Installation Instructions

1170 N Red Gum St, Anaheim, CA 92806

© ALUZ All Rights Reserved. ALUZ reserves the right to make changes or withdraw specifications without prior notice.

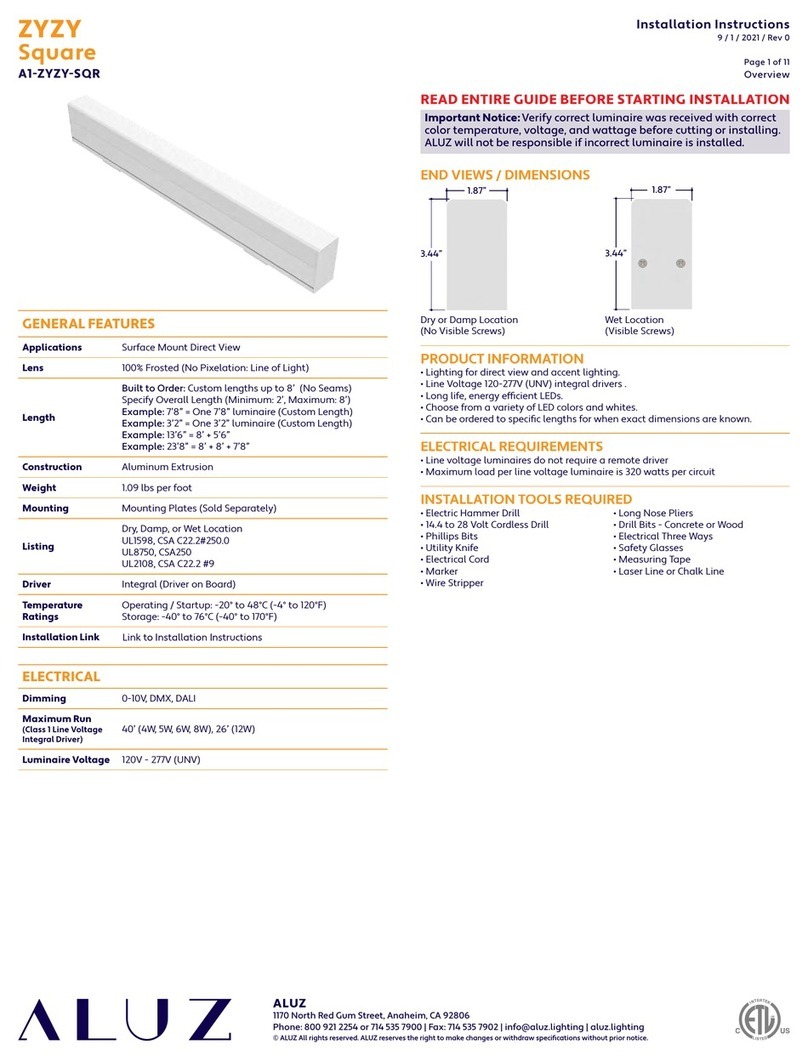

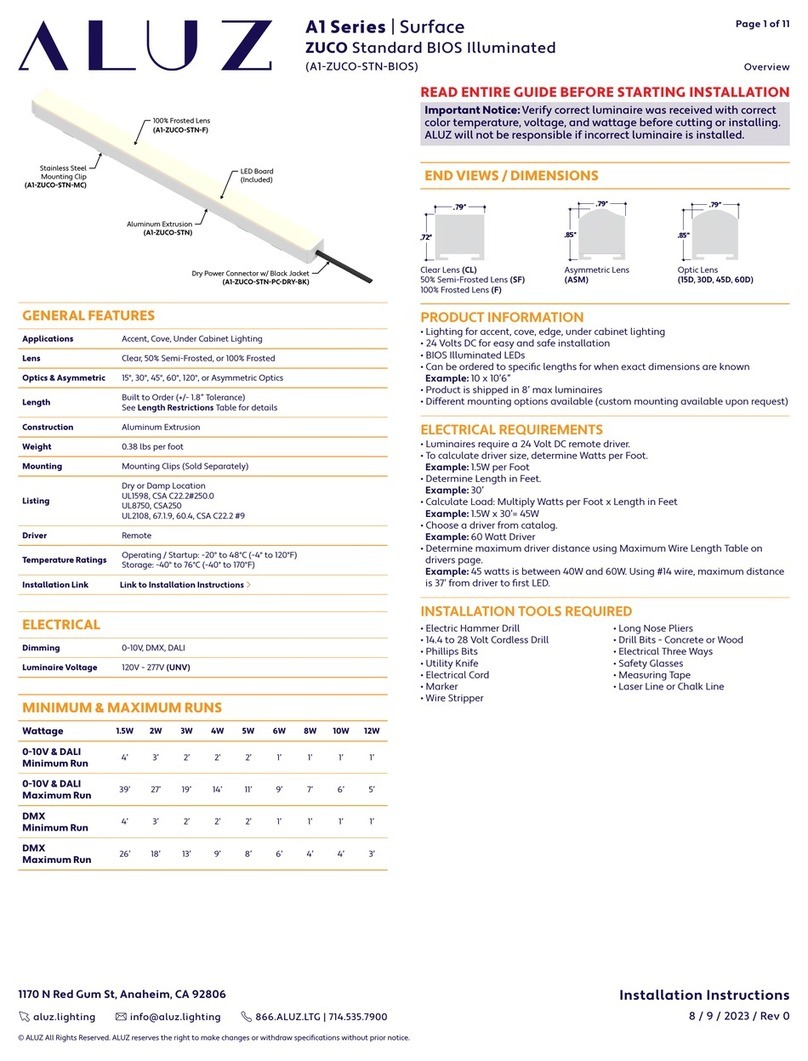

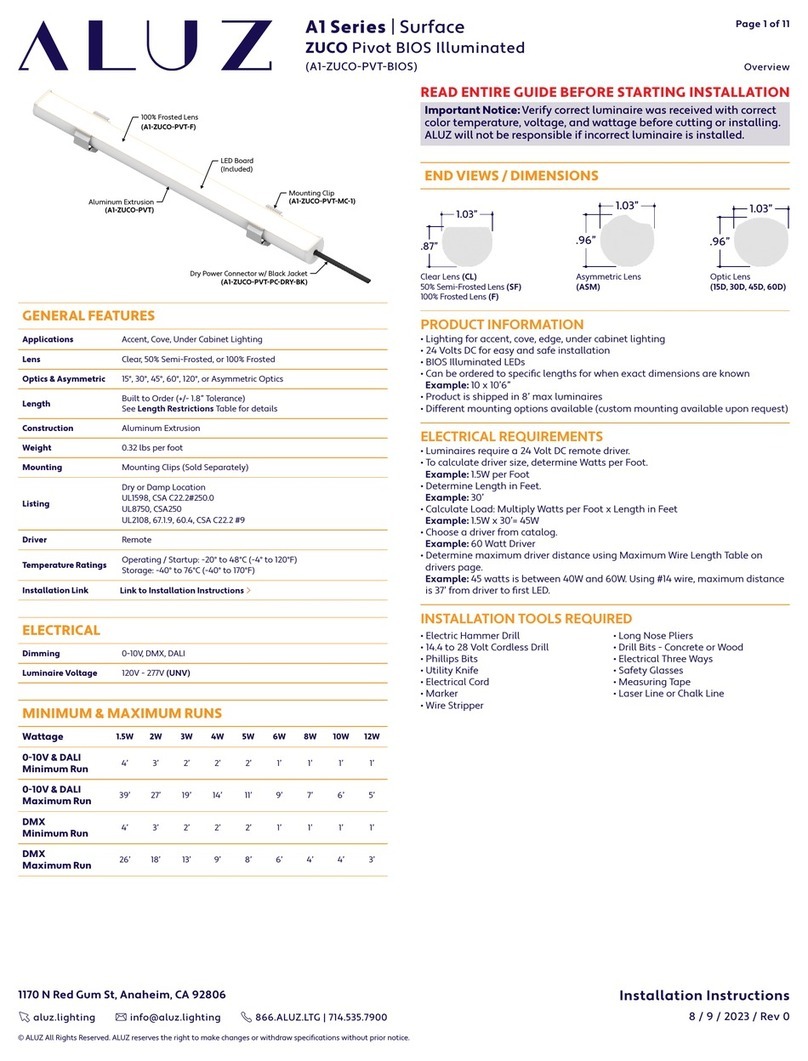

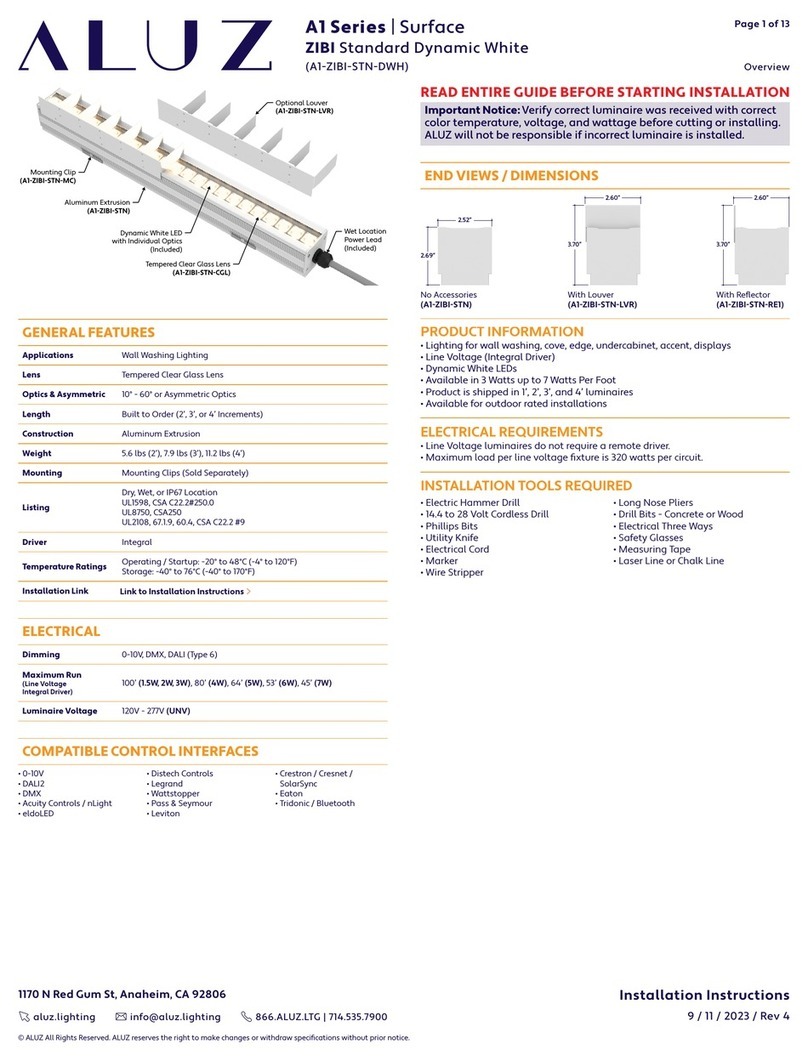

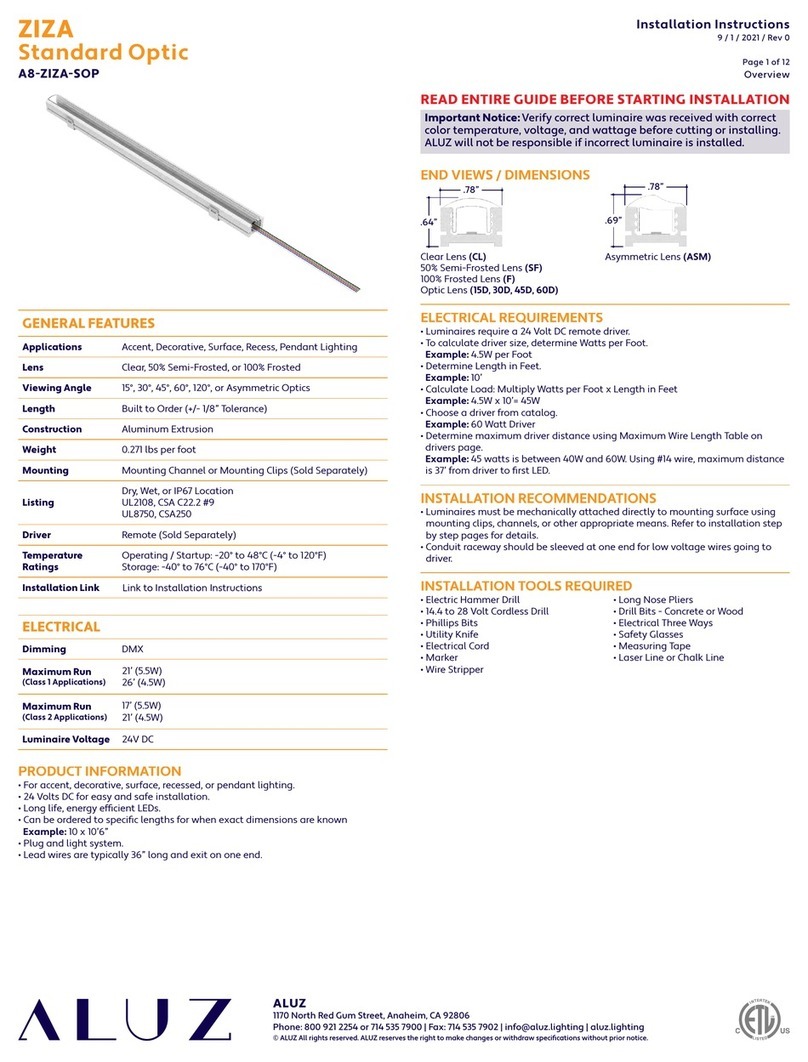

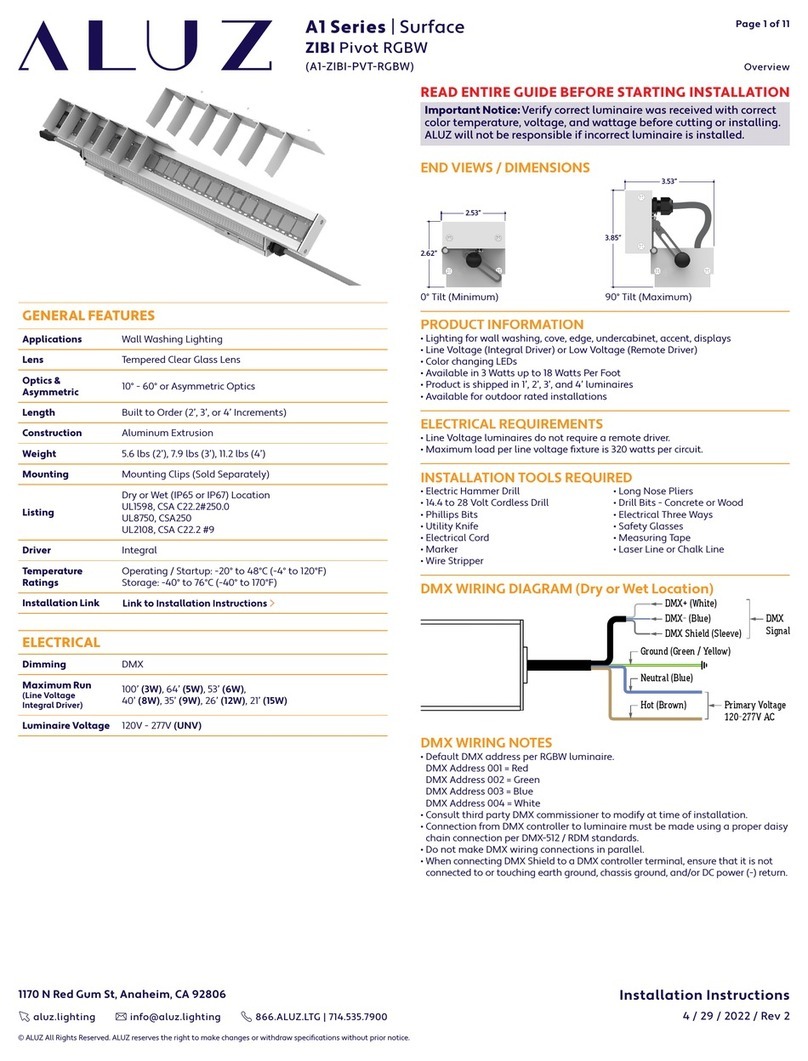

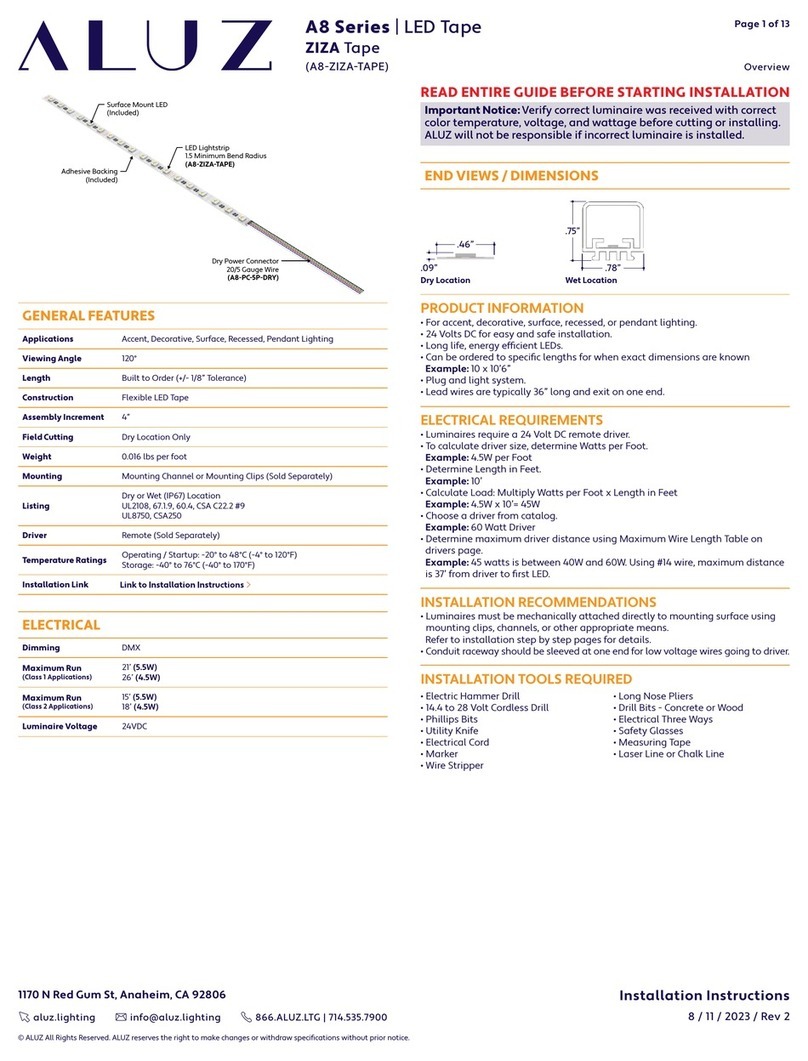

