AND AD-1690 User manual

AD-1690

Leak Tester

INSTRUCTION MANUAL

1WMPD4002043A

© 2009 A&D Company Ltd. All rights reserved.

No part of this publication may be reproduced, transmitted, transcribed, or translated

into any language in any form by any means without the written permission of A&D

Company Ltd.

The contents of this manual and the specifications of the instrument covered by this

manual are subject to change for improvement without notice.

1

CONTENTS

1. INTRODUCTION.......................................................................................................2

2. FEATURES ...............................................................................................................2

3. PART NAMES・CONSTITUTION.............................................................................3

3.1. Main unit ............................................................................................................3

3.2. Accessories ......................................................................................................3

4. CONFIRMING BEFORE USE ...................................................................................4

5. MEASUREMENT PREPARATION............................................................................6

6. KEY OPERATION .....................................................................................................7

7. MEASUREMENT ......................................................................................................8

8. CHANGING THE JUDGMENT CONDITION...........................................................10

9. FUNCTION..............................................................................................................13

10. MAINTENANCE AND NOTES.............................................................................16

11. RS-232C INTERFACE .........................................................................................20

12. SPECIFICATIONS ...............................................................................................21

12.1. Optional accessories and Sold separately...................................................22

12.2. Dimensions.....................................................................................................22

2

1. INTRODUCTION

This manual describes how the AD-1690 Leak Tester works and how to get the most

out of it in terms of performance.

Read this manual thoroughly before using the Leak Tester and keep it at hand for

future reference.

2. FEATURES

- This Leak Tester judges a leak by a pressure change, after the initial pressure is set

inside the instrument, to a maximum of -20kPa ± 4kPa.

The Leak Tester can verify a leak in a small instrument easily (Example: Micro

pipette. etc).

The amount, -20kPa, attained by evacuating the air with the Leak Tester, is

approximately 0.2 atmospheres (based on atmospheric pressure at sea level).

(100kPa is approximately 1 atmosphere (based on atmospheric pressure at sea

level).)

- This Leak Tester is a tool for judging leakage, and it can not measure pressure

values accurately. The Leak Tester displays -20kPa as a reference pressure and

measures leakage as a pressure change from this amount.

-This Leak Tester is designed to test the leakage of a pipette or dispenser and prevent

foreign particle from invading the Leak Tester when evacuating the air at the nozzle of the

instrument.

This Leak Tester is protected against invading dust by an air filter located on the

main unit bottom side.

- The accessories provide attachments for three different pipettes tip sizes.

You can select an attachment where the tip and pipette size match up.

With the Micro pipette, the available test capacity is up to 10000μℓ.

3

3. PART NAMES・CONSTITUTION

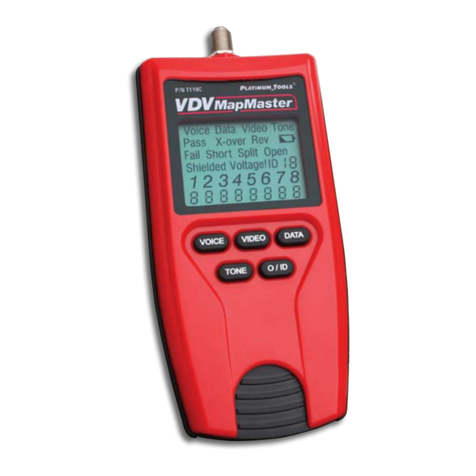

3.1. Main unit

3.2. Accessories

Power supply adapter

Adapter and Attachment

A

C adapter

ID label

Note

Please confirm that the AC adapter type is correct

for your local voltage and receptacle type.

Display

Keys

RS-232C

interface

Plug for accessory

adapter opening

:

left

(Connector hole [1])

A

C adapto

r

j

ack

M

a

i

n un

it

bottom side

A

ir filter unit

(Inside

:

Air filter element)

Main unit

Plug for accessory

adapter opening

:

right

(Connector hole [2])

For micro pipette with

more than 5000μℓ to

less than 10000μℓ

For micro pipette

with 1000μℓ

For micro pipette with

more than 2μℓ to

less than 200μℓ

Adapter

Disconnect button

Tip

A

ttachmen

t

(Large)

Tip

Connector Connector

(Main unit side)

A

ttachmen

t

(Medium)

A

ttachmen

t

(Small)

Connector

4

4.

