Page 1 of 3

50 Hanover Road, Florham Park, New Jersey 07932 www ascovalve com All Rights Reserved

E176939

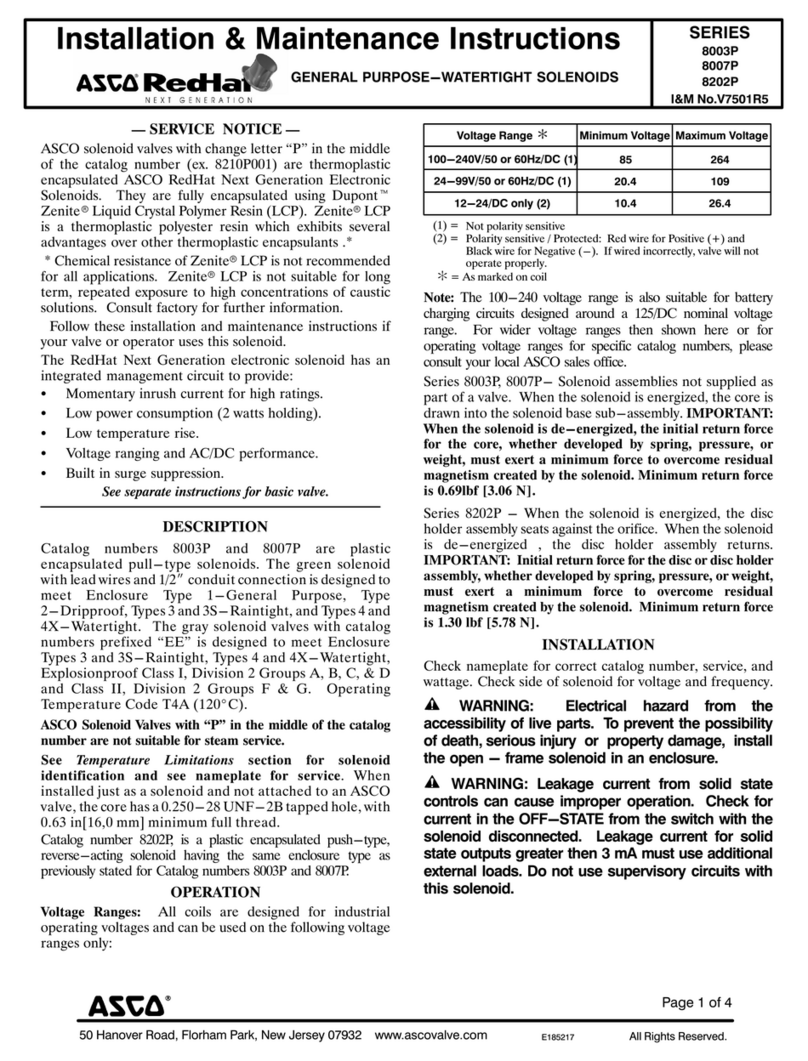

Installation & Maintenance Instructions SERIES

I&M No.V7533

8314NORMALLY O EN AND UNIVERSAL O ERATION

3/64I, 3/32I, 1/8I AND 5/32I ORIFICES

1/8I AND 1/4I N T

MIDGET 3-WAY SOLENOID VALVES NORMALLY CLOSED,

NOTICE: See separate solenoid installation and

maintenance instructions for information on: Wiring,

Solenoid Temperature, Cause of Improper Operation and

Coil Replacement.

