Table of Contents

Table of Contents...................................................................................................................................................5

1. Introduction ..................................................................................................................................................7

2. Warranty .......................................................................................................................................................7

3. Contact Information......................................................................................................................................7

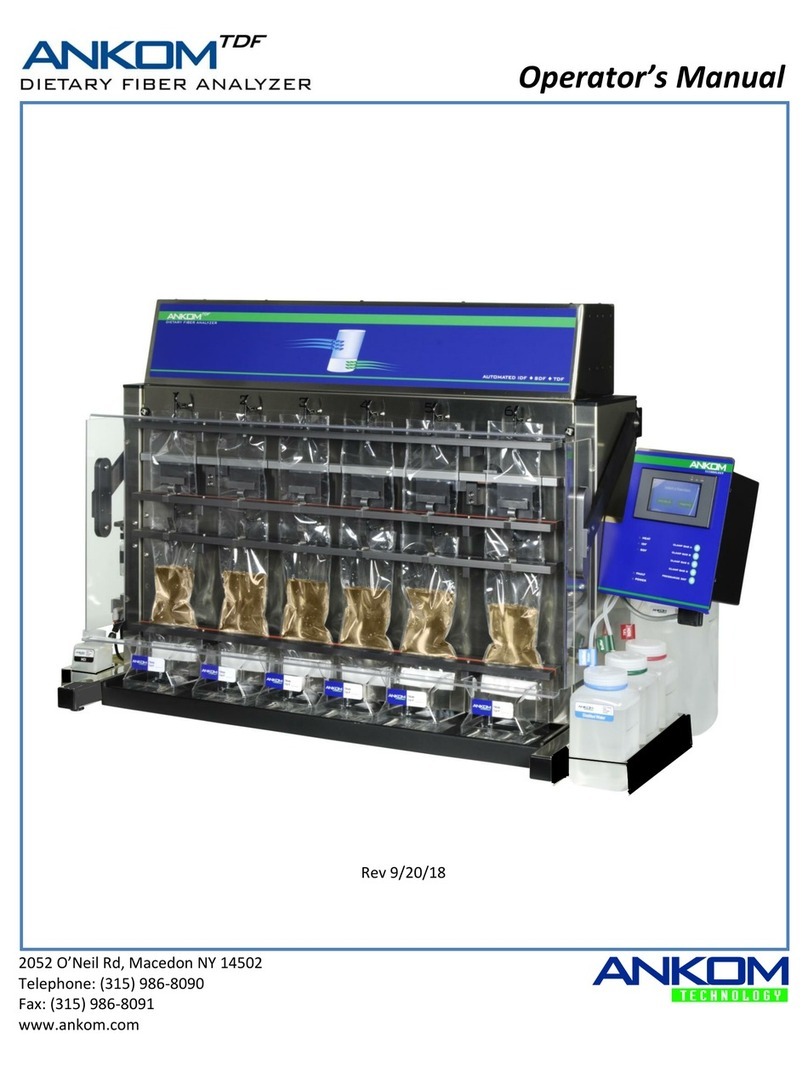

4. Instrument Description.................................................................................................................................8

5. Safety Precautions.........................................................................................................................................9

6. Instrument Installation................................................................................................................................10

Site Requirements and Operating Environment.............................................................................10

Unpack and place the instrument where it will be used................................................................10

Unpack the attachments and accessories. .....................................................................................10

Wipe down components.................................................................................................................12

Make Connections ..........................................................................................................................12

Power On ........................................................................................................................................14

Setting Nitrogen Pressures .............................................................................................................15

Setting Nitrogen Flow Rate.............................................................................................................18

Prime Reservoir and Pump Lines ....................................................................................................19

7. HMI Navigation ...........................................................................................................................................24

Home Screen...................................................................................................................................24

Methods..........................................................................................................................................25

Diagnostics......................................................................................................................................26

Records and Updates......................................................................................................................28

Training and Maintenance..............................................................................................................29

ANKOM Products ............................................................................................................................29

Who we are.....................................................................................................................................29

8. Starting an Assay.........................................................................................................................................30

Confirm Nitrogen Pressure .............................................................................................................30

Fill the Solution Reservoir Bottles...................................................................................................30

Assemble Digestion Vessels............................................................................................................31

Load Method...................................................................................................................................32

Weigh Sample.................................................................................................................................33

Install Digestion Vessels..................................................................................................................34

Add Internal Standard.....................................................................................................................34

Manually Close Digestion Oven Door .............................................................................................35

Install SPE Columns.........................................................................................................................35

Install Round Bottom Flasks............................................................................................................36