ARB 3917140 User manual

24-04-13 Page 1 of 12 3786417

If you have any queries regarding the installation of this productplease contactthe distributor from whom it was purchased, oralternatively the ARB office in your state.

Head Office – ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

WA:(08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

ARB WINCH/NON WINCH BUMPER TO SUIT 08/2004

ONWARDS NISSAN GU PATROL

PRODUCT NO: 3917140

5100050 Top Tube Kit

5100160 Buffer Kit – With hole (required when fitting Top Tube)

5100170 Buffer Kit – With no hole

FITTING KIT NO: 6172355

WARNING

FOR VEHICLES EQUIPPED WITH SRS AIRBAG

WHEN INSTALLED IN ACCORDANCE WITH THESE INSTRUCTIONS, THE FRONT

PROTECTION BAR DOES NOT AFFECT OPERATION OF THE SRS AIRBAG.

TAKE NOTE OF THE FOLLOWING:

•THIS PRODUCT MUST BE INSTALLED EXACTLY AS PER THESE INSTRUCTIONS

USING ONLY THE HARDWARE SUPPLIED.

•IN THE EVENT OF DAMAGE TO ANY BULL BAR COMPONENT, CONTACT YOUR

NEAREST AUTHORISED ARB STOCKIST. REPAIRS OR MODIFICATIONS TO THE

IMPACT ABSORPTION SYSTEM MUST NOT BE ATTEMPTED.

•DO NOT USE THIS PRODUCT FOR ANY VEHICLE MAKE OR MODEL, OTHER THAN

THOSE SPECIFIED BY ARB.

•DO NOT REMOVE LABELS FROM THIS BULL BAR.

OPTIONAL LIGHT SETS TO SUIT THIS PRODUCT:

- ARB 6821201 Fog Light Kit Suit 3163015

- Up to IPF 900 SERIES FOG OR DRIVING LIGHT SETS

IMPORTANT

This winch bumper is suitable only for Warn winches up to 9500lb.