A1 Series |Surface

ZIBI Standard RGBW

(A1-ZIBI-STN-RGBW)

Page 2 of 12

4 / 29 / 2022 / Rev 2

Product Care & Maintenance

• Ensure power is off before installation begins, during replacements, additions,

or repairs.

• Do not use luminaires if damaged, such as broken boards, loose connections, or

frayed wire insulation. Inspect before installing.

• Do not install luminaires in hazardous locations.

• Do not cover luminaires with any material. Covering may cause LEDs to overheat,

melt, or ignite.

• Do not paint on or over fixture lens or LEDs.

Paint or any other substance on lens or LEDs will cause a shift in color temperature.

• Soffit must be evenly painted with a neutral white to avoid color shift.

• Do not modify luminaires in the field.

• Do not overlap luminaires in any way.

(Fig. 1)

• Luminaires have line voltage risk of shock. Consult factory for any malfunctions.

Do not attempt to repair.

• Only use luminaire with specified rated voltages. Do not exceed the specified

voltage for any luminaire.

• Do not use extrusion as a raceway for additional wire. Non-factory feed through

wires inside luminaire will void warranty.

• Ground Fault Circuit Interrupter (GFCI) protections should be provided on circuits

or outlets when luminaire is used for outdoor applications.

• Surge protector must be set up for electrical power system to avoid damaging

lighting system.

• Do not make wiring connections without referring to wiring diagrams.

• Do not cut wire while energized.

(Fig. 2)

• Do not exceed maximum run lengths.

• Always follow sequence labeling for continuous runs. Continuous run segments

are labeled in alphabetical order.

• Polarity of continuous run segments must be aligned.

• Do not assemble continuous runs prior to installing into mounting clips.

