AMI Analyzer Manual Watchdog Oxygen Analyzer

5

Watchdog Oxygen Analyzer

Introduction

The Watchdog provides the essential elements of a complete oxygen analyzer, but omits features that are

duplicated by the flow computers with which it is intended to be used. If provides a complete sample

control system, a means of calibration and a user-configurable analog and digital output.

This manual is divided into two major sections: a quick reference section for experienced users, and a

detailed exploration of all the many features of the analyzer for all users.

This manual covers software version 5.21, issued August 2013.

Features:

10 user selectable output ranges to choose

from. (See Note 1)

High resolution 3 digit LCD.

RFI protected.

1-5VDC and 4-20mA isolated analog output

signals.

USB virtual comport and Modbus Bidirectional

RS485 communication for advanced features.

(See Note 1)

Datalog –10 days oxygen reading recording at

1 minute per sample. (See Note 1)

Calibration history –stores the last five

calibrations with time, date, span factor and

calibration gas. (See Note 1)

Brown-out history –stores the last five brown-

outs and recoveries. (See Note 1)

Power up history –stores the last ten times

the unit was powered up.(See Note 1)

Advanced analog output calibration.

Power requirements: 10-28VDC.

Low minimum detection limit.

Excellent repeatability.

Fast upscale/downscale response times.

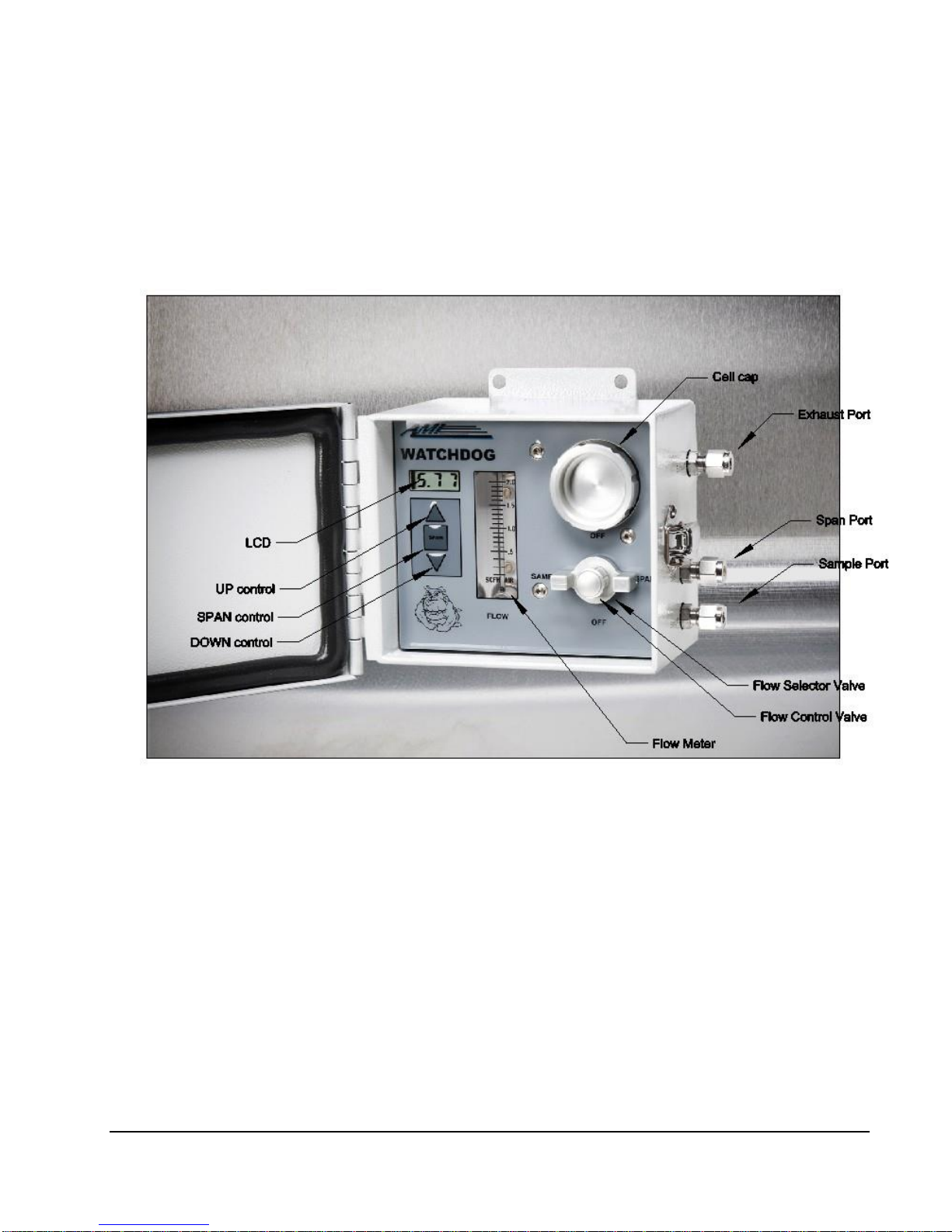

Patented Cellblock Technology: Integrates all

components such as: flow control valve, flow

meter, 3-way calibration valve,

Sample/Span/Off and compression fittings to

be an integral part of the cellblock,

eliminating tubing and fittings. The cell block

also provides a compact size, fast response

time and front panel sensor access without

the need for tools.

Area Classification: Designed to meet

requirements for Class 1, Div. 2, Groups C,D

application.

Unaffected by changes in flow rate from 0.1 to

2.0 SCFH

Wall mount or 2.0” pipe with standard pipe

clamp.

Compact size.

2 year warranty for analyzer, parts and labor.

6 month sensor warranty, life expectancy 1-2

years.

Note 1: Requires optional AMI User

Interface Software