24-04-13 Page 2 of 12 3786417

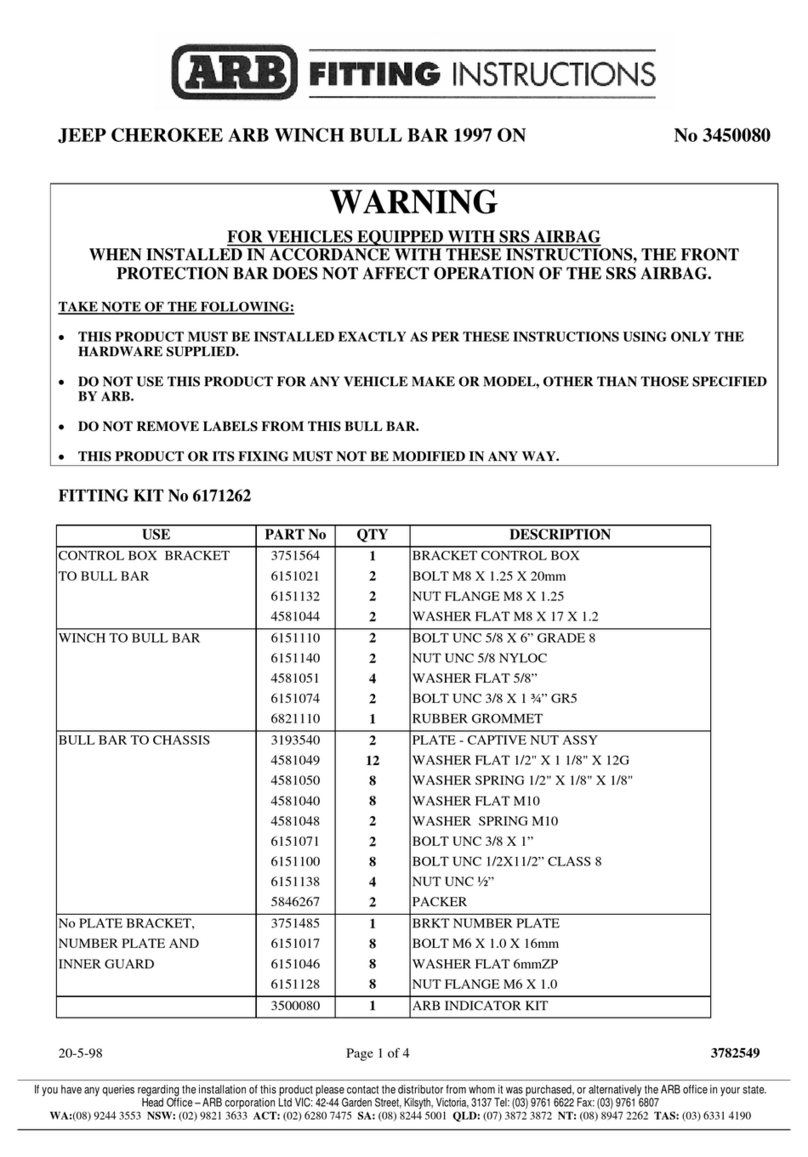

USE.

PART NO.

QTY.

DESCRIPTION

CHASSIS BRACKETS TO

CHASSIS

4581088

2

Chassis rail extension adjuster bolt

6151096

7

Bolt M12 x 1.25 x 40mm

6151095

1

Bolt M12 x 1.25 x 35mm

6151135

2

Nut M12 x 1.25

6151189

2

Nut M12 x 1.75

4581049

2

Washer M12 Flat

4581050

8

Washer M12 Spring

4581007

8

Washer 13mm Heavy duty

4581008

2

Washer 13mm Offset heavy duty

6151087

2

Bolt M10 x 1.25 x 25mm

6151133

2

Nut M10 x 1.25

4581040

4

Washer M10 Flat

4581048

2

Washer M10 Spring

BULL BAR TO CHASSIS

BRACKETS

3756395L

1

Chassis bracket LHS

3756395R

1

Chassis bracket RHS

6151135

4

Nut M12 x 1.25

6151095

4

Bolt M12 x 1.25 x 35mm

4581050

4

Washer Spring M12

4581071

4

Washer shoulder M12

4581070

8

Washer Flat M12

TOP TUBE TO BAR

(5100050)

6131516

1

Top Tube assembly

6151255

2

Bolt M12 x 1.75 x 40mm

4581049

2

Washer M12 Flat

4581050

2

Washer M12 Spring

BUFFERS

(5100160 Required if fitting Top

Tube)

6151128

12

Flange nut M6

3162153

1

Buffer LH

3162154

1

Buffer RH

BUFFERS

(5100170

Required if not fitting Top Tube)

6151128

12

Flange nut M6

3162471L

1

Buffer LH

3162471R

1

Buffer RH

WINCH COVER

6522030

1

Panel winch cover

6151256

2

Button head screw M6 x 16mm

4581304

2

Washer flat M6 S/S

6151128

2

Flange nut M6

6191005

1

Winch cover extrusion

INDICATORS TO BULL BAR

3163015

1

Combination Light Surround Kit

180701

6

Scotch lock

6821152

2

Turn signal/clearance light loom

6821151L

1

TURN SIGNAL/CLEARANCE LIGHT

6821151R

1

TURN SIGNAL/CLEARANCE LIGHT

24-04-13 Page 3 of 12 3786417

USE.

PART NO.

QTY.

DESCRIPTION

NO. PLATE

6151017

2

Bolt M6 x 16mm

6151046

2

Washer flat M6

6151128

2

Flange nut M6

6781408

1

Double sided tape

AIR DEFLECTOR

6522873

1

Air deflector front

3314852

1

Air deflector extension

6151017

10

Bolt M6 x 16mm

6151046

10

Washer flat M6

6151128

7

Flange nut M6

6151315

3

Cage nut M6

WINCH FITMENT

3756499

1

Control box bracket

6151020

2

Bolt M8 x 16mm

4581044

2

Washer flat M8

6151132

2

Flange nut M8

4581040

4

Washer flat 3/8”

6151074

4

Bolt UNC 3/8” x 1 ¾”

BLB 560

3

Winch lead 560mm black

EG50

2

Rubber grommet

180302

10

Cable ties

AERIAL

3162152

2

CB aerial cap

TOOLS REQUIRED.

