ZA-M BAG0234.3

5.6.2 Boundary spreading at the field boundary ............................................................................ 46

5.6.3 Boundary spreading from the road, avoid spreading in the track ......................................... 46

5.7 PTO shaft .............................................................................................................................. 47

5.7.1 Coupling the PTO shaft......................................................................................................... 50

5.7.2 Uncoupling the PTO shaft ..................................................................................................... 51

5.7.3 PTO shaft with friction clutch (optional)................................................................................. 52

5.8 Hydraulic connections ........................................................................................................... 53

5.8.1 Coupling the hydraulic hose lines ......................................................................................... 54

5.8.2 Uncoupling the hydraulic hose lines...................................................................................... 54

5.9 3-point attachment frame ...................................................................................................... 55

5.10 Setting chart .......................................................................................................................... 56

5.11 EasyCheck ............................................................................................................................ 58

5.12 Mobile test rig ........................................................................................................................ 58

5.13 On-board computer EasySet 2.............................................................................................. 59

5.14 Transport and parking device (removable, optional)............................................................. 60

5.15 Swivelable hopper cover (optional) ....................................................................................... 61

5.16 Hopper extensions (optional) ................................................................................................ 61

6Commissioning ......................................................................................... 62

6.1 Checking the suitability of the tractor .................................................................................... 63

6.1.1 Calculating the actual values for the total tractor weight, tractor axle loads and load

capacities, as well as the minimum ballast ........................................................................... 63

6.2 Adjusting the length of the PTO shaft to the tractor .............................................................. 67

6.3 Securing the tractor / machine against unintentional start-up and rolling ............................. 69

7Coupling and uncoupling the machine ................................................... 70

7.1 Coupling the machine............................................................................................................ 71

7.2 Uncoupling the machine........................................................................................................ 73

8Adjustments............................................................................................... 75

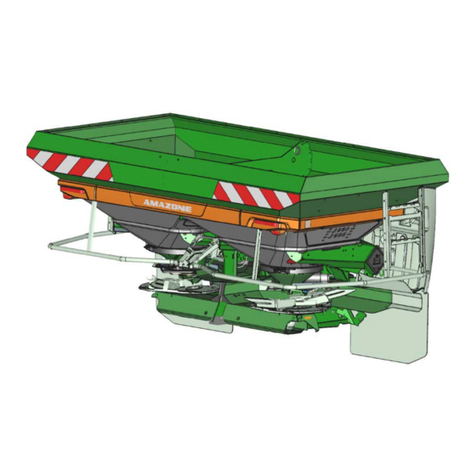

8.1 Adjusting the mounting height............................................................................................... 76

8.2 Setting normal fertilising/late top dressing ............................................................................ 77

8.3 Setting the spread rate .......................................................................................................... 78

8.4 Determining/entering the fertiliser calibration factor.............................................................. 78

8.4.1 Preparations for determining the fertiliser calibration factor using the left shutter ................ 79

8.5 Determining the fertiliser calibration factors with the lateral calibration device..................... 80

8.6 Adjusting the working width................................................................................................... 81

8.6.1 Replacing the spreading discs .............................................................................................. 82

8.6.2 Adjusting the spreading vane positions................................................................................. 83

8.7 Checking the working width and lateral distribution .............................................................. 85

8.8 Boundary, ditch and side spreading...................................................................................... 86

8.8.1 Boundary spreading with limiter M boundary spread deflector ............................................. 87

8.8.2 Boundary spreading with the Tele-Set boundary spreading disc ......................................... 90

8.8.3 Special situations during boundary spreading (where the distance between the centre of the

tramline and field edge does not correspond to half the working width)............................... 92

8.8.4 Notes on OM 10-12 and OM 10-16 spreading discs............................................................. 93

9Transportation ........................................................................................... 94

10 Use of the machine ................................................................................... 95

10.1 Filling the centrifugal broadcaster ......................................................................................... 97

10.2 Spreading operation .............................................................................................................. 98

10.2.1 Recommendation for working in headlands ........................................................................ 101

10.3 Complete discharging.......................................................................................................... 102

10.4 Notes for spreading slug pellets (e.g. Mesurol) .................................................................. 103

11 Faults........................................................................................................ 104

11.1 Eliminating agitator malfunctions ........................................................................................ 104