Fume Arms

2

Fume Arms

2

INDEX

1 Introducon ................................................. 3

2 InformaonontheMAXAIRfumearm............................ 3

3 Presentaon ................................................. 4

3.1 Each MAXAIR unit includes ....................................... 4

4 Modelnumbers .............................................. 5

4.1 Hanging or table / bench mount................................... 5

4.2 Telescopic fume arm ............................................ 5

5 Normaluse .................................................. 6

6 Operaonandpurpose ........................................ 6

7 Components ................................................. 7

7.1 MAXAIR main components (hanging version) ........................ 7

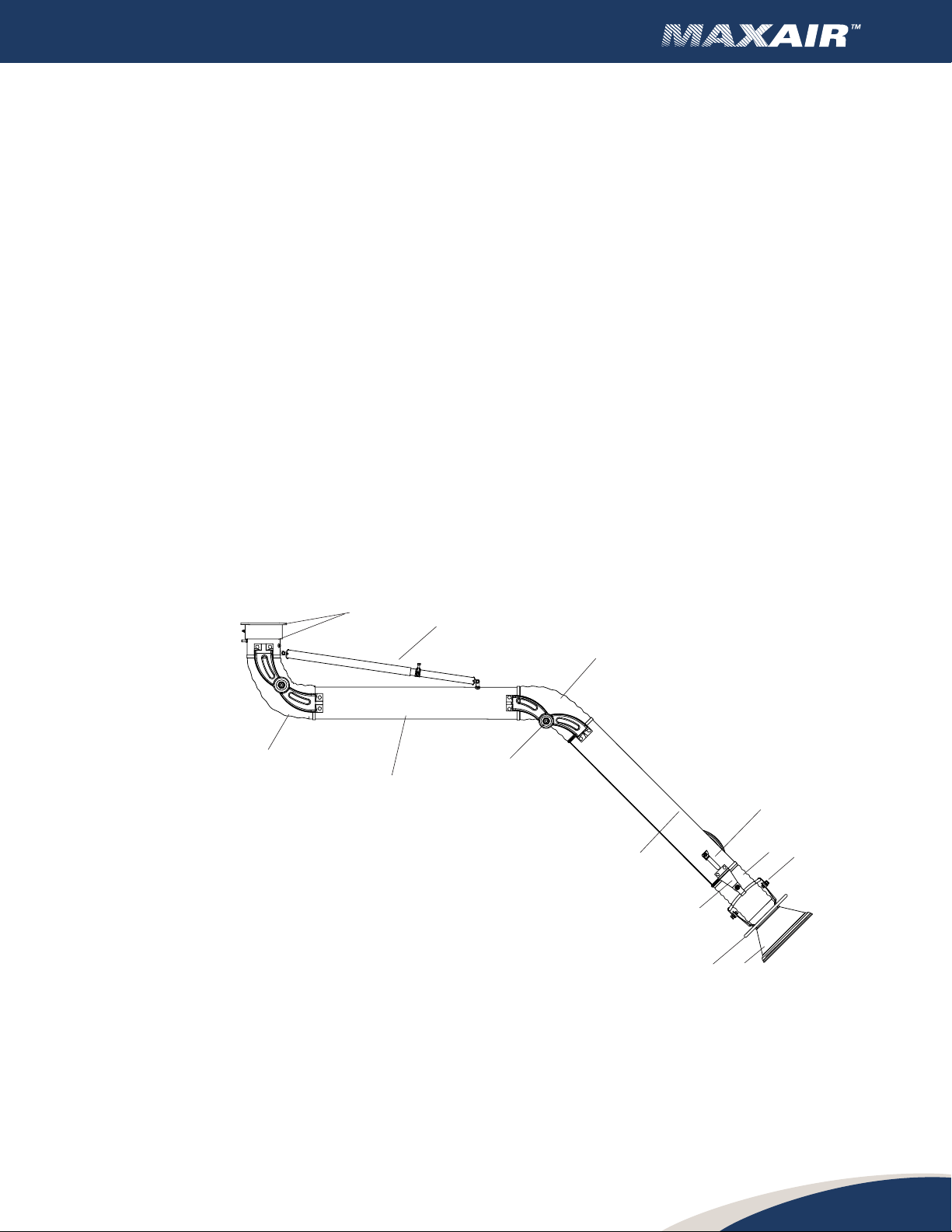

7.2 MAXAIR main components (bench mount / portable version) .......... 8

7.3 MAXAIR main components (telescopic version) ...................... 9

8 Installaon .................................................. 10

8.1 Inspeconofgoods ............................................. 10

8.2 Locaon....................................................... 10

8.3 Armandwall/postbracketinstallaon

(hanging type, no exhaust fan) .................................... 11

8.4 Armandceilingbracketinstallaon(hangingtype) ................... 13

8.5 Armandbracketinstallaon(hangingtypewithexhaustfan) .......... 14

9 Oponalequipment........................................... 15

9.1 MAXAIRtypicalinstallaons...................................... 15

10 Start up ..................................................... 18

10.1 Check list ..................................................... 18

11 Lightkitpartslistandinstallaon................................ 18

12 Electricalconnecons.......................................... 19

12.1 MAXAIR single phase fan starter (without light kit) ................... 19

12.2 MAXAIR three phase fan starter (without light kit).................... 19

12.3 MAXAIR single phase fan starter (with light kit) ...................... 20

12.4 MAXAIR three phase fan starter (with light kit)....................... 20

13 Maintenanceandinspecon ................................... 21

14 Troubleshoong .............................................. 22

15 Warranty.................................................... 23

16 Limitaonofliability .......................................... 24

17 Applicability ................................................. 24

18 Governinglaw ............................................... 24