Basic tool kit: torque wrench, drill, 10mm drill bit, stepped ring spanners.

24-04-13 Page 4 of 12 3786417

BULL BAR PREPARATION

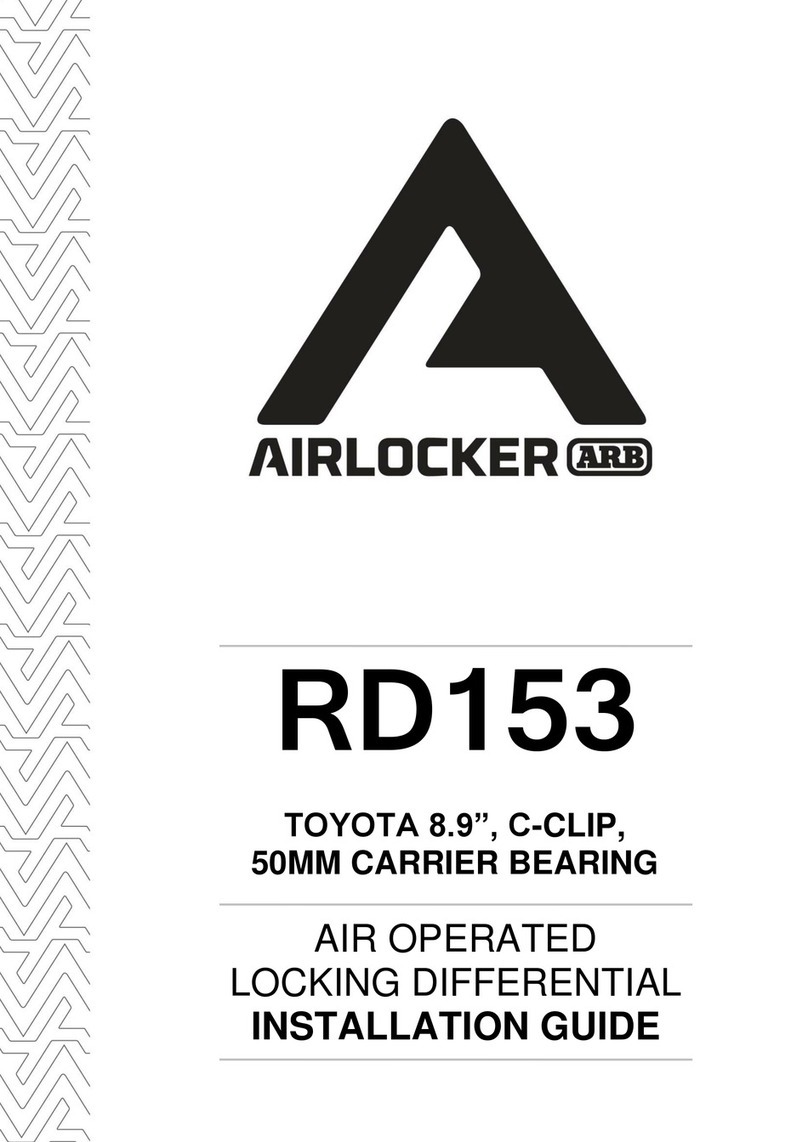

1. Assemble the two chassis brackets to

the bull bar using two per side, M12 x

35mm bolts, heavy duty D washers,

shoulder washers, heavy duty D

washers, spring washers and nuts.

2. Position the impact absorbers centrally

on the upright slots. These slots were

provided to accommodate chassis height

variations.

3. Tighten the bolts firmly; though do not

fully tighten as they may be adjusted at

step 31.

4. Rest the bar face down on two stands so

assembly can be carried out.

5. Assemble a 12mm nut to each chassis

rail extension adjuster bolt and fully

screw into bull bar.

6. Do not tighten, as this will be adjusted

later.

