ARB 341 4460 User manual

05/10/11 Page 1 of 21 378 7983

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

Head Office – ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

WA: (08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

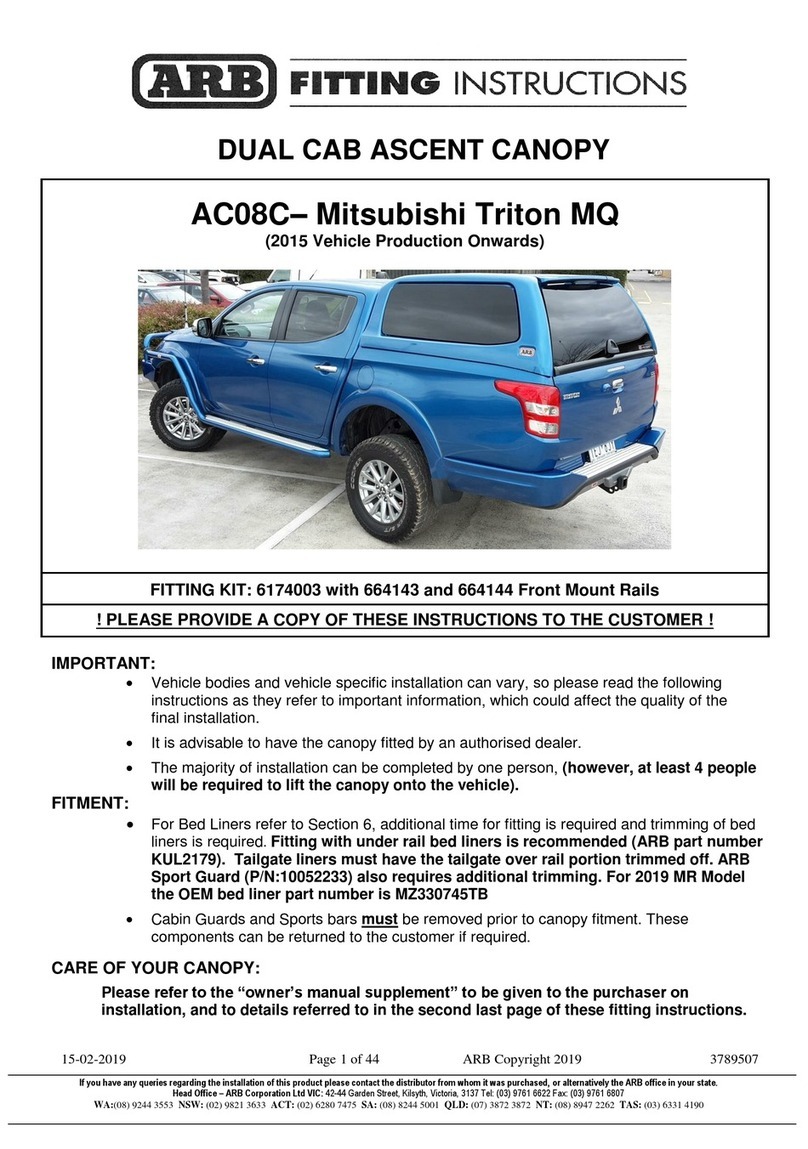

HILUX ARB BULL BAR, 2011 ONWARDS

(SRS AIR BAG EQUIPPED MODELS)

PRODUCT NUMBER: -

341 4460 - Winch Bull Bar, to suit flared vehicles only.

341 4450 – Winch Bull Bar to suit non-flared vehicles only.

321 4460 - Bull Bar Non Winch, to suit flared vehicles only.

321 4450 – Bull Bar Non Winch to suit non-flared vehicles only.

FITTING KIT: -

6173152 -To suit winch bull bars. (341 4450/60)

6173155 - To suit non-winch bars. (321 4450/60)

WARNING

NOTE THE FOLLOWING: -

♦This product must be installed exactly as per these instructions using only the hardware supplied.

♦In the event of damage to any bull bar component, contact your nearest authorised ARB stockist.

Repairs or modifications to the impact absorption system must not be attempted.

♦Do not use this product for any vehicle make or model, other than those specified by ARB.

♦Do not remove labels from this bull bar.

♦This product or its fixing must not be modified in any way.

♦The installation of this product may require the use of specialized tools and/or techniques

♦It is recommended that this product is only installed by trained personnel

♦These instructions are correct as at the publication date. ARB Corporation Ltd. cannot be held

responsible for the impact of any changes subsequently made by the vehicle manufacturer

♦During installation, it is the duty of the installer to check correct operation/clearances of all

components

♦Work safely at all times

♦Unless otherwise instructed, tighten fasteners to specified torque

05/10/11 Page 2 of 21 378 7983

GENERAL CARE AND

MAINTENANCE

By choosing an ARB Bar, you have bought a product that is one of the most sought after 4WD

products in the world. Your bar is a properly engineered, reliable, quality accessory that represents

excellent value. To keep your bar in original condition it is important to care and maintain it following

these recommendations:

Prior to exposure to the weather your bar should be treated to a Canuba based polish on all

exposed surfaces. It is recommended that this is performed on a six monthly basis or following

exposure to salt, mud, sand or other contaminants.

