50 Hanover Road, Florham Park, New Jersey 0793 www.ascovalve.com

Page of 4 Form No.V660 R5

4. If leakage exists, depressurize valve and turn off electrical

power supply. Tighten pipe connections, pipe plug or

retaining plate screws evenly (when valve has been rebuilt)

and retest following the above steps.

MAINTENANCE

WARNING: To prevent the death, serious

injury or property damage, turn off electrical

power, depressurize valve, extinguish all open

flames, and avoid any type of sparking or ignition.

Vent hazardous or combustible fluid to a safe area

before servicing the valve.

NOTE: It is not necessary to remove the valve from the

pipeline for repairs.

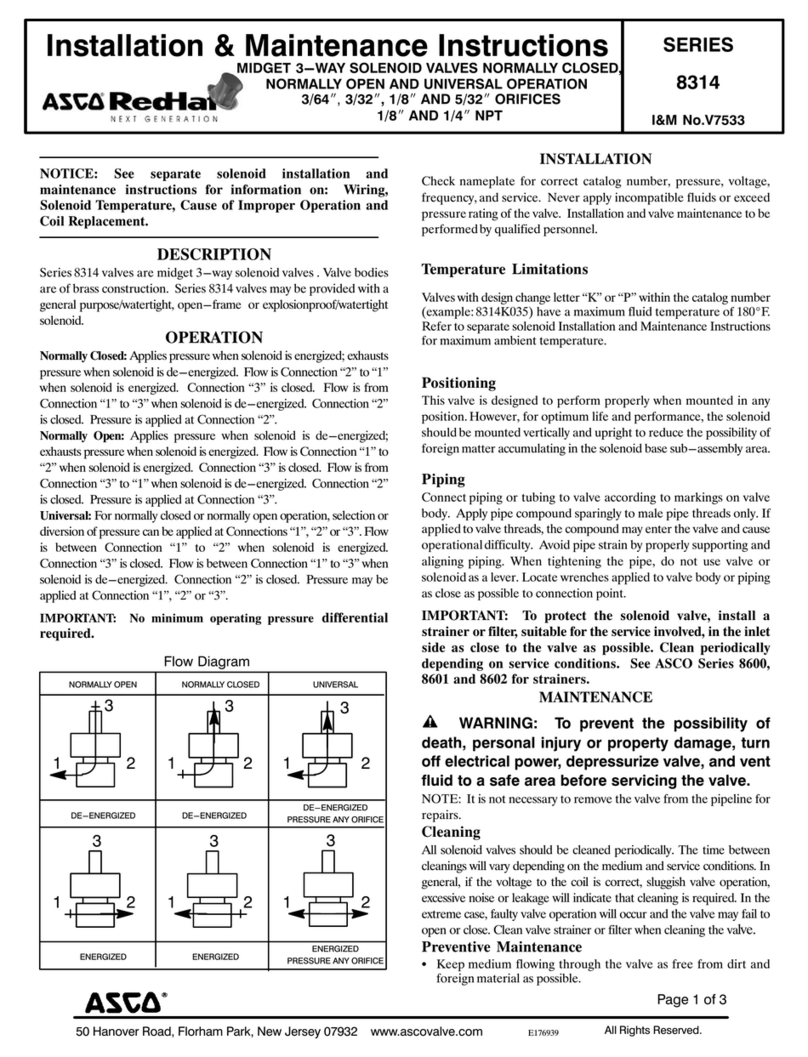

Cleaning

All solenoid valves should be cleaned periodically. The time

between cleanings will vary depending on the medium and

service conditions. In general, if the voltage to the coil is

correct, sluggish valve operation, excessive noise or leakage

will indicate that cleaning is required. In the extreme case,

faulty valve operation will occur and the valve may fail to open

or close. Clean strainer or filter when cleaning the valve.

Pre enti e Maintenance

SKeep the medium flowing through the valve as free from dirt

and foreign material as possible.

SWhile in service, the valve should be operated at least once

a month to insure proper opening and closing.

SDepending on the medium and service conditions, periodic

inspection of internal valve parts for damage or excessive

wear is recommended. Thoroughly clean all parts. If parts

are worn or damaged, install a complete ASCO Rebuild Kit.

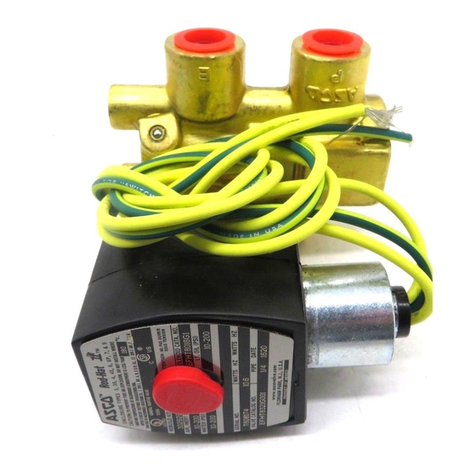

Causes of Improper Operation

SIncorrect Pressure: Check valve pressure. Pressure to valve

must be within range specified on nameplate.