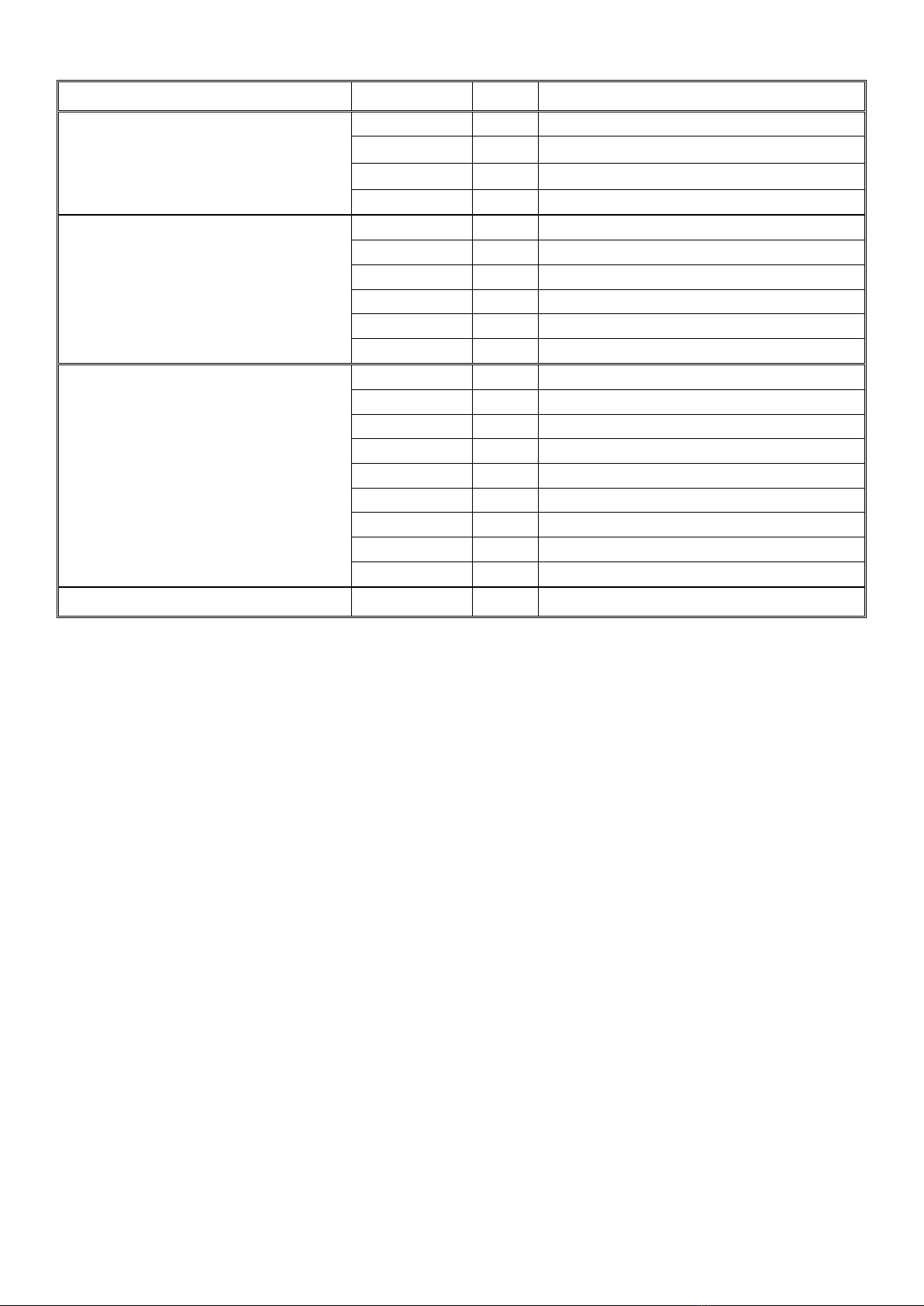

1. Fit the buffers. Buffer studs fit through

the slots in the wings and the pan.

Fasten using M6 flange nuts.

