Page 5 of 8 (Section 2 of 2)

50-60 Hanover Road, Florham Park, ew Jersey 07932

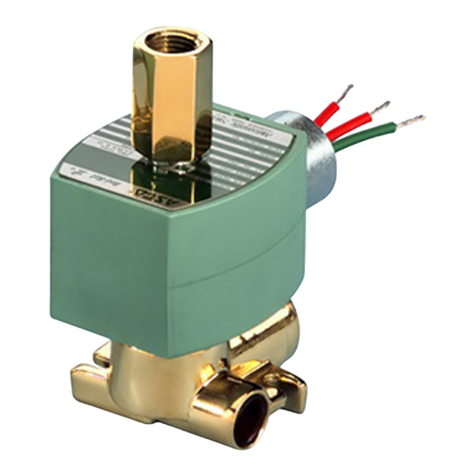

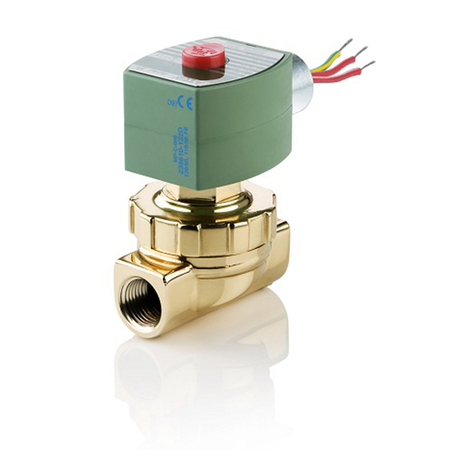

ASCO Valves

eMCMXCVII All Rights Reserved. Printed in U.S.A.

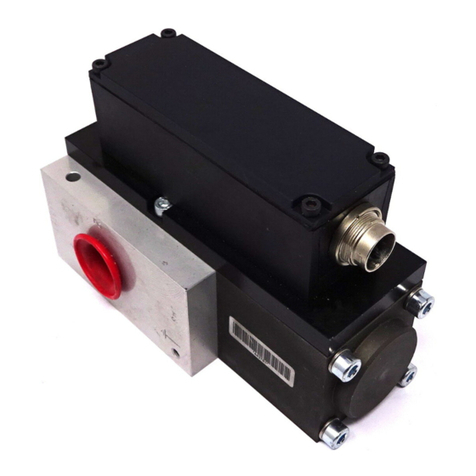

Installation & Maintenance Instructions SERIES

2 POSITION, 3-WA AND 4-WA FUNCTION 8401

ADAPTER BASE MOUNTED SOLENOID PILOTED VALVES

FOR KE STONE, NAMUR AND GH-BETTIS AIR ACTUATORS - 1/4I NPT Form No.V6844R2 - Sec. 2

(Section 2 of 2)

NOTICE: See Installation and Maintenance Instructions, Form No.V6844 - Section of 2 for detailed instructions.

Continued from Form No. V6844 - Section 1 of 2

Solenoid Temperature

Series 8401 valves are supplied with coils designed for conĆ

tinuous duty service. When the solenoid is energized for a

long period, the solenoid coil beco es hot and can be

touched with the hand for only an instant. This is a safe opĆ

erating te perature. Any excessive heating will be indiĆ

cated by the s oke and odor of burning coil insulation.

MAINTENANCE

WARNING: To prevent the possibility of

personal injury or property damage, turn off

electrical power, depressurize valve, and

vent fluid to a safe area before servicing the

valve.

NOTE: The entire solenoid valve ust be re oved fro the

actuator for inspecting, cleaning, and/or rebuilding. It is not

necessary to solenoid valve for coil or pilot valve replaceĆ

ent.

Cleaning

All solenoid valves should be cleaned periodically. The ti e

between cleaning will vary depending on the ediu and

service conditions. In general, if the voltage to the coil is corĆ

rect, sluggish valve operation, excessive noise, or leakage

will indicate that cleaning is required. In the extre e case,

faulty valve operation will occur and the valve ay fail to

shift. Clean strainer or filter when cleaning the valve.

Preventive Maintenance

SKeep the ediu flowing through the valve as free fro

dirt and foreign aterial as possible.

SWhile in service, the valve should be operated at least

once a onth to ensure proper operation.

Causes Of Improper Operation

SFaulty Control Circuits: Check the electrical syste s by

energizing the solenoid. A etallic click signifies that the

solenoid is operating. Absence of the click indicates loss

of power supply. Check for loose or blown fuses,

open-circuited or grounded coil, broken lead wires or

splice connections.