CONFIRMING BEFORE USE

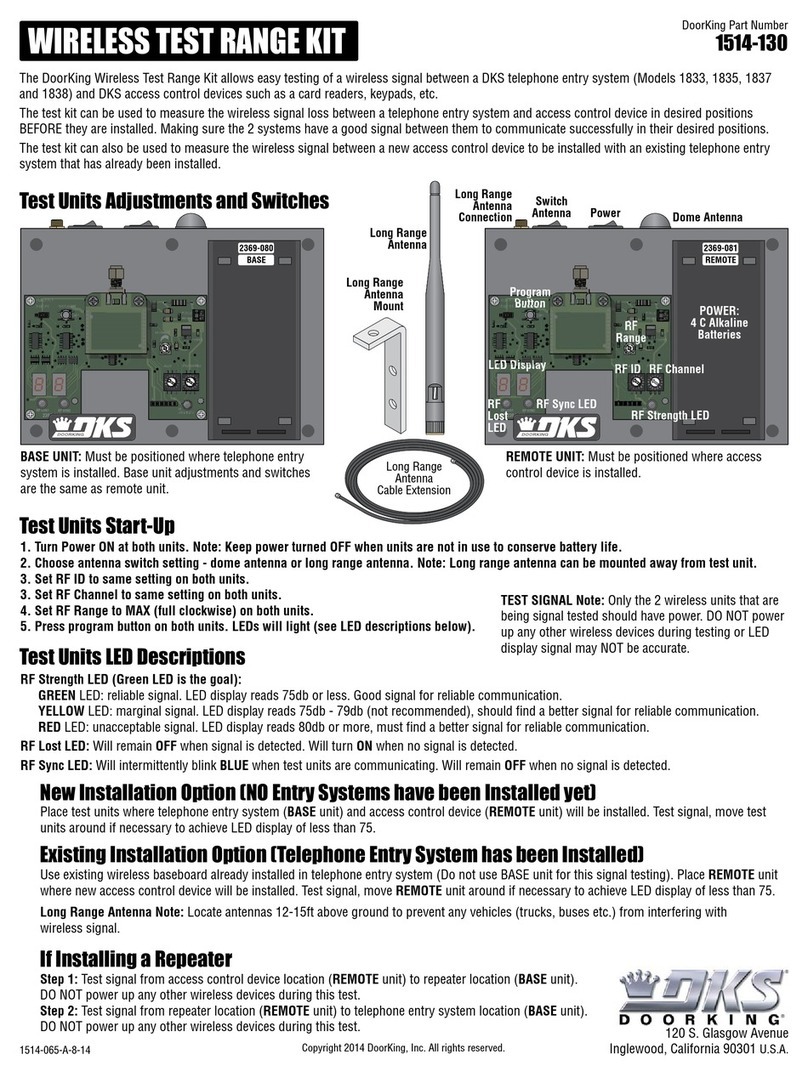

(1) Confirming the main unit

With following state, confirm that the right

and left air plugs (○parts) are pushed

in the connector holes firmly.

Confirm that the filter unit is installed in

the holder located on the main unit

bottom side correctly.

(2) Confirming the operation

1. Connecting the ac adapter to the main unit

Open the AC adapter jack cover located

on the side of the main unit, insert the AC

adapter plug into the AC adapter jack.

Plug the AC adapter into an appropriate

electrical outlet.

Note

-Please confirm that the AC adapter type is correct for your local voltage and

receptacle type.

-The AC adapter plug is protected against dust and may be difficult to insert.

When inserting the plug, turn the plug while pushing on it.

2. Main unit conformation

Press the ON:OFF key. The display is“REDY”(that means READY) and the Leak

Tester is in the measurement standby mode.

With the right and left air plugs installed, press the START key.

When displaying “pa55” after operating the pump, the instrument is operating

normally.

When displaying “fa1l”, confirm that the right and left air plugs, and the filter unit

located on the main unit bottom side are connected correctly.

When not solving the “fa1l”display, there may be a leak inside Leak Tester.

Contact the local A&D dealer for service.

Main unit

bottom side

A

C ada

p

te

r

5

After confirming, return the inside pressure of the Leak Tester to atmospheric

pressure by removing either the right or left air plug. (If an air plug is not removed,

the pressure inside the instrument remains in a state of vacuum.) When not starting

another measurement immediately, reconnect the air plugs and close the cover on

the AC adapter jack, to avoid dust from invading the main unit.

6

Matching up tip

Tip provided

5. MEASUREMENT PREPARATION

(1) Connecting the adapter (tube) to the main unit

Remove the air plug located on either side of the main

unit. Connect the tube of the adapter to the main unit.

* The air plugs and the adapter tube are connected

by a coupling having a lock function. When

removing the air plug or tube, while pushing on

the release ring located on the connector opening

(1), pull it out (3) after pushing the air plug or

tube lightly (2).

* When connecting, confirm that the air plug or adapter

tube is pushed in the connector hole firmly.

(2) Connecting the attachment (pipette side)

The accessory attachments provided have three

different pipettes tip sizes. Select the attachment in

order that the tip and pipette size match up, then

connect the attachment to the adapter.

When the pipette does not match up with the attachment provided, replace the

tip of the attachment with a tip that matches the pipette.

Attachment

A

ttachment

A

dapte

r

1

2

3

Push the

release

ring

Push in and pull out

A

ir plug

A

dapter tube

Removing the ai

r

plug

Connecting the adapte

r

7

* When replacing the attachment, remove it by pushing

the disconnect button (blue part).

(3) Connecting the ac adapter to the main unit

Open the AC adapter jack cover located on the side of the main unit, insert the AC

adapter plug into the AC adapter jack. Plug the AC adapter into an appropriate

electrical outlet.

Note

-Please confirm that the AC adapter type is correct for your local voltage and

receptacle type.

-The AC adapter plug is protected against dust and may be difficult to insert.

When inserting the plug, turn the plug while pushing on it.

6. KEY OPERATION

Key Description

Turns the power supply of the main unit on and off.

These keys are in two positions, to the right and left.

These two keys have same function. Start (or stop) the

measurement.

Enter into the setting mode by pressing and holding for 2

seconds.

Store the setting condition that was changed by pressing.

When setting the mode, change the setting value (the quantity of

pressure change and monitor time of the leak judgment

condition).

When using “UP”, the value is increased. When using “DOWN”,

the value is decreased.

