057625 - 10/2012

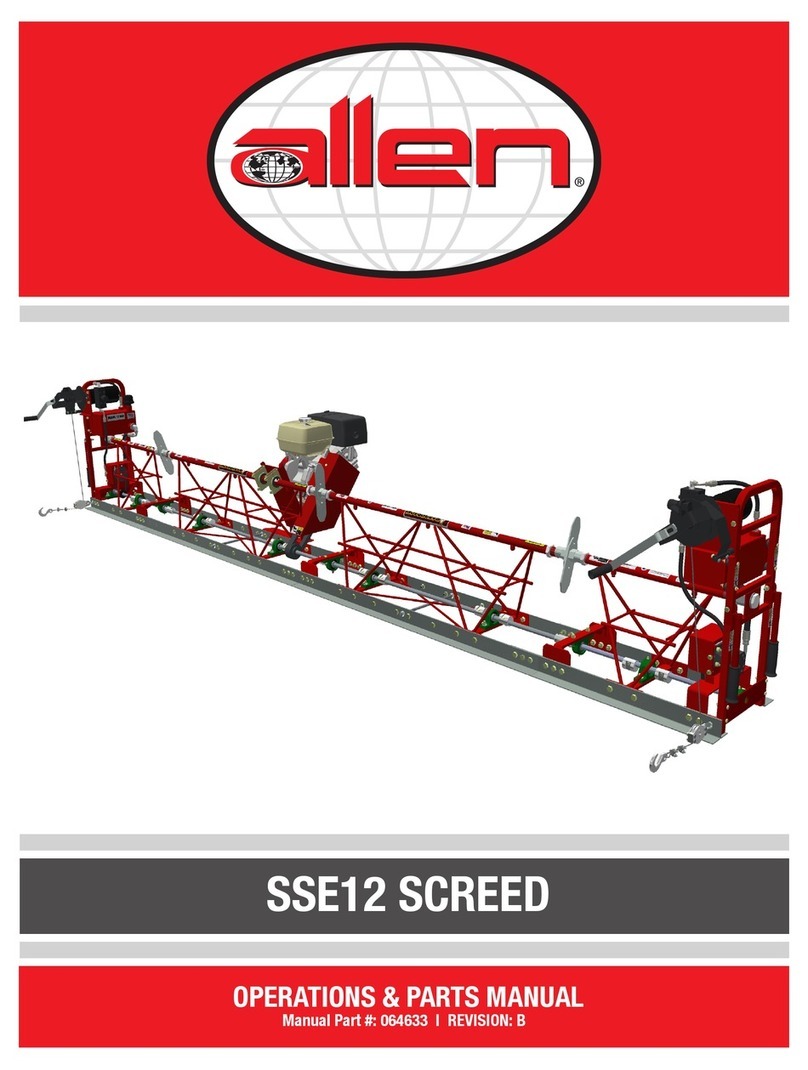

Roller Screed

OPERATIONS - PARTS MANUAL

Page i

This manual covers the products listed below:

Part No. Description

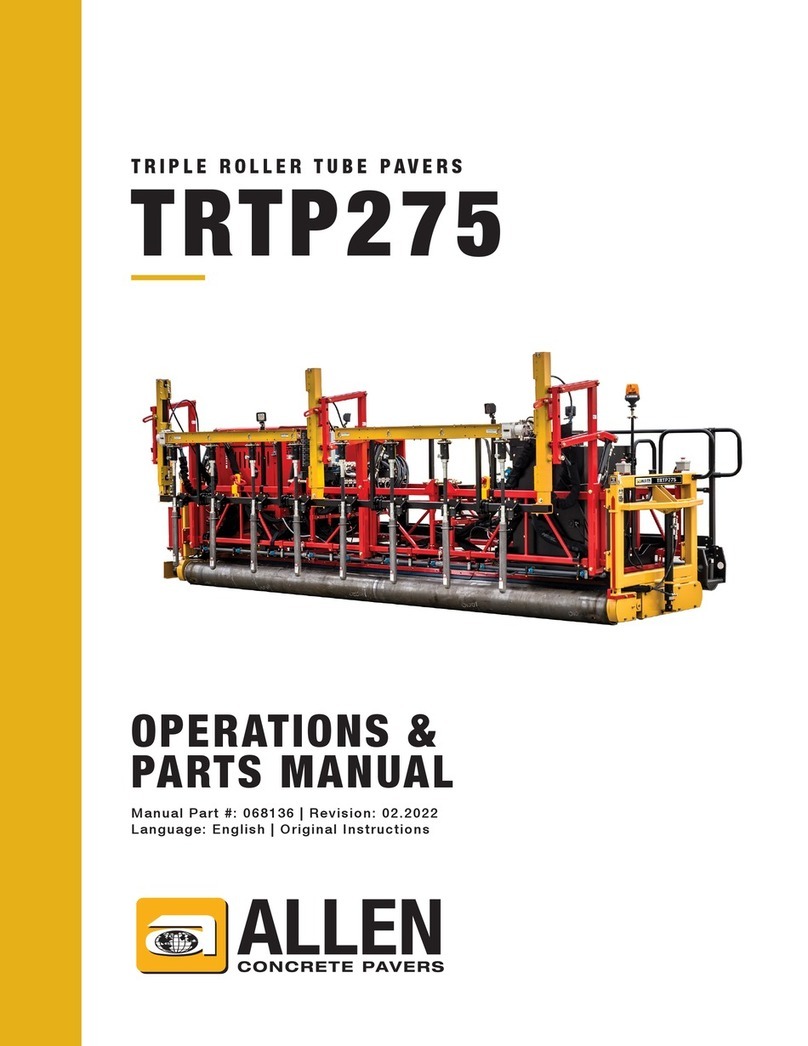

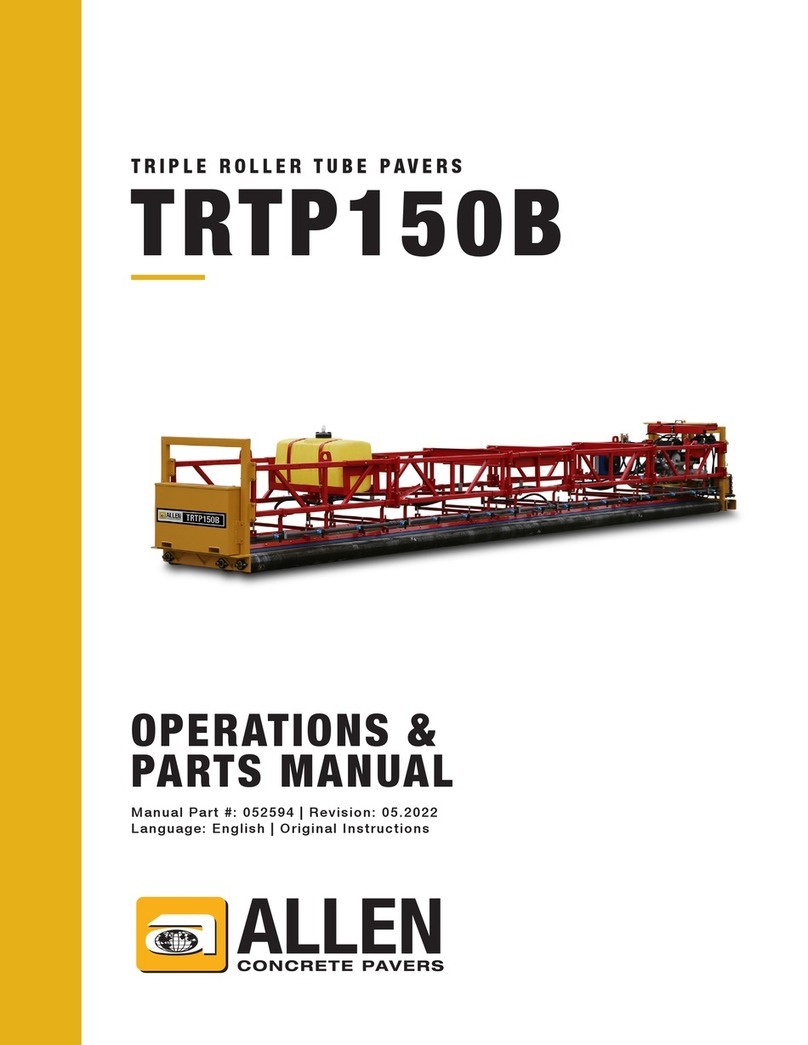

057250 RS844 ROLLER SCREED

Copyright © 2012 Allen Engineering Corporation

All rights reserved

All information, specications, and illustrations in this manual are subject to change without notice and

are based on the latest information at the time of publication. No part of this manual may be reproduced

or transmitted in any form or by any means, electronic or mechanical, for any purpose, without the

express written permission of Allen Engineering Corporation (AEC). AEC assumes no responsibility or

liability for any errors or inaccuracies that may appear in this manual.

Allen Products are covered under one or more of the following patent numbers:

U.S. Design Patents: 344,736; 400,542; 400,544; 402,998; 402,999; 403,332; 404,041; 404,042;

410,931; 413,127; 416,564; 465,897; 466,909; 474,203.

U.S. Utility Patents: 5,108,220; 5,238,323; 5,328,295; 5,352,063; 5,405,216; 5,476,342; 5,480,257;

5,480,258; 5,533,831; 5,562,361; 5,567,075; 5,613,801; 5,658,089; 5,685,667; 5,803,658; 5,816,739;

5,816,740; 5,890,833; 5,934,823; 5,967,696; 5,988,938; 5,988,939; 6,019,433; 6,019,545; 6,048,130;

6,053,660; 6,089,786; 6,106,193; 6,857,815; 5,288,166; 6,582,153 B1, 7,108,449; 7,114,876;

7,316,523; 7,690,864 B2

Canadian Patents: 2,039,893.

First Issue: October 2012

AEC Manual Part No.: 057625

Printed in U.S.A.