Aqualisa Q User manual

EXPOSED CONTROLLER

INSTALLATION GUIDE

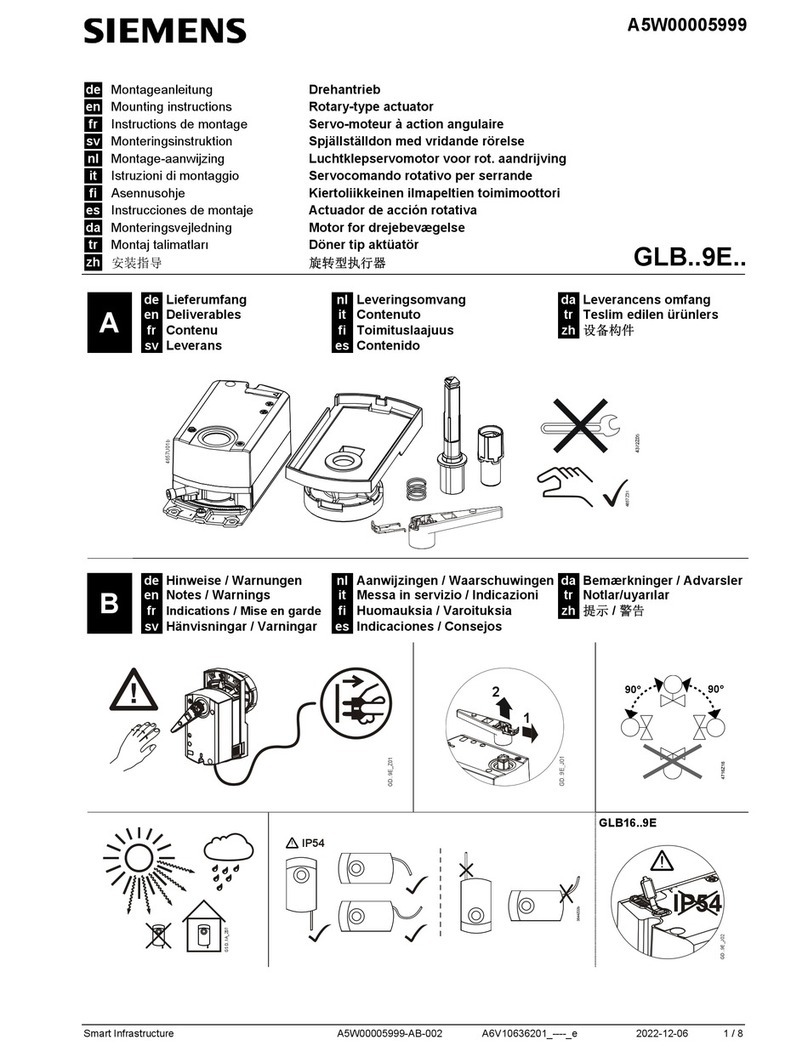

COMPONENTS

Data cable,

(already fitted to rail)

2 3

QuartzTM smart valve components not shown, refer to QuartzTM smart valve installation guide

for more details.

CANBUS

Converter

VitaTM

Shower head

PINCH GRIPTM

Ceiling

cover plate

Riser rail

Controller

back plate

Gel holder

Shower hose

Top rail

bracket

Rail insert

cover plate

Place your level here

Hole diameter

for guidance

purposes only

Hole diameter

for guidance

purposes only

Minimum distance between top

bracket and the ceiling is 100mm

Ensure vertical

alignment by

using a spirit

level against the

vertical lines if

necessary

FINAL ARTWORK SHEET

DESCRIPTION Q EXPOSED RAIL ASSEMBLY

DRAWING No.

7536

ARTWORK No.

703127

DATE

22/12/16

DRAWN BY

KH

REVISION

A

SCALE

1:1

CEILING MOUNTED FIXING TEMPLATE

Part No: 703127 Issue 01 Jan 17

Fixing template

QTM smart

controller

CANBUS

Data Cable

90° Push

fit Elbow

Stardust Silver

accent ring

INDEX

COMPONENTS PAGE 3

SAFETY INFORMATION PAGES 4 & 5

GRAVITY SYSTEMS PAGE 5

HIGH PRESSURE/COMBINATION BOILERS PAGE 5

CONNECTION TO SUPPLIES PAGE 6

FLUSHING PAGE 7

QTM CONTROLLER INSTALLATION PAGE 8

ATTACHING ACCESSORIES PAGE 15

WALL MOUNTED FIXED HEAD PAGE 16

CEILING MOUNTED FIXED HEAD PAGE 19

BATH OVERFLOW AND FILLER PAGE 21

COMMISSIONING PAGE 24

WATER SAVE MODE PAGE 25

CLEANING AND MAINTENANCE PAGE 25

TROUBLE SHOOTING GUIDE PAGE 26

Data cable

removal tool

IMPORTANT INFORMATION

4 5

Safety information

This product must be installed by a competent person in

accordance with all relevant current Water Supply Regulations.

ALL PRODUCTS REQUIRING AN ELECTRICAL CONNECTI0N

MUST BE INSTALLED BY A QUALIFIED PERSON FOLLOWING

THE LATEST REVISION OF BS 7671 (WIRING REGULATIONS)

AND CERTIFIED TO CURRENT BUILDING REGULATIONS.

This system should be installed so that other taps or appliances

operated elsewhere within the premises do not significantly aect

the flow.

The QTM shower sytems must not be used with a hot water supply

temperature of over 65ºC.

The QuartzTM smart valve is supplied factory pre-set at maximum

temperature of 45ºC. The maximum temperature is fully

adjustable to suit site conditions. If adjusted, we recommend the

outlet temperature is set to a MAXIMUM of 46ºC.