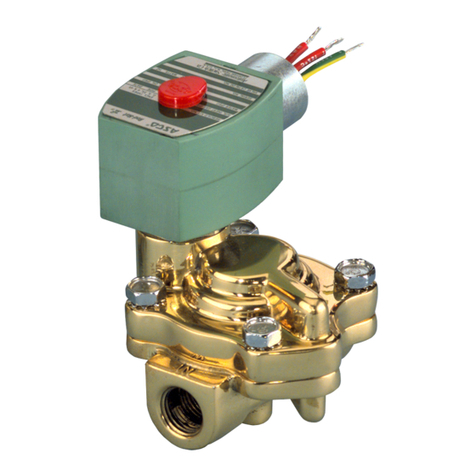

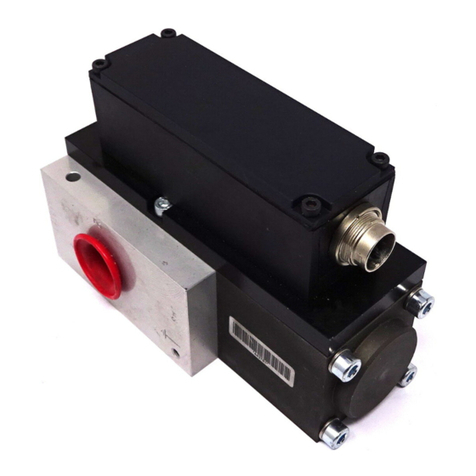

DESCRIPTION

Series 8314 valves are midget 3-way solenoid valves . Valve bodies

are of brass constr ction. Series 8314 valves may be provided with a

general p rpose/watertight, open-frame or explosionproof/watertight

solenoid.

OPER TION

Normally Closed: Applies press re when solenoid is energized; exha sts

press re when solenoid is de-energized. Flow is Connection 2" to 1"

when solenoid is energized. Connection 3" is closed. Flow is from

Connection 1" to 3" when solenoid is de-energized. Connection 2"

is closed. Press re is applied at Connection 2".

Normally Open: Applies press re when solenoid is de-energized;

exha sts press re when solenoid is energized. Flow is Connection 1" to

2" when solenoid is energized. Connection 3" is closed. Flow is from

Connection 3" to 1" when solenoid is de-energized. Connection 2"

is closed. Press re is applied at Connection 3".

Universal: For normally closed or normally open operation, selection or

diversion of press re can be applied at Connections 1", 2" or 3". Flow

is between Connection 1" to 2" when solenoid is energized.

Connection 3" is closed. Flow is between Connection 1" to 3" when

solenoid is de-energized. Connection 2" is closed. Press re may be

applied at Connection 1", 2" or 3".

IMPORT NT: No minimum operating pressure differential

required.

