Tel: +43 316 257-0 Created on 17 December 2012 C72IB004EN-B

www.anton-paar.com Created by HJ Page 5 of 7

Lovis 2000 M/ME – SOP

Standard Operating Procedure

6 Adjusting Lovis Measuring Systems (Manager and Administrator only)

TIP: Ifyouhaveordered a factory adjustment,import theadjustmentfromtheUSB flashdrivedelivered

with the capillaries. See chapter 3, p. 2

1. Perform a Level Adjustment. See "Performing a Level Adjustment", p. 4.

2. Tap "Menu > Checks/Adjustments > Other Adjustments > Lovis Module". Select "Standard

Adjustment" (range: 20° to 70° angle) or "Single Point Adjustment" (at one user-defined angle).

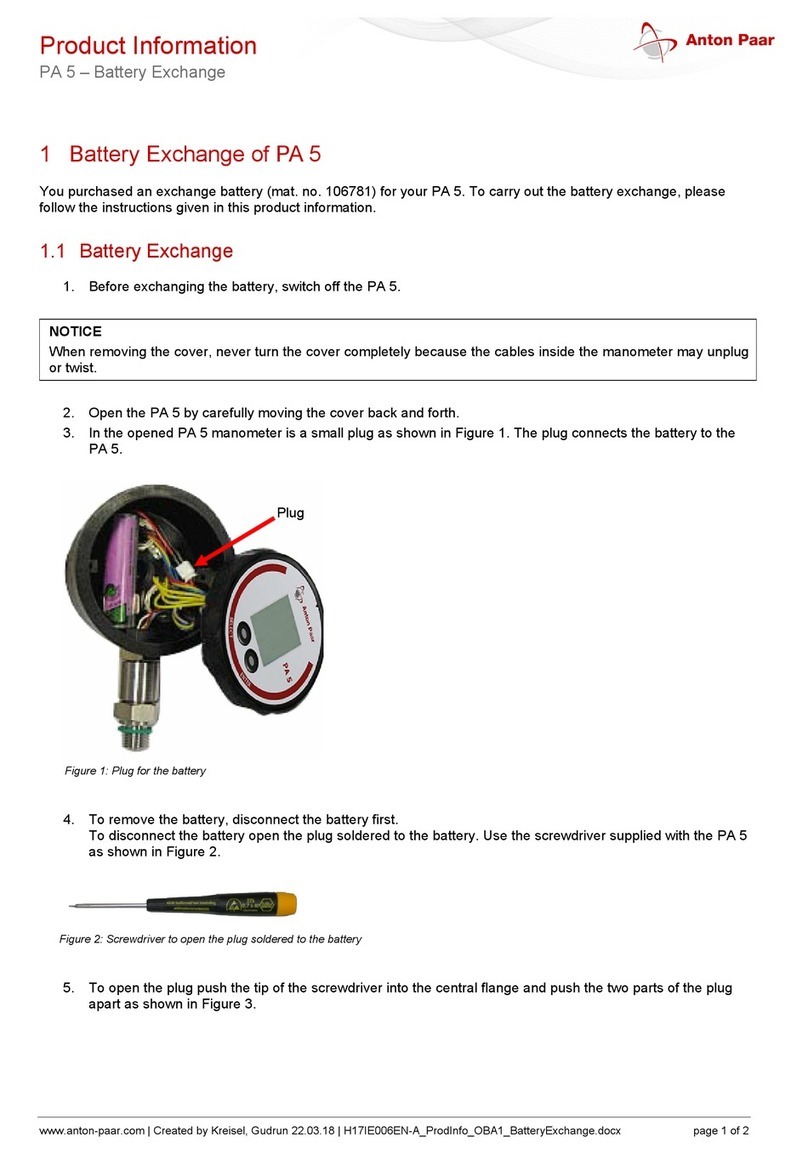

3. Follow the instructions on the display. Select the capillary (from the list of stored measuring

systems, see chapter 3, p. 2). Enter the ball batch no. and the ball density (see label of ball

vessel) and the adjustment temperature.

4. Enter a reference medium (viscosity standard liquid) and its dynamic viscosity and density at the

adjustment temperature. By default Lovis uses the values for reference medium "water". Fill the

capillary with your standard liquid (see chapter 4, p. 2) and start the adjustment.

When finished, Lovis displays the ball runtimes at the adjusted angle(s) and the maximal

variation coefficient that occurred during the adjustment.

5. Tap <Verify> to make sure the adjustment was correct.

6. Confirm the allowed deviation between adjustment and verification (default 0.5 %).

7. Fill the capillary once again with your standard liquid. Do NOT change the ball. Follow the

instructions on the display.

When the verification is finished the runtime deviations for each adjusted angle are displayed.

TIP: After a verification the runtime deviations to the values of the preceding original adjustment

are displayed. Typically, these values are higher than the variation coefficient of the original

adjustment.