THE QUARTZTM SMART VALVE MUST BE INSTALLED IN AN

ACCESSIBLE LOCATION FOR SERVICING AND MAINTENANCE.

The QuartzTM smart valve must not be installed in situations where

either the ambient temperature is likely to exceed 40ºC or where

freezing may occur.

The QTM controller must not be installed in situations where the

ambient temperature is likely to fall below 5ºC or rise above 40ºC.

We do not recommend the use of QTM controller in steam therapy

facilities.

This appliance must be earthed.

Cables which are chased into the wall must be protected by a

suitably sized conduit or sheathing to allow for removal in the event

of service and maintenance purposes. Ensure that the conduit is

run to avoid the controller fixing holes.

Surface mounted cables must also be protected by a suitable

approved conduit, even in a loft, where there may be a risk of

damage from vermin.

The power lead must only be replaced by the manufacturer or

his accredited agent.

The QTM controller is supplied from a safety low voltage source.

This product is suitable for domestic use only.

Aqualisa smart products are supplied complete with a 1 year

guarantee that can be upgraded to 5 years by registering the

shower with Aqualisa.

This product is not intended for use by persons (including children)

with reduced physical, sensory or mental capabilities or lack of

experience and knowledge, unless they have been given initial

supervision or instruction concerning the use of the product by

a person responsible for their safety.

Children should be supervised to ensure they do not play with the

product.

Installation of pumped QuartzTM smart valve (for gravity

stored systems)

The pumped QuartzTM smart valve is designed to operate up to

maximum static pressure of 100kPa ((1 bar)(10 metres head)

(14.5psi)).

Under no circumstances must the pumped QuartzTM smart valve

be connected directly to the water main or in line with another

booster pump.

The minimum actual capacity of the cold water storage cistern

should be not less than 225 litres (50 gallons). The capacity of the

hot water cylinder must be capable of meeting anticipated demand.

Installation of QuartzTM smart valve (for balanced high

pressure and unvented systems, combination boiler

systems and separately pumped gravity systems)

Pressures: The QuartzTM smart valve system is designed to operate

up to a maximum static pressure of 700kPa ((7 bar)(100psi)). Where

pressures are likely to exceed 700kPa ((7 bar)(100psi)), a pressure

reducing valve must be fitted to the incoming mains supply.

A setting of 400kPa ((4 bar)(60psi)) is recommended. It should be

noted that daytime pressures approaching 600kPa ((6 bar)(80psi))

can rise above the stated maximum overnight.

Special notes for combination boiler systems

The appliance must have a minimum domestic hot water rating

of 24kW (80,000BTU) and be of the type fitted with a fully

modulating gas valve. If in any doubt, please contact the appliance

manufacturer before installation commences.

PLEASE NOTE: DUE TO PERFORMANCE CHARACTERISTICS

OF COMBINATION BOILERS, SEASONAL INLET TEMPERATURE

CHANGE WILL AFFECT THE QUARTZTM SMART VALVE OUTLET

FLOW RATE RESULTING IN VARYING SHOWER FLOW RATES.

INLET TEMPERATURE CHANGE MAY ALSO CAUSE THE

TEMPERATURE DISPLAY TO FLASH; THIS IS NOT NECESSARILY

CHANGING THE OUTLET TEMPERATURE.

Special notes for separately pumped gravity systems

We recommend a twin ended pump with a MINIMUM pump rating

of 1.5 bar. For optimum performance a twin ended 2.5 bar pump

should be used.The minimum actual capacity of the cold water

storage cistern should be not less than 225 litres (50 gallons). The

capacity of the hot water cylinder must be capable of meeting the

anticipated demand.

THIS PRODUCT IS NOT SUITABLE FOR USE WITH A SINGLE

ENDED PUMP.

FOR DIVERT MODELS A UNIVERSAL TWIN ENDED PUMP

MUST BE USED.

Connections

This product incorporates ‘push fit’ type connections.

Tube should be cut using a rotary type cutter and lubricated using a

silicone-based lubricant or petroleum jelly (Vaseline or similar)

prior to insertion into the fitting.

If plastic pipe is used, the tube insert must not increase the tube

diameter or extend the cut-o length by more than 2mm.

TO MAXIMISE FLOW RATES WE RECOMMEND USING COPPER

PIPE WITH THE MINIMUM AMOUNT OF ELBOWS. THESE

FITTINGS ARE NOT SUITABLE FOR STAINLESS STEEL TUBE.

Pipe sizing

Long pipe runs, on both inlet and outlet, will reduce the flow rate

at the shower head. If long pipe runs are unavoidable, use copper

pipe rather than plastic. If plastic pipe is used, minimise the number

of elbows as the pipe inserts are very restrictive. Consideration

should be given to using 22mm plastic or copper pipe especially if

a diverter is installed.

Flushing

Some modern fluxes can be extremely corrosive and, if left in

contact, will attack the working parts of this unit. All soldering

must be completed and the pipe work thoroughly flushed out in

accordance with current Water Supply Regulations prior to

connection of the product.

Declaration of Conformity

Aqualisa Products Limited declares that the QTM Controller, in

conjunction with the smart valve, complies with the essential

requirements and other relevant provisions of the Low Voltage

Directive (2014/35/EU), the EMC Directive (2014/30/EU) and

the RE Directive (2014/53/EU).

6 7

)

. . Helpful tip...