Note: This applies to both blank buffers and

for those with the hole for optional frame.

CAUTION: DO NOT OVER TIGHTEN THE M6

NUTS AS YOU RISK PULLING THE STUDS

OUT OF THE BUFFERS.

Chassis Rail Extension

Adjuster Bolt

(Wind Fully In)

Bull Bar

Bolt M12x35m

Washer 12mm

Shoulder Washer

Nut M12

Washer 12mm

Spring Washer

Bull Bar Upright (RHS)

Chassis Bracket (RHS)

24-04-13 Page 5 of 12 3786417

WINCH FITMENT

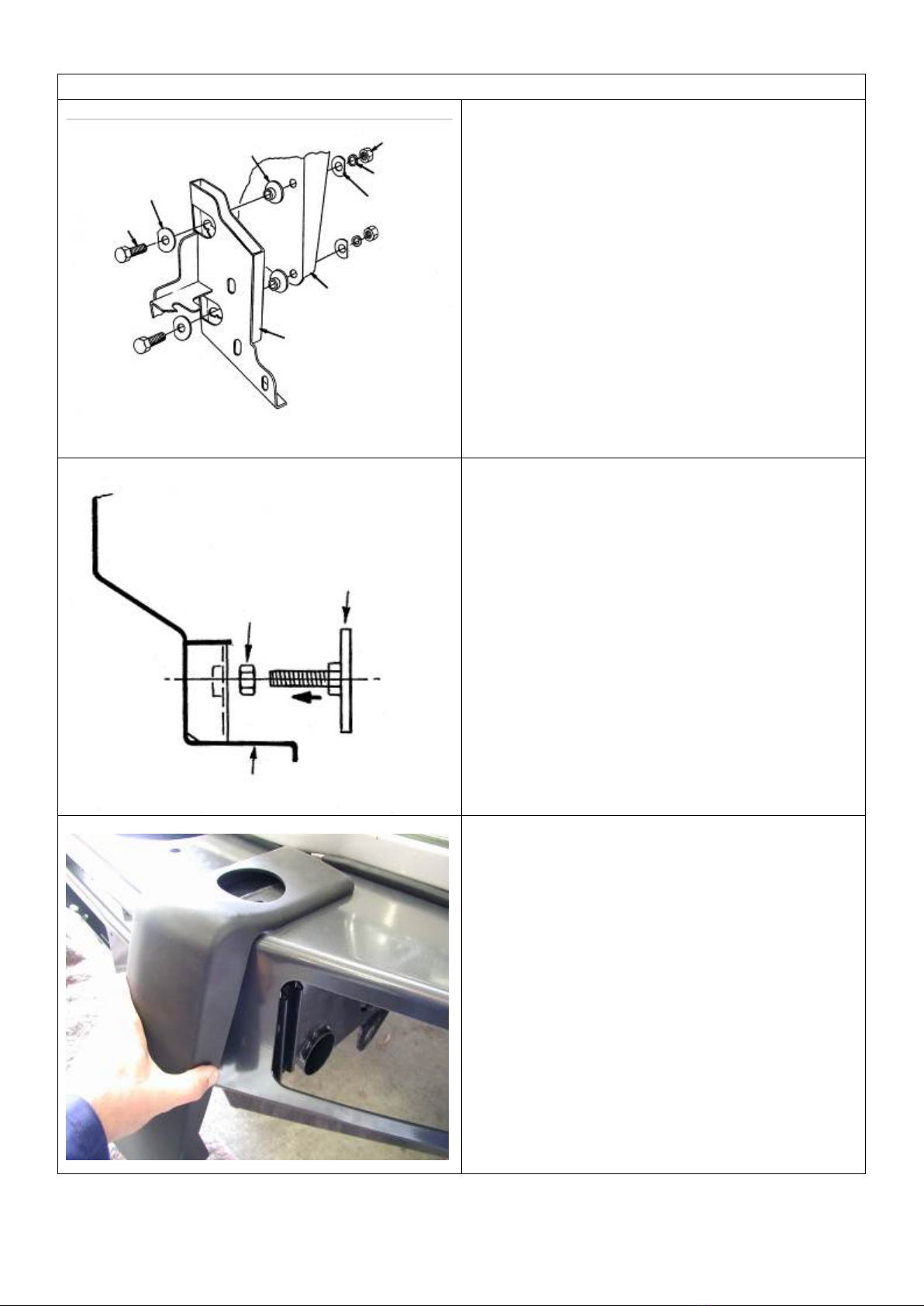

7. For ease of access the winch gearbox

handle needs to be rotated. To do this,

first undo all the cap screws and

carefully lift the gearbox clear of the

winch body so as not to damage the

gasket. (Do not lift the gearbox more

than a couple of millimetres) Rotate

the gearbox 144° anti clockwise. Re-fit

the caps-crews.

