3

Customer Care Center 1-800-898-1879 www.askousa.com

Date: November 2006

The contents of this user manual describe the

drying cabinet’s:

Function

Use

This user manual

Contents

and contains instructions for:

Installation

Maintenance

Important safety instructions . . . . . . . . 4

Symbols . . . . . . . . . . . . . . . . . . . . . 4

Important safety information . . . . . . 4

Description of the drying cabinet . . . . 5

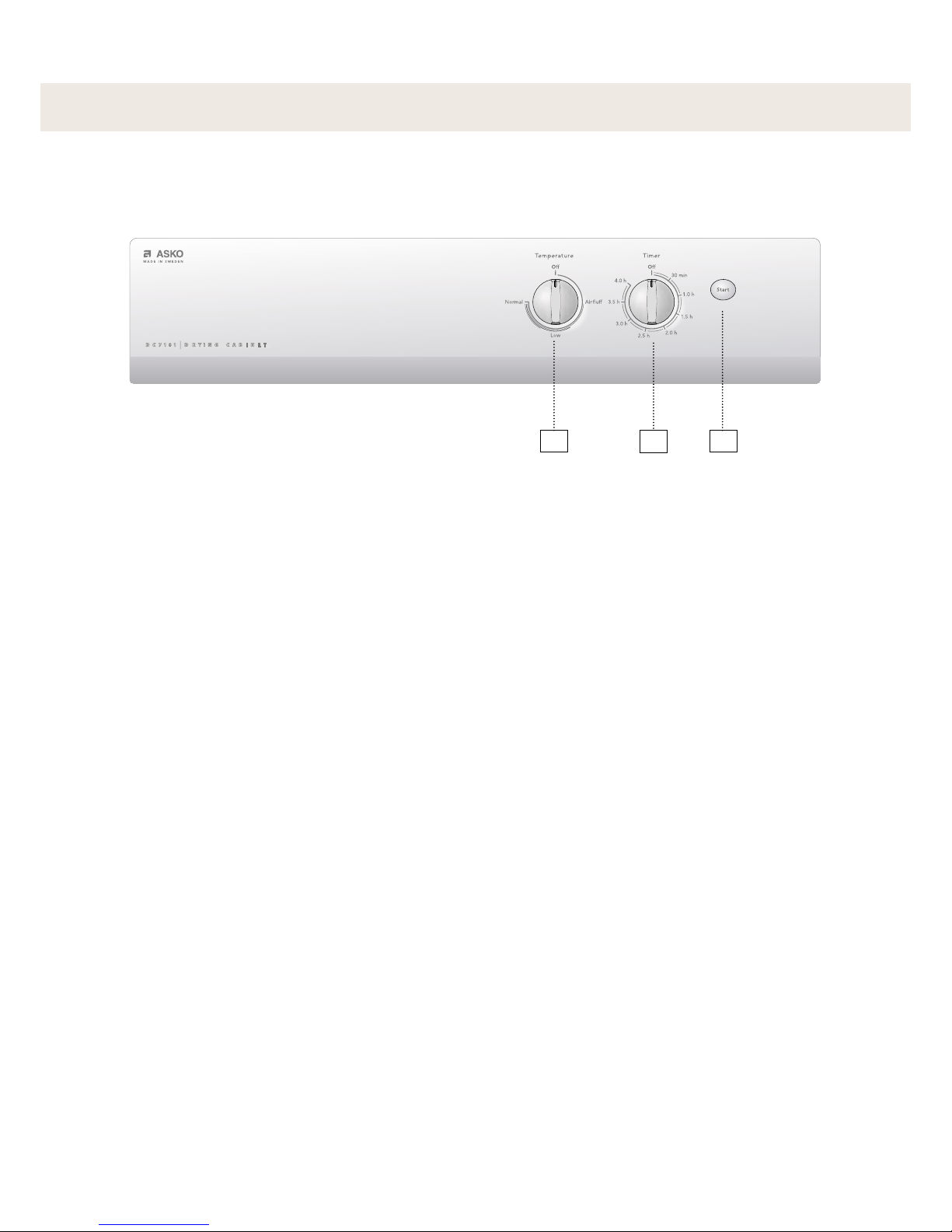

Control panel . . . . . . . . . . . . . . . . . . . . . 6

Location requirements . . . . . . . . . . . . . 7

Electrical requirements . . . . . . . . . . . . . 8

User liability. . . . . . . . . . . . . . . . . . . 8

Electrical connection . . . . . . . . . . . . 8

Grounding instructions . . . . . . . . . . 8

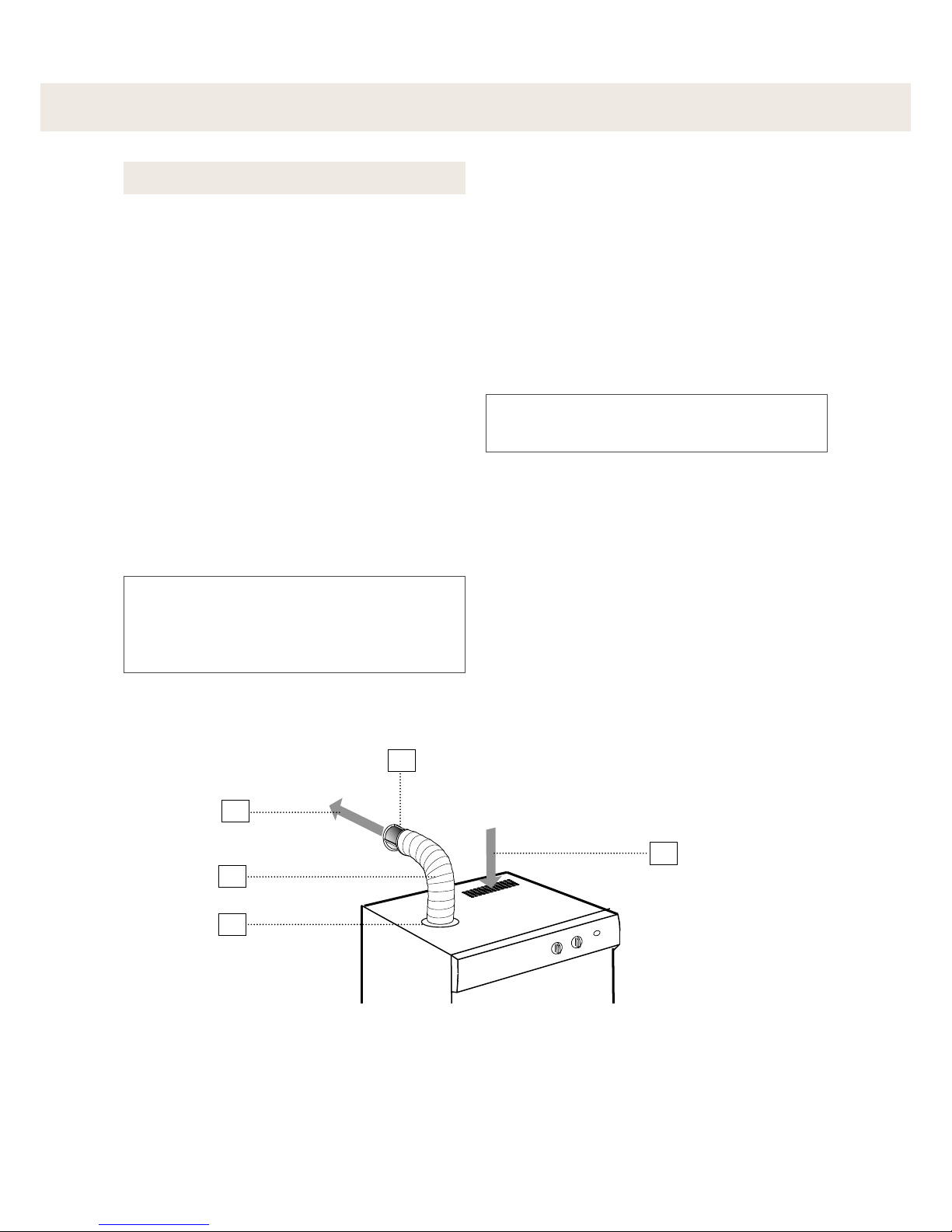

Ventilation requirements . . . . . . . . . . . . 9

Ventilation out into the room where

the drying cabinet is located . . . . . . 9

Connection to a vent duct . . . . . . . 10

Installation instructions . . . . . . . . . . . 12

Unpacking drying cabinet . . . . . . . 12

A complete delivery includes . . . . 12

Recommended tools . . . . . . . . . . . 12

Assembly kit . . . . . . . . . . . . . . . . . 13

Reverse door swing . . . . . . . . . . . . 14

Level drying cabinet . . . . . . . . . . . 15