AQUALISA QTM

In addition to the guide below it is essential that the Important information

section is read and understood and that you have all the necessary

components before commencing installation. Failure to install the product in

accordance with these instructions may adversely aect the warranty terms

and conditions. Do not undertake any part of this installation unless you are

competent to do so. Prior to starting, ensure that you are familiar with the

necessary plumbing regulations required to install the product correctly and

safely.

1

Install QuartzTM smart valve and diverter box (if applicable) following the

separate installation guide.

2Locate a suitable entry point in the ceiling or coving for the riser rail, avoiding

joists and services. Position the rail assembly against bathroom wall in desired

position and mark centre of rail on ceiling/coving.

The centre of the riser rail stands 45mm from the wall.

3Drill a hole in the ceiling/coving that is a minimum Ø30mm maximum Ø40mm.

If coved ceiling remove the ceiling cover plate from the riser rail.

8 9

4Ax the paper template to the wall in the desired location ensuring the shower

controller is at a suitable height.

5Mark the fixing points as indicated on the template.

Helpful tip...

Prior to drilling the fixing holes oer the assembly into position and check

the following points:

The chrome riser rail is positioned within the drilled ceiling hole,

(no copper pipe visible in the shower area).

There is adequate working clearance above the top of the rail in the

roof space.

The controller is at a suitable height for all family members.

Location of the top bracket does not interfere with the maximum usage

height of the PINCH GRIPTM.

)

. .

Use a spirit level where indicated on the paper template to ensure your

template is square.

6Drill the fixing points as previously marked using a suitable 6mm drill bit and fit

the supplied wall plugs (if suitable).

7Feed the data cable followed by the rail assembly

containing the supply pipe through the hole in

the ceiling.

INSTALLATION

•

!

)

. . Helpful tip...

Positioning the QTM controller

The QTM controller is activated by a proximity sensor on the front of the

QTM controller. This sensor detects motion from up to 0.5m, directly in

front of the device. It is therefore important that the device is positioned

so that it will detect the user approaching and moving away from the

shower at 0.5m.

The position should also be taken into consideration when utilising the

Water Save mode, refer to point 63.

)

. .

If the ceiling height is over 2.4m (8ft) a riser rail extension kit will be

required. Contact our Customer Service department to purchase a 550mm

riser rail extension kit, (Part No. 910596).

)

. . Helpful tip...

9Place the top rail bracket support pillar behind the riser

rail and align with the fixing points.

8Hold the riser rail assembly in position, secure the

left hand fixing point of the bottom rail bracket

(as shown).

10 Slide the fixing bracket over the rail and the support pillar

and secure to the wall with the screws provided

(if suitable).

11 Slide the top rail bracket cover onto the fixing bracket

flush with the finished wall surface and click the

sides firmly into position.

12 If being used slide the plate up to the ceiling to

cover the entry hole.

13 Cut the cable tie and tilt the wall plate forward

from the top to expose the rear of the wall plate.

Remove the paper liner from the gasket, apply

silicone sealant to the channel (as shown).

Helpful tip...

For cosmetic reasons we recommend using clear silicone.

)

. .

10 11

14 Tilt the wall plate back and secure to the wall with

the remaining 3 screws provided, (if suitable)

ensuring the data cable is correctly located in the

wall plate (as shown).

15 Slide rail insert cover into place.

Your QuartzTM smart controller is supplied with

a colour accent ring that must be fitted.

For fitting instructions refer to the user

manual.

16 Position the QTM controller into the

wall plate with the power symbol

at the 7 o’clock position.

Gently apply pressure to the

screen with one hand. Use the

other hand to rotate the

controller counter clockwise

using the QTM lever until it stops

and is securely seated on the wall

plate.

If supplied screws are not used, use a screw with the

same size and head design, the screws used must be

non corrosive.

Allow the silicone to set before moving to point 16.

•

!

Power supply to the QuartzTM smart valve must be switched o before

connecting the QTM controller.

•

!

18 If the QuartzTM smart valve is close to the shower then the cable can be trimmed.

Ensure that a minimum 20mm of wire and 5mm of copper is exposed,

(we recommend leaving minimum 100cm of cable spare).

The data cable must be run in conduit to allow for servicing and replacement

if required. A minimum size of 15mm conduit is recommended.

•

!

17 Tighten the screw located on the bottom of the

QTM controller.

19 Connect the 10m data cable into

the CANBUS converter box

following the wiring order as

shown in the image and on the

label. White (WH), Blue (BL),

Black (BK), Red (RD).

Insert one end of the 500mm

black CANBUS data cable

into CANBUS converter.

Only the supplied cable in the Green bag can be used. Do not use any another

cable. If any other cable is used, damage will occur to the unit.

•

!

12 13

0.6

8.1

25

3.5

1.9

Do not overtighten

•

!

Helpful tip...

If you connect the wrong wire use the supplied cable removal tool to remove the

cable, any other tool may damage the CANBUS converter.

)

. .

20 Remove top case of QuartzTM smart valve, plug in

CANBUS data cable and replace top case. Fix the

CANBUS converter box to joist/board with

self-tapping screws provided.

21 Connect the 2m patch lead cable to both the

diverter box and the secondary socket on the

QuartzTM smart valve. Feed the cable out of the

QuartzTM smart valve and diverter ensuring it is

correctly routed within the data cable channel.

If diverter is not being installed please proceed to point 22.

22 Run a supply pipe from the QuartzTM smart valve to

the top of the rail assembly.

If using a divert product run the supply from outlet

A to the top of the rail assembly.

14 15

23 For divert products run a supply pipe from outlet B of the diverter box to the

secondary outlet.

24 If installing a single outlet model, please go to point 60 for further instructions.

The 90° elbow must be used and kept easily accessible for future servicing

and product replacement.