As part of any Pre Trip Preparation, or on an annual basis, it is recommended that a thorough

visual inspection of the bar is carried out, making sure that all bolts and other components are

torqued to the correct specification. Also check that all wiring sheaths, connectors, and fittings are

free of damage. Replace any components as necessary. This service can be performed by your

local authorized ARB Stockist.

HAVE AVAILABLE THESE SAFETY ITEMS WHEN FITTING PRODUCT: -

Protective eyewear Hearing protection

NOTE: ‘WARNING’ notes in the fitting procedure relate to OHS situations, where to avoid a

potentially hazardous situation it is suggested that protective safety gear be worn or a safe

work procedure be employed. If these notes and warnings are not heeded, injury may result.

FASTENER TORQUE SETTINGS: -

SIZE Torque Nm Torque lb/ft

M6 9Nm 4lbft

M8 22Nm 16lbft

M10 44Nm 32lbft

M12 77Nm 57lbft

05/10/11 Page 3 of 21 378 7983

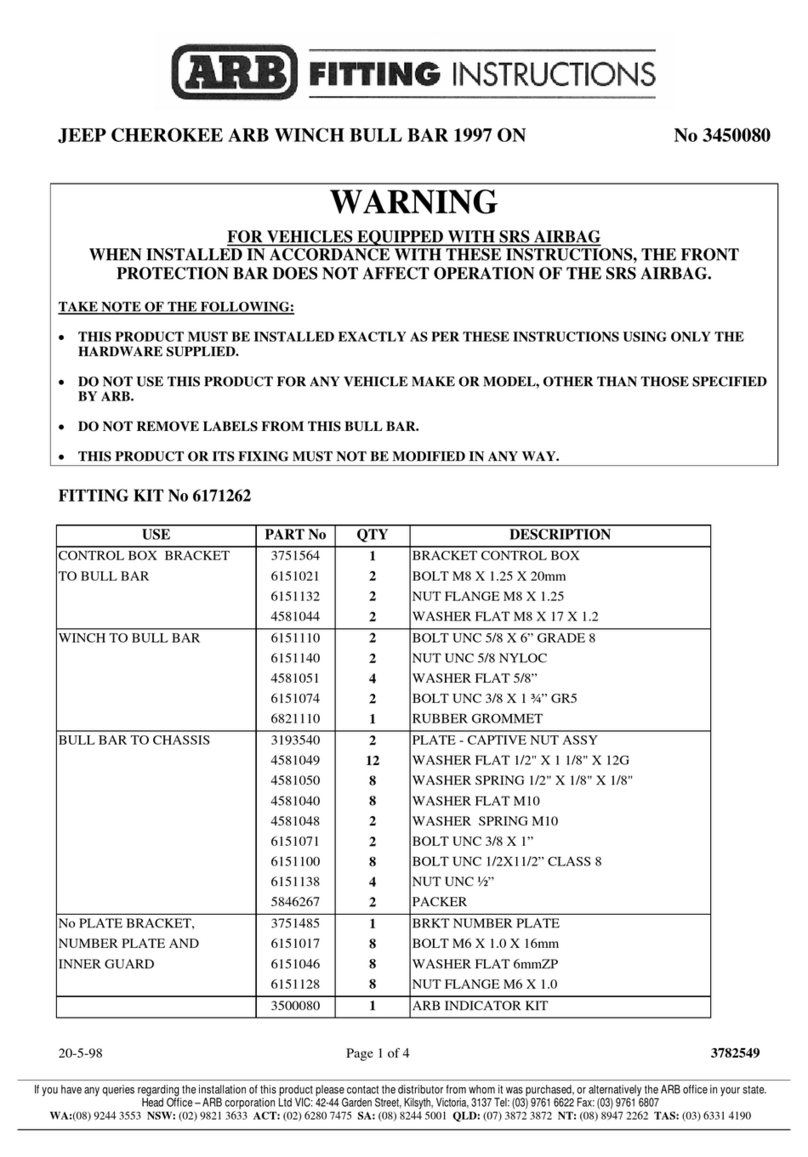

USE PART No QTY

DESCRIPTION

3756499 1 CONTROL BOX BRACKET

6151234 2 BOLT, M8 x 1.25 x 25 LONG (BLACK)

CONTROL BOX FITMENT 4581045 2 WASHER FLAT M8 (BLACK)

(WINCH ONLY) 6151132 2 NUT FLANGE M8

EG50 2 GROMMET RUBBER

180302 8 CABLE TIES

4581040 2 WASHER FLAT 3/8”

WINCH (8000/9000/9500 LB) 6151074 2 BOLT UNC 3/8” x 1 ¾”

BLB850 3 CABLE BLACK 850mm

6151304 4 NUT CAGE M10

4581040

8 WASHER FLAT M10

IMPACT ABSORBER TO BULL BAR 4581288 4 WASHER FLAT M10 (OVER-SIZED)

4581048

8 WASHER, SPRING, M10

6151232

8 BOLT, M10 x 1.5 x 30 LONG

6151026 4 NUT, HEX, M10 x 1.5

3162470R 1 BUFFER (RH)

BUFFERS TO BULL BAR 3162470L 1 BUFFER (LH)

