension on

the string (NO SAG)

• The carriage rail adjuster lock nuts need to be loosened

to allow movement of the carriage rail.

CAREFUL not to make them too loose.

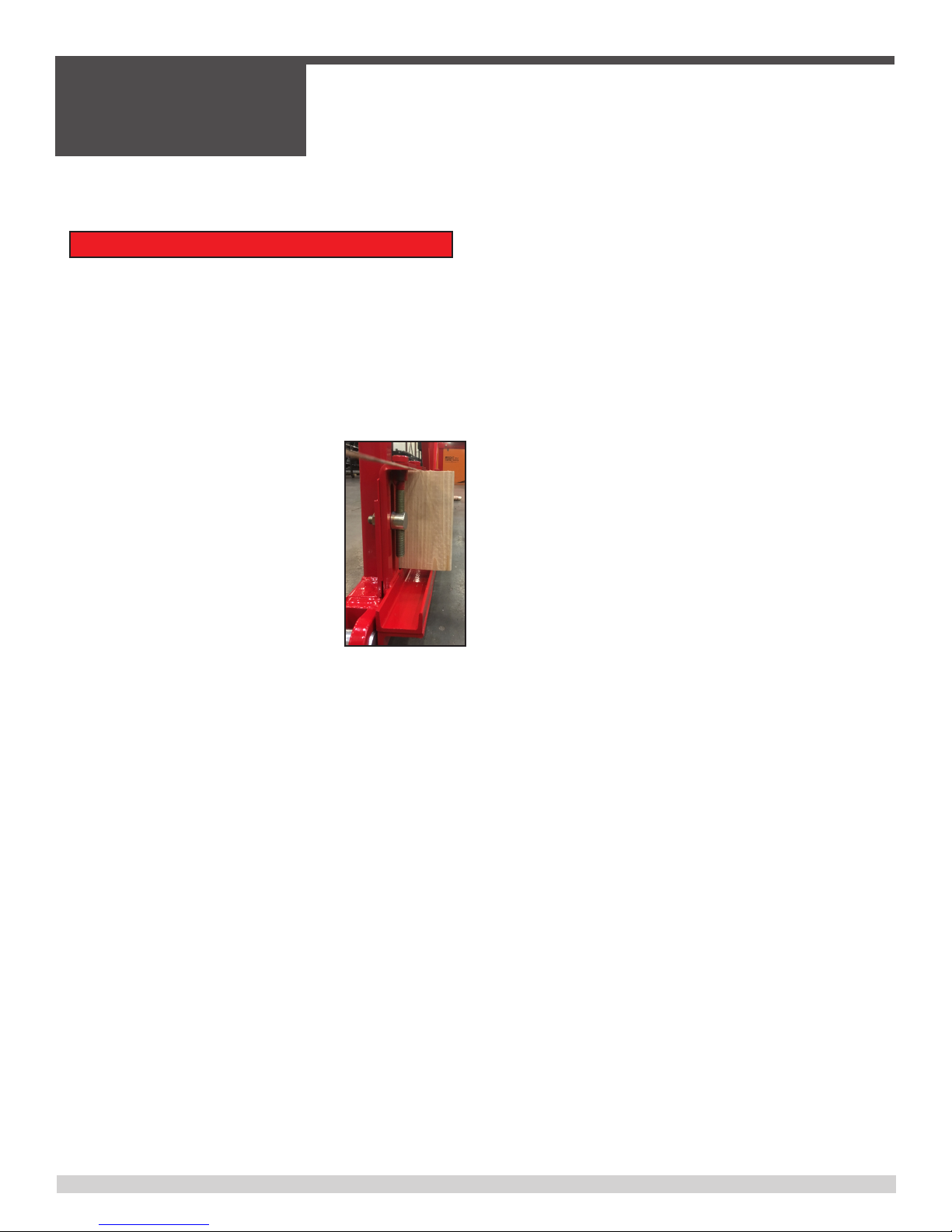

• You will need (4) - 2” x 6” wood blocks,

use the factory edge for the string-line to

rest on & the other factory edge resting

on the carriage rail (SEE PICTURE).

• Any number of items can be used to

check the carriage rail height to the

string-line – Wood block, chamfer strip,

grade stake.

• Adjust the carriage rail holder bolt up or down so that the

carriage rail matches the same height across the frame.

• When the carriage rail adjustment has been completed and

looks straight, tighten all of the carriage rail locknuts. SAME

ON BOTH SIDES.