To ensure optimum performance use as few elbows as possible.

To maximise flow rates we recommend using copper pipe.

Run the outlet pipe from the QuartzTM smart valve or diverter to the top of the

shower rail at a mildly upward gradient to reduce water dumping after use.

25 Attach the hose to the base thread at the bottom of the rail. The hose must be

tightened to point where washer forms a seal.

Current water supply regulations state that the handset should not be

allowed to pass a point 25mm above the spill over level of the bath or shower

tray. If this cannot be achieved, the hose must be passed through the gel

hook which has been designed to be utilised as a hose restraint.

•

!

•

!

ATTACHING ACCESSORIES

27 Ensure the hose washer is in the correct position and screw the pivot hose

connector into the hose.

26 To attach the handset to the hose disengage the pivot clip from the bottom of

the handset by pressing the tab and pulling the pivot hose connector clear.

Helpful tip...

If Installing a diverter, the QuartzTM smart valve secondary socket MUST be used

to connect the QuartzTM smart valve to the diverter. This is located next to the

QTM smart valve main socket and is accessed by carefully snapping and removing

the entry pillar.

)

. .

16 17

28 Re-insert the pivot hose connector into the handset

and push the tab to lock into position.

29 Insert handset into PINCH GRIPTM slider.

32 Ensure the pipe is clean and free of dust and slide the

fixing bush onto the pipe flush with the wall spacer.

WALL MOUNTED FIXED HEAD

33 Slide the fixed head arm over the fixing bush flush with the wall surface and mark

the four fixing points.

34 Carefully remove the fixed head arm and drill and prepare the fixings using the

fixings provided, if suitable, taking care to avoid pipework hidden in the wall.

35 Ensuring the fixing bush is clean and free of dust,

fit the 15mm O-ring against the end of the fixing

bush. Lubricate the O-ring using a suitable

silicone based lubricant.

Refer to point 60 of commissioning

instructions.

•

!

The O-ring must be positioned on the 15mm pipe flush to the fixing

bush, not onto the fixing bush shaft.

•

!

30 Cut the outlet pipe to the finished length (55mm – 150mm measured from the

finished wall surface) using a rotary type cutter. If a hacksaw is used, the pipe

end must be carefully de-burred and chamfered. Slide the wall spacer down the

projecting pipe flush with the finished wall surface.

31 Slide the spacer on to the projecting pipe flush with

the finished surface.

36 Refit the shower arm and secure it to the wall using

the screws provided (if suitable).

38 Run the shower for a few seconds to clear any debris that may be present.

37 Fit the fixing cover plate.

39 Ensuring the rubber washer is in the correct

position, attach the showerhead to the fixed arm

and carefully secure using a suitable spanner, or

a tool with smooth jaws, suciently to lock the

head into position.

CEILING MOUNTED FIXED HEAD

18 19

The ceiling mounted fixed head is supplied with screws for fixing the product

to a noggin. A NOGGIN MUST BE USED AS PART OF THIS INSTALLATION.

•

!

40 Run a 15mm outlet pipe from the outlet B of the diverter box to the preferred

position for the fixed head.

41 Locate the position for the fixed head in the

bathroom and firstly drill a pilot hole to mark the

position before checking that there is suitable

space behind the ceiling for the fixing assembly.

42 Drill a hole (minimum ø28mm, maximum ø40mm) through the ceiling and the

noggin.

43 Remove the fixing bracket carefully from the fixed head arm.

44 Set the fixing bracket into position and mark the

fixing points. Remove the bracket and drill and

prepare suitable fixings. Refit the fixing bracket

and secure it through the ceiling and into the

noggin using the screws provided (if suitable).

The minimum height required behind the ceiling is 50mm and the space must

allow for an 80mm wide,

50mm deep noggin to be used to support the assembly.

•

!

Refer to point 60 of commissioning

instructions.

•

!

49 Ensuring the rubber washer is in the correct position,

attach the shower head to the fixed arm and carefully

secure using a suitable spanner, or a tool with

smooth jaws, suciently to lock the head into

position.

BATH OVERFLOW FILLER

50 Carefully unscrew and remove the overflow filler

outlet from the body assembly and set aside.

20 21

45 Feed the arm through the fixing bracket to the

correct depth. Tighten the nut using a 32mm

spanner if necessary to facilitate.

46 Cut o the excess pipe allowing for a suitable working length to allow for the

required 22mm connection. If a push fit connector is to be used then the pipe

must be abraded to remove all chrome plating.

47 Connect the pipe work from the QuartzTM smart valve or diverter to the end of

the fixed head pipe using a suitable coupling.

48 Lubricate the ‘O’ ring if necessary and carefully

slide the cover plate back over the fixed head arm

and into position against the ceiling.

Secure the cover plate to the arm using the grub

screw and 2.5mm hexagonal key provided.

Run the shower for a few seconds to clear any debris and to check for

any leaks.

•

!

Refer to point 60 of commissioning instructions.

•

!

The bath overflow filler is suitable for baths up to a maximum thickness

of 24mm.

•

!

51 Carefully unscrew and remove the bath waste clicker

assembly from the waste body and set aside.

52 Oer the bath waste into position ensuring the rubber

washer is correctly aligned between the waste

assembly and the bath base.

53 Ensuring the rubber washer is correctly aligned, pass

the bath waste clicker through the bath and secure to

the waste body assembly.

54 Connect the bath waste to a suitable waste pipe.

55 Oer the outlet body assembly into position at the

rear of the bath ensuring the rubber washer is correct

aligned between the outlet body assembly and

bath wall.