6151128 12 NUT FLANGE M6

NUMBER PLATE TO BULL BAR 6821189 2 GROMMET ROUND FL

6151384 2 SCREW PAN HD PHIL BLK 5 X 16mm

INDICATORS TO BULL BAR

6821151R 1 INDICATOR KIT, RHS

6821151L 1 INDICATOR KIT, LHS

6821116 4 NYLON PLUG

6151308 4 SCREW, SELF TAPPING

6821152 2 WIRING LOOM

6821198 1 INDICATOR RELAY LOOM

3163052R 1 TRIM, WING (LH), HILUX 11

WING TRIM FITMENT 3163052L 1 TRIM, WING (RH), HILUX 11

4581082 10 WASHER, FLAT, M6 (BLACK, 20 OD)

6151384 2 PAN HEAD SCREW 5X16MM BZ

6151162 8 NUT, NYLOC, M6x1

3756721 1 BRKT, CHASSIS MOUNT, HILUX 05

IMPACT ABSORBER TO CHASSIS 4581040 4 WASHER, FLAT, M10

4581048

4 WASHER, SPRING, M10

6151133 4 NUT, M10 x 1.25

3199756R 1 PLATE (RH), CHASSIS, HILUX 05

3199756L 1 PLATE (LH), CHASSIS, HILUX 05

CHASSIS STIFFENING PLATE 6151088 6 BOLT, M10 x 1.25 x 35 LONG

TO CHASSIS & IMPACT 4581040 12 WASHER, FLAT, M10

ABSORBER 4581048 6 WASHER, SPRING, M10

6151133 6 NUT, M10 x 1.25

3758129 1 BRKT GRILL MNT HILUX 05

LOWER GRILL BRACKET 6151234 2 BOLT, M8 x 1.25 x 25 LONG (BLACK)

4581045 2 WASHER, FLAT, M8 (BLACK)

4581047 2 WASHER, SPRING, M8 (BLACK)

6151132 2 NUT FLANGE M8

3163006 1 FOG LAMP SURROUND RHS

FOG LAMPS TO BULL BAR 3163005 1 FOG LAMP SURROUND LHS

6821183 2 FOG LAMP LOOM

05/10/11 Page 4 of 21 378 7983

6522649 1 PANEL STONE GUARD UPPER HILUX 05

6522650 1 PANEL STONE GUARD LOWER HILUX 05

6151303 8 CAGE NUT, M8 (3mm PLATE)

CENTRE STONE DEFLECTORS 4581045 8 WASHER, FLAT, M8 (BLACK)

4581047

8 WASHER, SPRING, M8 (BLACK)

6151234

8 BOLT, M8 x 1.25 x 25 LONG (BLACK)

6522816R 1 PANEL, WING (RH), HILUX 11

6522816L 1 PANEL, WING (LH), HILUX 11

6151315 10 CAGE NUT, M6 (1.6mm PLATE)

4581082 10 WASHER, FLAT, M6 (BLACK, 20 OD)

WING STONE DEFLECTORS 4581287 10 WASHER, SPRING, M6 (BLACK)

6151213 10 BOLT, M6 x 1.0 x 20 (BLACK)

6151094 2 BOLT M12 x 1.25 x 30 LONG

4581049 2 WASHER, FLAT M12

4581050 2 WASHER, SPRING M12

6151234 2 BOLT, M8 x 1.25 x 25 LONG (BLACK)

6151303 2 CAGE NUT, M8 (3mm PLATE)

4581045 2 WASHER, FLAT, M8 (BLACK)

4581047 2 WASHER, SPRING, M8 (BLACK)

3758190R 1 BRACKET WING STONE SHIELD RH

3758190L 1 BRACKET WING STONE SHIELD LH

Tools required: -

10 mm & 5 mm drill bits and a electric drill, Satin black can of spray paint, scissors or

sharp knife, metric ruler, basic metric spanner and socket set & screw driver set, neutral

cure silicon, and a stepped ring spanner to suit 3/8” bolt. (If installing a winch)

05/10/11 Page 5 of 21 378 7983

ASSEMBLY SEQUENCE FOR BULL BAR INSTALLATION.

1. Remove existing bumper and grill from

the vehicle.

Once these are removed:

-Remove the light bracket fitting and

discard; this is done by first removing

the light and then unscrewing the

bracket from the rear of the light fitting.

-Remove the bumper braces and

discard.

-Remove the chassis cross-brace and

discard.

-Remove the factory fog lamps from the

bumper bar and keep aside.

2. Remove the plastic bumper retention

blocks from either side of the vehicle.

3. Replace the front most screws (these

secure the head lights).

4. Spray paint the metal underside of the

fender and the underside of the

headlamp black.

Ensure the area to be painted is well

masked to ensure no over spray on other

components.

05/10/11 Page 6 of 21 378 7983

5. Fasten the lower grill bracket to the

vehicle head lights, as shown, using M8

x 25 black bolts, flat washers, spring

washers and flange nuts.

6. Reassemble the vehicle’s grill removed

at step 1; make sure the 2 lower grill

tabs are pushed into the clips in the

lower grill bracket. Bend lower grill

bracket tab upwards slightly.

7. Remove the vehicles headlights.

8. Carefully read the wiring diagram

supplied at the end of these

instructions.