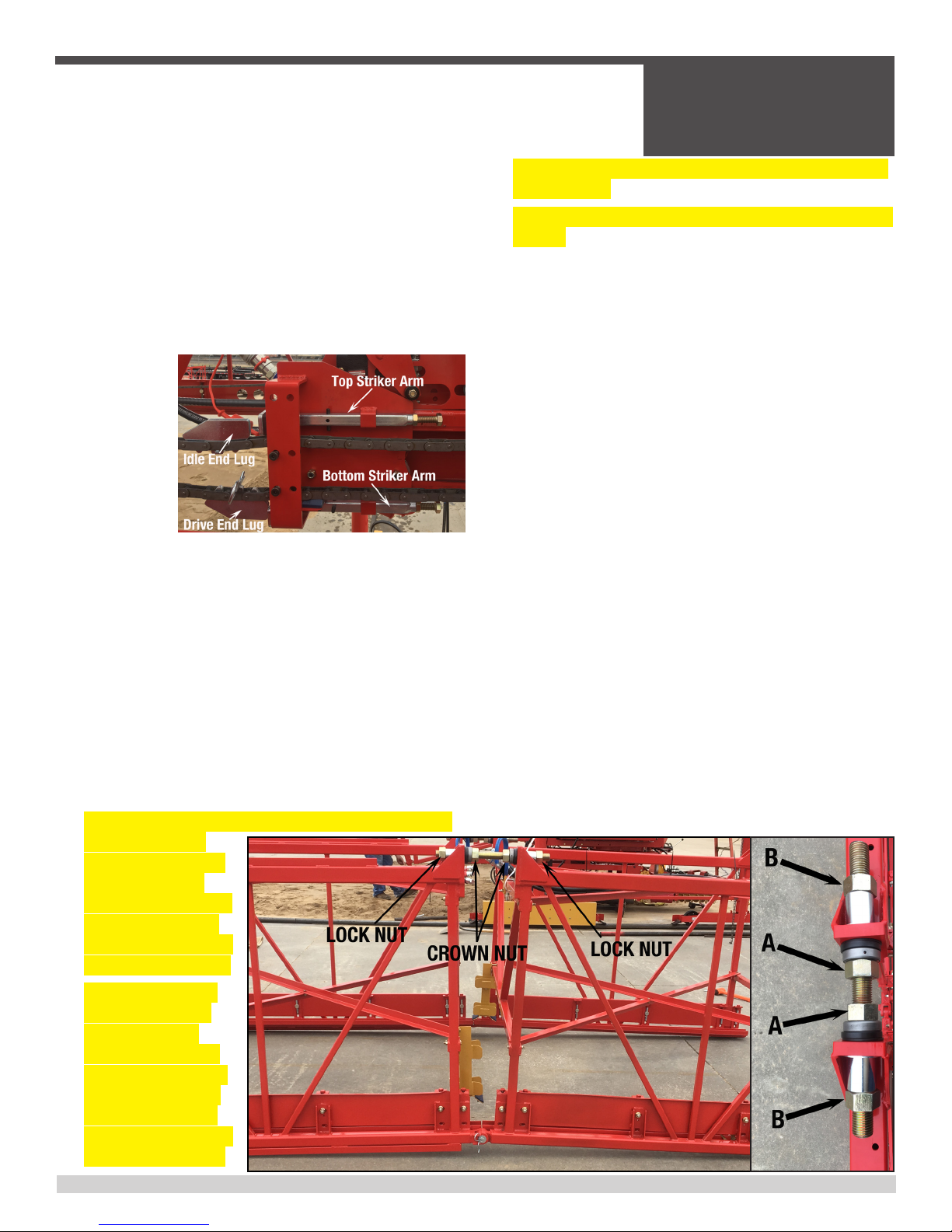

SQUARING THE PAVING CARRIAGE

• Make sure that the lower carriage slide blocks make contact

with the upper carriage skew ring and there are no gaps.

MAY NEED SHIMS.

• Make sure that the lower carriage is in the down position

and look at the blocks against the ring.

• If there are gaps, remove the cotter pin and turn the castle

nut located under side of the upper - lower carriage. Also

check for wear on the slide blocks, may need replacing.

• After starting the engine, engage the on/off lever to shift the

lower carriage by manually pushing or pulling the reversing

valve rod.

• Adjust the turntable pivot nut until lower carriage pivots

freely and there are no gaps, shut off the engine and replace

the cotter pin in the castle nut.

• Align the paving rollers so that they are parallel with the

upper carriage.

• Use a level, metal bar or string-line across the top of each

side of the upper carriage from carriage rail to carriage rail.

• Place a 4’-6’ long straight edge or level across the top or

the bottom of both ends of the paving rollers.

• Measure the distance from the top of the carriage rail to the

bottom of the paving roller, which is top of concrete grade

and make sure this is the same on all 4 roller corners.

ADJUSTING THE PAVING ROLLERS

• To adjust the elevation of the paving rollers, ONLY loosen the

bolts on the front of the carriage holding the roller bearing.

• Also, ONLY loosen the bolts that support the motor mount

plates on the back of the lower carriage.

• Using a tape measure or wooden ruler, measure down from

the string-line to the top of the straight edge or level.

• The distance must be the same at all four corners.

• Adjust the elevation of each roller end by turning its adjuster

bolt clockwise to raise and counter clockwise to lower.

• When all four corners are equal, the paving rollers will be

parallel with the carriage rail.

• Tighten all loose mounting bolts.

• Use the auger adjusting crank and reset the augers to 1/8”

to 1/4” above the bottom of the paving rollers.

ROLLERTAMPERS

• The roller tamper drums are used to consolidate the top

surface of the concrete with the desired density.

• It helps to seal hard to nish concrete with harsh mix

designs and low slumps.

• It may also help to seal when dealing with wind exposure,

causing abnormal surface drying and unforeseen delays in

the concrete delivery.

• Place a 4’-6’ level under the paving rollers and under the

roller tamper drum to check the elevation.

• Loosen the locking set screws and the lock nuts for the

drum adjustment on both sides of the roller tamper with the

front and back set to grade.

• The drums can be adjustable from 1/2 inch above concrete

grade to 3/4 inch below concrete grade.