Table of Contents

Introduction ..................................................................................................................................................................5

Warranty.......................................................................................................................................................................5

Filter Bags .....................................................................................................................................................................5

Contact Information .....................................................................................................................................................5

Method Comparison (Manual vs. Automated).............................................................................................................6

Instrument Description.................................................................................................................................................7

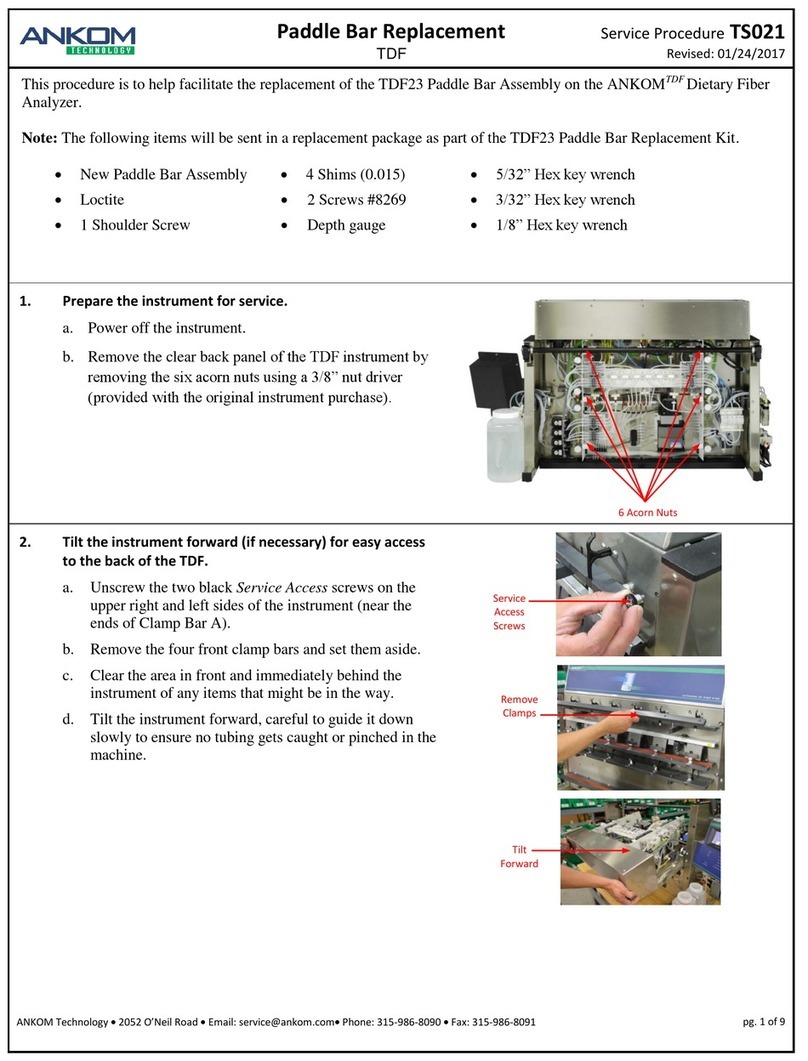

Service Access Position...............................................................................................................................................10

Operating Environment ..............................................................................................................................................10

Safety Precautions ......................................................................................................................................................10

Instrument Installation ...............................................................................................................................................11

Dietary Fiber Analysis Support Items..........................................................................................................................16

Analysis Options using the ANKOMTDF Dietary Fiber Analyzer ...................................................................................16

Blanks..........................................................................................................................................................................16

IDF/SDF Analysis .........................................................................................................................................................17

TDF Analysis (AOAC 991.43) .......................................................................................................................................31

TDF Analysis (AOAC 985.29 / 2001.03).......................................................................................................................44

Protein Determination................................................................................................................................................59