START

SET

UP DOWN

ON:OFF

1

2

A

ttachment

A

dapte

r

Disconnec

t

button

8

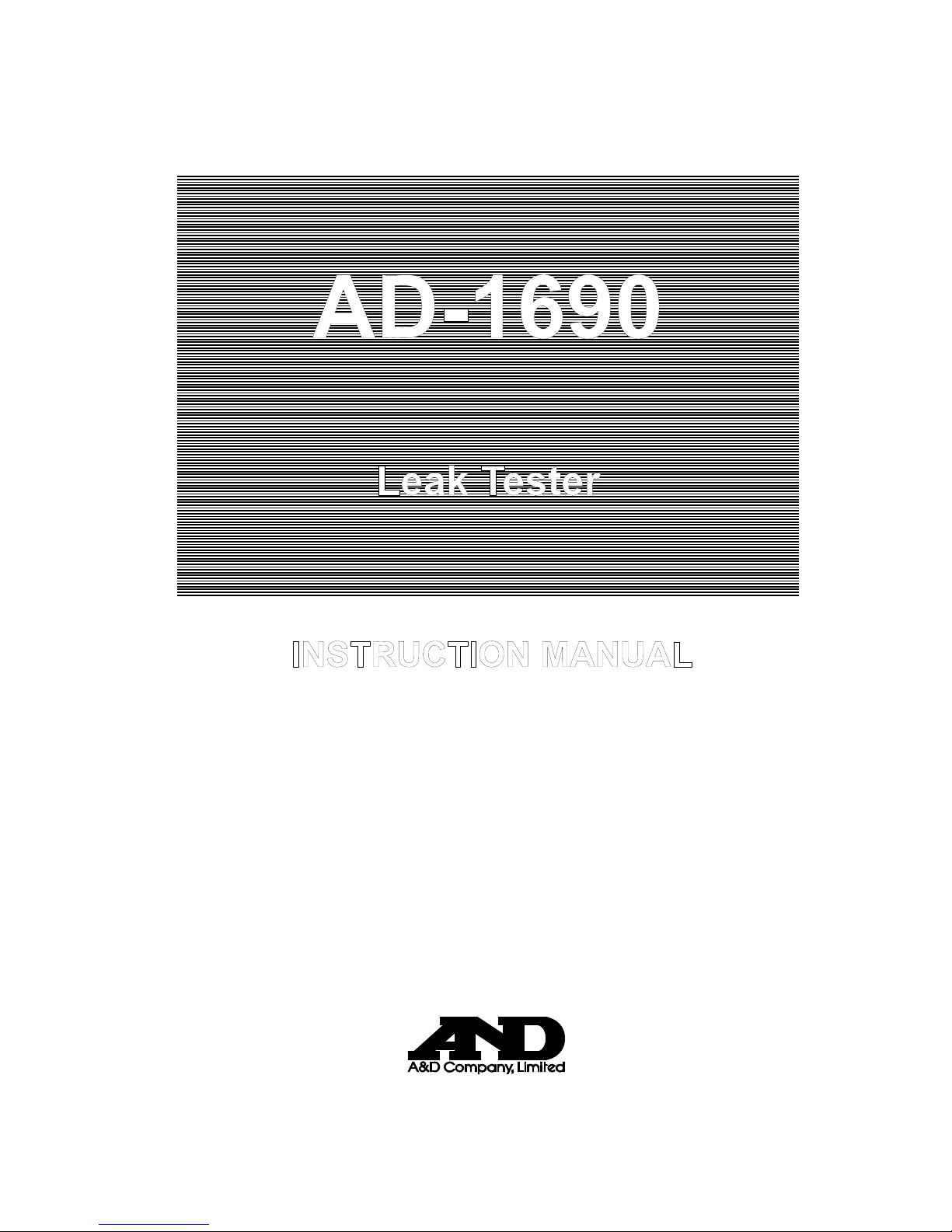

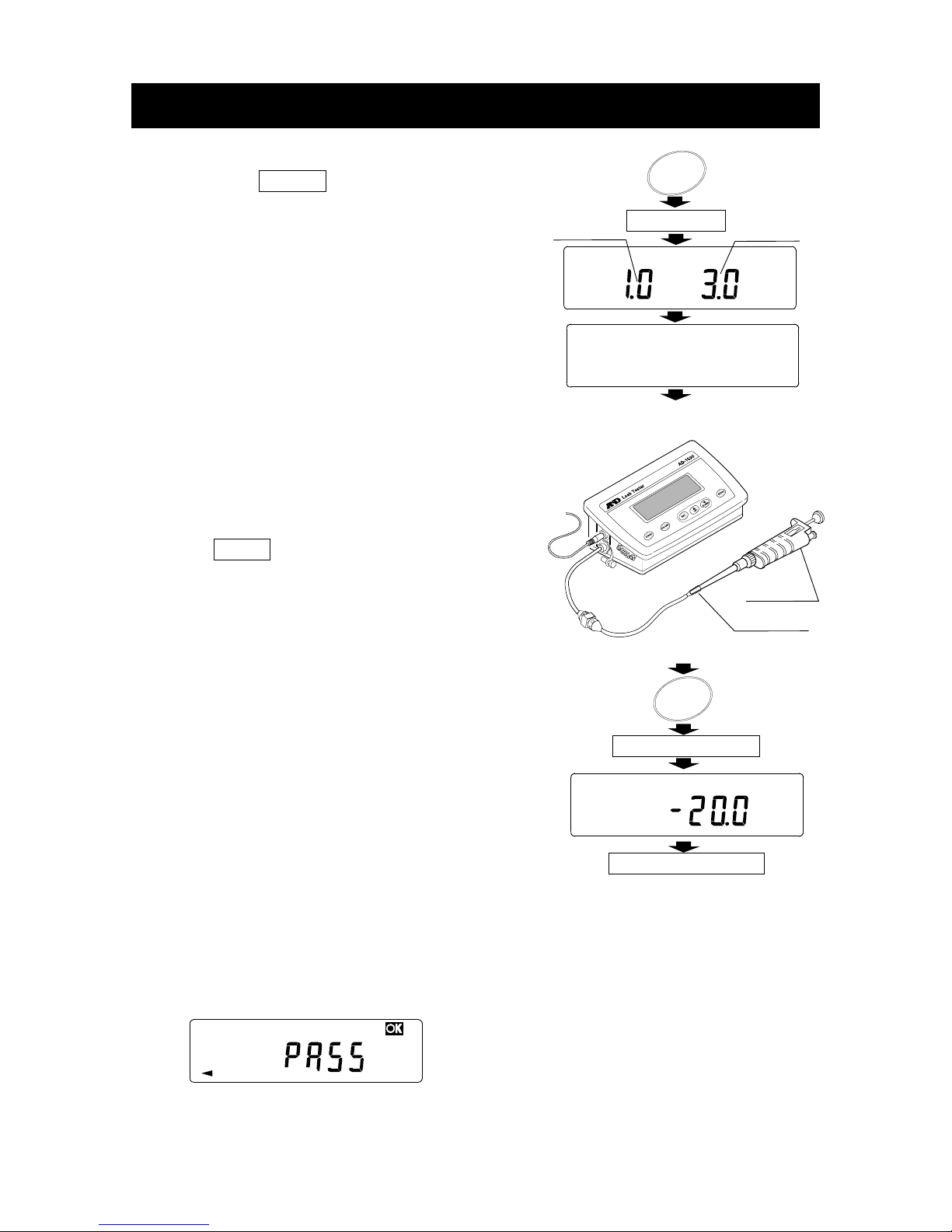

7. MEASUREMENT

(1) Power supply

Press the ON:OFF key (The display is

“display all”). After displaying the setting value

(quantity of pressure change and monitor time

for leak judgment), the display is“REDY”

(that means READY) and is in the

measurement standby mode.

(2) Starting measurement

Connect the test pipette to the tip of the

attachment securely.

Press START key. The main unit starts the

measurement by operating the pump,

evacuating the air to -20kPa. (“TEST”

display)

When - 20kPa is reached, the pump stops.

*-20kPa is approximately 0.2 atmospheres that

means that the air has been partially evacuated.

* While stabilizing the inside pressure, the display

may change by 0.1 to 0.2 kPa.

The main unit measures the quantity of the

pressure changed by the monitor time set.

(“MEAS”display)

* Factory setting: monitor time is 3 seconds, quantity

of pressure changed is +0.3kPa.

(3) Measurement result

When the quantity of pressure change with leakage is in less than the setting value,

the Leak Tester judges that there is no leak and displays “pa55” (normal).

START

TEST kPa

Measurement start

Measurement result

Pi

p

ette

Ti

p

Quantity of

pressure

change

All displayed

Monitor

time

kPa SEC

ON:OFF

REDY

9

When the pressure, with any leakage does not reach -20kPa or when the quantity

of pressure change is over the setting value after reaching -20kPa, the Leak Tester

judges that there is a leak and displays “fa1l” (abnormality).

When pressing the START key, while in the middle of a measurement, the

measurement stops and “5top” is displayed.

When pressing the START key again, the Leak Tester judges the measurement

result (“pa55”/”fa1l”) after operating the pump again.

When finishing the measurement, remove the

pipette from the tip of the attachment.

If the pipette has the ejector (for releasing the

tip), remove the pipette by operating the ejector.

When measuring another pipette, press the

START key again after connecting the pipette

to be measured (return to “(2) Starting

measurement”). The leak tester starts the

measurement. At this time, the display is the

measurement result.

* When kept in a state of having the air evacuated, in the case of not removing the

pipette, the pump does not operate again.

(4) Measurement end

When finishing the pipette measurement, Press the ON:OFF key to turn the power

supply off. (After “off” is displayed, the power supply turns off.) Then, disconnect the

AC adapter from the main unit.

For storing, refer to “10. MAINTENANCE AND NOTES”.

