ARB AIRLOCKER RD216 User manual

Table of contents

Other ARB Automobile Accessories manuals

ARB

ARB Airlocker RD152 User manual

ARB

ARB Airlocker RD210 User manual

ARB

ARB 3444070 User manual

ARB

ARB Airlocker RD137 User manual

ARB

ARB ESPERANCE 802200 User manual

ARB

ARB 3424010 User manual

ARB

ARB 3434040 User manual

ARB

ARB LINX LX100 User manual

ARB

ARB 341 4480 User manual

ARB

ARB AIRLOCKER RD136 User manual

ARB

ARB Air Locker RD204 User manual

ARB

ARB Airlocker RD140 User manual

ARB

ARB AIRLOCKER RD153 User manual

ARB

ARB 3921120 User manual

ARB

ARB RD121 Operating and maintenance instructions

ARB

ARB AIRLOCKER RD188 User manual

ARB

ARB 3432050 User manual

ARB

ARB AIRLOCKER RD196 User manual

ARB

ARB 3917140 User manual

ARB

ARB Airlocker RD232 User manual

Popular Automobile Accessories manuals by other brands

Ricon

Ricon Activan ELECTRICAL AND PNEUMATIC CIRCUIT DIAGRAMS PLUS DIAGNOSTIC FLOW CHARTS

Prorack

Prorack K807 Fitting Instructions for Basic Carrier

Cruz

Cruz Alu-Cargo Assembly instructions

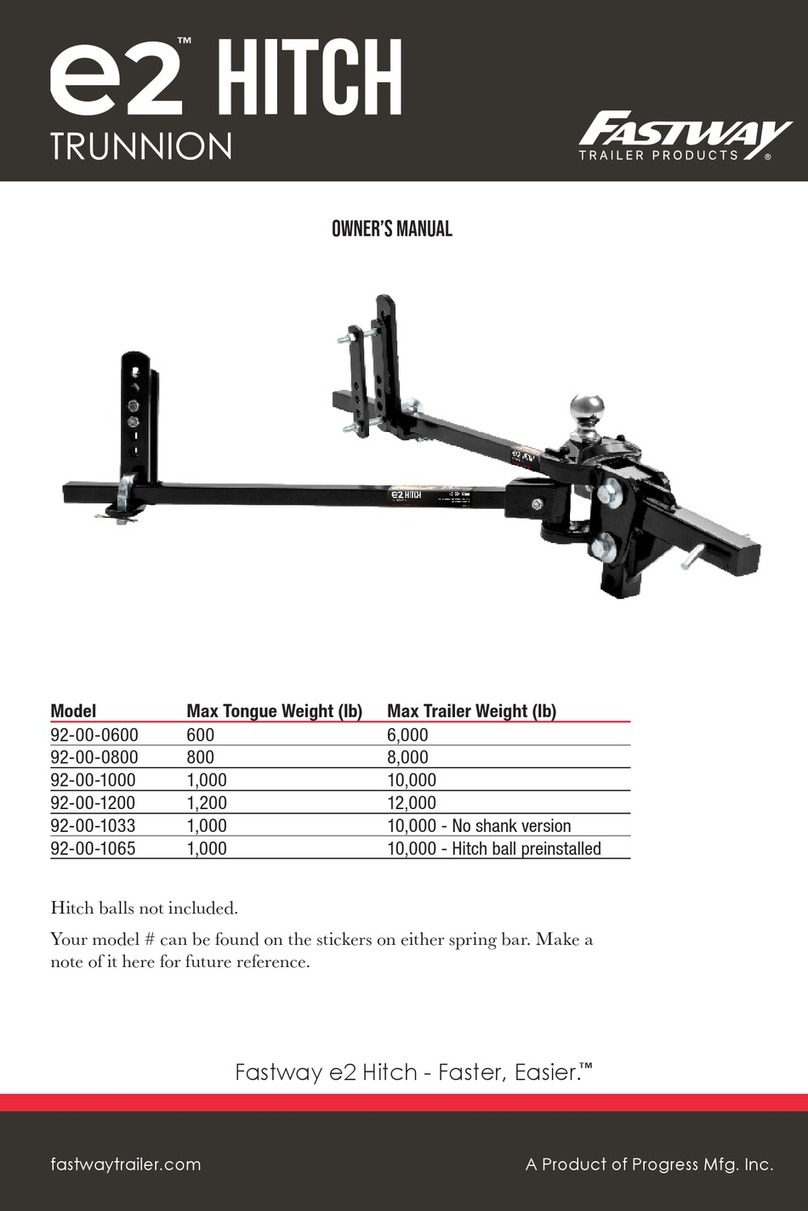

Progress

Progress FASTWAY e2 92-00-0600 owner's manual

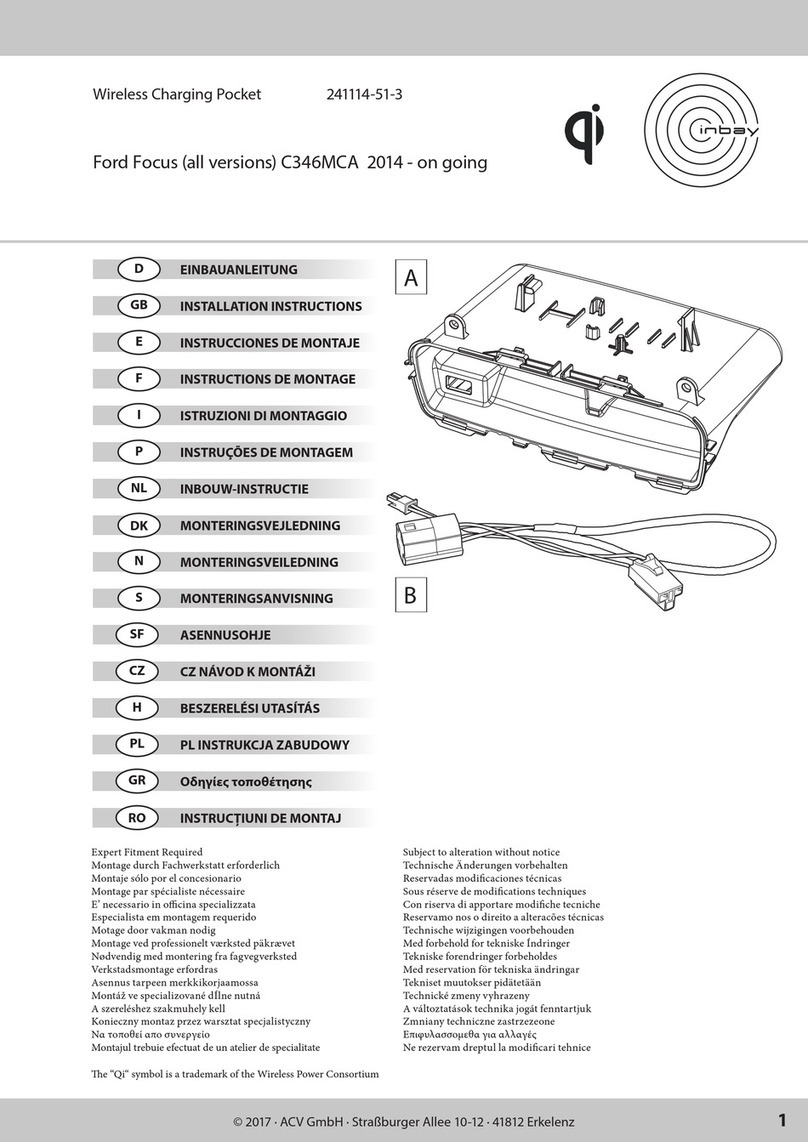

Inbay

Inbay 241114-51-3 installation instructions

RSi Smartcanopy

RSi Smartcanopy EVO Fitment Instructions