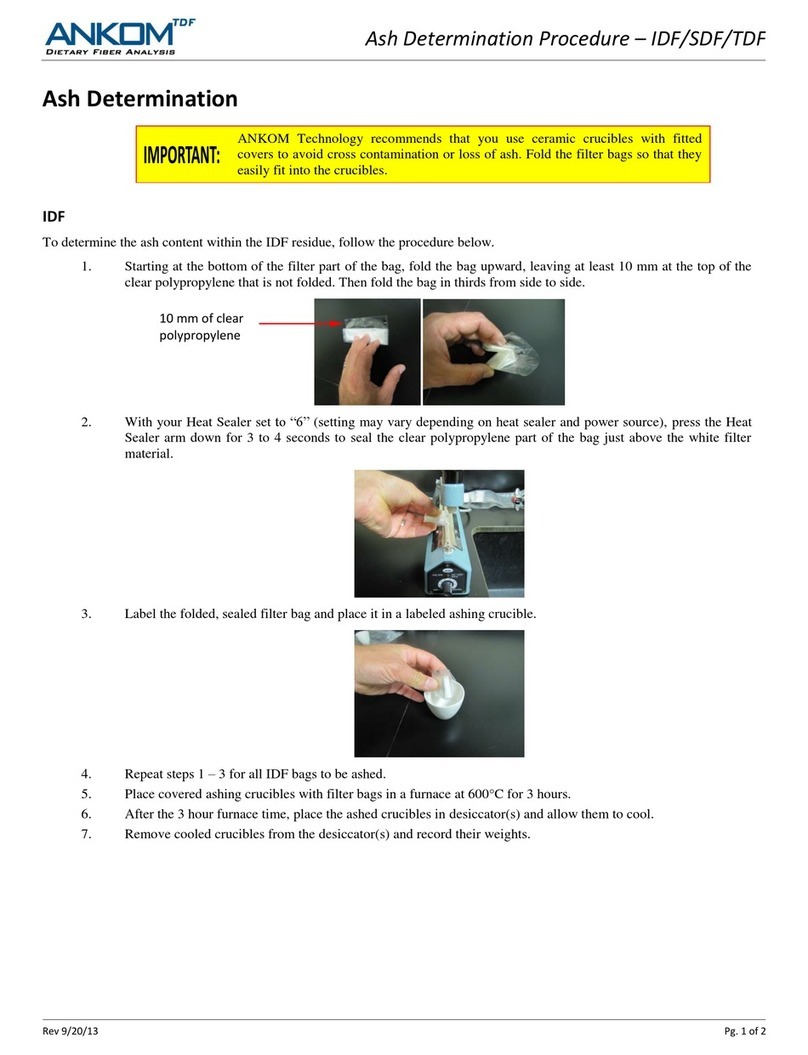

Ash Determination......................................................................................................................................................61

Productivity Enhancement .........................................................................................................................................63

Status Screen ..............................................................................................................................................................67

Fault Handling.............................................................................................................................................................71

Diagnostics Mode .......................................................................................................................................................73