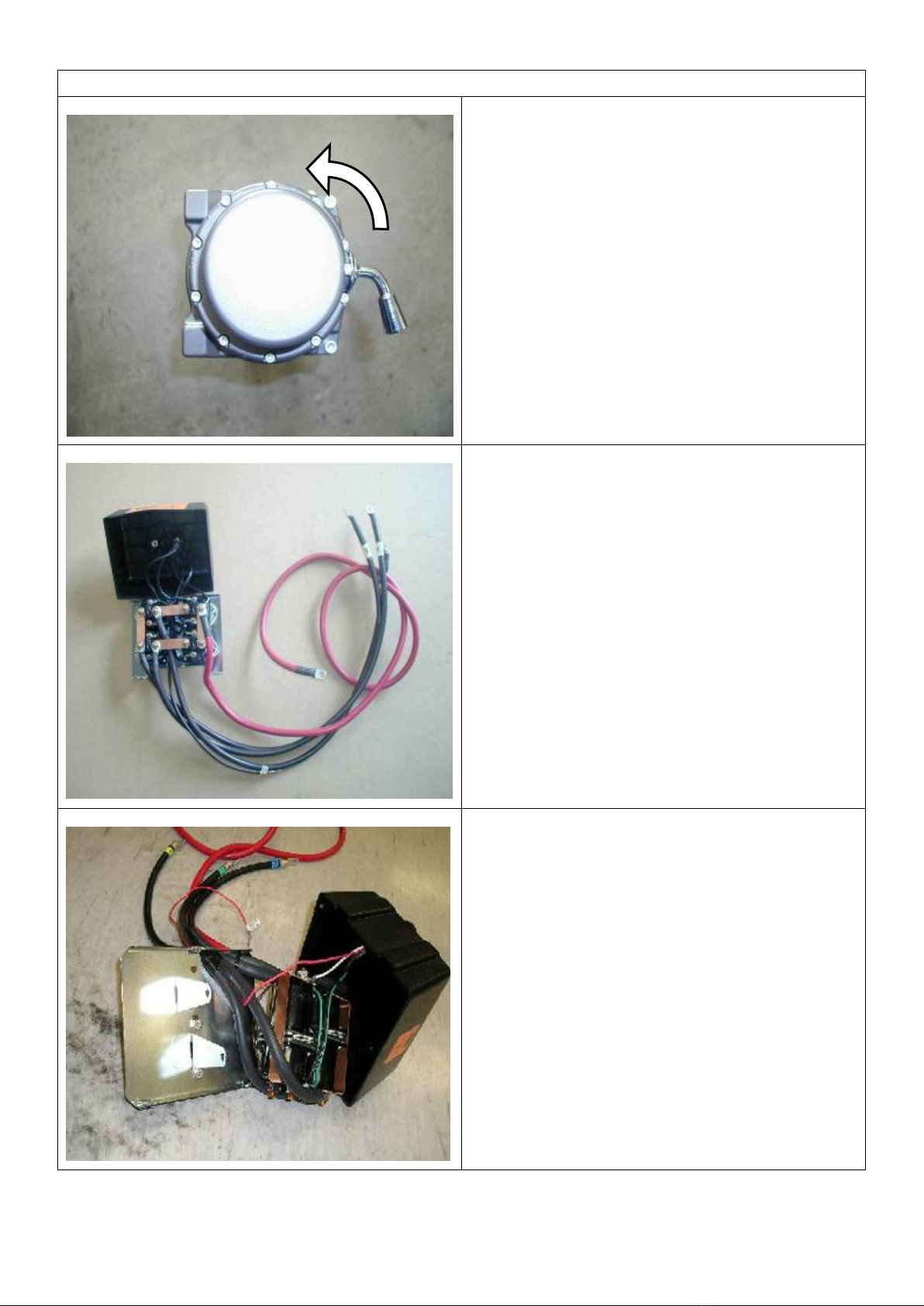

8. Remove the cover from the control box.

9. The three main power cables that go

from winch to control box must be

changed over using longer cables from

bolt kit. Make sure that you identify the

colour codes on the new cables before

re-fitting the control box cover.

NOTE: This must be done for whatever

winch is to be fitted to the bull bar.

10. If fitting the XP 9.5 winch, remove the

cover from the control box. Remove the

two cap screws, nuts and spacer

washers that hold the four solenoids in

place.

11. Remove the four solenoids from the

base of the control box using the copper

bus bar as an aid and hold to one side.

24-04-13 Page 6 of 12 3786417

12. Remove the two bolts in the base of the

control box and reposition them into the

more centralised holes.

13.

Replace the 4 solenoids, making sure

they line up with the holes in the base.

14.

Replace the 2 cap screws, washers and

nuts removed in step 13 above into

original holes.

15. Replace the black cover and refit the

three cover screws. (DO NOT OVER

TIGHTEN)

16.

Bolt the control box bracket to the

control box.

17. Fit the two grommets into the round

holes then thread the cable through.

18. Mount the control box bracket onto the

top pan, using M8 bolts, flat washers

and flanged nuts. Use the cable ties to

ensure the winch cables are secure,

clear of moving parts and sharp edges

and tie them together.

24-04-13 Page 7 of 12 3786417

19. Place winch on a stand with mounting

holes facing upwards and lower bull bar

onto winch. Align all four holes and

secure using 1 ½” x 3/8” bolts on top

