Installation Cut Sheet

3 / 7 / 2022 / Rev 0

Page 2 of 2

1170 North Red Gum Street, Anaheim, CA 92806

© ALUZ All rights reserved. ALUZ reserves the right to make changes or withdraw specifications without prior notice.

A8 Series |LED Tape

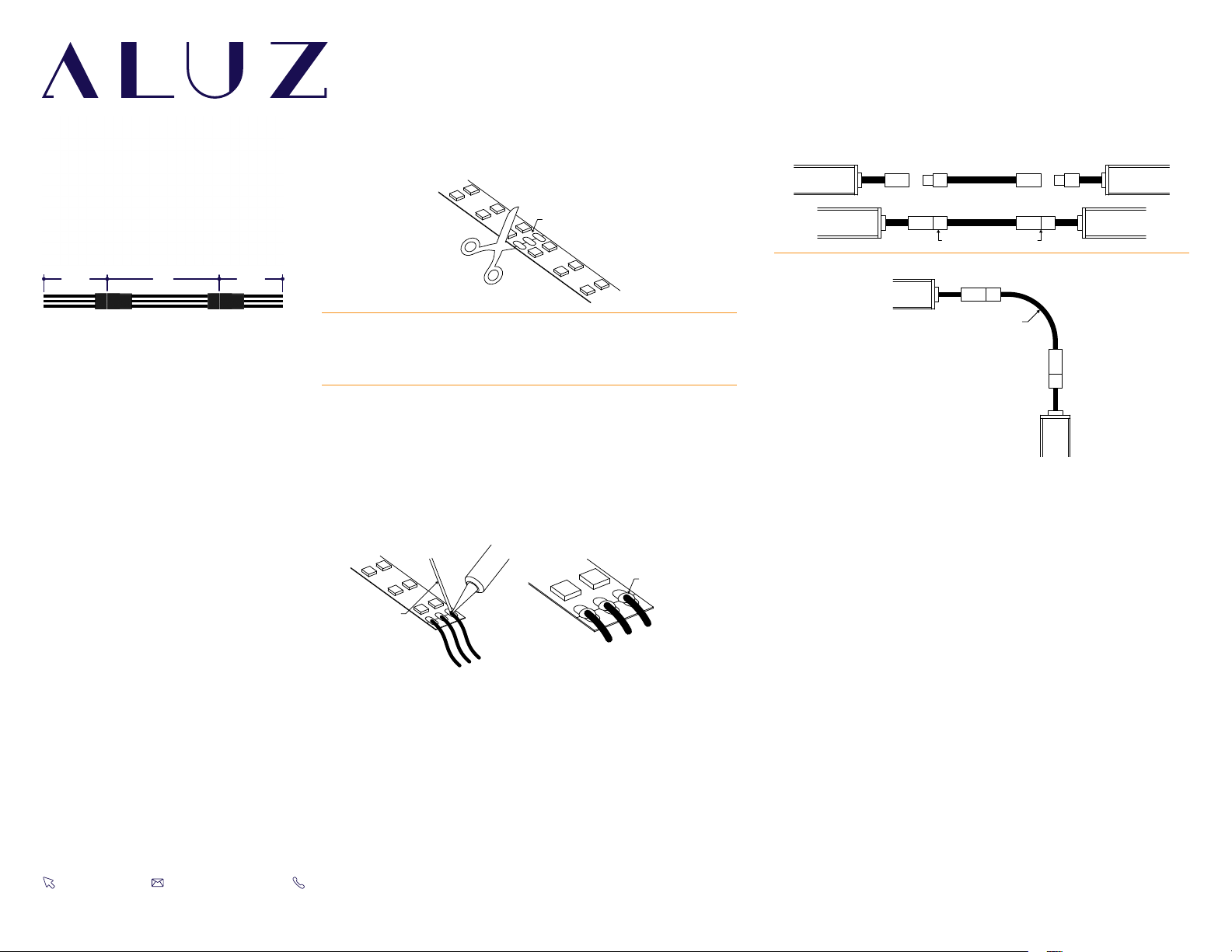

CONNECTOR Dry Continuous Connector

(A8-CC-3P-DRY)

This document is issued in strict confidence on condition that it is not used as

a basis for manufacture or sale and is not copied, reprinted, or disclosed to a

third party either wholly or in part without the prior written consent of ALUZ.

Dry Continuous Connector

20/3 Gauge Wire

(A8-CC-3P-DRY-X)

X = Specify Length, 3” Default

POSITION WIRES

1

After soldering is completed, make connections between connectors

by plugging the male and female disconnects together.

2Position connectors as needed.

Note: Appearance of lightstrip may differ from example shown.

Refer to wiring diagrams before soldering any wires.

