Updates ..................................................................................................................................................................................................................................................4

Introduction .........................................................................................................................................................................................................................................5

Troubleshooting strategy ..............................................................................................................................................................................................................6

Product overview .............................................................................................................................................................................................................................7

Technical data ......................................................................................................................................................................................................................................9

Component descriptions .......................................................................................................................................................................................................... 10

Components and measurement values ......................................................................................................................................................................10

Components and function description ........................................................................................................................................................................12

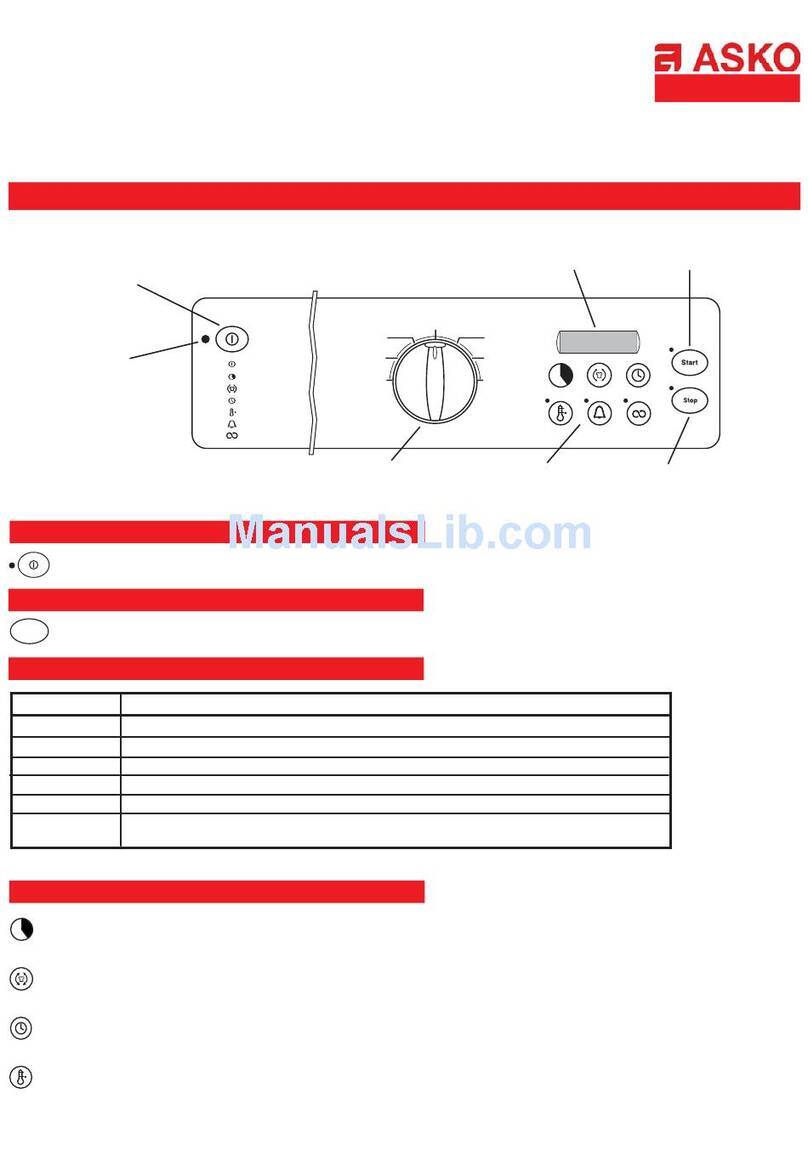

Control unit ......................................................................................................................................................................................................................................16

Circuit diagram TD70.1 ........................................................................................................................................................................................................16

Circuit diagram TD70.2 ........................................................................................................................................................................................................18

Circuit diagram TD70.2 HP ................................................................................................................................................................................................20

Circuit diagram TD70.2 HWC .........................................................................................................................................................................................22

Circuit diagram TD70.3 ........................................................................................................................................................................................................24

Troubleshooting ..............................................................................................................................................................................................................................26

Fault indicators TD70.1 .........................................................................................................................................................................................................26

