ZA-X BAG0235.4

5.5.2 Uncoupling the hydraulic hose lines...................................................................................... 45

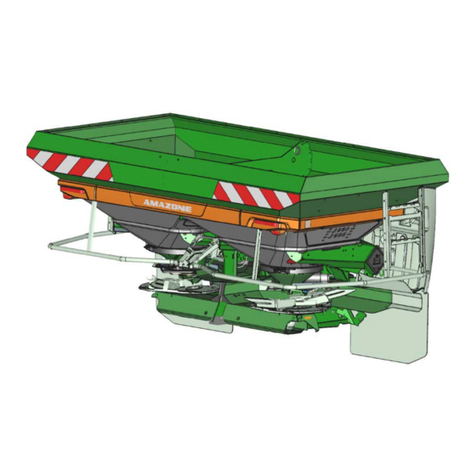

5.6 Spreading discs..................................................................................................................... 46

5.7 Agitator .................................................................................................................................. 46

5.8 Slider ..................................................................................................................................... 47

5.9 Two-way control .................................................................................................................... 48

5.10 Three-way control (optional) ................................................................................................. 49

5.11 3-point attachment frame ...................................................................................................... 50

5.12 Boundary spreading/side spreading...................................................................................... 51

5.13 Calibration kit (optional)......................................................................................................... 52

5.14 Transport and parking device (removable, optional)............................................................. 53

5.15 Coupling device..................................................................................................................... 54

5.16 Hopper cover (optional)......................................................................................................... 54

5.17 Hopper extensions (optional) ................................................................................................ 55

5.18 Row spreading attachment for specialised crops ................................................................. 56

5.19 Setting chart .......................................................................................................................... 60

5.20 EasyCheck (option) ............................................................................................................... 62

5.21 Mobile test rig (option)........................................................................................................... 62

6Commissioning ......................................................................................... 63

6.1 Checking the suitability of the tractor .................................................................................... 64

6.1.1 Calculating the actual values for the total tractor weight, tractor axle loads and load

capacities, as well as the minimum ballast ........................................................................... 64

6.2 Adjusting the length of the PTO shaft to the tractor .............................................................. 68

6.3 Securing the tractor / machine against unintentional start-up and rolling ............................. 70

7Coupling and uncoupling the machine ................................................... 71

7.1 Coupling the machine............................................................................................................ 71

7.2 Uncoupling the machine........................................................................................................ 74

8Adjustments............................................................................................... 75

8.1 Adjusting the mounting height............................................................................................... 76

8.1.1 Late topdressing.................................................................................................................... 77

8.2 Setting the spread rate .......................................................................................................... 78

8.2.1 Setting the slider position using the setting lever.................................................................. 78

8.2.2 Setting the spread rate according to the setting chart .......................................................... 79

8.2.3 Determining the slider position using the calibration kit (optional) ........................................ 80

8.3 Setting the working width ...................................................................................................... 83

8.3.1 Adjusting the spreading vane positions................................................................................. 84

8.4 Checking the working width using the mobile fertiliser test rig (optional) ............................. 86

8.5 Boundary, ditch and side spreading...................................................................................... 87

8.5.1 Boundary spreading with limiter X (optional) ........................................................................ 88

8.5.2 Boundary and side spreading with the Tele-Quick border spreading vane .......................... 91

8.5.3 Setting and installing the Tele-Quick border spreading vane ............................................... 91

8.5.4 Boundary spreading with border spread deflector (optional) ................................................ 94

8.6 Switching the agitator head on and off.................................................................................. 95

9Transportation ........................................................................................... 96

10 Use of the machine ................................................................................... 98

10.1 Filling the centrifugal broadcaster ....................................................................................... 100

10.2 Spreading operation ............................................................................................................ 101

10.2.1 Complete discharging.......................................................................................................... 104

10.3 Recommendation for working in headlands ........................................................................ 105

10.4 Notes for spreading slug pellets (e.g. Mesurol) .................................................................. 106

10.4.1Spread rate check with the machine at a standstill............................................................. 107

11 Faults........................................................................................................ 109