Catalogue

Foreword................................................................................................................................................................................3

1. Machine parameters ........................................................................................................................................................3

2. Flow Diagram for Quick Use Manual.............................................................................................................................3

3. Important Notice and Attentions.....................................................................................................................................3

4. Preparatory Work..............................................................................................................................................................4

5. Preinstallation Checklist ..................................................................................................................................................4

5.1 Step Way of Opening Box.....................................................................................................................................4

5.2 Take an account of kits..........................................................................................................................................4

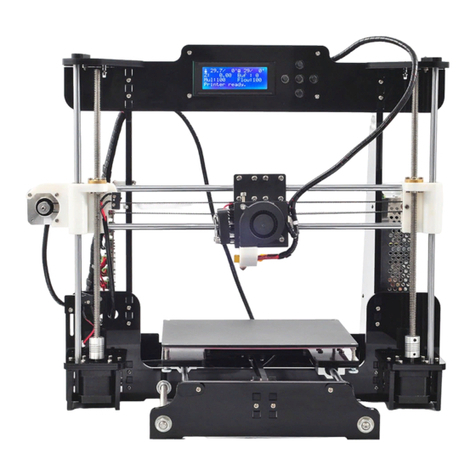

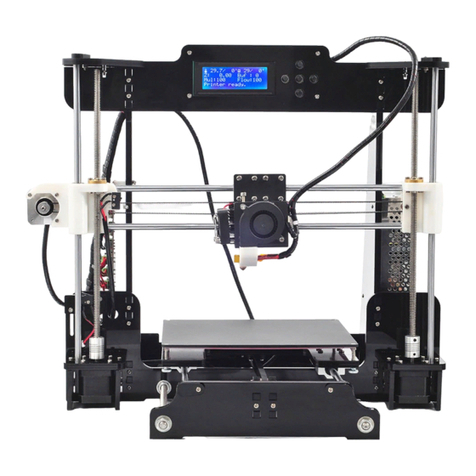

6.Assembly and Calibration for M508...............................................................................................................................4

6.1 The main machine structure.................................................................................................................................5

6.2 Step1 Frame assembly..........................................................................................................................................5

6.3 Step2 Y axis assembly and hotbed assembly....................................................................................................6

6.4 Step3 Z axis assembly and X axis assembly...................................................................................................10

6.5 Step4 Extruder assembly....................................................................................................................................13

6.6 Step5 LCD assembly...........................................................................................................................................15

6.7 Step6 power and mainboard assembly.............................................................................................................16

6.8 Step7 Filament rack assembly...........................................................................................................................17

7. Testing and Commissioning..........................................................................................................................................18

7.1 Power on test........................................................................................................................................................18

7.1.1 Turn on the power switch, LCD display, as shown in Figure..............................................................18

7.1.2 Fan check...................................................................................................................................................18

7.1.3 Nozzle and hot bed heating inspection..................................................................................................18

7.1.4 Back to the origin inspection....................................................................................................................18

7.2 Hotbed leveling test:............................................................................................................................................19

7.2.1 Rough Debugging to level hotbed..........................................................................................................19

7.2.2 Accurate Debugging .................................................................................................................................20

7.2.3 Fine Debugging when printing................................................................................................................20

7.3 Change the Filament............................................................................................................................................20

7.3.1 Change the Filament when not printing.................................................................................................20

7.3.2 Change the Filament When Printing......................................................................................................21

7.4 Feature Demonstration........................................................................................................................................21

7.4.1 Instruction of Operation part for Off-line Printing..................................................................................21

7.4.2 The first Memo Interface..........................................................................................................................22

7.4.3 The secondary memo interface ..............................................................................................................22

7.4.4 Prepare for printing (prepare)..................................................................................................................23

7.4.5 Move the axis and input& output the filament (Move Axis).................................................................23

7.4.6 The ParameterAdjustment when not printing (Control)......................................................................24

7.4.7 Real-time parameter adjustment (Tune)................................................................................................25

7.4.8 Parameter adjustment when printing (Control).....................................................................................26

7.4.9 Print from SD .............................................................................................................................................26

8. Printing Test.....................................................................................................................................................................26

9. Senior Instruction............................................................................................................................................................27

9.1 Off-line Printing.....................................................................................................................................................27

9.1.1 How to use Cura 15.04.............................................................................................................................27

9.1.2 Online Printing.....................................................................................................................................34

10. Frequently Asked Questions and Solutions..............................................................................................................37

10.1 “Err: MINTEMP”Alarm processing method....................................................................................................37

10.2 Trouble: LCD screen is not bright....................................................................................................................38

10.3 Trouble: Rotation button cannot be up and down the selection menu.......................................................38

10.4 No extruded filament when printing.................................................................................................................39

10.5 Problems on the distance between nozzle and hotbed................................................................................39

10.6 Model Dislocation when printing......................................................................................................................39

11. Wire Diagram of Main board.......................................................................................................................................41