TableofContents

Introduction..................................................................................................................................................................5

Warranty.......................................................................................................................................................................5

FilterBags.....................................................................................................................................................................5

OperatingEnvironment................................................................................................................................................5

ContactInformation.....................................................................................................................................................6

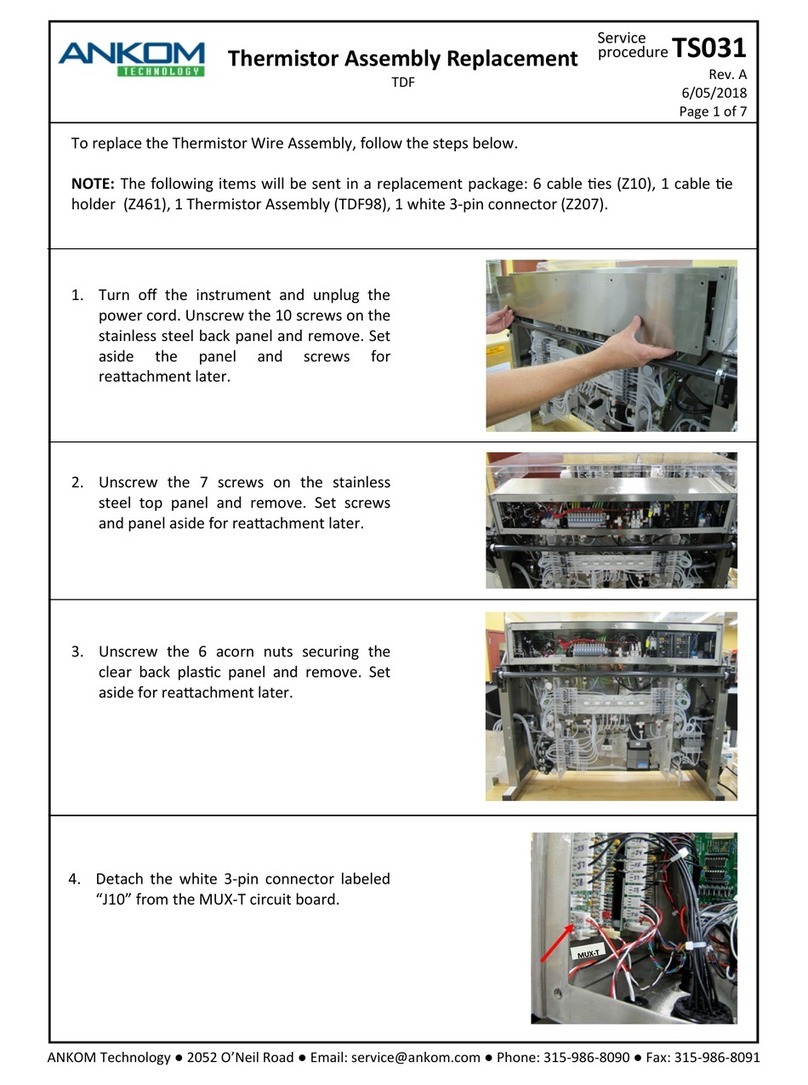

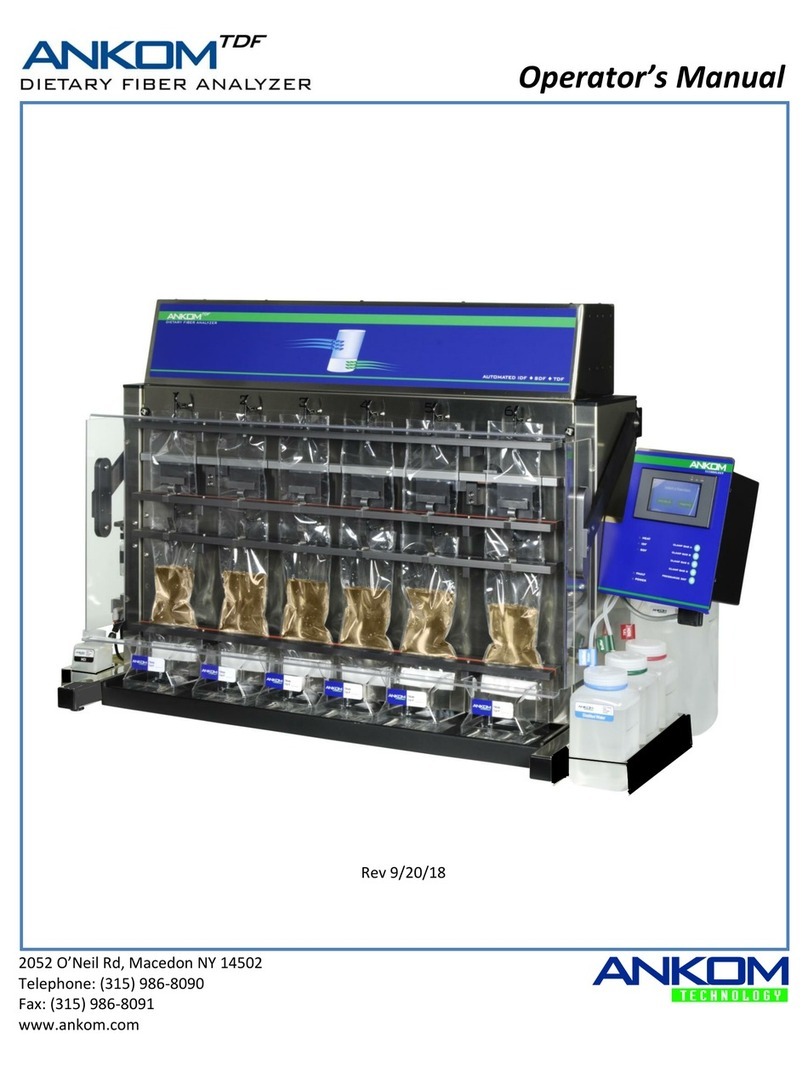

InstrumentDescription.................................................................................................................................................6

SafetyPrecautions......................................................................................................................................................10

InstrumentInstallation...............................................................................................................................................11

DietaryFiberAnalysisSupportItems..........................................................................................................................15

AnalysisOptionsusingtheANKOMTDFDietaryFiberAnalyzer...................................................................................15

IDF/SDFAnalysis.........................................................................................................................................................17

TDFAnalysis................................................................................................................................................................30

ProteinDetermination................................................................................................................................................43