SExcessi e Leakage: Disassemble valve and clean all parts. If

parts are worn or damaged, install a complete ASCO

Rebuild Kit.

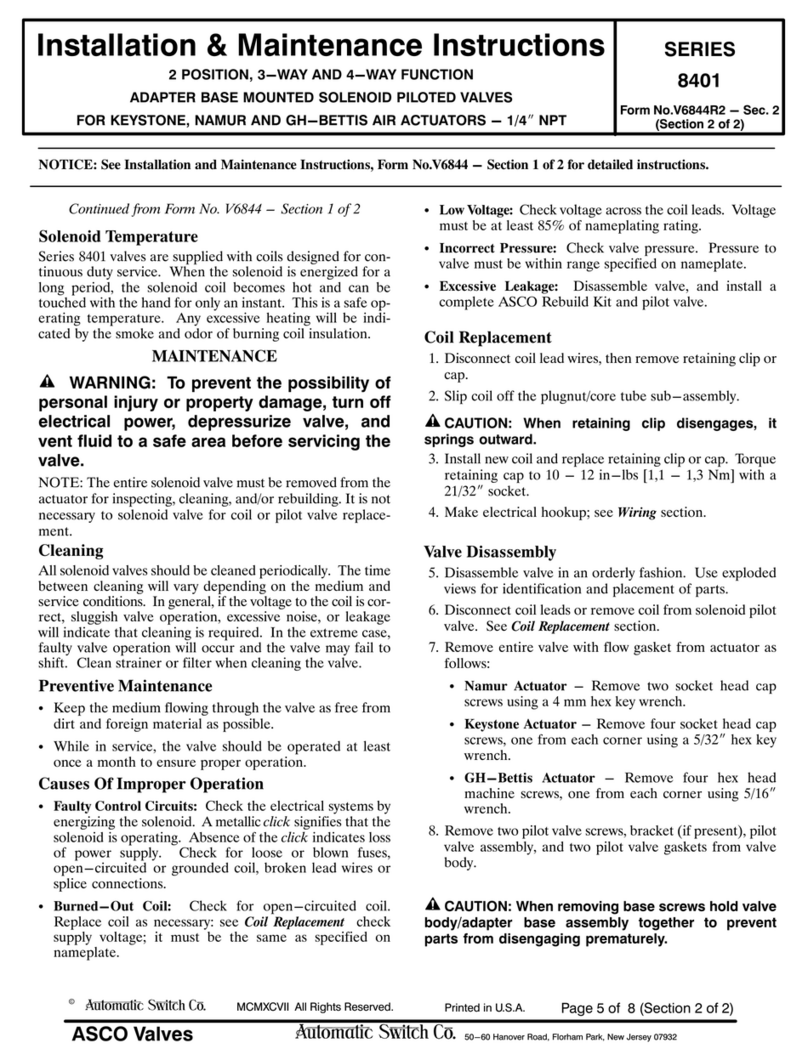

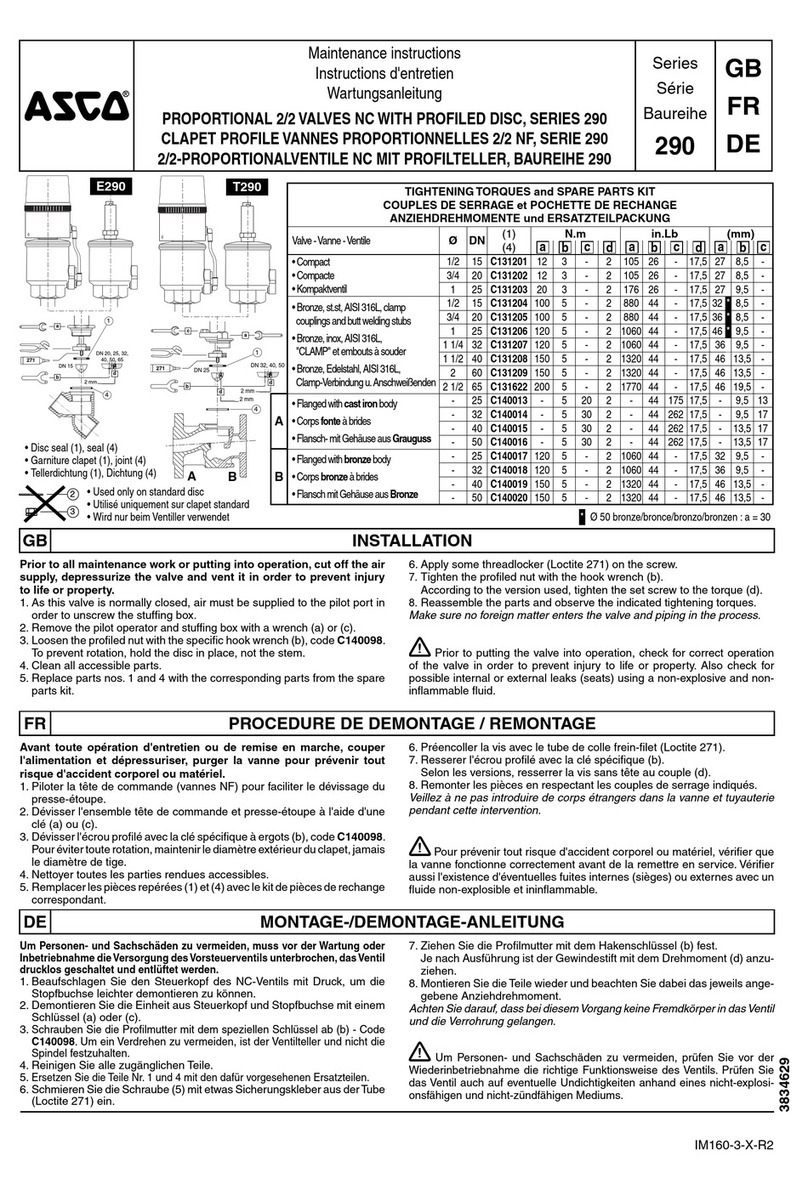

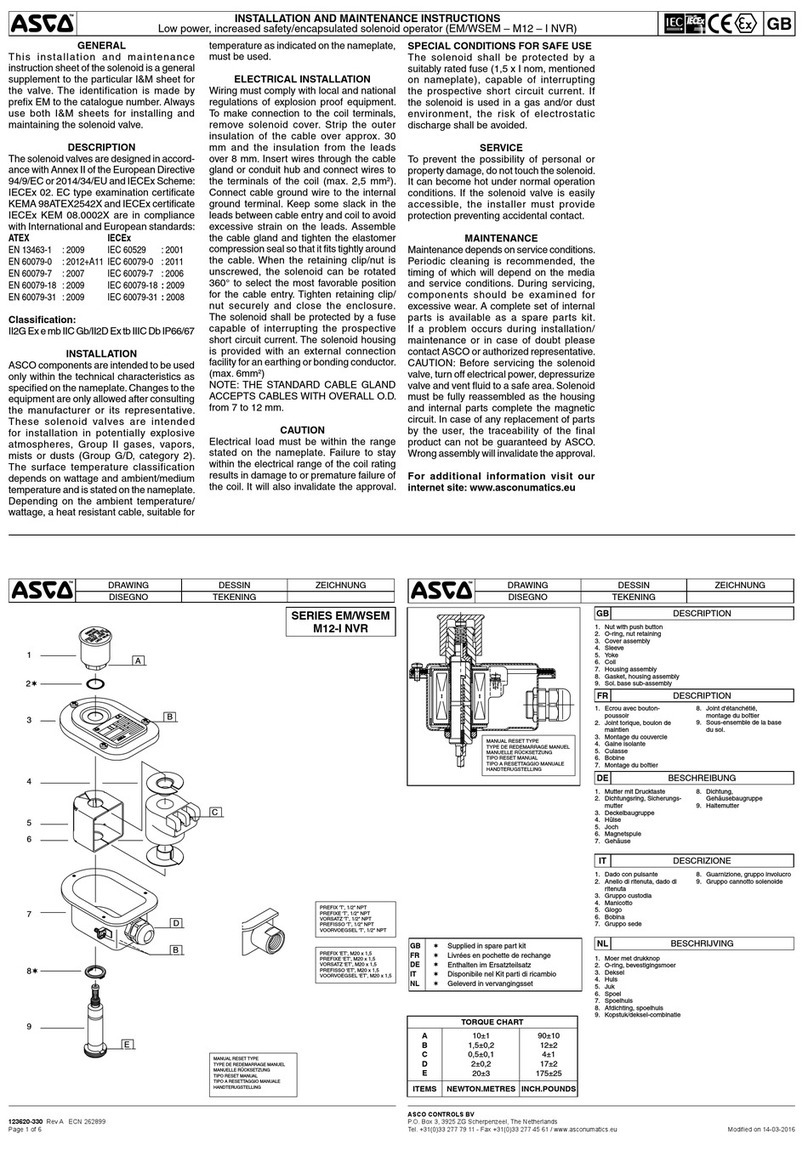

Val e Disassembly (Refer to igure 2)

1. Disassemble valve in an orderly fashion.

2. Remove solenoid enclosure, see separate instructions.

3. Remove retaining plate screws, then remove retaining

plate, retaining plate gasket, plugnut/core tube

sub-assembly, core spring, core assembly, body gasket,

and support.