holes and 1 ¾” x 3/8” bolts on lower

holes, plus 3/8” spring and flat washers.

20.

When all bolts are fitted and finger tight,

centralize bolts in holes and tighten top

holes only, using a stepped ring spanner.

21. Remove lower bolts.

22. Fit roller fairlead into cutout and refit bolts

and tighten firmly.

23. Connect the winch control box cables to

the winch. Refer to Warn installation

instruction manual when wiring up winch.

Ensure that all cables are installed well

clear of all sharp or moving parts, by

using cables ties from bolt kit.

BULL BAR FITMENT

FUNCTION

INDICATOR

HARNESS

VEHICLE COMBINATION LAMP

RIGHT

LEFT

TURN LAMP

GREEN

GREEN / RED

GREEN / YELLOW

EARTH

BLACK

BLACK

BLACK

PARK LAMP

RED

BLUE/BLACK

BLUE/BLACK

24. Remove the splash guards attached to

the bumper and remove the bumper and

grille from vehicle.

25. Remove the vehicle’s head lamps and

wire the indicator looms provided in the

kit to the vehicle’s indicator loom using

scotch locks. Leave these new looms

hanging freely for easy access when the

bar is fitted.

26. Re-attach the vehicle’s head lamps and

grille.

24-04-13 Page 8 of 12 3786417

27. Before fitting the bull bar, using black

paint, paint the section between bull bar

wing and the bottom of the headlight.

28. Position the bull bar on top of the

chassis rails and bolt into place using

the M12 x 40mm bolts, heavy-duty

washers and spring washers.(Do not

tighten)

NOTE: Due to variations in the vehicle

chassis rails it may be necessary to place a

packer between the chassis rail top and the

bull bar. A heavy-duty washer is supplied

for this purpose.