Attaching drying cabinet to wal

l . . . . 15

Mounting into custom cabinetry

. . . . 16

Ventilation connection . . . . . . . . . . 18

Electrical connection . . . . . . . . . . . 18

Final inspection . . . . . . . . . . . . . . . 19

Operation instructions . . . . . . . . . . . . 20

Starting your drying cabinet . . . . . 20

Pausing or restarting. . . . . . . . . . . 20

Stopping your drying cabinet . . . . 20

Loading . . . . . . . . . . . . . . . . . . . . . 20

Cycle and drying tips. . . . . . . . . . . 21

Cycles . . . . . . . . . . . . . . . . . . . . . . 22

Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Cleaning the drying cabinet . . . . . 23

When the drying cabinet is not in

use . . . . . . . . . . . . . . . . . . . . . . . . 23

Troubleshooting . . . . . . . . . . . . . . . . . . 24

Service and Warranty . . . . . . . . . . . . . 25

Technical data . . . . . . . . . . . . . . . . . . . 27

Technical characteristics . . . . . . . . 27

Exhaust . . . . . . . . . . . . . . . . . . . . . 27

Energy consumption and drying

times . . . . . . . . . . . . . . . . . . . . . . 27

Manufacturing standards . . . . . . . . 27

Installation spacing for custom

cabinetry . . . . . . . . . . . . . . . . . . . . 27

Personal notes . . . . . . . . . . . . . . . . . . . 28