Horizontal downow pleated cartridge dust collector

22

INDEX

1 Introducon ................................................. 3

2 Informaononthedustcollector ................................ 3

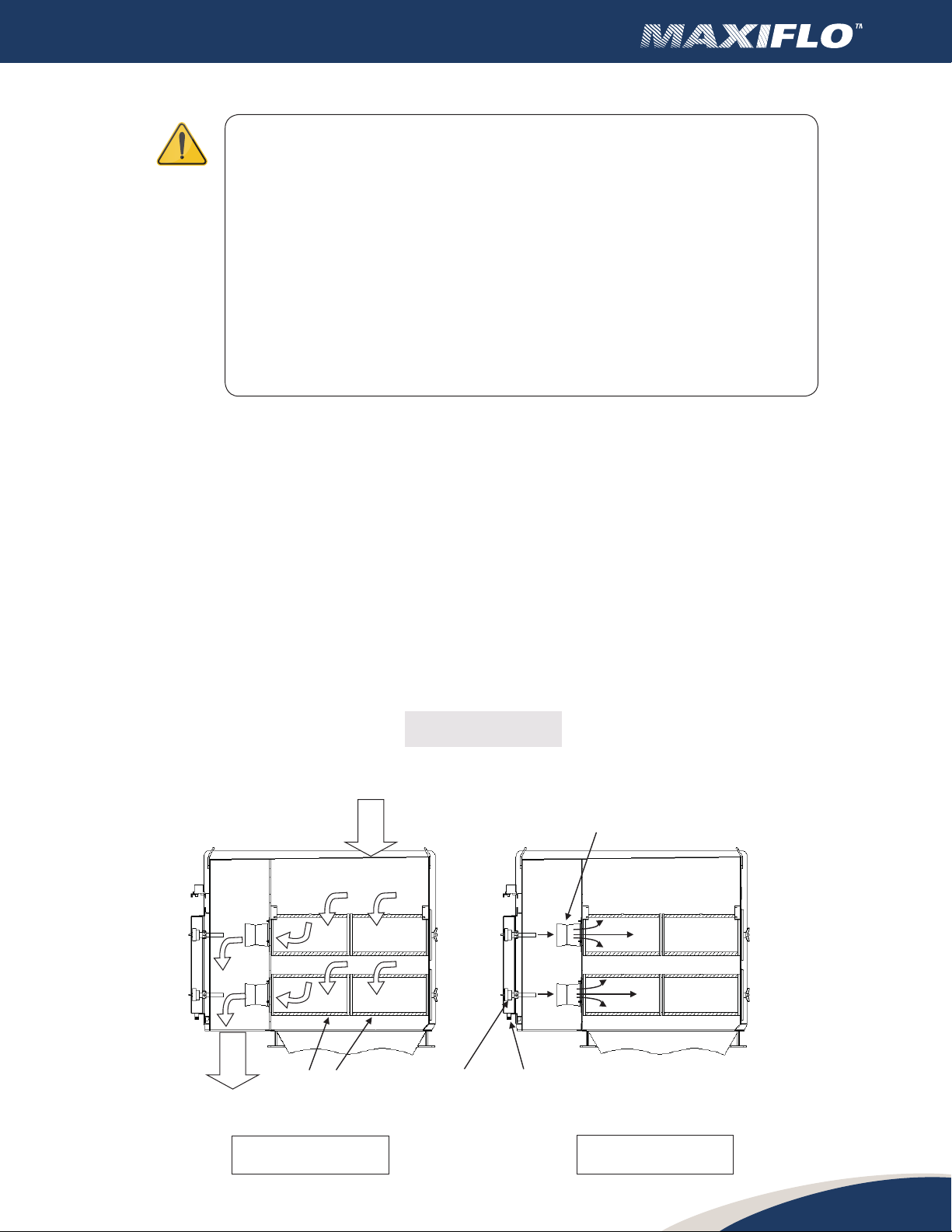

3 Presentaon ................................................. 4

3.1 Each MAXIFLO unit includes ...................................... 4

4 Normaluse .................................................. 4

5 Operaon ................................................... 5

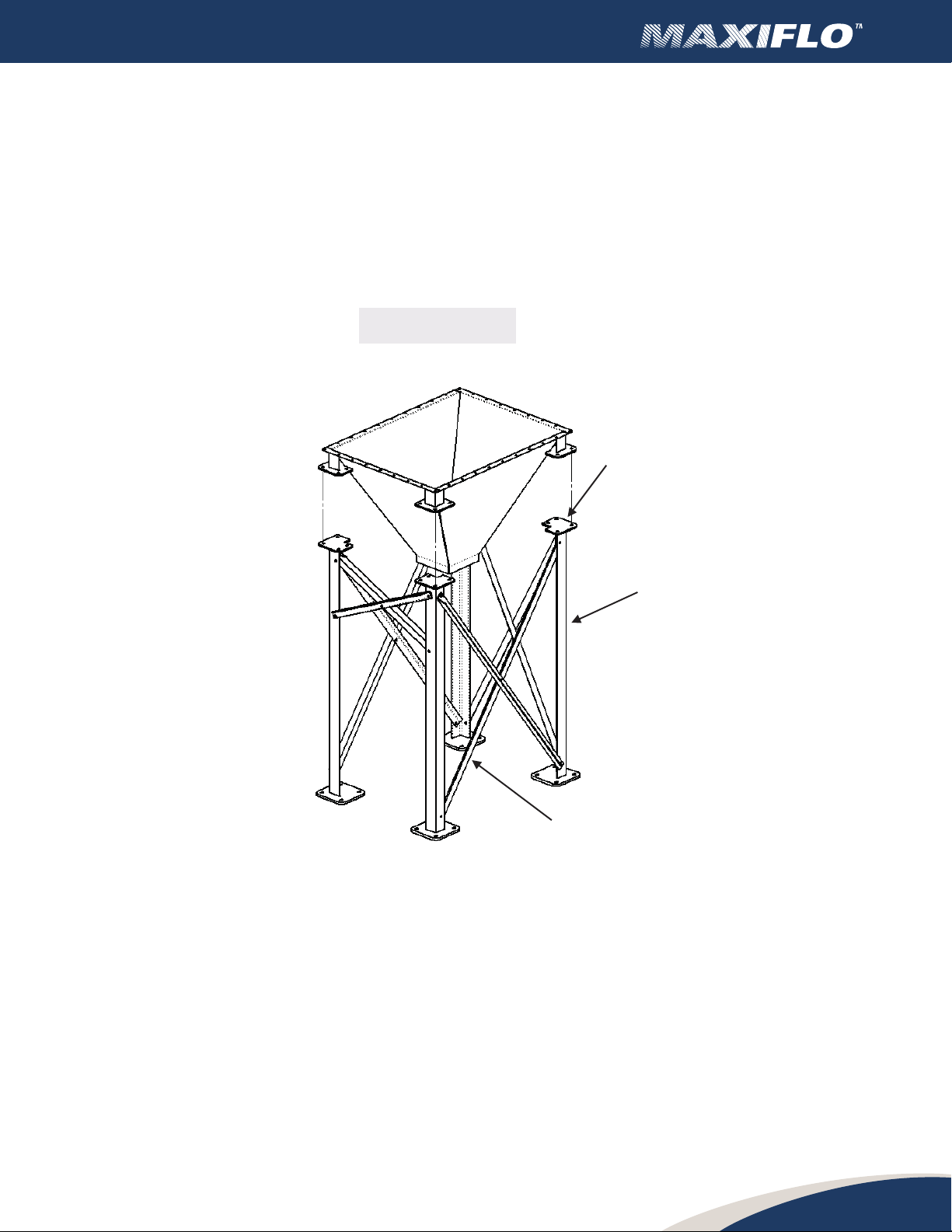

5.1 Cartridge cleaning .............................................. 5

6 Installaon .................................................. 6

6.1 Inspeconofgoods ............................................. 6

6.2 Locaon....................................................... 6

7 Assembly ................................................... 7

7.1 Requiredtools ................................................. 7

8 Assembly.................................................... 7

9 Structureassembly............................................ 8

10 Electricalconnecon .......................................... 10

10.1 ElectricalconneconforDCT-500sequencer ........................ 10

10.2 ElectricalconneconforDCT-1000sequencer ...................... 11

10.3 Compressedairconnecon....................................... 13

10.4 Venlaonducng.............................................. 13

11 Start up ..................................................... 13

11.1 Check list ...................................................... 13

12 Electricalconnecons ......................................... 14

12.1 Check list ...................................................... 14

12.2 Electricalconnecons ........................................... 14

12.3 Oponalequipment............................................. 14

12.4 An-abrasiveinlet .............................................. 15

12.5 Plaormandladder ............................................. 16