A

ttachment

Pi

p

ette

10

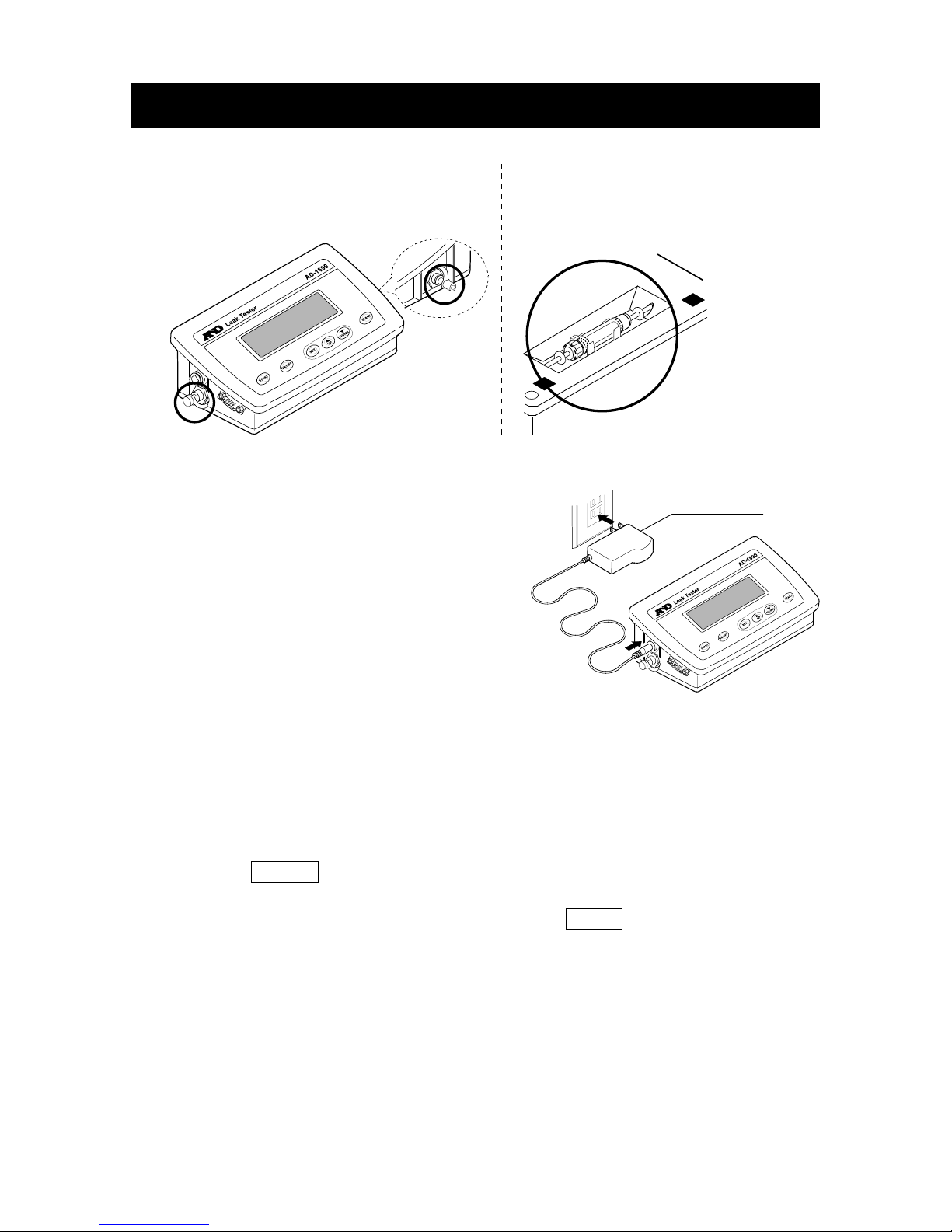

8.

CHANGING THE JUDGMENT CONDITION

You can change “quantity of pressure

change” and “monitor time” if necessary to

set the conditions for judging if there is a

leak or no leak.

When canceling the setting halfway, press the

ON:OFF key to turn the power supply off.

(1) Changing the setting value

When “REDY”*(that means READY) or the

measurement result* is displayed, press and hold

the SET key (Approx. 2 seconds).

The main unit displays the setting value of the

quantity of pressure change flashing (left side of

the display) and the monitor time (right side of the

display).

* Refer to “(1), (3)” of “7. MEASUREMENT”.

(2) Changing the quantity value of pressure change

After evacuating the air, when the pressure

changing is more than the setting value, the Leak

Tester judges a leak and “fa1l”is displayed.

The Leak Tester judges the leak by the quantity

value of pressure change of the pressure

increase. (Unit: kPa)

Changing the minimum value is by 0.1kPa.

(Factory setting:1.0 kPa)

Change the value by using the DUPNor DOWN key.

* The value displayed with the “○” mark (left side of

the display) is the value in memory. But, while

changing the displayed value, the “○” mark turns

off.

Press the SET key to store the value.

(The “○” mark turns on, at the left side of the

display)

After the quantity value of pressure change stops

flashing, the monitor time value (right side of the

display) is flashing.

Time

-20kPa

Monitor time

setting value Judgment of no leak

“pa55”dis

p

la

y

Judgment of leak

“fa1l”display

Setting value of quantity

of pressure change

Pressure

Evacua

t

ing

the air

Quantity of

pressure

change

When displaying“REDY”o

r

the measurement result

Monitor

time

Press and

hold

kPa SEC

SET

Turning

on

Changing the

monitor time

Press

Store

UP DOWN

kPa SEC

SET

kPa

11

* If the quantity value of pressure change is

insufficient when measuring, “fa1l” may be

displayed by changing the measurement system

pressure (Leak Tester, adapter, attachment).

(3) Changing the monitor time

The leak tester judges the leak by the monitor

time. (Unit: second)

Changing the minimum value is by 0.5 seconds.

(Factory setting:3.0 seconds)

Change the value by using the DUPNor DOWN key.

* The value displayed with the “○” mark (left side

of the display) is the value in memory. But while

changing the displayed value, the “○” mark is

turned off.

Press the SET key to store the value.

After setting finish,“SET end”is displayed for

approximately 1 second. (the“end”is flashing)

(4) End of setting

The Leak Tester returns to the measurement

standby mode by non-operation, or by pressing the

SET key, to memorize the setting value changed

with “(2), (3)” above.

