BPC65 / BDIST / MDIST – Installation Guide

U-0456-0142.doc – Issue: 03 complete, approved

Page 3 of 20

1 General Information

Technical Specification Summary

BPC65

AC Supply Voltage.........................................................................................................................230 V ±10% RMS 50Hz AC

In-rush Current (worst case) ......................................................................................................................................... 40 A

Maximum AC VA Rating (110 V).................................................................................................................................. 253 VA

AC Supply Fuse Rating............................................................................................................................... T3.15A IEC60127

Output Voltage .............................................................................................................................................. 27.3 V (@ 20°C)

Charger Output Fuse Rating ...................................................................................................... 7.5 A (mini blade type fuse)

Lowest voltage to which the battery can be discharged .................................................................................................21 V

Rated Continuous Maximum Output Current (Imax. a) ................................................................................................... 1.75 A

Rated Maximum Output Current (Imax. b) ........................................................................................................................... 5 A

Minimum Loading of the Equipment (Imin) ................................................................................................................... 50 mA

Maximum value of internal battery resistance

for which rack functionality can be maintained (Ri max)..................................................................................................0.1 Ω

Charger Output Current.................................................................................................... 3 A / Type C Mini Circuit Breaker

Battery Output Current ................................................................................................... 25 A / Type C Mini Circuit Breaker

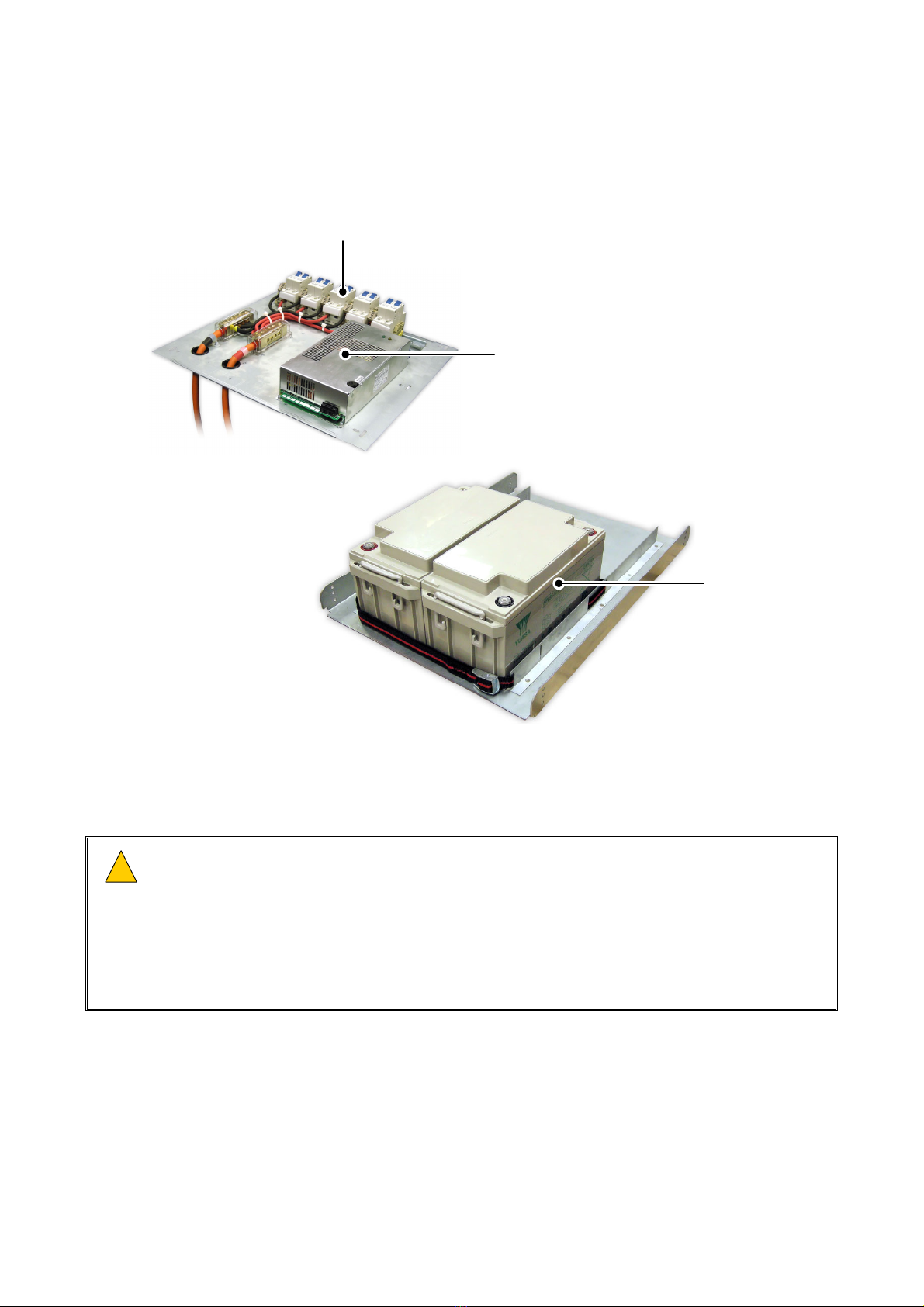

Batteries ....................................................................................................................................2 x Yuasa NPL65-12 (VLRA)

Charging Time..............................................................................................................24 hours to charge to 100% capacity

Temperature Compensation......................................................................................................................... –36 mV/cell/°C

Fault Status Output (Pins 1 and 3)........................................................................... volt-free relay contacts (N/O and COM)

Overall Dimensions (H x W x D) / Weight:

Charger and BDIST Tray.......................................................................................... 80 mm x 450 mm x 385 mm / 5.5 kg

Battery Tray with Batteries (for 800 mm deep rack) ........................................... 176 mm x 476 mm x 660 mm / 55.4 kg

Battery Tray with Batteries (for 600 mm deep rack) ........................................... 176 mm x 476 mm x 460 mm / 51.6 kg

Battery (Yuasa NPL65-12) ...................................................................................... 174 mm x 350 mm x 166 mm / 23 kg

MDIST

Operating Voltage ........................................................................................................................230 V ±10% RMS 50 Hz AC

Input Current ..........................................................................................................................................................32 A max

Output Current (per output)....................................................................................................................................10 A max

General

Temperature ............................................ −20°C to +50°C (storage, fully charged condition) / −10°C to +50°C (operation)

(battery performance is dependent on average operational temperature;

refer to manufacturer’s literature)

Humidity Range.......................................................................................................................... 0% to 93% non-condensing

!

!

At the time of the publication of this Installation Guide, only the BPC65 battery system for Schroff

800 mm Eurorack is EN54-16 and EN 54-4:1997+A1:2002+A2:2006 certified. Please refer to ASL for

further details.