9. Take the relay loom (6821198) from the

kit and position in the engine bay so

that all wires will reach the appropriate

connections.

05/10/11 Page 7 of 21 378 7983

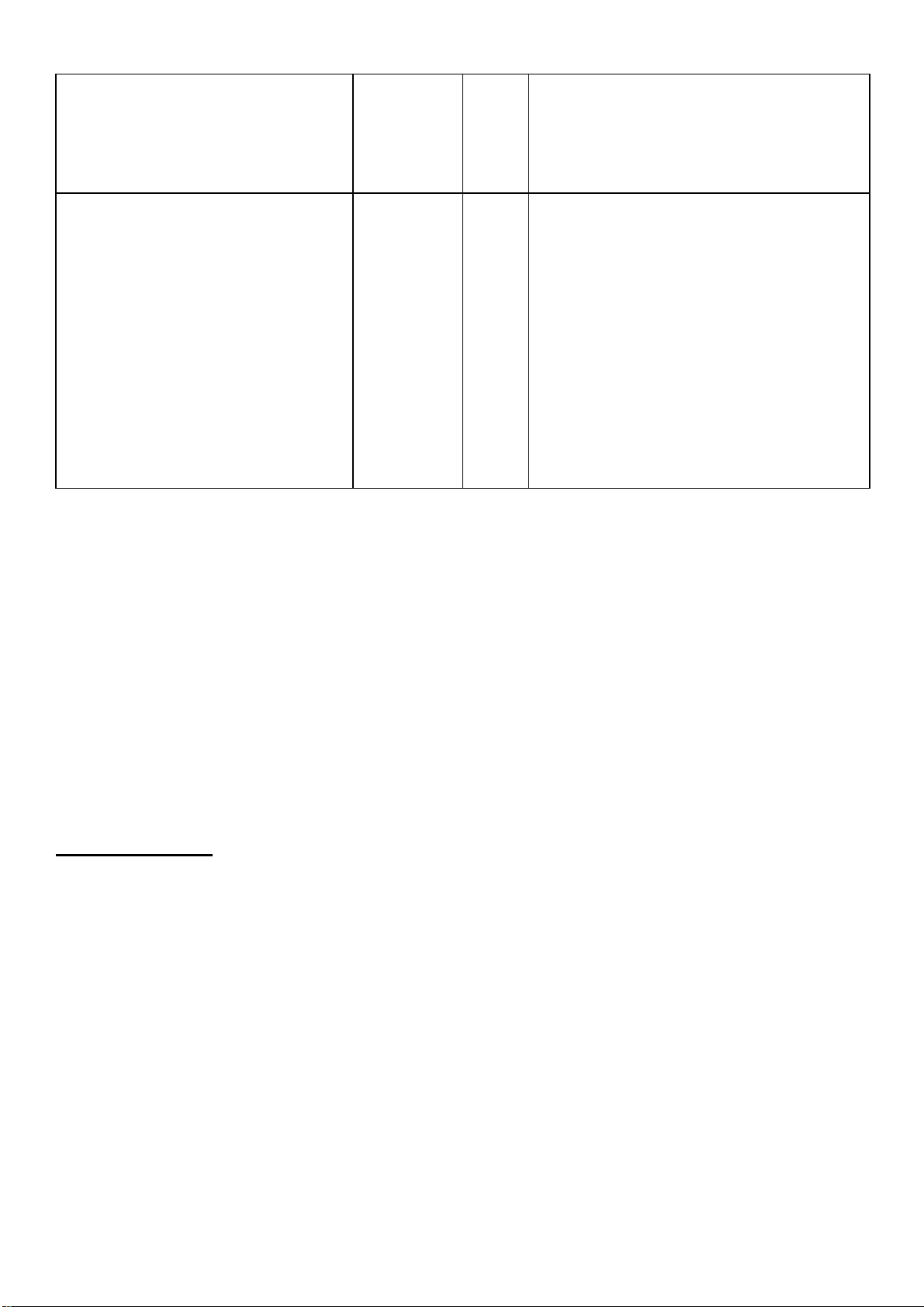

10.Starting with the passenger side, use

scotch locks to connect the red wire

from the indicator loom (6821152) to

the green wire from the vehicles front

park lamp.

11.Connect the Yellow / Black wire from

the relay loom to the Green / Black wire

from the vehicles left indicator.

12.Connect the Yellow and Black wires

from the relay loom to the Green and

Black wires from the indicator loom.

13.Let the indicator loom hang freely for

connecting to the bull bar indicators

later on.

14.Do the same for the drivers side using

the wiring diagram supplied as a

reference for the correct wire colors.

15.Find a suitable place and mount the

relay.

NOTE: Always mount the relay upright

to help prevent water ingress.

05/10/11 Page 8 of 21 378 7983

16.Run the main black wire to a suitable

earth.

17.Connect the main power wire (red) to

the positive terminal of the battery.

(Main battery if a dual battery system is

installed)

18.Using the cable ties supplied, secure

the loom being sure to keep clear of

any hot, sharp or moving surfaces.

19.Remove the protruding bracket in front

of the radiator, as it is no longer

required (note: the vertical member of

this bracket must not be removed as it

holds the bonnet latch in position). This

may be done by either drilling out the

existing spot-welds with a 5mm drill as

shown, or by cutting it off with a grinder.