REDY

Press

Store

SET

kPa SEC

SET

UP

DOWN

12

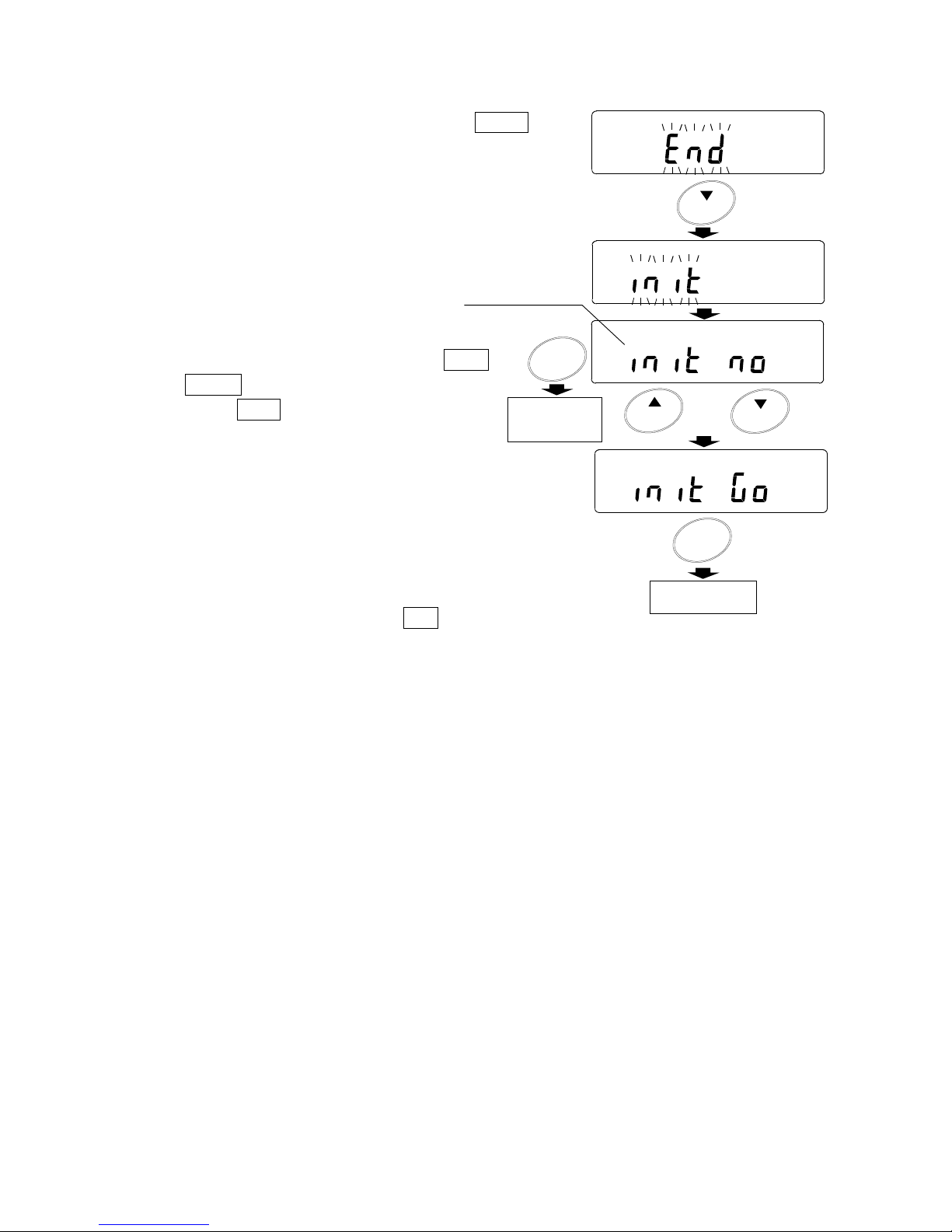

(5) Initializing the setting value

When displaying*“end”of (3), press the DOWN

key at once.

* Refer to “(3) Changing the monitor time”.

After displaying “init”, “init no” is

displayed.

If you want to initialize, press the 1UP1

or DOWN key to change to“go”, and

press the SET key.

After the setting value returns to the value

initialized (quantity of pressure change:

0.3kPa, monitor time: 3.0 seconds), the

display returns to measurement standby

mode (“REDY”display).

If you do not want to initialize, when

displaying the“no”, press the SET key.

The display returns to measurement

standby mode (“REDY ”display) after

displaying“end”.

No

Initialize

Press

Or

Press

Initialize

Initialize

confirming

display

Press

SET

SET

UP DOWN

SET

SET

SET

DOWN

SET

13

press

press

and

hold

(2) Selecting the mode of the

function (item) (4) Setting mode

Displaying the procedure

for measurement result

Serial interface

output format

Go to A) of (4)

By this setting, after displaying the

j

udgment result, the Leak Tester can

display the final pressure.

Go to B) of (4)

By this setting, when connected

to an AD-8121B, the date and

time can be added to the outpu

t

data.

Setting finish*

Leak Tester is in

the measuremen

t

mode.

To function

(3)

(3)

(3)