56 Ensuring the rubber washer is correctly aligned, pass

the overflow filler outlet through the bath and secure

to the body assembly.

57 Remove the relevant inlet blanking plug and attach

the flexible hose to the blended inlet connection.

58 Connect the flexible hose to the blended supply pipe ensuring suitable non

restrictive double check valves are fitted in line with current Water Supply

Regulations (not supplied).

22 23

24 25

Configuring outlets for a Divert model

If you are installing a Divert model, the icons that will appear on the User Interface are:

Outlet A this will be the Primary outlet

Outlet B

To change these icons, or to redefine the primary outlet, wake up the QTM controller and

navigate to SETTINGS>CONFIGURE OUTLETS. Then follow the on-screen instructions.

Setting up for Bath models

If you have installed a QTM shower with a bathfill, the QTM controller can oer specific

bath functionality (storing bath depths). To enable this you must first wake up the QTM

controller and navigate to SETTINGS>CONFIGURE OUTLETS. You must then select the

BATH icon to enable the bath functionality.

59 Once the QuartzTM smart valve and diverter (if applicable) are fully installed,

continue to commissioning instructions below.

61 Pipework for all outlets must be flushed through for at least 15 seconds to clear

any debris before fitting any handsets or heads, (refer to the quick start guide for

basic operation.

62

COMMISSIONING

60 When power is applied to the QTM smart valve, the controller will display the

following message, PREPARING HOLD LEVER TO SKIP wait for the message to

clear before commencing commissioning.

63

WATER SAVE MODE

This feature allows the user to save water. When the shower is on, if the user moves away

from it, (eg to shampoo hair), the water flow will reduce to Min. The flow will

automatically return to the users preference, when they return to within 0.5m of the QTM

controller.

It is switched o by default. To switch it on navigate to

SETTINGS>WATER SAVE MODE, and select ON.

Factory Settings

Warm Up Mode OFF (This feature is only available with Q Edition)

Water Save Mode OFF

Cleaning Mode OFF

Auto Repeat Shower OFF

Auto Save Shower ON

Run Both Outlets At Warm Up OFF

Water O At End Of Timer OFF

Refer to user guide for cleaning advice.

CLEANING & MAINTENANCE

This function is not suitable for use with Combi systems.

•

!

0.5m 0.5m

Helpful tip...

Refer to user guide for further information.

)

. .

Helpful tip...

Refer to user guide for further information on the above.

)

. .

NOTES

26 27

Water output is

either all hot or all

cold, or cold only

Reverse inlet supplies Check that the supplies

correspond with the inlet

markings

The cylinder temperature

should be at least 15ºC

hotter than the blend

Check the flow rate

recommendations with the

heater manufacturer.

If fitted to a combination

boiler adjust the flow

control knob on the mixer

valve to reduce flow until

a comfortable showering

or bathing temperature is

achieved

The temperature of the

hot water cylinder is too

low

Water flow through the

hot water appliance is

too fast

Water output is

not hot enough

Flow rate is poor

and water

temperature is

low Check the pipework is laid

out in accordance with

correct practices, paying

particular attention to

potential air-traps

Airlock in the hot

water supply (gravity

or pumped systems

only)

Water temperature

swings regularly

between hot and

cold

Cold water pressure

is too high

If the static water pressure

exceeds 10 bar, install a

pressure reducing valve

(PRV) in accordance with

the installation guide

Poor flow rate Twisted hose

Debris in shower head

Debris in filters

Check for debris and clear

as necessary

SYMPTOM POSSIBLE CAUSE ACTION

Unbalanced supplies Check both sources are

equal pressures

TROUBLE SHOOTING GUIDE

Aqualisa Products Limited

The Flyers Way

Westerham Kent TN16 1DE

Customer Services: 01959 560010

Warranty registration: 0800 408 4243

Brochure hotline: 0800 652 3669

Website: www.aqualisa.co.uk

Live Chat at aqualisa.co.uk

Email: [email protected]

Republic of Ireland

Sales enquiries: 01-864-3363

Service enquiries: 01-844-3212

Follow us on:

Please note that calls may be recorded for training

and quality purposes.

The company reserves the right to alter, change or

modify the product specifications without prior warning.

® Registered Trademark Aqualisa Products Limited.

Did you know we oer free

installer training?

• Locations across the UK

• Expert installation advice

• Deals on the day

Book your place!

aqualisa.co.uk/training

01959 560042

Part No.702935 Issue 01 Jan 17

Supply

Vent and draw-o

pipe to hot water

Hot water cylinder

Connect

‘A’ or ‘B’

Cold feed

to cylinder

B

A

NB: THE BASE OF THE QUARTZTM

SMART VALVE MUST BE SITED NO

HIGHER THAN THE BASE LEVEL

OF THE CISTERN

10m

max

smart

shower

control

Supply

Pressure

reducing valve

if required

10m

max

smart

shower

control

Supply

Hot water

cylinder

10m

max

smart

shower

control

10m

max

smart

shower

control

Central

heating

boiler

Supply

Supply

Vent and draw-o

pipe to hot water

Underside of cistern

Hot water

cylinder NB: 1.5 bar MINIMUM pump rating

Cold feed

to cylinder

Connect

‘A’ or ‘B’

B

A

10m

max

smart

shower

control

Typical gravity system installation

(compatible with pumped Quartz smart valve)

Typical combination boiler installation

(compatible with standard QuartzTM smart valve)

Typical UHW system installation

(compatible with standard QuartzTM smart valve)

Typical thermal storage unit system installation

(compatible with standard QuartzTM smart valve)

Typical pumped system installation

(compatible with standard QuartzTM smart valve)

TM

IMPORTANT INFORMATION

Safety information

This product must be installed by a competent person in accordance with all relevant current Water Supply Regulations.