Re - locate the air temp sender (if fitted)

to one of the holes in the vertical

bracket.

Paint exposed metal to prevent rusting.

CABLE TIE

LOOM

05/10/11 Page 9 of 21 378 7983

20.Fit the buffers to the bull bar using the

6mm flange nuts provided.

(DO NOT OVER TIGHTEN)

21.Fit cage nuts and nylon plugs to the

bull-bar.

M10 cage nuts. (4 off) Caged portion is to

centre of bull bar.

M8 cages nuts. (4 off) Caged portion is to top

of bull bar.

22.Remove the fastening screws and nuts

supplied with the turn signal/clearance

lamps and replace these with the four

screws provided in the kit. Push the

square plastic plugs into the holes on

the turn signal bracket. Fasten the turn

signal lamps to the bull bar as shown.

NOTE: - The drain holes in the lamp are at the

bottom. (As shown)

IMPORTANT: -

The turn signal (amber section) is to face to

the inside of the bull bar.

Drain Holes

05/10/11 Page 10 of 21 378 7983

23.Fit the factory fog lamp to the bull bar

bracket by engaging the peg on the fog

lamp (right hand side shown) into the

hole in the out board (shorter) side of

the bracket as shown.

24.Align the black clip located at the back

of the lamp into the corresponding hole

in the bracket.

Push the inner edge of the fog lamp into the

bracket to fully retain the fog lamp.

25.To ensure a tight fit of the fog lamp into

the bracket bend the tabs on the

bracket in towards the lamp with a

screwdriver.

Repeat this on the other side.

NOTE: - If the removal of the fog light is

necessary pry the tabs outward from the

lamp and using a screw driver between the

body of the lamp and bracket on the inner

(longer) side of the bracket flex the bracket

to disengage the fog lamp post from the

bracket.

26.The fog lamp surround is held to bar

using silicon adhesive. Apply a bead of

silicon adhesive around light cut out on

the bull bar and hold the fog light

housing to the bull bar using masking

tape until the silicon adhesive dries,

then remove the tape.

05/10/11 Page 11 of 21 378 7983

27.Loosely fit the wing trims using 5

oversized M6 washers, 4 M6 nyloc nuts

and 1 self-tapping screw on each side

of the bar

These nuts will be tightened after the bar

has been fitted to the vehicle and the wing

trims have been positioned in an optimal

position.

TO FIT A WINCH BAR

(If not fitting a winch proceed to step 51)

28.To fit an 8/9/9.5/000lb winch, rotate

gearbox 72° counterclockwise.

29.Stand the winch upright and undo the

capped head screws. Lift the gearbox

up - only a couple of millimeters, to

allow the gearbox to be rotated to the

new position. Once in position, refit all

screws and tighten firmly.

WARNING: Do not lift gearbox more than a

couple of millimeters.

ORIGINAL

ROTATED

VIEWED FROM

LHS OF VEHICLE

05/10/11 Page 12 of 21 378 7983

30.Remove the cover from the control box.

31.Replace the three main power cables

that go from winch to control box. Make

sure that you identify the colour codes

on the new cables before closing

control box cover.

32.This must be done for whatever winch

is to be fitted to the bull bar.

33.If fitting the XP 9.5 winch, remove the

cover from the control box, otherwise

proceed to step 36.

Remove the two cap screws, nuts and

spacer washers that hold the four

solenoids in place.

34.Remove the four solenoids from the

base of the control box using the

copper bus bar as an aid and hold to

one side.