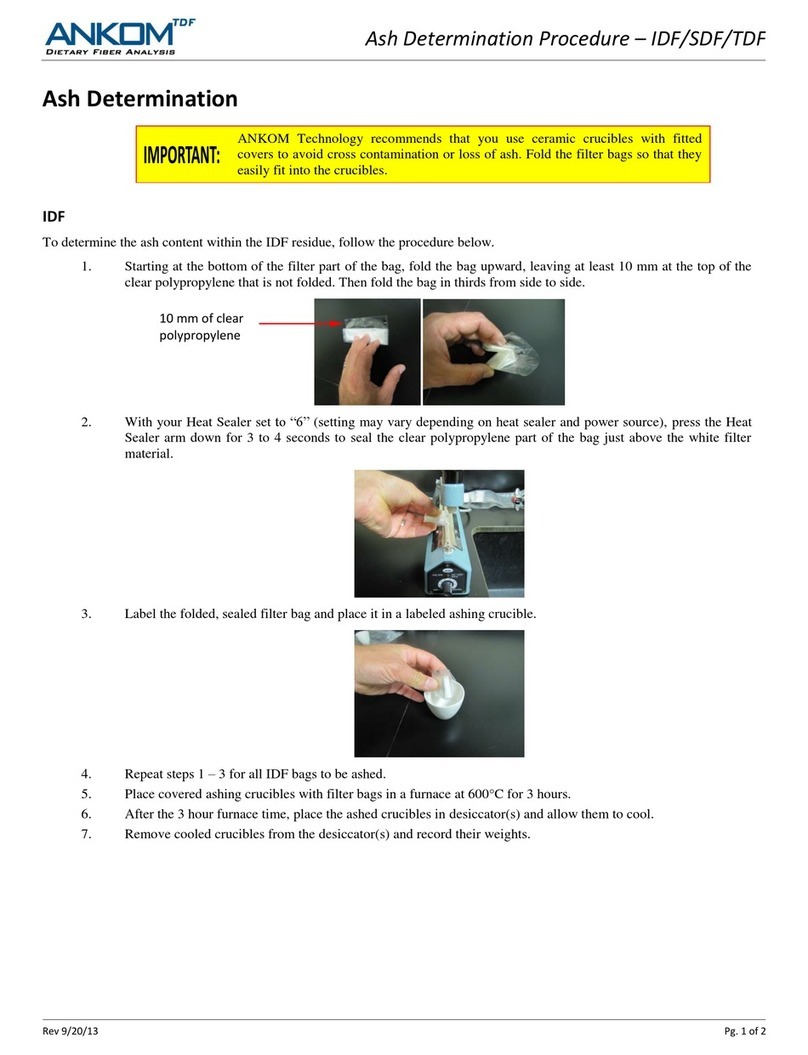

AshDetermination......................................................................................................................................................46

Enhanceyourproductivity..........................................................................................................................................49

UnderstandtheStatusScreen....................................................................................................................................53

FaultHandling.............................................................................................................................................................56

DiagnosticsMode.......................................................................................................................................................59