Each segment must be installed one by one into mounting clips. The weight of

the assembled segments will put strain on junctions, causing the board, pin, or

terminals to break.

• Do not install continuous runs without a mounting clip at each junction between

two segments.

• Do not secure luminaire with nails or like means that might damage the wiring

inside. Only secure by using mounting clips.

• Do not mount luminaire inside tanks or enclosures of any kind.

• Do not install downward facing luminaires without set screws.

• Do not use improper screw head type on mounting clips. It will cause the

mounting clip to open up and become dysfunctional.

• Do not modify mounting clips.

• Do not weld mounting clips to surface. Mounting clips must be mechanically

attached with screws appropriate for mounting surface and weight of luminaire.

• Do not mount fixture with less than the minimum number of mounting clips

required. See mounting clips section for details.

• Do not install mounting clips on uneven surfaces. Use shims to level out height

of mounting clips if necessary.

• Do not install mounting clips after luminaires have been assembled.

Install mounting clips first, then install luminaire into mounting clips.

• Do not force luminaire into a space that is too small.

• Do not force luminaire with cord grip into soffit.

(Fig. 3)

• Do not install luminaire at an angle within a cove. Only install fixtures straight

within a cove. (Fig. 4)

• Do not bend extrusion around radius.

• Do not submerge dry or wet location luminaire in any liquid.

• Do not install wet location in outdoor coves without proper drainage.

(Fig. 5)

• Do not install luminaire in any area that is continuously exposed to flowing or

pooling water, such as underneath drain pipes, sprinklers, fountains, misters, etc.

• Do not cut, puncture, or penetrate aluminum housing, end caps, or lens covers.

• Do not drop, bang, or rest weight upon luminaire.

• Do not apply excessive pressure to any part of luminaire.

• Do not remove end caps from luminaire.

• Do not bend power cord or continuous connector past permitted bend radius.

Bending past permitted bend radius will break the seal of the cordgrip or

damage the insulation. (Fig. 6)

Wet Location: 3.5” minimum bend radius

Dry Location: 1.5” minimum bend radius

• Do not install in places where the power cord is subject to continuous flexing.

• Do not twist continuous connector or power cord.

• Do not hold, carry, or suspend luminaire by the power cord.

• Do not install on ceilings without mounting clips and set screws.

(Fig. 7)

When using luminaires for any application, basic safety precautions

should always be followed to reduce the risk of fire, electric shock, and

personal injury. Luminaires must be installed in accordance with the

NEC or CEC as applicable. ALUZ will not be responsible for damage or

malfunction caused by the following:

WARNING FIGURES

INCORRECT

Figure 1

Figure 5

Figure 6

MOUNTING CLIP

SET SCREW

Figure 7

Figure 2

INCORRECT

Figure 3

INCORRECT

Figure 4

CLEANING MATERIALS

The use of solvents and/or cleaners which are not compatible with

polycarbonate will result in the softening, crazing, and/or cracking

of the plastic part. This is especially true of polycarbonate lamps

and mounting bases which may be under stress in their normal

applications.

COMPATIBLE WITH POLYCARBONATE

• Mild soap and water

• Mineral Spirits

• Isobutyl Alcohol

• VM and P Naphtha

• Varsol No.2

• Mexane

• Freone TF and TE-35

• Ethanol

• Dirtex

• 2% Sol. Reg. Joy

• 10% Sol Bon Ami

• White Kerosene

• Methyl Alcohol

• Heptane

• Petroleum Ether / 65°C

• Isopropyl Alcohol

• Lacryl PCL-2035

Polycarbonate Cleaner

NOT COMPATIBLE WITH POLYCARBONATE

• Trichlor

• Gasoline

• Liquid Detergents

• Acetone

• Carbon Tetrachloride

• Pink Lux (Phosphate free)

• Triclene

• Chlorinated Hydrocarbons

• #1 & #3 Denatured Alcohol

• Methyl Ethyl Keytone (MEK)

• Texize-8006, 8129, 8758

• MIBK

• Liquid Cleaner – 8211

• Toluol

• Agitene

• Benzol

• Ajax

• Kleenol Plastics

• Lysol

• Stanisol Naphtha

• Oils

• Lemon Joy (phosphate free)

• Diversol

• Lestoil