4. All parts are now accessible to clean or replace. If parts are

worn or damaged, install a complete ASCO Rebuild Kit.

Val e Reassembly

1. Reassemble using exploded view for identification and

placement of parts.

2. Lubricate all gaskets with DOW CORNINGr 111

Compound lubricant or an equivalent high-grade silicone

grease.

3. Position support, flat side down into valve body. Position

body gasket on support between bevel and side wall of

valve body.

4. Install core spring in core assembly. Put wide end of core

spring into core first, closed end protrudes from top of

core.

5. Position retaining plate gasket over plugnut/core tube

sub-assembly.

6. Install plugnut/core tube sub-assembly with core spring

and core assembly into the support in the valve body.

7. Replace retaining plate and retaining plate screws. Torque

retaining plate screws in a crisscross manner to 16 ± 2

in-lbs [1,8 ± 0,2 Nm].

8. Replace solenoid, see separate instructions.

WARNING: To prevent the death, serious

injury or property damage, check valve for proper

operation before returning to service. Also

perform internal seat and external leakage tests

(with a nonhazardous, noncombustible fluid if

practical).

9. Check valve for external leakage as indicated under the

Piping section, and for internal (seat) leakage as follows.

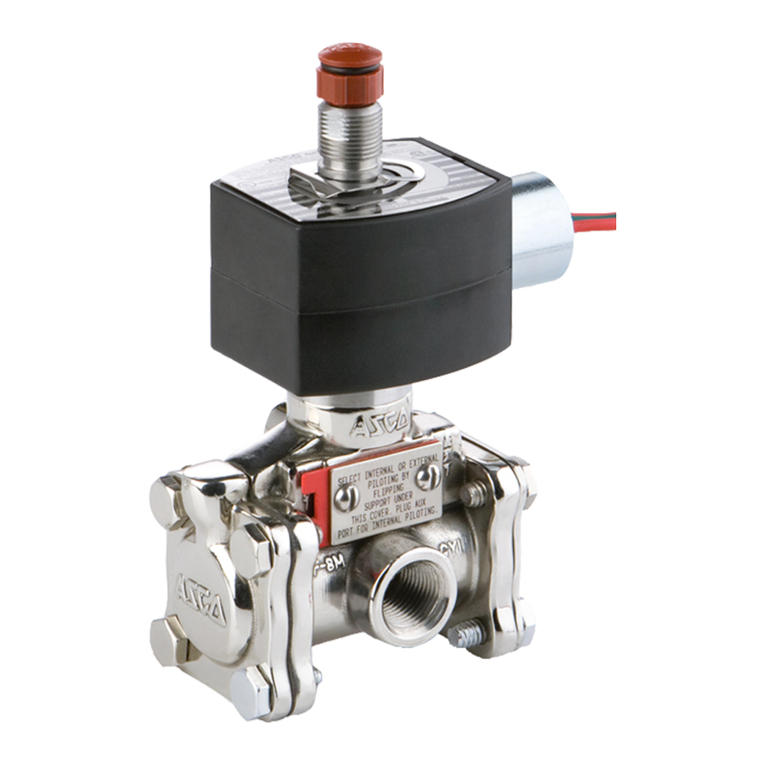

Testing for Internal (Seat) Leakage (Refer to igure 1)

CAUTION: Be sure valve can be tested without

affecting other equipment.

1. Shut off both the upstream and downstream manual gas

cocks. The downstream manual gas cock should remain

closed throughout the entire test procedure.

2. Program the control system to operate the valve through

five cycles. Listen carefully for the solenoid coil to click

indicating proper operation.

3. Open the upstream manual gas cock. Program the control

system to energize and maintain the valve in the open

(energized) position. Check all valve and piping

connections for external leaks with rich soap and water

solution or a commercially available leak detecting

solution.

4. Shut off the upstream manual gas cock and de-energize

valve. Remove the plug from the leak test tap or

downstream pressure tap in the valve body. Connect leak

test equipment with the test petcock in the closed

position, see igure 1.

WARNING: Some gas will be released to the

atmosphere when the 1/8I NPT pipe plug is

removed.

5. Open the upstream manual gas cock. Program the control

system to energize the valve to the full open position, then

immediately de-energize it to seat the valve

operationally.

6. Immerse the 1/4I leak test tubing vertically into a jar of

water to a depth of about 1/2I. Slowly open the test

petcock. Bubbles may appear in the water as the pressure

equalizes.