ALL PRODUCTS REQUIRING AN ELECTRICAL CONNECTI0N MUST BE INSTALLED BY A QUALIFIED PERSON FOLLOWING THE LATEST REVISION OF BS 7671

(WIRING REGULATIONS) AND CERTIFIED TO CURRENT BUILDING REGULATIONS.

This system should be installed so that other taps or appliances operated elsewhere within the premises do not significantly aect the flow.

The QuartzTM smart valve must not be used with a hot water supply temperature of over 65ºC.

The QuartzTM smart valve is supplied factory pre-set at maximum temperature of 45ºC. The maximum temperature is fully adjustable to suit site conditions. If adjusted, we

recommend the outlet temperature is set to a MAXIMUM of 46ºC.

The QuartzTM smart valve must be installed in an accessible location for servicing and maintenance.

The QuartzTM smart valve must not be installed in situations where either the ambient temperature is likely to exceed 40ºC or where freezing may occur.

The QTM controller must not be installed in situations where the ambient temperature is likely to fall below 5ºC or rise above 40ºC.

We do not recommend the use of smart controls in steam therapy facilities.

This appliance must be earthed.

Cables which are chased into the wall must be protected by a suitably sized conduit or sheathing to allow for removal in the event of service and maintenance purposes.

Ensure that the conduit is run to avoid the controller fixing holes.

Surface mounted cables must also be protected by a suitable approved conduit, even in a loft, where there may be a risk of damage from vermin.

The power lead must only be replaced by the manufacturer or his accredited agent.

The QTM controller is supplied from a safety low voltage source.

This product is suitable for domestic use only.

Aqualisa smart products are supplied complete with a 1 year guarantee that can be upgraded to 5 years by registering the product with Aqualisa.

This product is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities or lack of experience and knowledge, unless they have

been given initial supervision or instruction concerning the use of the product by a person responsible for their safety.

Children should be supervised to ensure they do not play with the product.

Installation of QuartzTM smart valve (for gravity stored systems)

The QuartzTM smart valve is designed to operate up to maximum static pressure of 100kPa ((1 bar)(10 metres head)(14.5psi)). Under no circumstances must the QuartzTM smart

valve be connected directly to the water main or in line with another booster pump. The minimum actual capacity of the cold water storage cistern should be not less than 225

litres (50 gallons). The capacity of the hot water cylinder must be capable of meeting anticipated demand.

Installation of the QuartzTM smart valve (for balanced high pressure and unvented systems, combination boiler systems and separately pumped gravity

systems)

Pressures: The QuartzTM smart valve is designed to operate up to a maximum static pressure of 700kPa ((7 bar)(100psi)). Where pressures are likely to exceed 700kPa ((7 bar)

(100psi)), a pressure reducing valve must be fitted to the incoming mains supply. A setting of 400kPa ((4 bar)(60psi)) is recommended. It should be noted that daytime pressures

approaching 600kPa ((6 bar)(80psi)) can rise above the stated maximum overnight.

Special notes for combination boiler systems

The appliance must have a minimum domestic hot water rating of 24kW (80,000BTU) and be of the type fitted with a fully modulating gas valve.

If in any doubt, please contact the appliance manufacturer before installation commences.

PLEASE NOTE: DUE TO PERFORMANCE CHARACTERISTICS OF COMBINATION BOILERS, SEASONAL INLET TEMPERATURE CHANGE WILL AFFECT THE QUARTZTM SMART

VALVE OUTLET FLOW RATE RESULTING IN VARYING SHOWER FLOW RATE AND FLOW CONTROL RANGE. INLET TEMPERATURE CHANGE MAY ALSO CAUSE THE

TEMPERATURE DISPLAY TO FLASH; THIS IS NOT NECESSARILY CHANGING THE OUTLET TEMPERATURE.

Special notes for separately pumped gravity systems, Universal pumps/divert

We recommend a twin ended pump with a MINIMUM pump rating of 1.5 bar (recommended 2.5 bar) which should be used for all separately pumped installations.

A twin ended pump is required for use with single outlet smart products, with the exception of divert models.

PLEASE NOTE: A Universal type twin ended pump (works on both positive and negitive head conditions) is required for use with divert products.

The minimum actual capacity of the cold water storage cistern should be not less than 225 litres (50 gallons). The capacity of the hot water cylinder must be capable of

meeting the anticipated demand.

THIS PRODUCT IS NOT SUITABLE FOR USE WITH A SINGLE ENDED PUMP.

Connections

This product incorporates ‘push-fit’ type connections. Tube should be cut using a rotary type cutter and lubricated using a silicone-based lubricant or petroleum jelly (Vaseline or

similar) prior to insertion into the fitting.

If plastic pipe is used, the tube insert must not increase the tube diameter or extend the cut-o length by more than 2mm.

THESE FITTINGS ARE NOT SUITABLE FOR STAINLESS STEEL TUBE. COMPRESSION FITTINGS MUST NOT BE USED.

Pipe sizing

Long pipe runs, on both inlet and outlet, will reduce the flow rate at the outlet, for gravity or gravity pumped systems 22mm pipe work should be used on inlets and reduce down

to 15mm as close to the QTM smart valve as possible to reduce pressure losses and help maintain flow rate. If using 15mm pipe, copper pipe is preferred, to optimise performance

minimise the number of elbows used. If long pipe runs are unavoidable on the outlet, use copper pipe rather than plastic, particularly if a diverter is used, and minimise the number

of elbows as the pipe inserts are very restrictive.