05/10/11 Page 13 of 21 378 7983

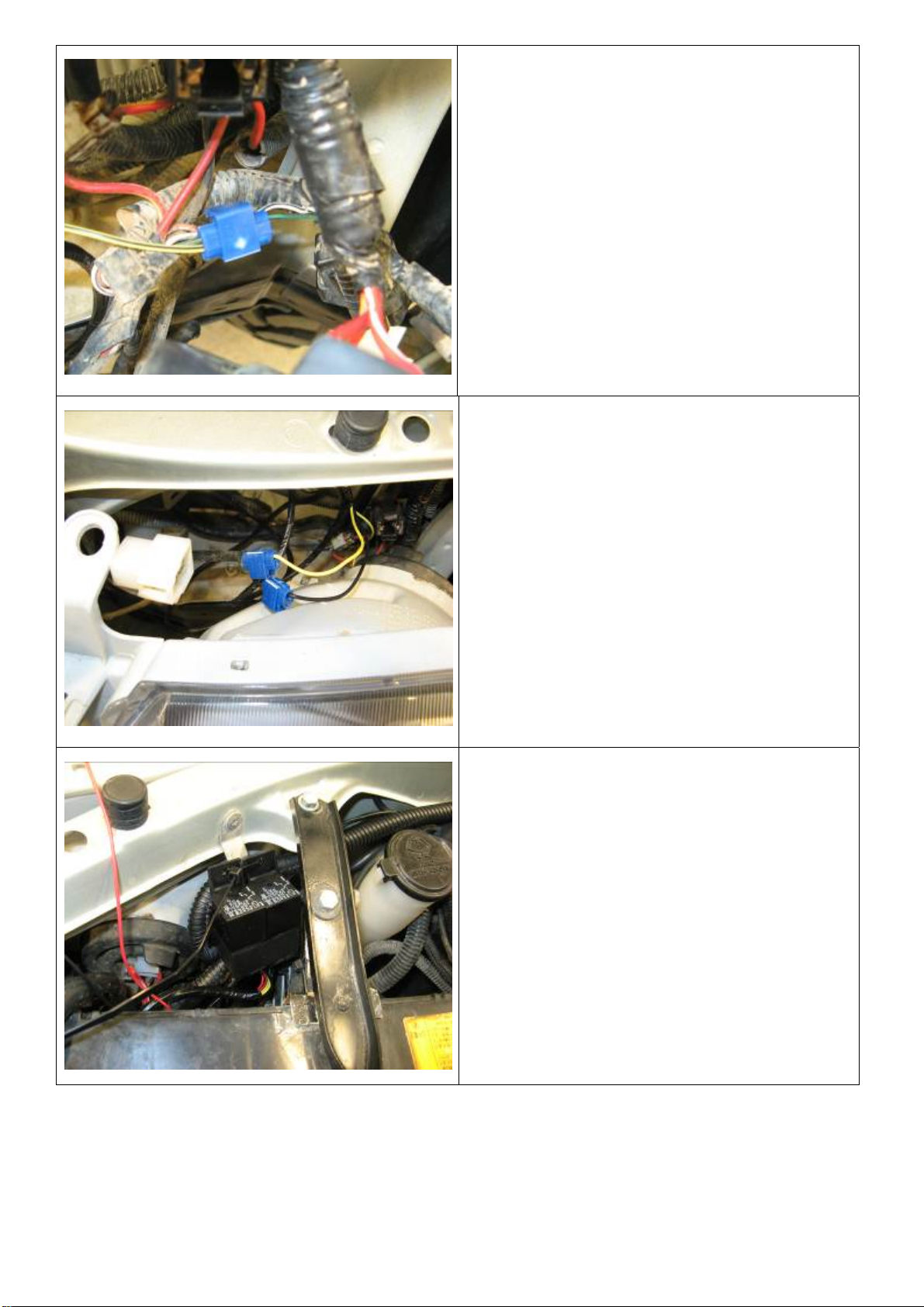

Before

35.Remove the two bolts in the base of the

control box and reposition them into the

more centralized holes.

After

36.Place the 4 solenoids over the 2 metal

stands that are facing upwards. Make

sure they line up with the holes in the

base.

