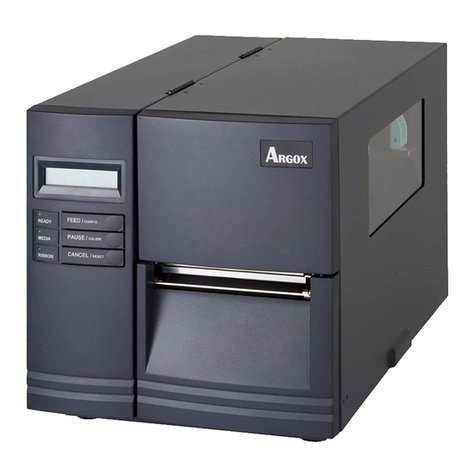

Argox X2000 User manual

Other Argox Printer manuals

Argox

Argox P4 Series User manual

Argox

Argox A-2240 User manual

Argox

Argox D4 250 User manual

Argox

Argox R-400plus User manual

Argox

Argox AME-2230B User manual

Argox

Argox A-50 User manual

Argox

Argox iX4 Series User manual

Argox

Argox X-2300 User manual

Argox

Argox Xellent X-1000VL User manual

Argox

Argox O4 Series User manual

Argox

Argox iX4 Series User manual

Argox

Argox PI-10X0 Owner's manual

Argox

Argox OS-214ZIP User manual

Argox

Argox OS Series User manual

Argox

Argox OS-2130DE User manual

Argox

Argox O4 Series User manual

Argox

Argox CP Series User manual

Argox

Argox Smart CP-2140 User manual

Argox

Argox O4 Series User manual

Argox

Argox O4 Series User manual