Installation & Maintenance Instructions

2-WAY DIRECT-ACTING SOLENOID VALVES

REVISION “H” & “R”

NORMALLY OPEN OR NORMALLY CLOSED OPERATION

BRASS OR STAINLESS STEEL CONSTRUCTION - 1/8 , 1/4 , OR 3/8 PIPE THREADS

SERIES

8262

8263

(Section 1 of 2)

IMPORTANT: See separate solenoid installation and maintenance

instructions for information on: Wiring, Solenoid Temperature,

Causes of Improper Operation, and Coil or Solenoid Replacement.

DESCRIPTION

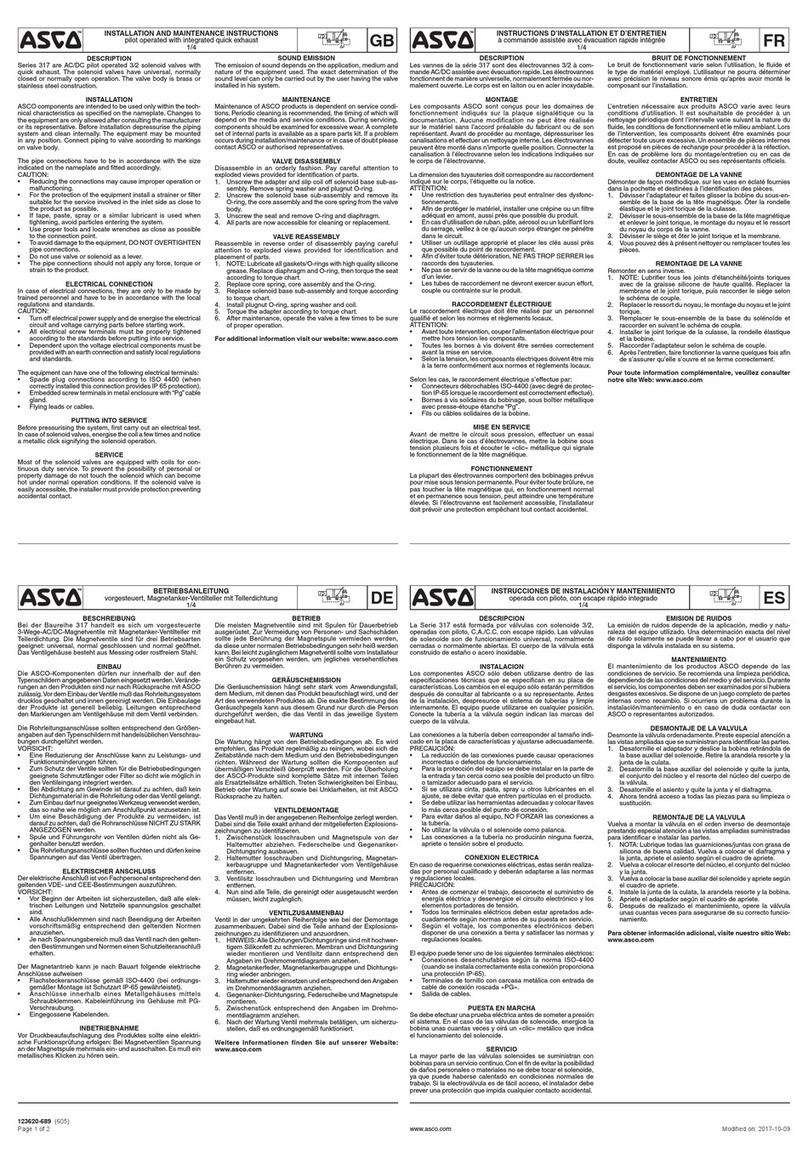

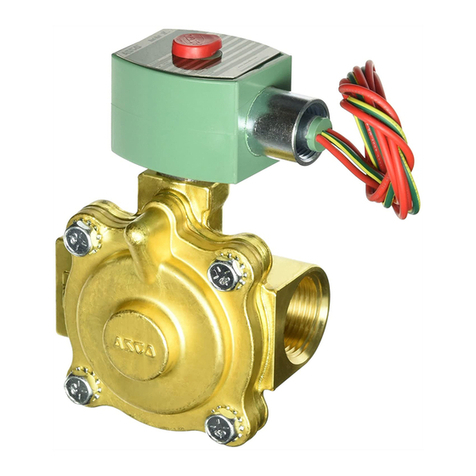

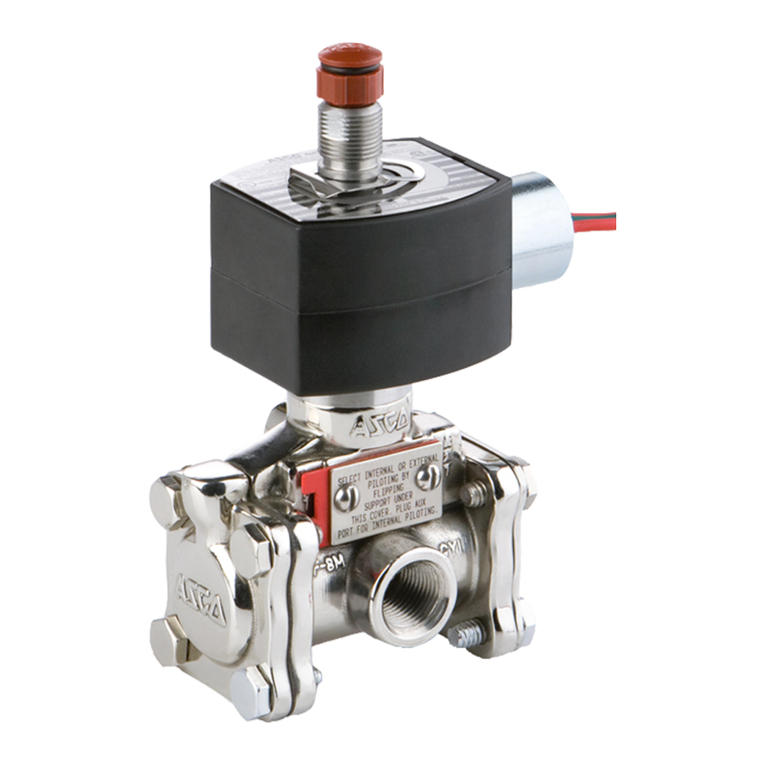

Series 8262 and 8263 valves are 2-way direct-acting general service

solenoid valves. Valves bodies are of rugged brass or stainless steel.

Series 8262 or 8263 valves may be provided with a watertight/

explosionproof solenoid enclosure.

Notice: Brass valves are not certified as lead-free under the Safe

Water Drinking Act SWDA 1417 and are not intended for use on

drinking water systems. They are intended for control of water in

industrial applications. Consult ASCO for valves rated for use in

potable water applications.

OPERATION

Normally Open: Valve is open when solenoid is de-energized; closed

when energized.

Normally Closed: Valve is closed when solenoid is de-energized;

open when energized.

IMPORTANT: No minimum operating pressure required.

Manual Operation (Valves with Suffix MS)

Manual operator allows manual operation when desired or during

an electrical power outage. To engage manual operator, rotate stem

on the side of the body clockwise until it hits a stop, approximately

90º from its original position. Do NOT rotate beyond stops. Do NOT

apply excessive force beyond stops. Valve will now be in the same

position as when the solenoid is energized. To disengage,rotate stem

counterclockwise until it hits a stop, approximately 90º from its original

position. Do NOT rotate beyond stops. Do NOT apply excessive force

beyond stops.

MS option is not available on normally closed valves that have a

pressure rating greater than 750 PSI. MS option is not available on

normally open valves.

CAUTION: Do NOT rotate beyond 90 stops. Do NOT

apply excessive force beyond stops. Rotating beyond the

90 result in equipment damage.

CAUTION: For valve to operate electrically, manual

operator stem must be fully rotated counterclockwise.

INSTALLATION

Check nameplate for correct catalog number, pressure, voltage,

frequency, and service. Never apply incompatible fluids or exceed

pressure rating of the valve. Installation and valve maintenance to be

performed by qualified personnel.