12.4 Explosionreliefvent............................................. 16

13 Magnehelicgauge ............................................ 17

14 Start/Stopprocedure .......................................... 17

14.1 Startupwithnewlters ......................................... 17

14.2 Regular start up ................................................ 17

14.3 Shutdown .................................................... 17

15 Safety ...................................................... 17

15.1 Sta-Workers .................................................. 17

15.2 Electricalcomponents ........................................... 18

15.3 Explosivedusts ................................................. 18

15.4 Anchors ...................................................... 18

15.5 Interiorinstallaon ............................................. 18

15.6 Sparkproducingacvies ........................................ 18

16 Maintenance................................................. 19

16.1 Remplacementofcartridges...................................... 19

16.2 Remplacementofcartridges...................................... 19

17 Compressedairsystem ........................................ 21

17.1 Explosionvent ................................................. 21

17.2 Controlpanel .................................................. 21

18 Programminginstrucons ...................................... 22

18.1 DCT-500sequencer ............................................. 22

18.2 DCT-1000sequencer ............................................ 22

19 Maintenanceandinspecon ................................... 23

20 Troubleshoong .............................................. 24

21 Warranty .................................................... 27

22 Limitaonofliability .......................................... 28

23 Applicability ................................................. 28

24 Governinglaw ............................................... 28