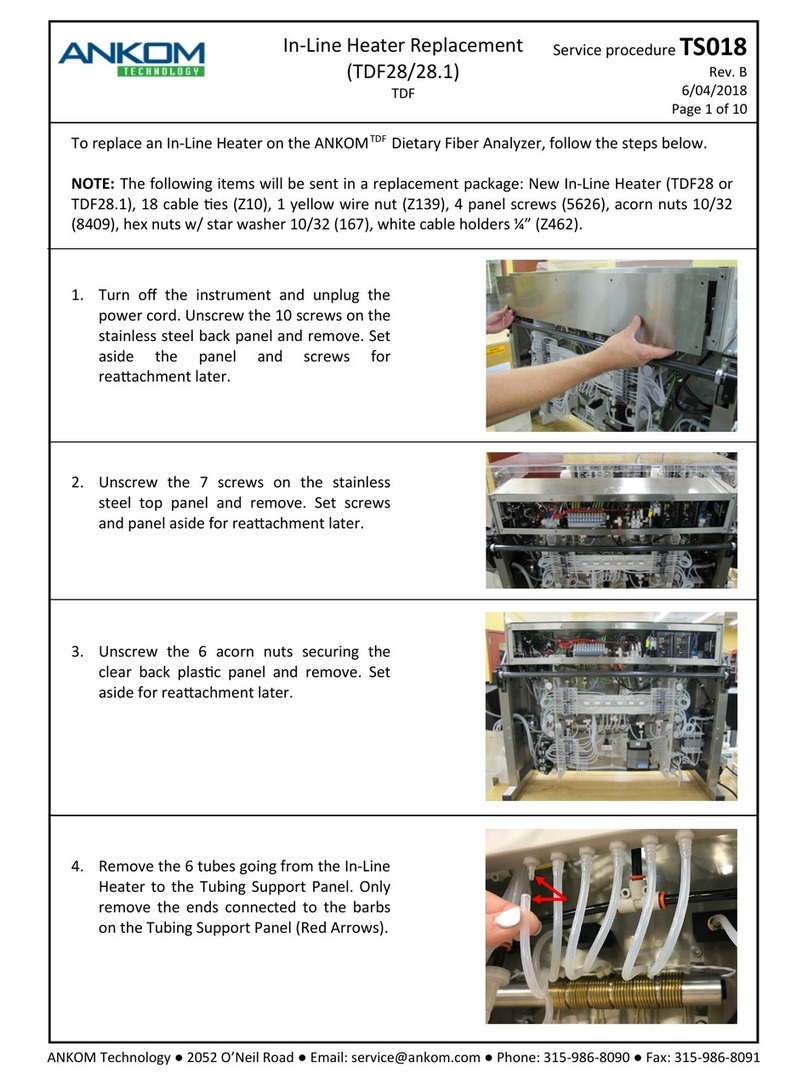

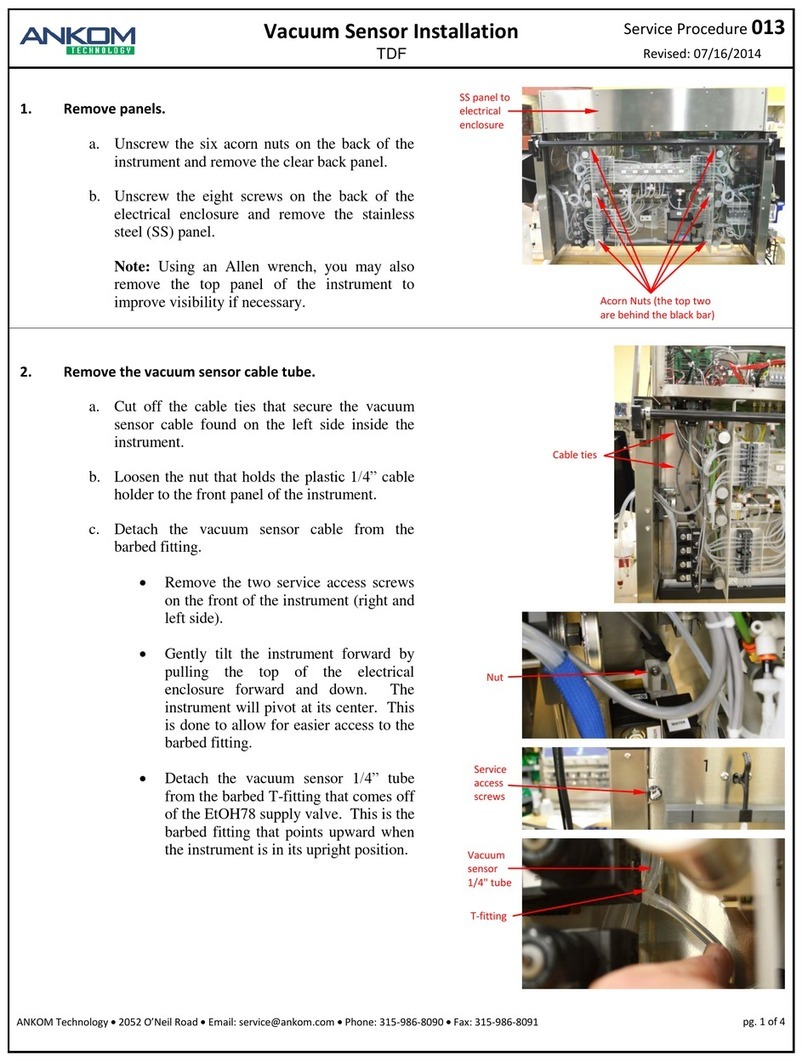

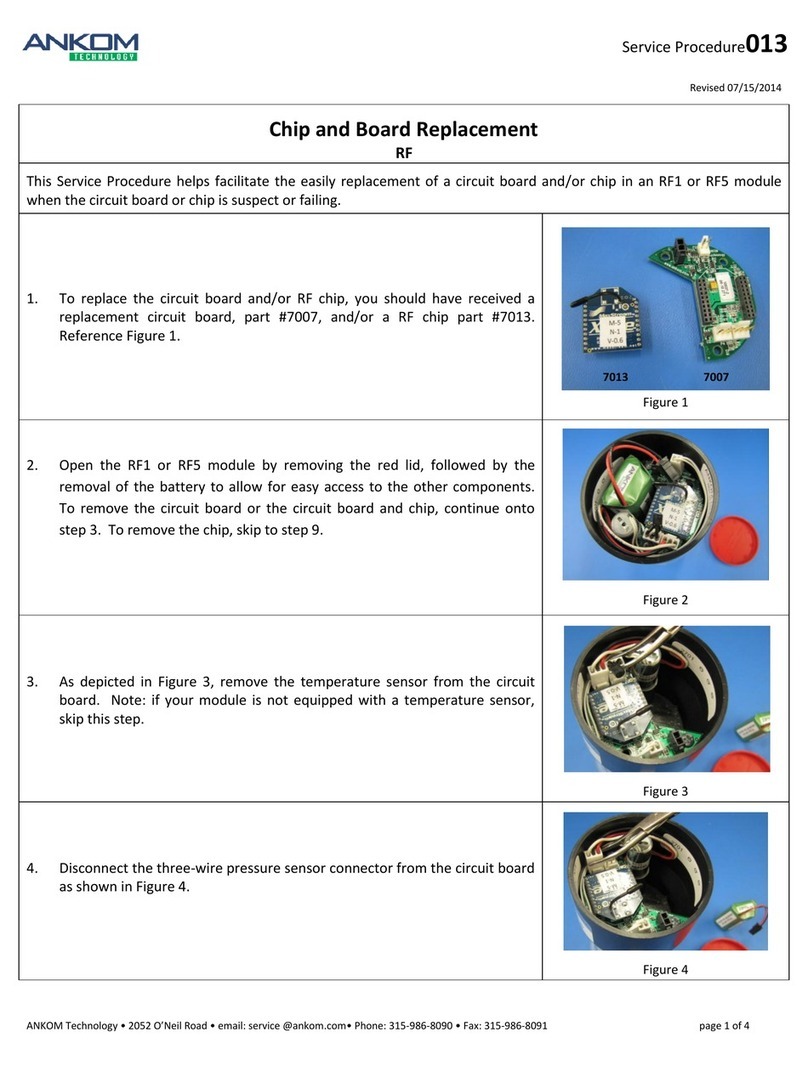

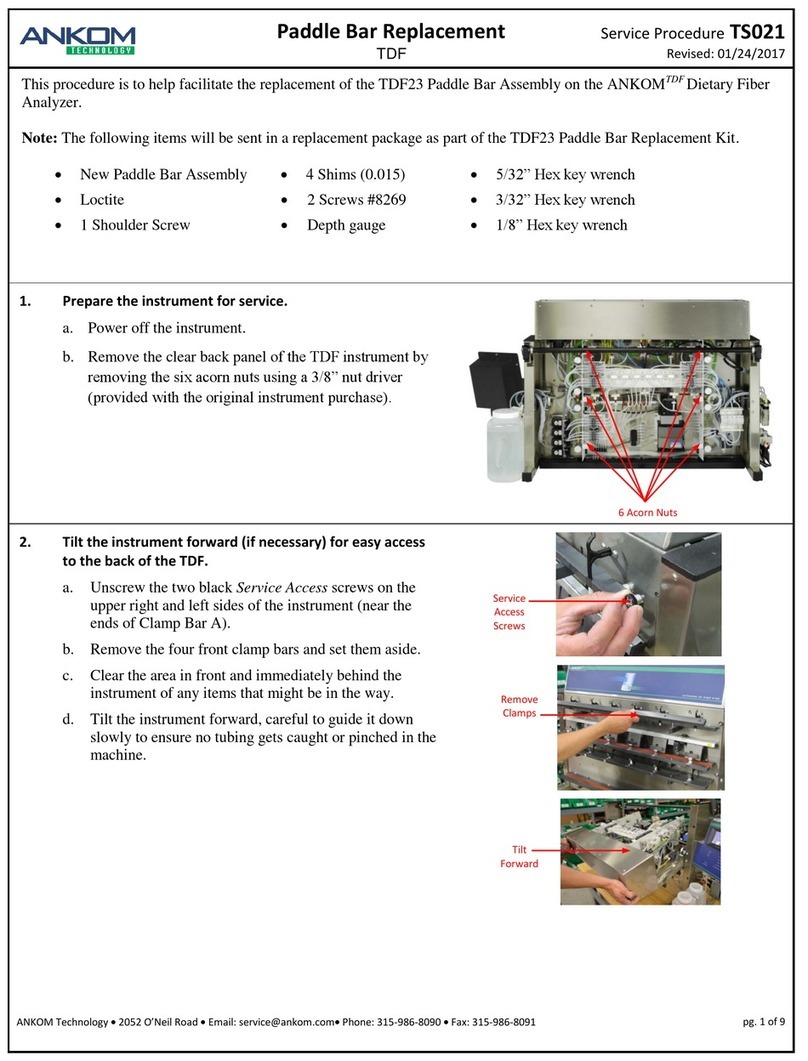

PeriodicMaintenance.................................................................................................................................................71

Troubleshooting..........................................................................................................................................................71

AppendixA–Reagents(AOAC991.43,AACC32‐07.01,NMKL129,2003)................................................................72

AppendixB–StorageProcedure................................................................................................................................74

AppendixC–Parts&Assemblies...............................................................................................................................75