SBurned-Out Coil: Check for open-circuited coil.

Replace coil as necessary: see Coil Replacement check

supply voltage; it ust be the sa e as specified on

na eplate.

SLow Voltage: Check voltage across the coil leads. Voltage

ust be at least 85% of na eplating rating.

SIncorrect Pressure: Check valve pressure. Pressure to

valve ust be within range specified on na eplate.

SExcessive Leakage: Disasse ble valve, and install a

co plete ASCO Rebuild Kit and pilot valve.

Coil Replacement

1. Disconnect coil lead wires, then re ove retaining clip or

cap.

2. Slip coil off the plugnut/core tube sub-asse bly.

CAUTION: When retaining clip disengages, it

springs outward.

3. Install new coil and replace retaining clip or cap. Torque

retaining cap to 10 - 12 in-lbs [1,1 - 1,3 N ] with a

21/32I socket.

4. Make electrical hookup; see Wiring section.

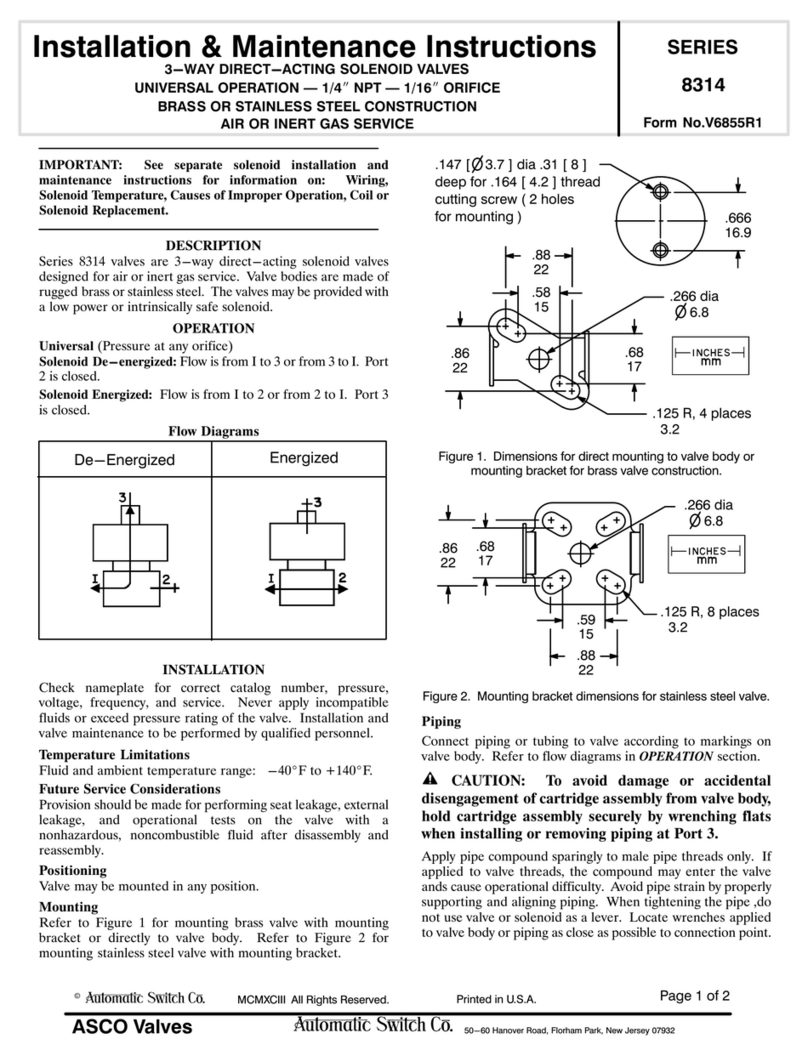

Valve Disassembly

5. Disasse ble valve in an orderly fashion. Use exploded

views for identification and place ent of parts.

6. Disconnect coil leads or re ove coil fro solenoid pilot

valve. See Coil Replacement section.

7. Re ove entire valve with flow gasket fro actuator as

follows:

SNamur Actuator - Re ove two socket head cap

screws using a 4 hex key wrench.

SKeystone Actuator - Re ove four socket head cap

screws, one fro each corner using a 5/32I hex key

wrench.

SGH-Bettis Actuator - Re ove four hex head

achine screws, one fro each corner using 5/16I

wrench.

8. Re ove two pilot valve screws, bracket (if present), pilot

valve asse bly, and two pilot valve gaskets fro valve

body.

CAUTION: When removing base screws hold valve

body/adapter base assembly together to prevent

parts from disengaging prematurely.