29. Fit M12 x 40mm bolts, spring washers

and heavy-duty flat offset washers

through bull bar side mounting holes into

original bumper bar captive nut mounting

holes. (Do not Tighten)

24-04-13 Page 9 of 12 3786417

30. Fit M12 x 40mm bolt (passenger’s side)

& M12 x 35mm bolt (driver’s side), ½”

flat washers, heavy duty flat washers,

spring washers and 12mm nuts to lower

bull bar mounting holes and vehicle tie

down plates. (Do not Tighten)

NOTE: Insert bolt from outside of lower

mount holes so heavy-duty washer covers

large hole on tie down plate.

31. Adjust the bull bar to achieve a uniform

gap to the grill and mudguards. If

additional height adjustment is required,

the M12 bolts fitted at step 5 may be

loosened for additional adjustment.

32. Tighten all the fitted bolts, including

those fitted at step 5, to a torque of

77Nm or 80 ft-lb.

33. Once the bar is secured, using the

10mm holes in chassis bracket as

template, drill 10mm hole through side of

chassis and secure using M10 x 40mm

bolt, flat washers, spring washer and nut.

34. Wind each impact absorber adjuster bolt

out until it is firm against the chassis rail

extensions and tighten the lock nut.

24-04-13 Page 10 of 12 3786417

IF FITTING TOP TUBE

35. Push the tube through the holes in the

top of the buffer and fix using the M12 X

40mm bolts washers and spring

washers.

36. Assemble and install combination light

surrounds (p/n 3163015) as per instructions

no. 3786421 supplied with surround kit. Note:

Optional fog lamps can be installed at this

point as per fitting instruction no. 3783315

supplied with fog lamp kit no. 6821201.

Wire the combination lamp to the vehicles

indicator and clearance lamps.

Caution: Cable tie all cables together and keep

all cables clear of sharp edges and moving

parts.

NOTE:

Torque these M12 fasteners to

44Nm only (Critical)

24-04-13 Page 11 of 12 3786417

37. Fit three M6 cage nuts to the upper

deflector panel as shown on the left.

38. For non-4.8 litre petrol engine vehicles,

assemble the second deflector panel

using M6x16mm bolts, washers and

flange nuts as shown on the left.

39. 4.8 litre petrol engine vehicles only

require the upper panel to be fitted to the

vehicle.

40. Fit the air deflector / deflectors using M6

nuts and bolts.

41. Fit three M6x16 bolts and washers

through the front of the upper deflector

into the cage nuts previously installed.

42. Fit two M6x16 bolts through the two slots

on each side of the deflector. Use M6

washers and flange nuts to fasten the

deflector to the mating impact absorbers.

These slots are accessible through the

cut-outs in the deflector.

24-04-13 Page 12 of 12 3786417

43. If no winch is fitted to the bar, wrap

rubber extrusion around winch cover.

44. Place stainless steel washers over the

winch cover fixing holes located on the

top middle face of the winch bar.

45. Place the winch cover on top of the bar

inline with the mount holes. Bolt together

using the M6 button head stainless steel

screws and M6 nuts.

46. Place the double-sided tape along the

top edge of the licence plate. Fit number

plate to bar using M6x16 bolts, washers

and flange nuts. The two photos display

the number plate positions for winch and

non-winch bars.

47. There are two diameter 16 holes located

on the top face of the bar. If no CB

aerials are fitted the holes can be

covered with the plastic plugs provided in

the fitting kit.

48. When finished make sure all bolts are

tightened and that all wiring is clear of

hot, sharp and moving parts.

This manual suits for next models

3

Table of contents

Other ARB Automobile Accessories manuals

ARB

ARB AIRLOCKER RD109 User manual

ARB

ARB Flinders User manual

ARB

ARB AIRLOCKER RD136 User manual

ARB

ARB AIRLOCKER RD189 User manual

ARB

ARB Airlocker RD161 User manual

ARB

ARB Airlocker RD146 User manual

ARB

ARB AIRLOCKER RD156 User manual

ARB

ARB Airlocker RD167 User manual

ARB

ARB AIRLOCKER RD127 User manual

ARB

ARB AIRLOCKER RD142 User manual

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction