APPLICATION NOTE 113

Arbiter Systems, Inc. 1324 Vendels Circle, Suite 121 Paso Robles, CA 93446 3

Additionally, the same meter that reads the

reference current also measures the probe

current, reducing equipment and other

calibration errors.

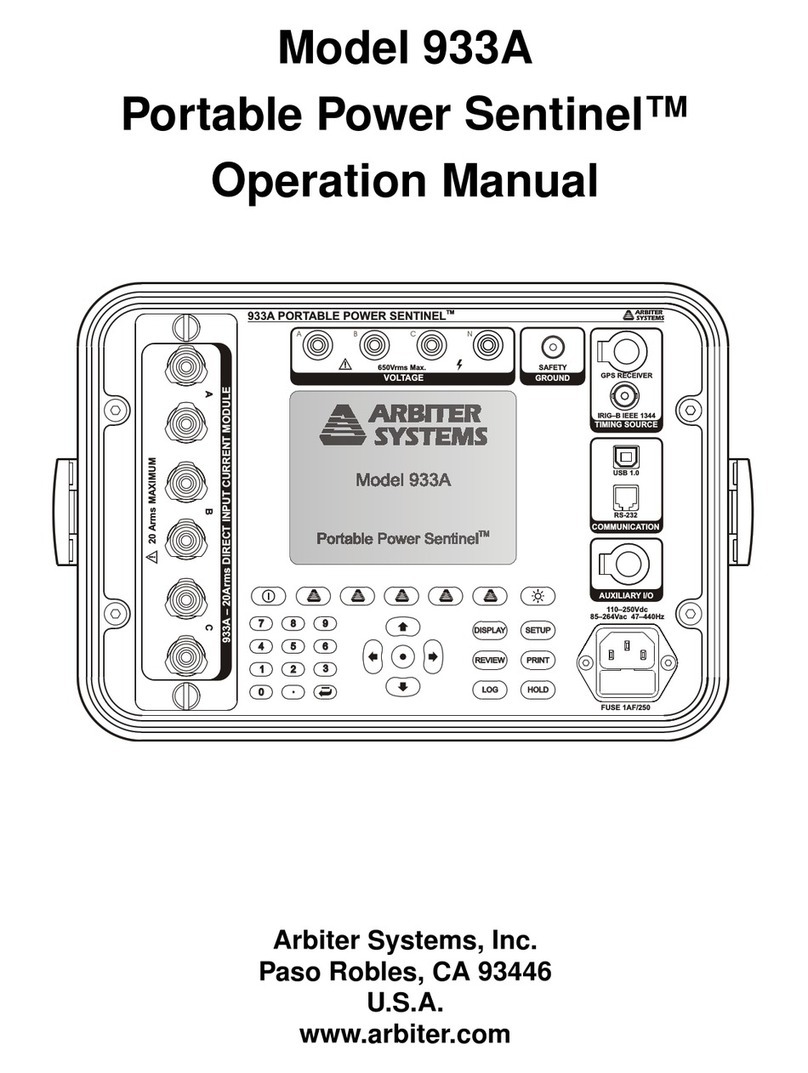

Since the Model 931A/930A/929A measures

true RMS values to 0.05% (3 kHz bandwidth),

any source of current may be used for

reference. It is important to make Channel A

the direct reference channel, and make Channel

B or C the channel to be calibrated (using the

current probe).

Calibrating the Power Analyzer

Set up the power analyzer as follows:

1. Switch on the power to the unit and wait for

it to show both channels.

2. Press the Channel 1 Select key and use the

cursor movement keys to select Channel 1

as Ia.

3. Press the Channel 2 Select key and use the

cursor movement keys to select Channel 2

as Ib.

4. Set the SCALE for Ib to the nominal CT

ratio (e.g. 100.00, see example 1).

5. Connect the direct current source to current

input A (Channel 1) and the current probe

leads to current input B (Channel 2).

6. Use a current amplitude near the value to be

measured. Make certain that the current

source to the Power Analyzer is less than

20 Amps.

7. Clamp the current probe over one of the

leads of current input A leads

8. If the current source is ON, then the CH1

and CH2 on the power analyzer should be

indicating two measurements very close in

value.

9. Press the CH1 / CH2 key and the analyzer

will mathematically compare Channel 2 to

Channel 1, and provide the exact magnitude

and phase values to program in to the

power analyzer.

10. Press the SHIFT and SCALE keys to view

the various scale values. Use the cursor

keys to move to Ib and press ENTER.

11. Use the cursor keys again to select the

correct digit and numerical scale value for

magnitude. When the value is correct –

with decimal point – press ENTER.

12. Repeat the procedure in 8 and 9 for phase

difference (between A and B).

The probe should now be calibrated to the

power analyzer, read current directly and

compensate for errors in magnitude and phase

shift. Three examples follow.

Calibrated Example 1

PROBE: AEMC Model MN170, Clamp-on Current

Probe, 100:1 ratio and maximum input current of 75

Amps

Using a Model 1040C as a current source, a

Model 931A to measure current, calibration

was performed at 5 Amps. Measurements at

other values were as follows:

1040C CH A CH B CH1/CH2 φ°

0.1 0.1000 0.1000 1.0004 0.21

1.0 1.0007 1.0014 0.9994 0.18

2.0 2.0003 2.0012 0.9995 0.13

3.0 3.0000 3.0008 0.9997 0.08

4.0 4.0004 4.0010 0.9999 0.04

5.0 5.0019 5.0020 1.0000 0.00

From left to right, the first three rows are in

amps. The fourth row is dimensionless (A/A),

and the last row is the phase difference in

degrees between the two measurement channels

(Channel 2 compared to 1).