Note: Inlet port will either be marked “1” or “IN”. Outlet port will be

marked “2” or “OUT”. (see Figure 1)

Future Service Considerations.

Provision should be made for performing seat leakage, external leakage,

and operational tests on the valve with a nonhazardous,noncombustible

fluid after disassembly and reassembly.

Temperature Limitations

For maximum valve ambient and fluid temperatures, refer to the

following tables. Use catalog number, coil prefix, suffix,and watt rating

on nameplate to identify the maximum ambient and fluid temperatures.

NOTE: The following Temperature Limitations Tables do not apply

to Magnetic Latch Valves: Catalog Numbers 8262A610 to 8262A627;

8263A615 to 8263A618, and 8263A624 to 8263A627. See separate

Instruction Manual.

= EF, EV data applies to Explosionproof coils only.

= DC Normally closed solenoid valves can be operated at maximum

ambient temperature of 55° C / 131° F with reduced pressure

ratings. See page 5 of 5, Section 2 of 2 for maximum operating

pressure differential.

= Solenoid coils with prefix EF & EV are limited to a maximum fluid

temperature of 99°C/ 210°F

= Urethane (UR) elastomer applies to catalog numbers 8262H079, 089,

096 099, 106, 107, 154, 155, 159, 161, 167, 168, 173, 175, 176, 180,

181, 198, 199, 200, 214 and 8262R107, 181, 155, 161, 168, 169.

= Normally open 8262H & 8263H valves fitted with HB 17.1 watt AC

coils have a maximum fluid temperature of 75°C (167°F)

I&M No. V 9575 R5 - Sec. 1

E244785 - 4/14 All Rights Reserved.

©ASCO Valve, Inc. 50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

I&M No. V 9575 R5 - Sec. 1

Page 1 of 5 (Section 1 of 2)

ASCO Valves®

Max. Ambient Temperature Limitations forAC and DC Coil Valves,

Catalog Numbers 8262H/R & 8263H/R

Prefix

Coil

Class

Watt Ratings Max Ambient

Temperature

AC DC Normally

Closed Normally

Open

60Hz 50Hz °C °F °C °F

EF,EV FT 6.1, 10.1 8.1, 10.1 -52 125 52 125

EF,EV FB 9.1, 17.1 11.1, 17.1 ---

FT 6.1, 10.1 8.1, 10.1 -55 131 55 131

FB 9.1, 17.1 11.1, 17.1 ---

HT --10.6, 11.6 40

104

55 131

HB --22.6, 18.6

EF,EV HT --10.6, 11.6

EF,EV HB --22.6, 18.6

HT 6.1, 10.1 8.1, 10.1 -

60 140

60 140

HB 9.1, 17.1 11.1, 17.1 -55 131

EF,EV HT 6.1, 10.1 8.1, 10.1 -60 140

EF,EV HB 9.1, 17.1 11.1, 17.1 ---

-2 2 2 60 140

Max. Ambient Temperature Limitations forAC and DC Coil Valves,

Catalog Numbers 8262H/R & 8263H/R

Valve

Elastomer/

Suffix Coil

Class

Watt Ratings Max. Fluid

Temp.

AC DC

60Hz 50Hz °C °F

UR/None

FT, FB,

HT, HB

6.1, 10.1,

9.1, 17.1,

2

8.1, 10.1,

11.1,

17.1, 2

10.6,

11.6,

18.6,

22.6, 2

60 140

NBR/

None82

180

CR/J

Lt-Nitrile/A 75 167

EPDM/E 99

210

FKM/V &

PTFE/T

FT 6.1, 10.1 8.1, 10.1 -

99

210

FB 11.1, 17.1 -

HT with

EF/EV

Prefix 6.1, 10.1 8.1, 10.1 10.6, 11.6

HB with

EF/EV

Prefix 9.1, 17.1 11.1, 17.1 18.6, 22.6

HT 6.1, 10.1 8.1, 10.1 10.6, 11.6 121

250

HB9.1, 17.1 11.1, 17.1 18.6, 22.6

-222