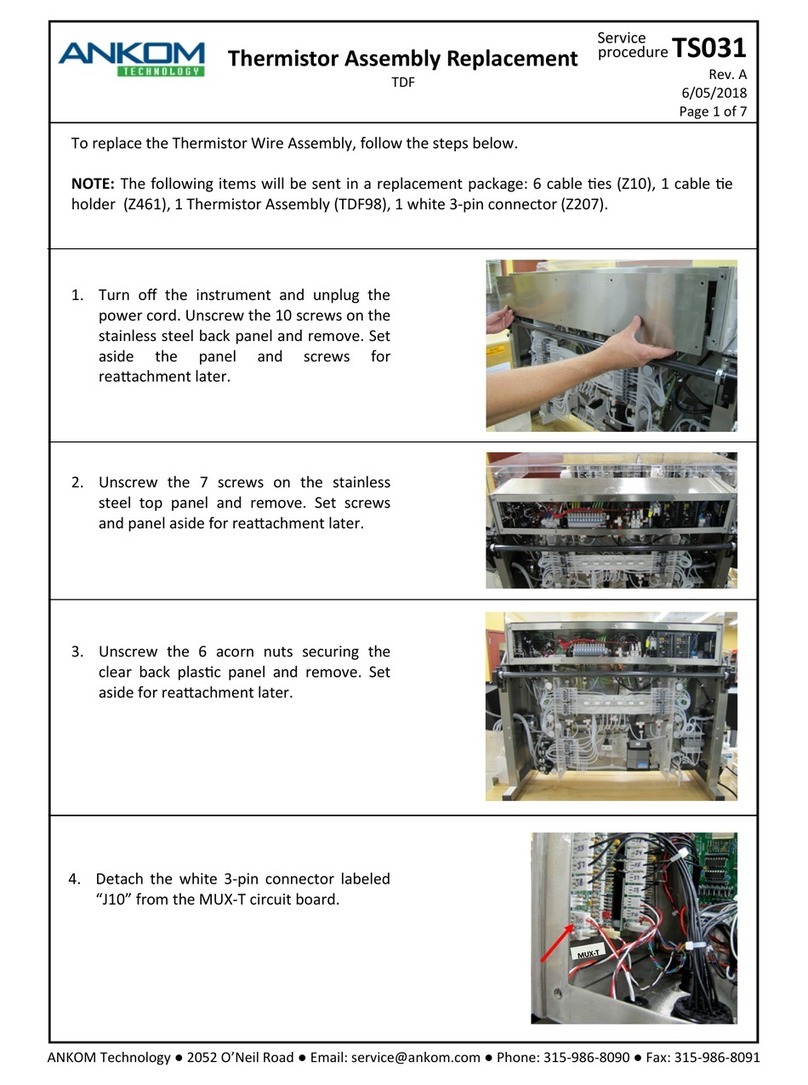

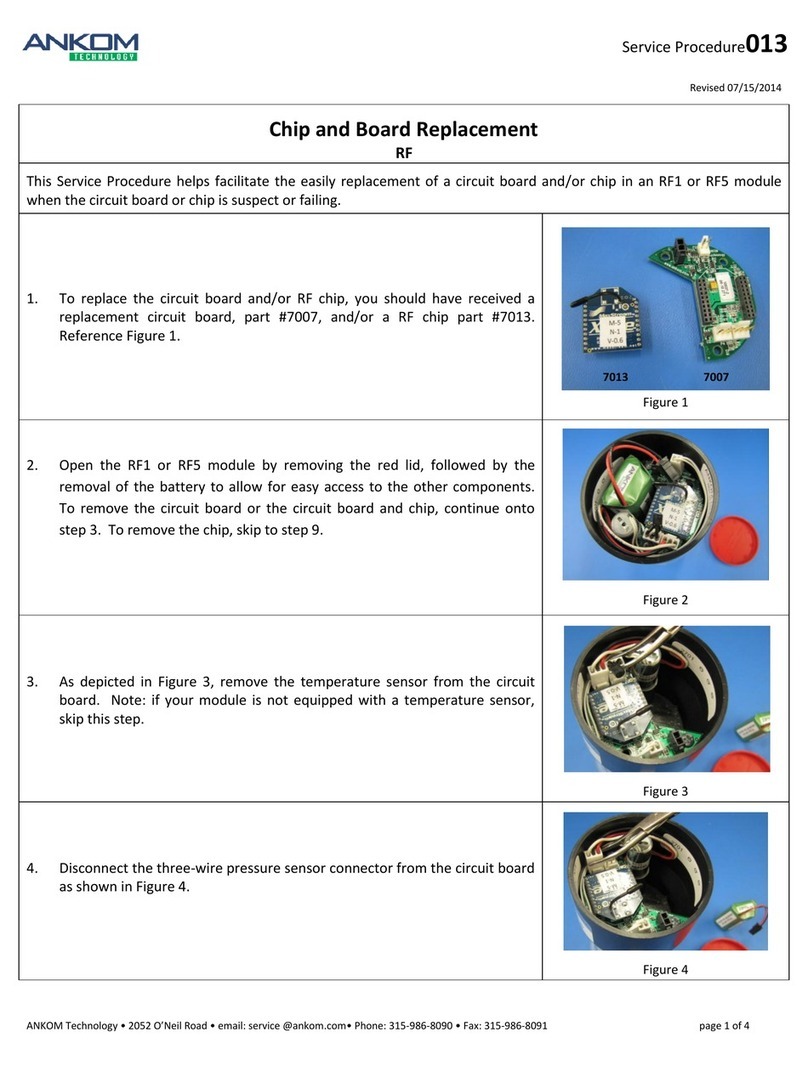

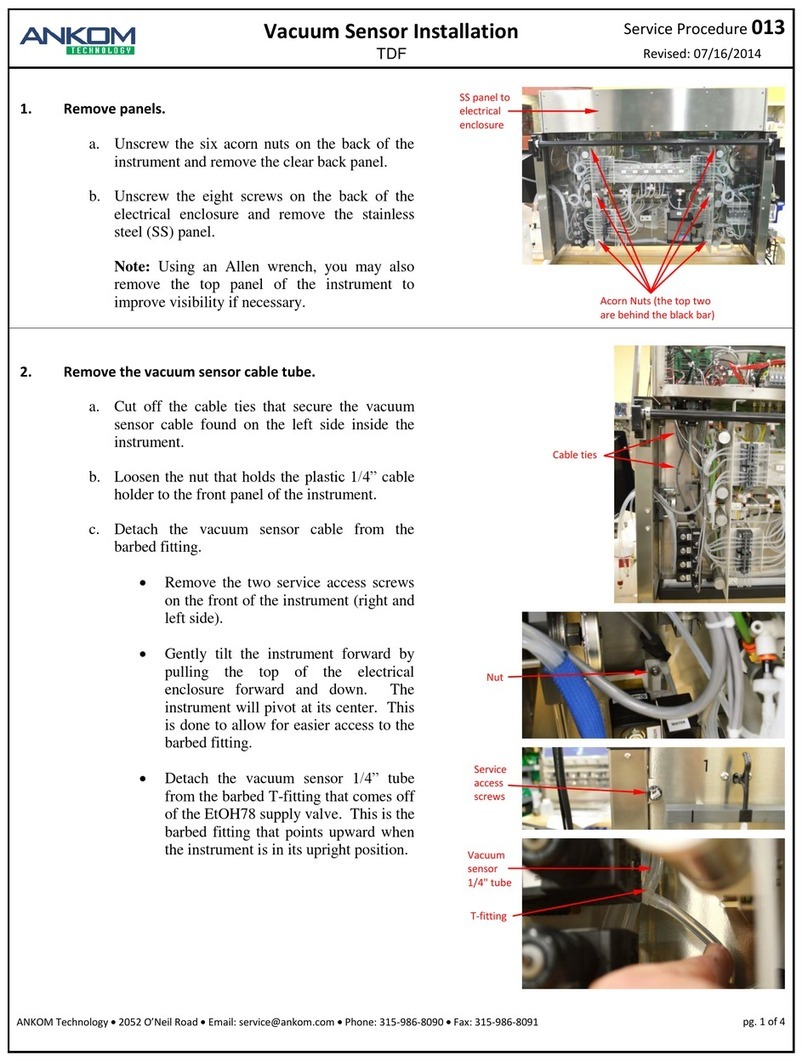

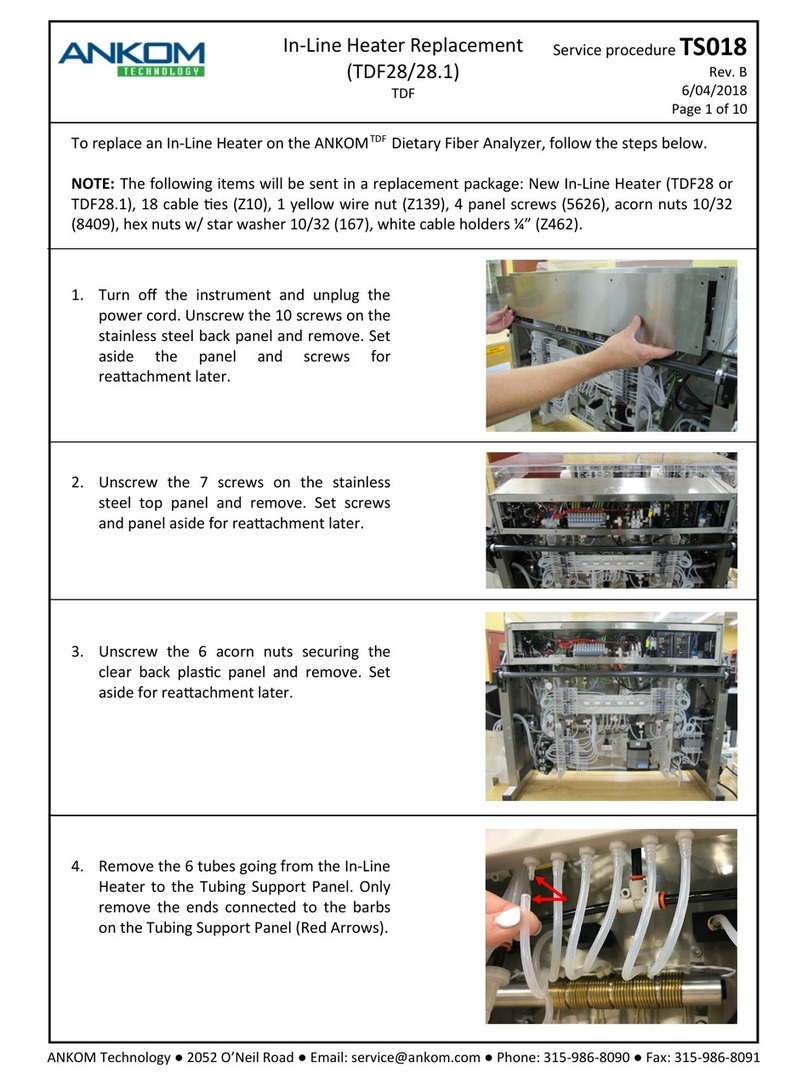

Periodic Maintenance.................................................................................................................................................81

Troubleshooting & Replacement Parts.......................................................................................................................82

QC / Calibration Checks ..............................................................................................................................................83

Appendix A –Reagents (AOAC 991.43, 985.29, 2001.03) ..........................................................................................89

Appendix B –Instrument Out-of-use Procedure........................................................................................................91

Appendix C –De-fatting Procedure ............................................................................................................................93

Appendix D –Accessories (sold separately) ...............................................................................................................95