ON:OFF

SET

DOWN

UP

DOWN

UP

SET

SET

SET

FUNC

FUNC

FUNC

FUNC

UP

DOWN

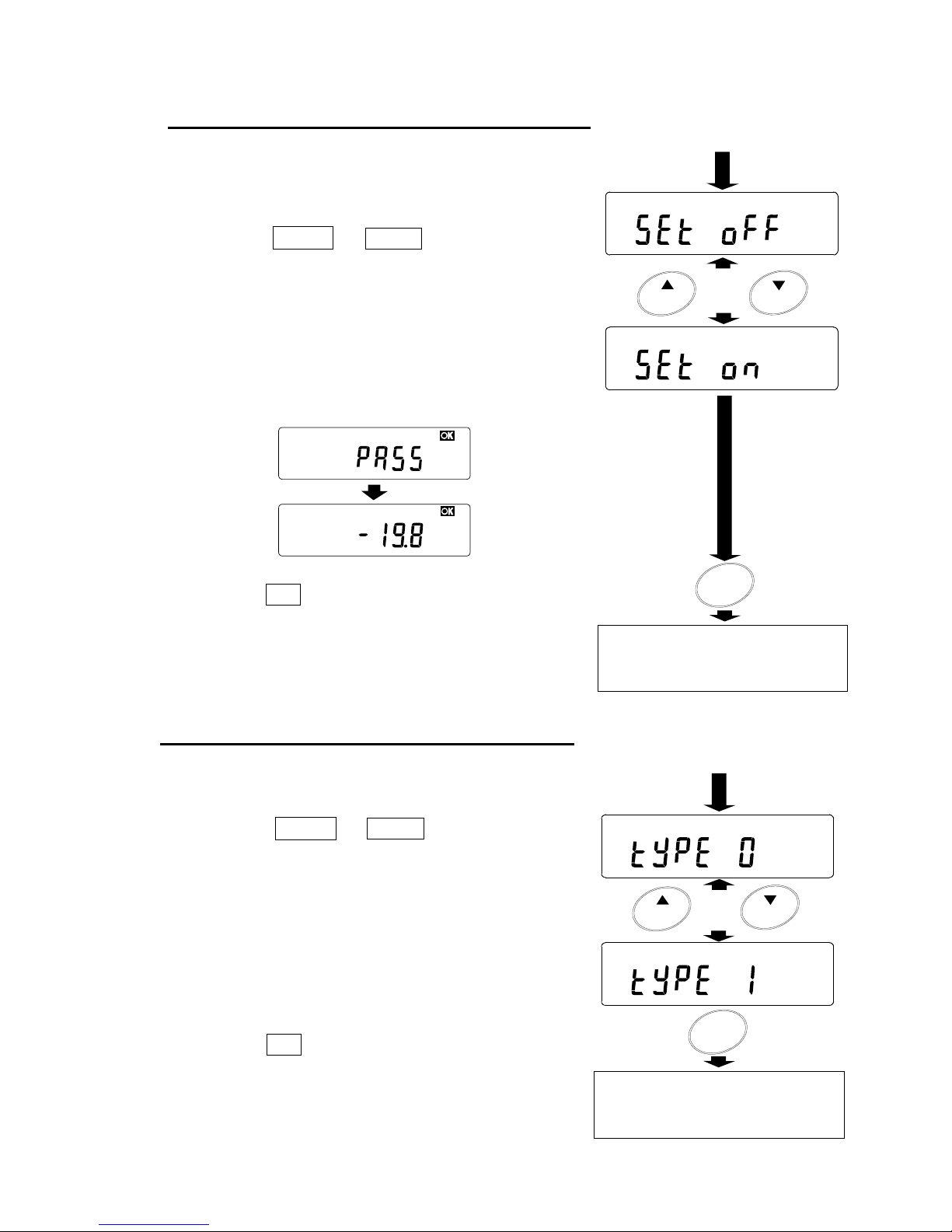

9. FUNCTION

Set the function by the following procedure.

(1) Entering the function

With the power turned off, press and hold the SET key

and press the ON:OFF key, to turn the power on.

After displaying “5eleCt”, “re5Ult” (flashing) is

displayed.

(2) Selecting the mode of the function (item)

Press the 1UP or DOWN key to select the item of the

function. (Refer to figure on the left below)

(3) Entering the setting mode

Press the SET key to enter the setting mode with the

item selected. (Refer to figure on the right below)

* Press the SET key while“end”is flashing.

14

(4) Setting mode

A) Selecting the procedure for measurement result

- The 5et procedure is displayed.

- Press the 1UP or DOWN key to select either

5et off or 5et on.

5et off:After measurement, Leak Tester display

the only judgment result (pa55 or

fa1l).

5et on:After measurement, Leak Tester display

the final pressure after displaying the

judgment result.

- Press the SET key to store the setting.

The display is in the next setting mode.

(5if or end)

* Factory setting: 5et off

B) Setting the output format of the serial interface

- The type procedure is displayed.

- Press the 1UP or DOWN key to select either

type 0 or type 1.

type 0:The setting to connect the Leak Tester to

either an AD-1688,PC,or AD-8121B.

type 1:The setting to output the date and time

by an AD-8121B.

(The date and time are added before each data

set)

- Press the SET key to store the setting.

The display is in the next setting mode.

(re5Ult or end)

* Factory setting: 5et off

A

pprox. 1 second

PASS kPa

DOWN

UP

SET

SIF PC

SIF Prn

Continued from (3 on page 13)

o

r

press

The setting is stored in memory..

The display is in the next setting

mode

(re5Ult or end).

Continued from (3 on page 13)

The setting is stored in memory.

The display is in the next setting

mode

(5if or end).

o

r

press

DOWN

UP

SET

RESL

RESL

15

■Print sample

type 0: type 1:

sample printed with AD-8121B

sample printed with AD-8121B

* The date and time of the print sample use the internal clock of the

AD-8121B. Set the AD-8121B date and time if necessary.

* The AD-1690 can send a special code for printing the date and time.

Therefore, set to “type 0”, when connecting the AD-1690 to instruments other

than the AD-8121B.

■Setting of the AD-8121B

When using with either type 0 or type 1, set the AD-8121B to MODE3.

Setting Info.

00.3kPa/03.0s

PASS -19.9kPa

FAIL -03.5kPa

DATE 2010/02/26

TIME 16:31:13

Setting Info.

