I&M No V7538

50 Hanover Road, Florham Park, New Jersey 07932 www ascovalve com

Page 2 of 3

Causes Of Improper Operation

Incorrect Pressure: C eck valve pressure. Pressure to valve must

be wit in range specified on nameplate.

Excessive Leakage: Disassemble valve and clean all parts. If parts

are worn or damaged, install a complete ASCO Rebuild Kit.

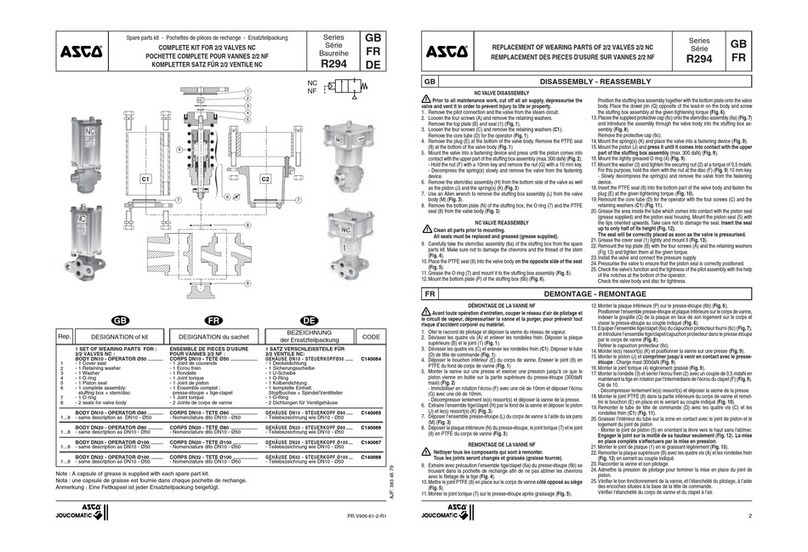

Valve Disassembly

1. Disassemble valve in an orderly fas ion using exploded views for

identification of parts.

2. Remove solenoid, see separate instructions.

3. If t e valve as a manual operator, refer to section on Manual

Operator Disassembly".

4. Unscrew solenoid base sub-assembly and remove core spring,

core assembly and body gasket.

5. A 4-40 mac ine screw provided in ASCO Rebuild Kit serves

as a self-tapping screw to remove insert from body. Turn screw

a few turns into t roug ole located in flat surface of t e insert.

C UTION: Do not damage center hole (pilot orifice) in raised

surface of insert. Remove insert by using a pair of pliers to grip

t e ead of t e screw.

6. Remove t ree gaskets from insert. Tag eac as t ey are

removed so t at t ey can be reassembled in t e same location.

Middle and lower gaskets ave t e same p ysical dimensions,

owever, t e lower gasket is a softer material. Remove disc

older sub-assembly and disc spring.

7. Remove end cap, end cap gasket and outer piston gasket.

8. Slide out piston assembly and inner piston gasket.

9. All parts are now accessible to clean or replace. Replace worn

or damaged parts wit a complete ASCO Rebuild Kit.

Valve Reassembly

1. Reassemble valve using exploded view for identification and

placement of parts.

2. Lubricate all gaskets wit DOW CORNING 111 Compound

lubricant or an equivalent ig -grade silicone grease.

3. Replace inner piston gasket and slide piston assembly into valve

body.

4. Replace outer piston gasket, end cap gasket and end cap

Torque end cap to 60"10 in-lbs. [6,8"1,1 Nm].

5. Position lower insert gasket and disc older spring

6. Snap upper and m,middle insert gaskets into grooves of insert.

Lower insert gasket fits into t e recess between t e lower

corner of t e insert and t e lower corner of t e body insert

cavity. Middle and lower insert gaskets are t e same size.

However, t e lower gasket is made of a softer material.

7. Place disc older assembly into insert. Install insert (wit gaskets

and disc older assembly) into body cavity, making certain t at t e

disc older spring is centered.

8. If t e valve being rebuilt as a manual operator, refer to section on

Manual Operator Reassembly."

9. Replace t e solenoid base gasket, core assembly wit spring.

10. Replace solenoid base sub-assembly (wit core assembly) into

valve body. Torque solenoid base sub-assembly to 175$25

in-lbs. [19,8$2,8 Nm].

11. Install solenoid, see separate instructions and make electrical

connections.

WARNING: o prevent the possibility of death,

serious injury or property damage, turn off electrical

power, depressurize solenoid operator and/or valve,

and vent fluid to a safe area before servicing.

12. Restore line pressure and electrical power supply to valve.

13. After maintenance is completed, operate t e valve a few times

to be sure of proper operation. A metallic click signifies t e

solenoid is operating.

Manual Operator Disassembly

WARNING: o prevent the possibility of death,

serious injury or property damage, turn off electrical

power, depressurize solenoid operator and/or valve,

and vent fluid to a safe area before servicing.

1. Remove retaining screws (2)

2. Slide out manual operator stem/knob/retainer sub-assembly.

3. Remove stem gasket, guide and guide gasket. Remove spring

(Suffix MS) only.

4. All manual operator parts are now accessible to clean or

replace. Replace worn or damaged parts wit a complete

ASCO Rebuild Kit.

Manual Operator Reassembly

1. Reassemble manual operator using exploded view for

identification and placement of parts.

2. Lubricate all gaskets wit DOW CORNING 111 Compound

lubricant or an equivalent ig -grade silicone grease.

3. Replace guide gasket, guide and stem gasket. Replace spring

(Suffix MS) wit small end on stem first.

4. Screw stem/knob/retainer into valve body using two retaining

screws. Torque retaining screws to 25"5 in-lbs. [2,8"0,6 Nm].

ORDERING INFORM TION

FOR SCO REBUILD KITS

Parts marked wit an asterisk (*) in t e exploded views are supplied

in Rebuild Kits. W en Ordering Rebuild Kits for ASCO valves,

order t e Rebuild Kit number stamped on t e valve nameplate. If t e

number of t e kit is not visible, order by indicating t e number of kits

required, and t e Catalog Number and Serial Number of t e valve(s)

for w ic t ey are intended.