Flushing

Some modern fluxes can be very corrosive and, if left in contact, will attack the working parts of this unit. All soldering must be completed and the pipe work thoroughly flushed

out in accordance with current Water Supply Regulations prior to connection of the product.

Declaration of Conformity

Aqualisa Products Limited declares that the QuartzTM smart valve, in conjunction with the diverter and smart controllers, complies with the essential requirements and other

relevant provisions of the Low Voltage Directive (2014/35/EU) and the EMC Directive (2014/30/EU) and the RE Directive (2014/53/EU.

After installation

Familiarise the end user with the smart operation and hand them this guide. Complete and post the guarantee card or register online at www.aqualisa.co.uk

•

!

•

!

QUARTZTM SMART VALVE

AND DIVERTER

INSTALLATION GUIDE

Aqualisa Products Limited

The Flyers Way

Westerham Kent TN16 1DE

Customer Services: 01959 560010

Warranty registration: 0800 408 4243

Brochure hotline: 0800 652 3669

Website: www.aqualisa.co.uk

Live Chat at aqualisa.co.uk

Email: [email protected]

Republic of Ireland

Sales enquiries: 01-864-3363

Service enquiries: 01-844-3212

Follow us on:

Please note that calls may be recorded for training

and quality purposes.

The company reserves the right to alter, change or

modify the product specifications without prior warning.

® Registered Trademark Aqualisa Products Limited.

Did you know we oer free

installer training?

• Locations across the UK

• Expert installation advice

• Deals on the day

Book your place!

aqualisa.co.uk/training

01959 560042

Part No.703213 Issue 01 Jan 17

QUARTZTM SMART VALVE AND DIVERTER

1To ensure safe operation and installation of this product, the QuartzTM smart valve and

diverter MUST be installed in one of the orientations shown.

PLEASE NOTE: If installing a diverter please also note all areas marked with this symbol.

INSTALLATION

•

•

For installation with the diverter.

2Isolation valves are supplied with the QuartzTM smart valve and

diverter valve and must be fitted on both inlets and the blended

water outlet/ outlets. For optimum performance on gravity fed

systems 22mm pipe work should be run as close to the QuartzTM

smart valve as possible before reducing down to 15mm. All pipe

work should be supported.

The inlet supply centres are 48mm.

Please note arrow on isolation valve to indicate direction of flow.

DO NOT use compression fittings on the inlet and outlet spigots this will aect the

warranty if fitted.

3Choose the position for your QuartzTM smart valve as close to the shower control as possible.

The QuartzTM smart valve may be sited in the roof space above the proposed shower site, in the

airing cupboard or behind a screwed bath panel if more convenient. If siting in the roof space,

ensure that freezing cannot occur and that no insulation material is placed under or over the

QTM smart valve or diverter. Please refer to the system layout.

•

If installing a diverter, choose the position for the QuartzTM smart valve as close to the

diverter as possible, within the range of the 2m connecting data cable provided.

4Place the QuartzTM smart valve on a solid mounting surface, and

place the fixing feet into suitable positions. Mark then drill and

prepare suitable fixings before securing the QuartzTM smart valve

to the mounting surface using the screws provided, (if suitable).

•

If installing the diverter this also needs to be installed as per the

above instructions in step 4

5Flush through both hot and cold supply pipes.

The maximum hot water inlet temperature must be no more than 65˚C.

6Attach the supply pipes to the QuartzTM smart valve, ensuring that

the cold and hot feeds are fitted into the appropriately marked

inlets.

Do not solder near to plastic components.

7Prepare and connect a pipe from the mixed water outlet on the

QuartzTM smart valve through the wall to the proposed siting for

the shower outlet.

Using pipe clips as appropriate, ensure that all pipe work is

perpendicular to the QuartzTM smart valve, i.e. not putting any

strain on the fittings.

•

If installing a diverter prepare and connect the pipe from the mixed water outlet on the QTM

smart valve through to the diverter inlet. The diverter can be fitted directly onto to the

QTM smart valve outlet if required on the HP/Combi system installation. A cranked M/F elbow

is supplied for the Gravity Pumped system for ease of installation. Refer to images in point 1.

•

Ensure the isolation valves are connected to the diverter outlets with the arrows correctly

aligned according to the direction of flow. Using pipe clips as appropriate, ensure that all pipe

work is perpendicular to the QuartzTM smart valve and diverter, i.e. not putting any str

ain on the fittings.

Prepare and connect the pipes from the diverter outlets to the proposed siting for the outlets.

To maximise flow rates we recommend using copper pipe with the minimum amount of

elbows on all pipes leading to and from the QuartzTM smart valve.

Ensure the pipe work connections have been flushed through.

If fitting a bath outlet, a suitable non restrictive double check valve (not supplied) MUST be

fitted to the blended outlet pipe in line with the current water regulations.

BEFORE ANY ELECTRICAL ADJUSTMENT IS ATTEMPTED, THE ELECTRICITYSUPPLY MUST BE

TURNED OFF AT THE MAINS SWITCH.

ELECTRICAL INSTALLATION MAY ONLY BE CARRIED OUT BY A QUALIFIED PERSON.

•

!

8Unscrew the single fixing on top of the QuartzTM smart valve and

carefully tilt the lid up and o the location lugs and pull the lid clear.

•

If installing the diverter also remove the lid following the

instructions above in step 8.

9As installation diers for dierent controls please refer to the relevant smart controller

installation guide for the QuartzTM smart valve and diverter wiring.

10 Connect the QuartzTM smart valve power lead to a double pole 3

amp fuse switched spur incorporated in the fixed wiring circuit, in

accordance with current wiring rules. Ensure that this is located

in an accessible, dry location and not in the bathroom.

