Doc No. 7401247

MODEL 9 SERIES WELD HEAD

OPERATION MANUAL

5.0 ROTATION (SPEED) MANUAL CALIBRATION (Contd.)

5.4 Add one additional level with a duration of 5 or more seconds, with

the rotation mode set to “OFF”. This additional level (with rotation

off) will hold the electrode at its stopped position allowing the operator

to see if it traveled too far (traveling too fast) or not far enough

(traveling too slow).

5.5 Be sure the power supply is in the “TEST” mode, and run the program.

Should the electrode rotate too fast (traveling more than 360 degrees),

stopping beyond the home position, slow it down by turning the

potentiometer counter clockwise (CCW). Should the rotation be too

slow (traveling less than 360 degrees) stopping before it reaches a full

360 degrees, turn the potentiometer clockwise (CW). Continue this

procedure until the electrode stops after 360 degrees of travel.

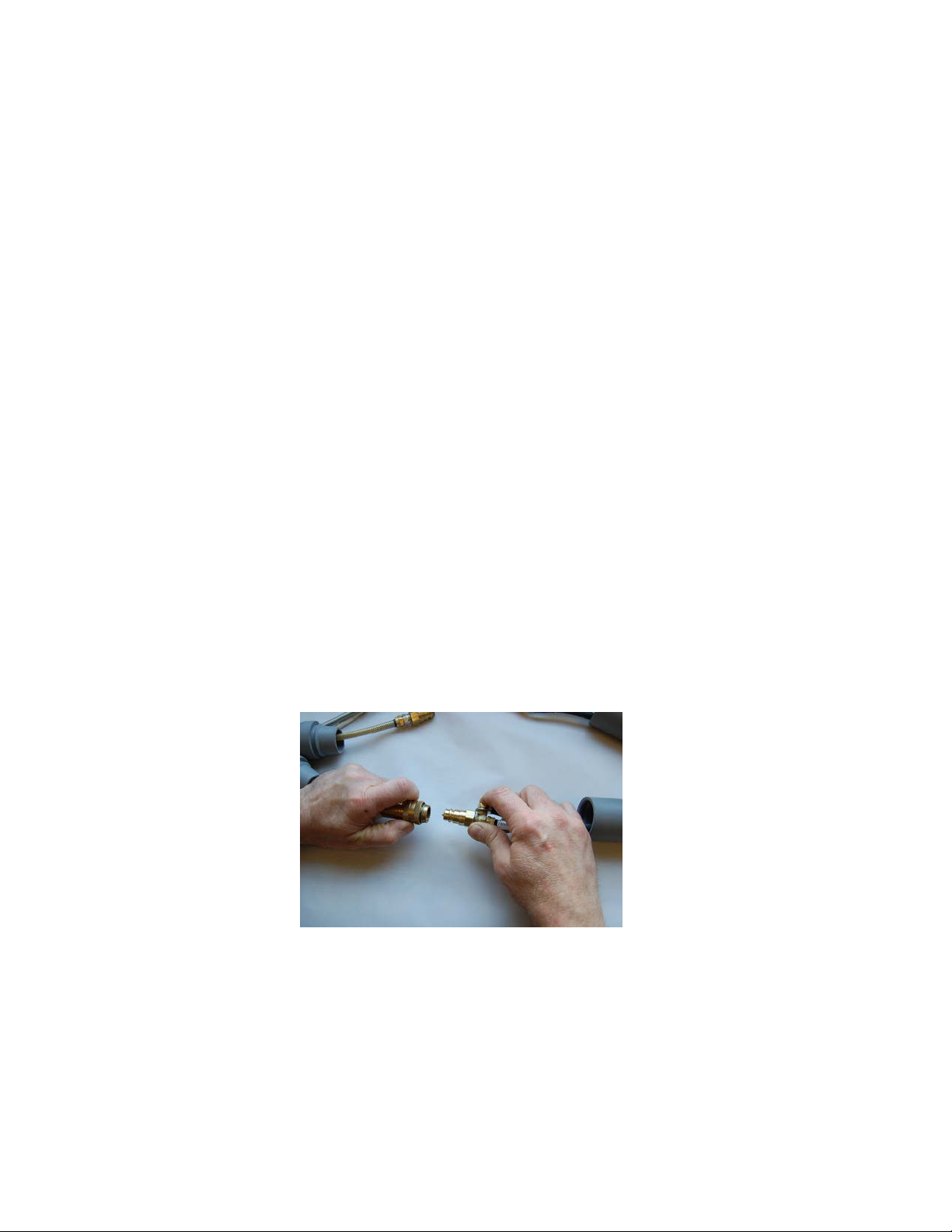

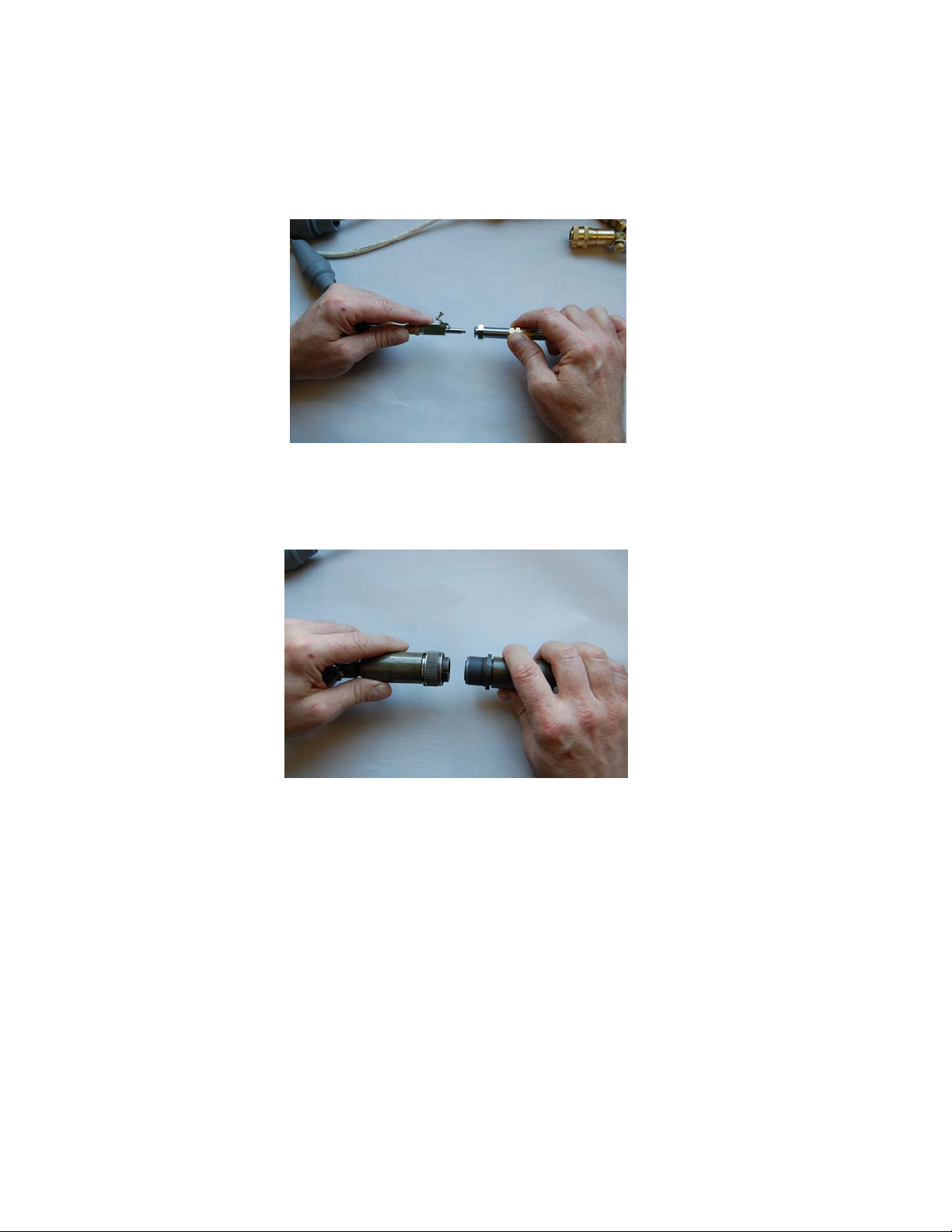

6.0 CLAMP INSERT & GAS SEAL INSTALLATION

Clamp inserts are designed for a specific tube or pipe size. Select the

appropriate clamp for the specific tube or pipe to be welded. A set of clamps fits

one side of the weld head. Except for some special applications, or when using a

model 9E or 9ER type weld head, two sets of clamps are required. One set fits

on each side of the head.

Note: A set of clamp inserts is made from one piece, and then split into two

halves. Each half is marked with matching alphanumeric characters.

Keeping matched sets together (on the same side of the weld head) will

result in the highest level of weld joint concentricity.

6.1 Before mounting the clamp insert into the head be sure both the clamp

and weld head clamp mounting groove are clean and free of dirt, oil or

other contaminants. The clamp mounting screw need only be lightly

snug. See fig. 6.

CAUTION

Use of the wrong size clamp, or clamping the head on the curved section of an

elbow or other irregular surface can result in damage to the clamp insert, weld

head clamp latch and/or hinge.