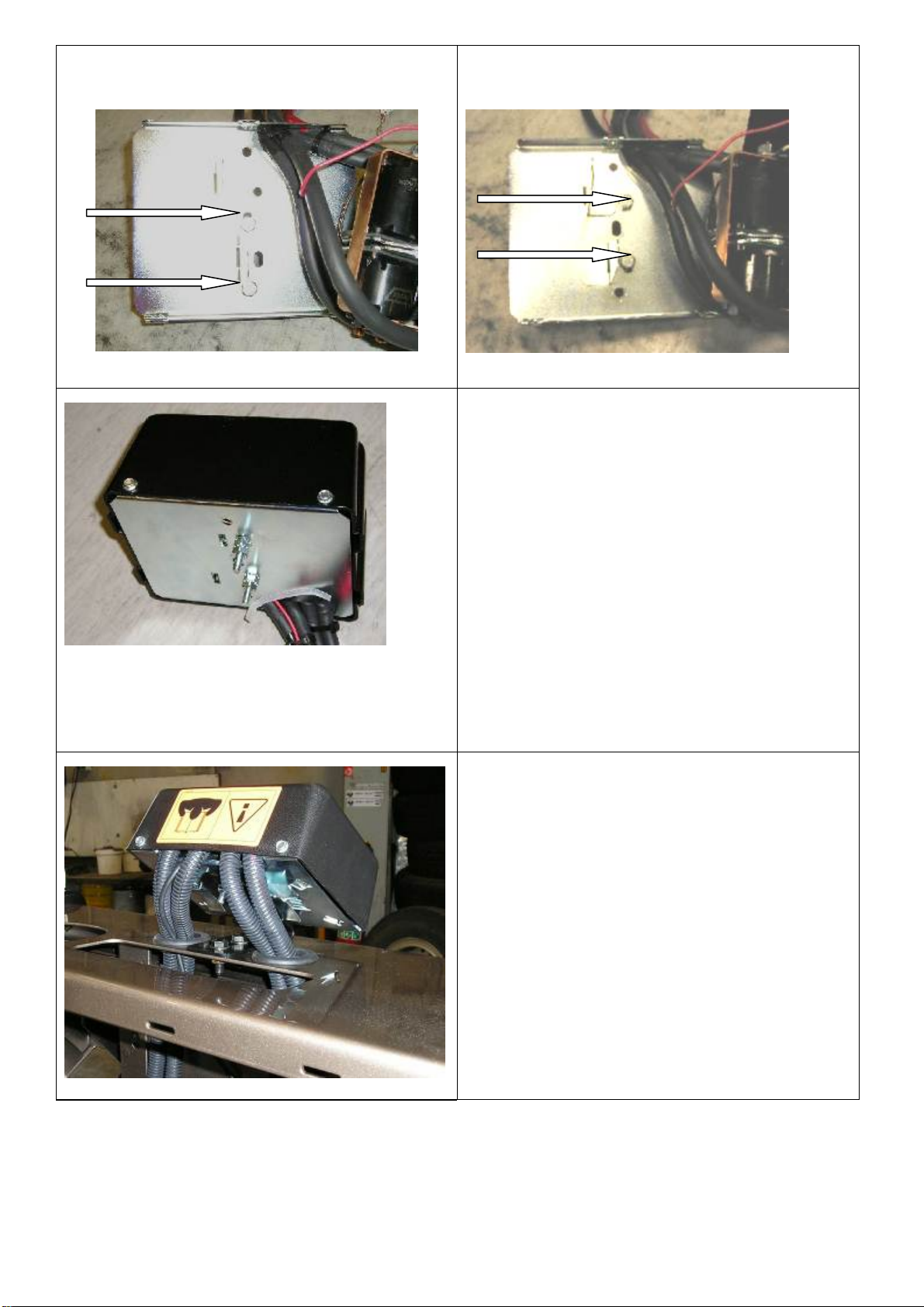

37.Replace the 2 cap screws, washers

and nuts removed in step 14 above into

original holes.

Replace the black cover and refit the three cover

screws. (DO NOT OVER TIGHTEN)

38.Bolt the control box bracket to the

control box.

39.Fit the two grommets into the round

holes in the top of the bull bar then

thread the cables through.

40.Mount the control box bracket onto the

top pan, using M8 bolts, flat washers

and flanged nuts. Use the cable ties to

ensure the winch cables are secure,

clear of moving parts and sharp edges

and tie them together.

05/10/11 Page 14 of 21 378 7983

41.Place winch on a stand with mounting

holes facing upwards and lower bull bar

onto winch. Align all four holes, using

the original 3/8” bolts that came with

the winch in the top two holes and the

longer 1 ¾” x 3/8” bolts, supplied in the

kit, in the lower two holes plus 3/8”

spring and flat washers with each bolt.

42.When all bolts are fitted and finger tight,

tighten top holes only, using a stepped

ring spanner and remove lower bolts.

Drill two new 13mm holes in the roller

fairlead provided in the kit, as shown on

the adjacent picture.

43.Fit roller fairlead into cutout and refit

bolts and tighten firmly.

NOTE. For ease of tightening the lower bolts,

use a stepped ring spanner.

\

05/10/11 Page 15 of 21 378 7983

44.Connect the winch control box cables

to the winch. Refer to Warn installation

instruction manual when wiring up

winch.

45.Ensure that all cables are installed well

clear of all sharp or moving parts, by

using cables ties from bolt kit.

46.Cable tie main cables that go to battery

in between underside of bar and brace.

Refer to photo to see where to cable tie to bull bar.

47.Fit the impact absorber to the bull-bar

using the two M10 x 30 bolts as shown,

M10 over-sized washers and M10

spring washers. Do not fully tighten

these bolts as they will be tightened on

the vehicle.

48.Fit four M8 cage nuts to the impact

absorber. (Cage nuts to suite 3mm

plate) Caged portion to top of bull bar.