THIS APPLIANCE MUST BE EARTHED

We recommend protecting surface mounted cables in suitable approved conduit to avoid the risk of

damage from vermin.

The power lead should also be clipped in place with ‘P’ clips or similar to avoid accidents.

•

!

11 The QTM smart valves are supplied factory set with the flow rate at

either ‘NORMAL HP’ or ‘NORMAL GRAVITY’ mode depending on

which system has been ordered.

BALANCED HP SYSTEMS:

Standard QTM smart valves fitted to balanced high pressure sys-

tems may be set to ‘NORMAL HP’ or for water economy ‘ECO’

modes.

STANDARD COMBINATION BOILER SYSTEMS:

For Standard QuartzTM smart valves installed on combi boiler

systems, for optimum performance we recommend setting to the

‘COMBI’ mode.

The ‘ECO’ flow rate mode should NOT be selected for shower or bath systems fitted

to combination boilers.

PUMPED QUARTZTM SMART VALVE:

Pumped QuartzTM smart valves are fitted to gravity systems may be set to ‘NORMAL

GRAVITY’ or for water economy ‘ECO’ modes.

When making any adjustment to the QuartzTM smart valve settings the power must

be isolated.

12 Run the shower at maximum temperature (factory pre set to

45ºC). If required, maximum temperature adjustment can be

made with a flat bladed screwdriver using the ‘MAX TEMP

ADJUSTMENT’ control as indicated. When the temperature

has been set to the desired position, carefully replace the

QuartzTM smart valve lid and secure the fixing screw, hand

tight only.

Site conditions can aect temperature settings, installer to adjust as required.

All copper pipe work must be cross-bonded and connected to a reliable earthing point.

13 Please refer to the separate QTM controller installation guide to complete installation.

QuartzTM smart valve connected

directly to diverter valve

QuartzTM smart valve connected to

diverter with additional pipe

QuartzTM smart valve connected

directly to diverter valve

QuartzTM smart valve connected

to diverter with additional pipe

HP/Combi QuartzTM smart valve

Gravity pumped QuartzTM smart valve

This product must be installed by a competent person in accordance with the relevant

current Water Supply Regulations.

In addition to the guide below it is essential that the written instructions overleaf are read

and understood and that you have all the necessary components (shown bottom right)

before commencing installation.

The QuartzTM smart valves are supplied with universal fixings intended to secure it to a

solid mounting surface.

•

!

•

!

The QuartzTM smart valve and diverter must be sited in a position that is safely accesible

for servicing and commissioning purposes. When fitted in the loft space, the route to and

the area around the QuartzTM smart valve must be boarded to ensure a safe working

environment.

The optimum position for the QuartzTM smart valve and diverter is in the roof space above

the QTM controller site to take full advantage of the ease and speed of installation.

The distance between the QuartzTM smart valve and main QTM controller must be within the

range of the 10m data cable supplied.

The diverter inlet has been designed to enable connection directly inline with the HP/

Combi QuartzTM smart valve outlet isolation valve connection or o the Gravity Pumped

QuartzTM smart valve outlet using the cranked M/F elbow connection fitting.

)

. .

•

!

•

!

•

!

•

!

•

!

•

!

Single outlet

Components (Gravity pumped) Components (HP/Combi)

Components (Gravity pumped) Components (HP/Combi)

Single outlet

With diverter With diverter

265mm

70mm

350mm

270mm

445mm

445mm

270mm

Max 2m

Max 2m

197mm

240mm

70mm

WAKE-UP TEMPERATURESTART SHOWERING FLOW OUTLET

is intuitive and easy to use,

as you’ll see from our Quick Start guide.

To get the most out of your Aqualisa QTM

shower, please read the full User Guide.

Simple, smart

showering

Turn over to get

more from your

If you would like more Quick Start guides,

or for any other queries, please visit

aqualisa.co.uk/q

Approach your Q™controller, or touch

the power symbol until the screen wakes up.

The Q™controller has a proximity sensor,

so the display wakes up and is ready to go.

Push the Q™lever to start the shower.

The Get Ready screen will appear on the display,

as soon as the lever is pushed.

Turn the Q™bezel to adjust temperature.

You can adjust the temperature at

any time, before or during showering.

Push and hold the Q™lever to divert.

If you have a divert model, you can alternate between

outlets by pushing and holding the Q™lever, then

releasing when the desired outlet is displayed.

This can be selected as you start, or during your shower.

Move the Q™lever left or right to adjust the flow.

You can adjust the flow at any time during

showering, from the Home screen.

HOME TIMERMY QTM SETTINGS RETURN TO HOME

Menus

aqualisa.co.uk/q

Q4307 Part No 703210 Rev03 July17 Quick Start

Push the QTM lever to enter MY Q™.

Then move the lever left or right to choose from a range of

experiences (eg. SPORT or ECO), or create your own personal profile.

If the shower is running this is the Home screen.

From here push and release the Q™lever to enter Menus.

If the shower is o, you will not need to push the Q™lever;

simply move the Q™lever left or right to browse Menus.

Push the Q™lever to enter Timer.

Then adjust the timer by moving the

Q™lever left or right.

Push the Q™lever to enter Settings.

Then move the Q™lever left or right to browse

the settings. Push again to adjust a setting.

Push the Q™lever to return to the Home screen,

or simply rotate the temperature bezel.

NOTE: Rotating the temperature bezel at any point in menus

or settings will return you to the Home screen.

User Guide

Other manuals for Q

2

Table of contents

Other Aqualisa Controllers manuals