00.3kPa/03.0s

DATE 2010/02/26

TIME 16:31:29

PASS -19.9kPa

DATE 2010/02/26

TIME 16:32:08

FAIL -03.5kPa

16

10. MAINTENANCE AND NOTES

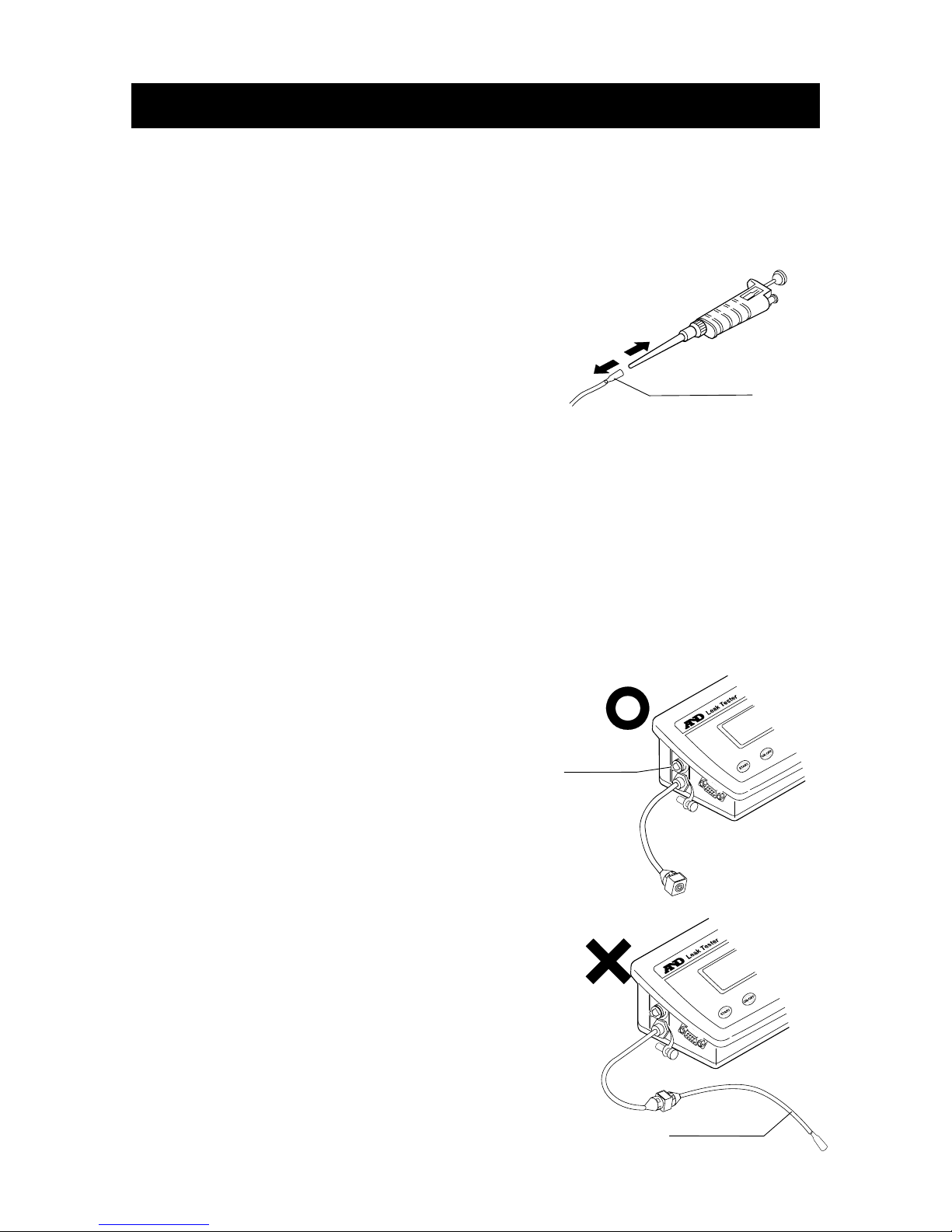

(1) Removing the attachment

After measurement, remove the pipette and accessory by the following procedure.

When storing the main unit, allow of the Leak Tester to equalize to atmospheric

pressure.

1. Remove the pipette from the attachment.

2. Remove the attachment from the adapter.

At this time, if the attachment is still

connected to a pipette, the inside

pressure of the Leak Tester will not

return to atmospheric pressure.

(2) Storing

When storing the leak tester, avoid dust from

invading the main unit and connector tube

(adapter, attachment).

Close the cover of the AC adapter jack.

1) Adapter

Dust can not enter the main unit when

connected to the accessory adapter.

The connector has the airlock function.

Therefore, the Leak Tester is protected from

invading dust. But if the connector part of the

adapter becomes dirty, dust may invade at the

next measuring.

2) If the attachment is connected to the adapter,

dust may invade through the attachment. When

storing, remove the attachment.

A

ttachment

Pi

p

ette

A

dapte

r

A

C adapte

r

j

ack

Attachment

17

3) Main unit

Push the cover in the AC adapter jack and

push the air plug in the connector hole

(right and left side), so that dust can not

invade the main unit.

4) Storing the attachment and adapter

Store the adapter and attachments in the

sealed bag. They will be protected from

invading dust.

18

(3) Exchanging the filter

The inside of the main unit is protected from invading dust by the air filter located on

the main unit bottom side.

Check the main unit regularly, replace the filter element or filter unit if necessary.

Turn the power supply of the main unit off by removing the AC adapter. And after

returning the inside of the leak tester to atmospheric pressure by removing the

pipette, follow this procedure.

1) Removing the filter unit

Invert the main unit and remove the

filter unit from the holder.

Pull the tubes out from both sides of

the filter unit.

(At this time, while pushing the

release ring lightly, pull the tube out

after pushing it in lightly.)

2) Replacing the filter element

When replacing only the filter element, follow this procedure:

1. Slide the red slide lock located on the

filter unit in opposite direction of the

arrow.

2. Turn the coupling in a counterclockwise

direction (180 degrees).

3. Remove the coupling from the filter

cover. Remove the old filter element

from the coupling.

4. Clean the dust from inside the filter

cover, if necessary.

5. After connecting the new filter element to the coupling,

insert it into the filter cover. Last, turn the coupling in a

clockwise direction.

6. Confirm that the positioning of the detent located on

the coupling and the slide lock match up and slide the

slide lock in the direction arrow. Confirm that the

coupling is securely locked.

Main unit

bottom side

1

2

Filter unit

Release

ring

Holde

r

Coupling

Filter element

Filter cove

r

Slide lock

1

2

5

3

6

Other manuals for AD-1690

1

Table of contents

Other AND Test Equipment manuals