• If the maximal deviation exceeds the allowed deviation, Lovis prompts you to tap <Redo>.

• Fill the capillary again and repeat the verification.

• If still exceeding the allowed deviation after the second <Redo>, clean and brush the

capillary (see chapter 9, p. 7), refill it and start a new adjustment.

8. To print or export an adjustment report, tap <Print>.

To save and apply the adjustment, tap <Apply>.

Recommended standard liquids:

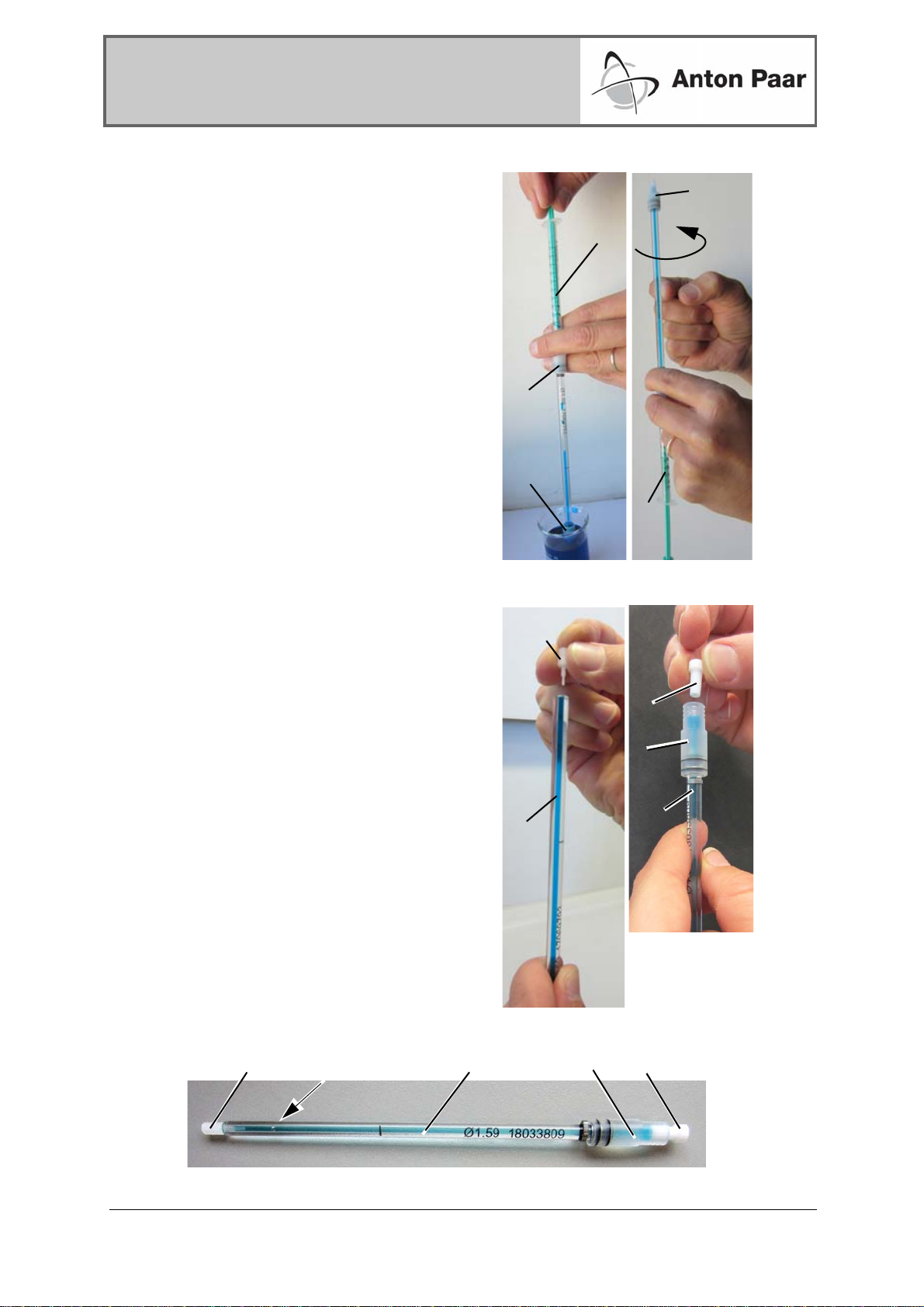

Capillary Temp. range Standard liquid

1.59 mm 20 °C to 40 °C water bi-distilled

1.59 mm 20 °C to 80 °C S3 oil

1.59 mm 40 °C to 100 °C N7.5 oil

1.8 mm 20 °C to 100 °C N26 oil

2.5 mm 20 °C to 60 °C N100 oil

2.5 mm 40 °C to 100 °C N415 oil