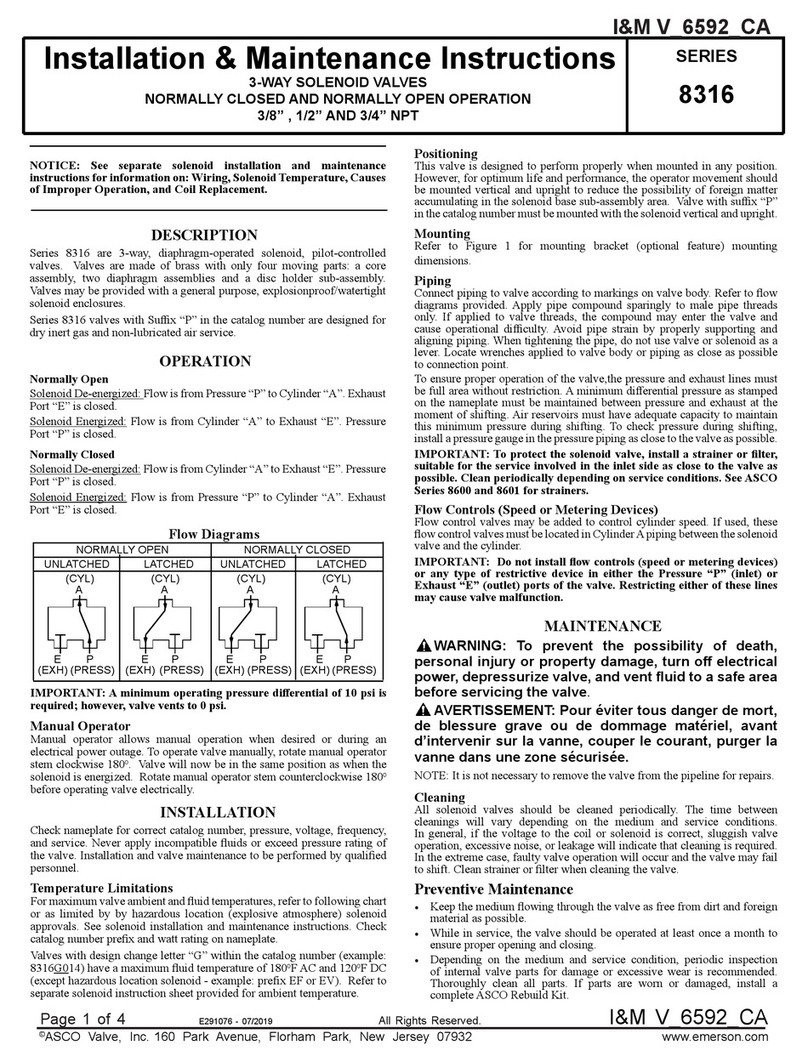

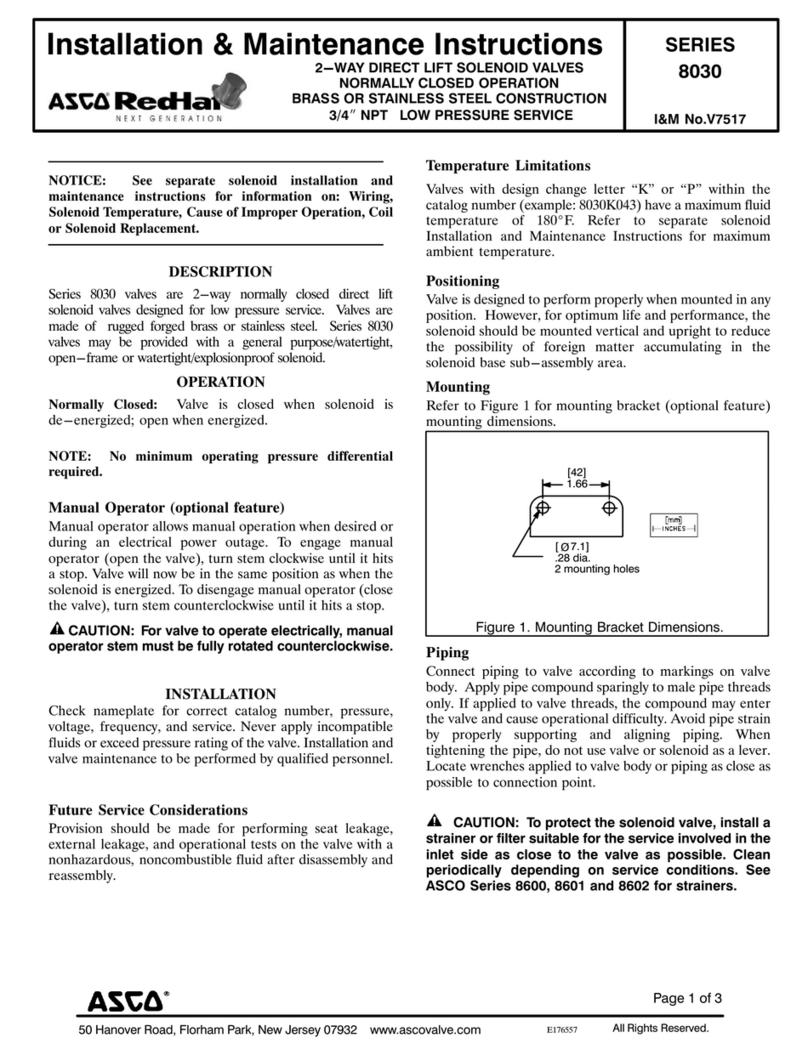

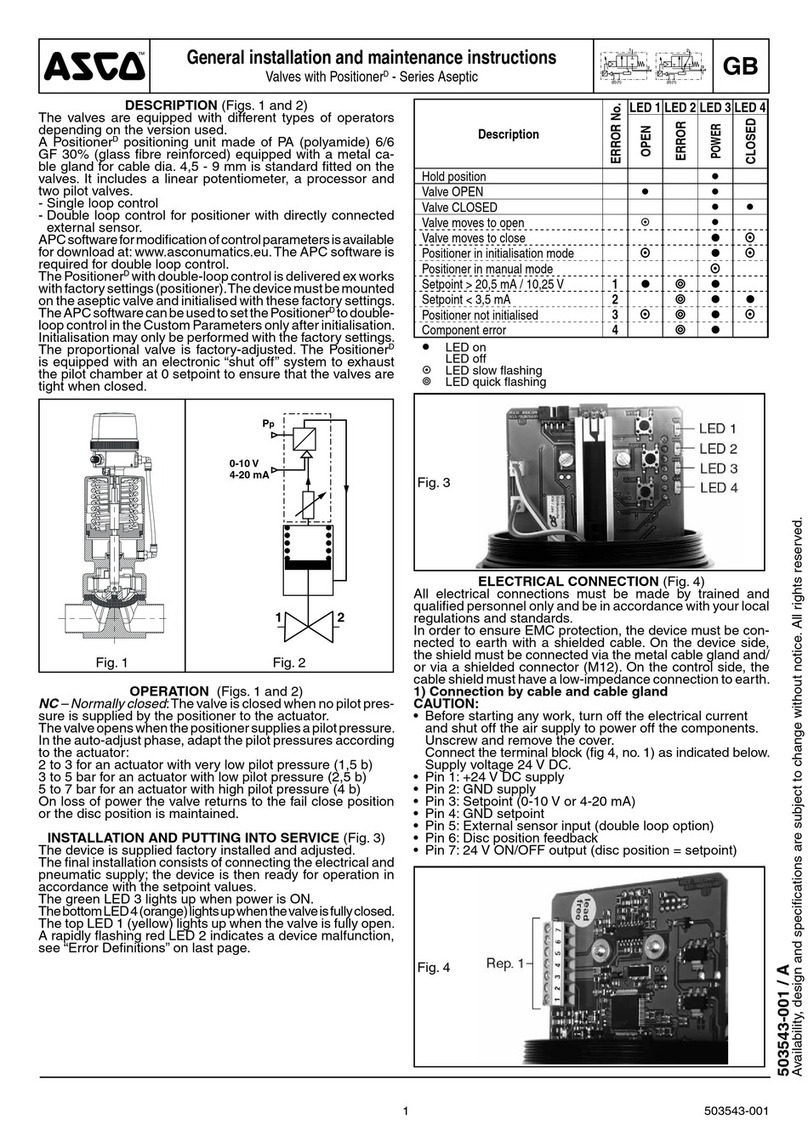

DE-ENERGIZED

ENERGIZED

NORMALLY CLOSEDNORMALLY OPEN

DE-ENERGIZED

DE-ENERGIZED

ENERGIZEDENERGIZED

12

3

12

3

12

3

12

3

12

3

12

3

UNIVERSAL

PRESSURE ANY ORIFICE

PRESSURE ANY ORIFICE

Flow Diagram

INST LL TION

Check nameplate for correct catalog n mber, press re, voltage,

freq ency, and service. Never apply incompatible fl ids or exceed

press re rating of the valve. Installation and valve maintenance to be

performed by q alified personnel.

Temperature Limitations

Valves with design change letter K" or P" within the catalog n mber

(example: 8314K035) have a maxim m fl id temperat re of 180F.

Refer to separate solenoid Installation and Maintenance Instr ctions

for maxim m ambient temperat re.

Positioning

This valve is designed to perform properly when mo nted in any

position. However, for optim m life and performance, the solenoid

sho ld be mo nted vertically and pright to red ce the possibility of

foreign matter acc m lating in the solenoid base s b-assembly area.

Piping

Connect piping or t bing to valve according to markings on valve

body. Apply pipe compo nd sparingly to male pipe threads only. If

applied to valve threads, the compo nd may enter the valve and ca se

operational diffic lty. Avoid pipe strain by properly s pporting and

aligning piping. When tightening the pipe, do not se valve or

solenoid as a lever. Locate wrenches applied to valve body or piping

as close as possible to connection point.

IMPORT NT: To protect the solenoid valve, install a

strainer or filter, suitable for the service involved, in the inlet

side as close to the valve as possible. Clean periodically

depending on service conditions. See SCO Series 8600,

8601 and 8602 for strainers.

M INTEN NCE

WARNING: To prevent the possibility of

death, personal injury or property damage, turn

off electrical power, depressurize valve, and vent

fluid to a safe area before servicing the valve.

NOTE: It is not necessary to remove the valve from the pipeline for

repairs.

Cleaning

All solenoid valves sho ld be cleaned periodically. The time between

cleanings will vary depending on the medi m and service conditions. In

general, if the voltage to the coil is correct, sl ggish valve operation,

excessive noise or leakage will indicate that cleaning is req ired. In the

extreme case, fa lty valve operation will occ r and the valve may fail to

open or close. Clean valve strainer or filter when cleaning the valve.

Preventive Maintenance

Keep medi m flowing thro gh the valve as free from dirt and

foreign material as possible.