ZOMU SOLDERING GUIDE

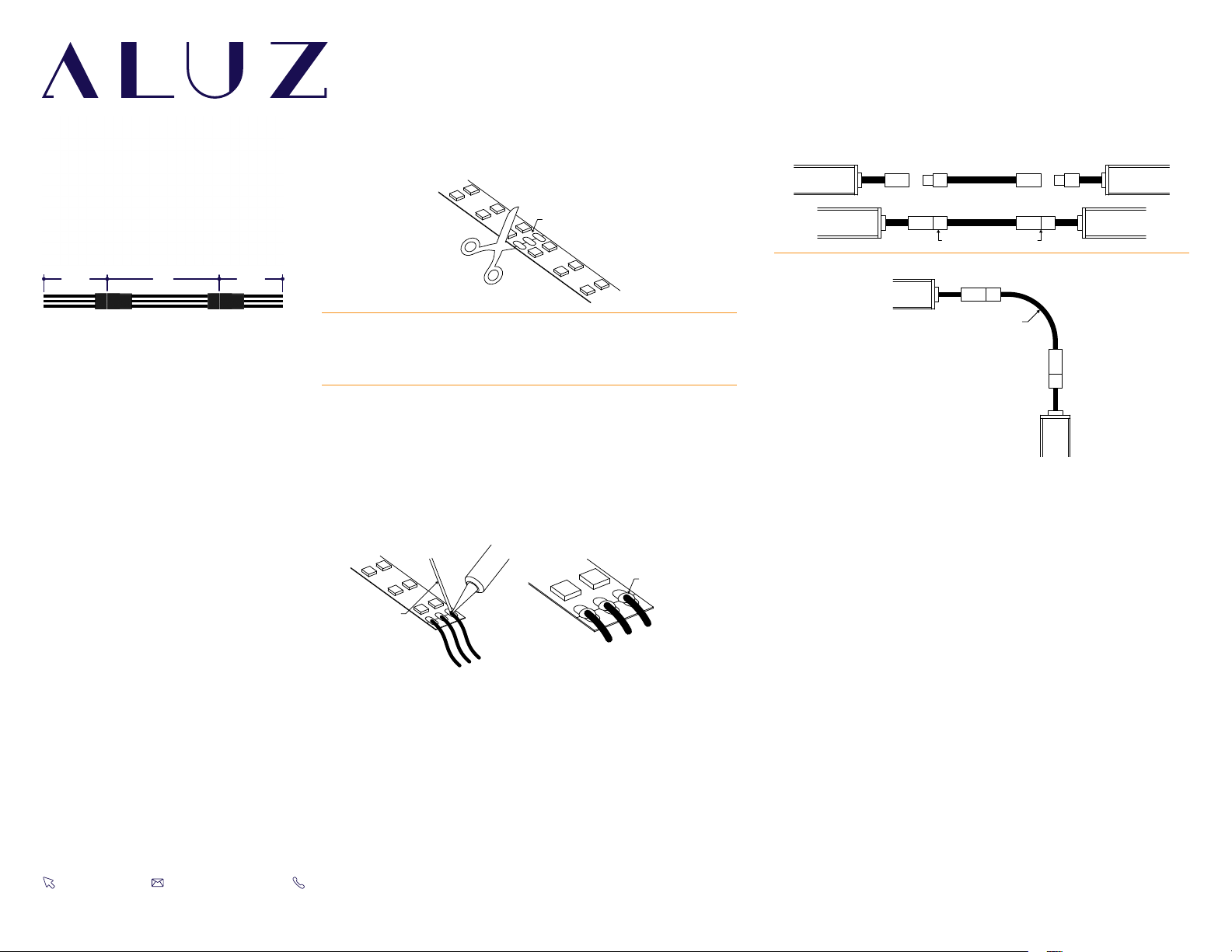

CUT TO SIZE

WELLER 0.50”

WIRE AND PADS

Cut lightstrip to desired length. Include both sets of solder pads by

cutting to the left or right of designated markings, allowing more

space for soldering.

Prepare wires by stripping 1/8” from the end of each wire, then tin

the tips of the wire with solder. Apply heat to stripped portion of

wire, then add a small amount of solder until stripped portion of

wire is fully covered in solder.

Solder lead wires to solder pads on the end of lightstrip.

• Solder the Brown wire to the pad marked “+”.

• Solder the White wire to the pad marked “W”.

• Solder the Yellow wire to the pad marked “WW”.

Note: Solder iron not to exceed 720°F. Heat joint with tip of iron.

Heat both the solder pad and the wire. Add a small drop of solder

on the tip of solder iron to transfer the heat to joint quickly; it

should melt and flow smoothly, covering the wire and pad.

Remove iron once enough solder has been added to the

components. Allow 5 seconds for the joint to cool.