Fault indicators TD70.2 .........................................................................................................................................................................................................27

Fault indicators TD70.3 .........................................................................................................................................................................................................29

Other faults .................................................................................................................................................................................................................................30

Service menu and settings ........................................................................................................................................................................................................ 32

Service menu TD70.1 ............................................................................................................................................................................................................ 32

Service menu TD70.2 ............................................................................................................................................................................................................ 34

Service menu TD70.3 ............................................................................................................................................................................................................ 36

Settings ........................................................................................................................................................................................................................................... 38

Activating heating element 2 TD70.1 ....................................................................................................................................................................38

Activating heating element 2 TD70.2 ....................................................................................................................................................................38

Activating heating element 2 TD70.3 ....................................................................................................................................................................38

Store program ......................................................................................................................................................................................................................38

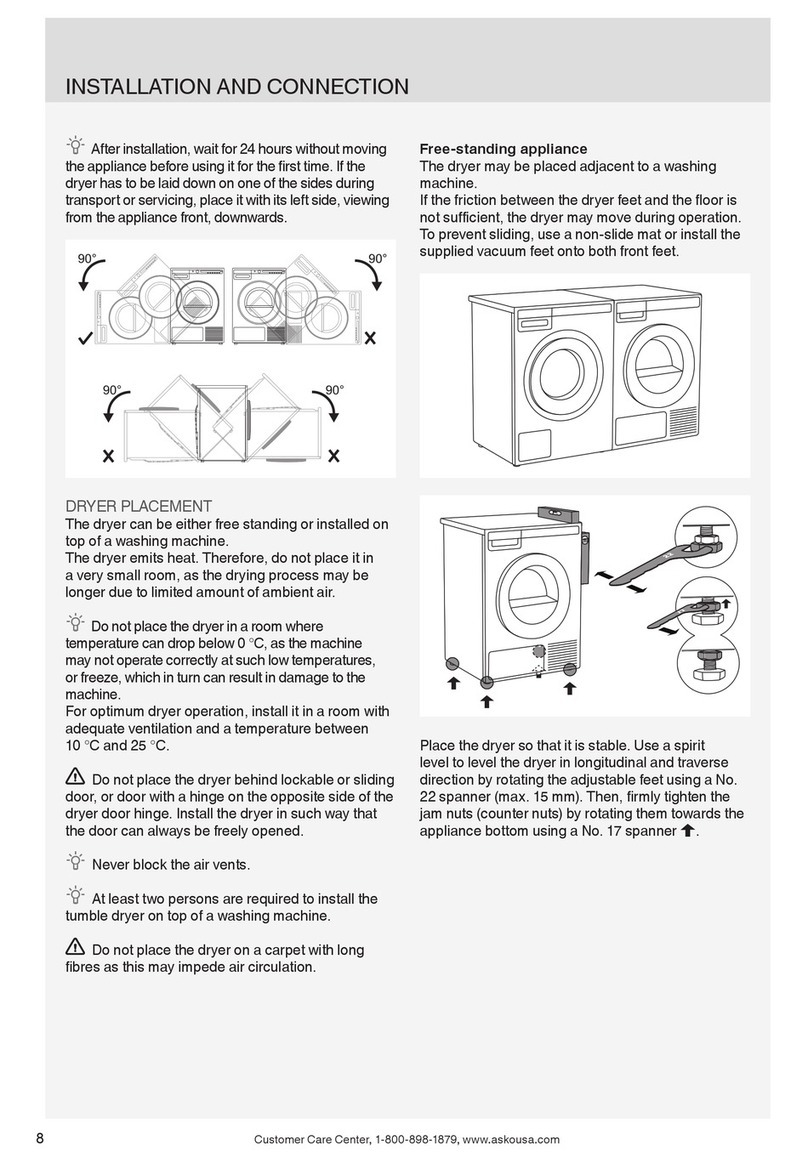

Service and installation

Removing top plate and rear panel .............................................................................................................................................................................39

Replacing the panel and the control unit ..................................................................................................................................................................41

Transporting a tumble dryer with a heat pump ....................................................................................................................................................43

Tumble Dryer TD70

Service Manual

Contents