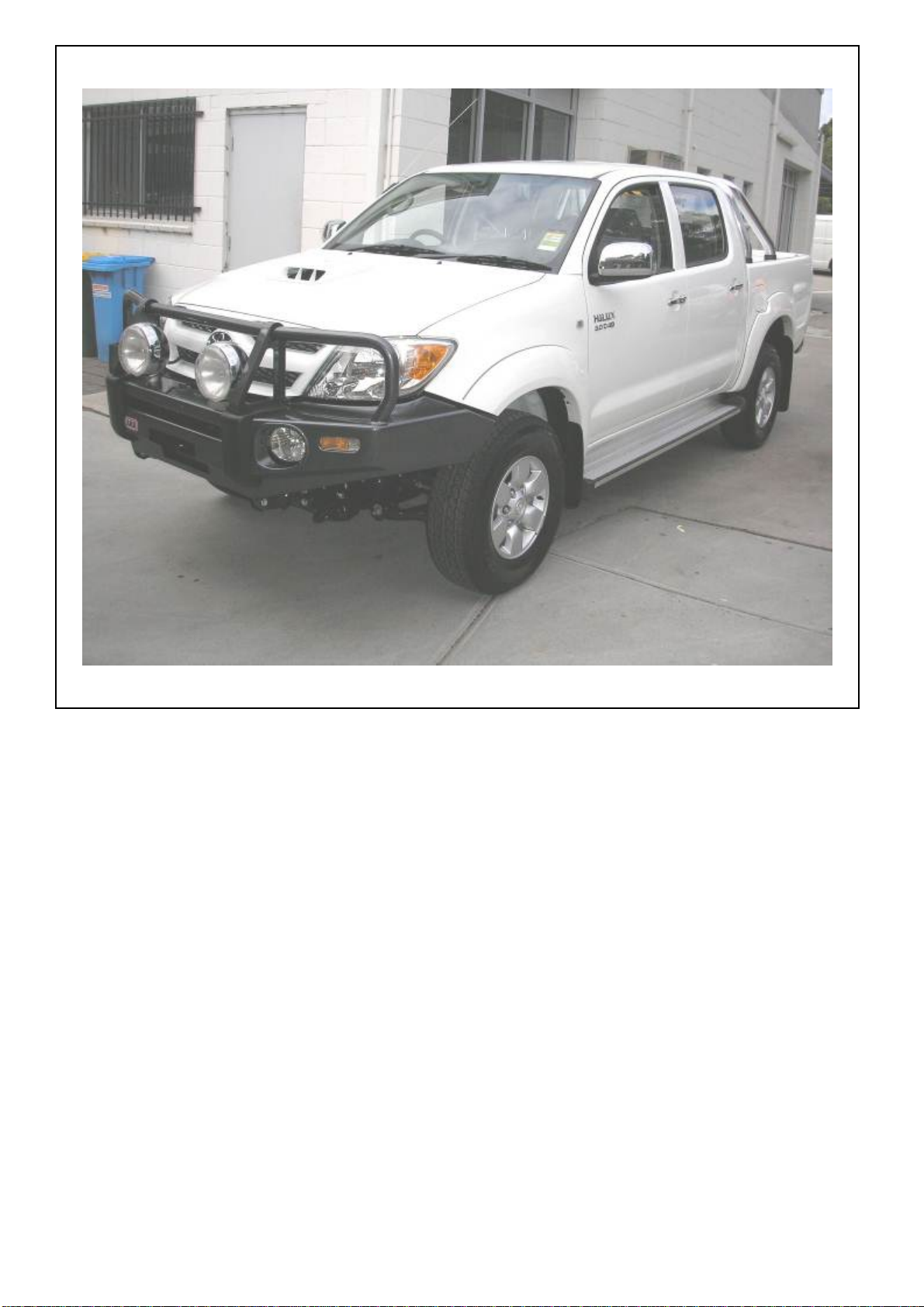

49.Position the bar on the vehicle and

fasten it to the chassis studs using the

M10 washers, spring washers and nuts

provided. Once satisfied that the bar is

centrally positioned on the vehicle

properly tighten the M10 nuts.

05/10/11 Page 16 of 21 378 7983

50.Adjust the bull bar position up/down

and in/out to achieve uniform gaps

between the bar and the fenders on

each side of the vehicle. The nominal

clearance between the bull-bar and the

fenders is 20mm. Firmly tighten the

bolts fitted at step 46.

Once satisfied with the position of the bull-bar,

using a 10mm drill, drill through the 10mm

holes in the impact absorber, 2 holes per side,

and secure using the M10 x 30 bolts, two flat

washers per bolt, spring washers and hex

nuts.

51.Fasten the chassis-stiffening bracket to

the chassis and the impact absorber as

shown. Fasteners required include: six

M10 x 35 bolts, twelve M10 flat

washers, six M10 spring washers, six

hex nuts

Leave this bolt hole clear for step 54.

05/10/11 Page 17 of 21 378 7983

52.Fit the centre stone guards as shown

using M8 x 25 black bolts, black M8 flat

washers and black M8 spring washers.

Use the original bolts in the lower two

holes.

53.Fit theM6 cage nuts to the wing stone

guards as shown.

Make sure the plastic wheel liner on the LH

side of the vehicle has been disconnected

from the washer bottle before fitting the wing

stone guards.

54.Fit the M8 cage nuts to the stone guard

brackets.

Loosely fit the brackets to the side of the

chassis rails using M12 x 30 Hex bolts, M12

Spring washers and M12 Washers.

05/10/11 Page 18 of 21 378 7983

55.Fit the wing stone guards to the bull bar

/ vehicle using M6 x 20 black bolts, M6

black washers, M6 black spring

washers.

Use the M8 x 25 black bolt, M8 black

flat washer and M8 black spring washer

to secure the stone guard to the

bracket fitted in step 55.

56.Mark lines along the inner guards using

the bottom edge of the stone guards as

a guide.

57.Remove the stone guards and cut

along the lines marked in the previous

step.

58.Tuck the inner guards into the stone

guards.

59.If fitting optional driving lights to vehicle

do so at this stage. Guide ratchet

spanner between the upper and lower

pans, as shown, to tighten the lights to

the bar.

05/10/11 Page 19 of 21 378 7983

60.Fit the plastic plugs into the square

holes in the lower or upper pan

depending on fitment. Fit the number

plate to the bull bar using the black self-

tapping screws.

The two photos display the number plate

positions for both winch and non-winch bars.

Provision for a high-lift jack has been provided

on both sides of bar.

05/10/11 Page 20 of 21 378 7983

Another photo for non winch

This manual suits for next models

5

Table of contents

Other ARB Automobile Accessories manuals

ARB

ARB Airlocker RD162 User manual

ARB

ARB AIRLOCKER RD208 User manual

ARB

ARB RD246 Product information sheet

ARB

ARB Airlocker RD161 User manual

ARB

ARB Airlocker RD152 User manual

ARB

ARB Airlocker RD259 User manual

ARB

ARB AIRLOCKER RD156 User manual

ARB

ARB 3414470 User manual

ARB

ARB 10900013 User manual

ARB

ARB RD177 User manual

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction