BPC65 / BDIST / MDIST – Product Manual

U-0456-0143.doc – Issue: 03 complete, approved

Page 3 of 32

Contents

1Overview .....................................................................................................................................................4

2Operation ....................................................................................................................................................5

2.1 Controls.......................................................................................................................................5

2.2 Indicators.....................................................................................................................................5

3Installation..................................................................................................................................................6

3.1 Equipment and Tool Requirements ............................................................................................6

3.2 Cabling Requirements.................................................................................................................6

3.3 Main Components........................................................................................................................7

3.4 Recommended Installation Procedure .......................................................................................7

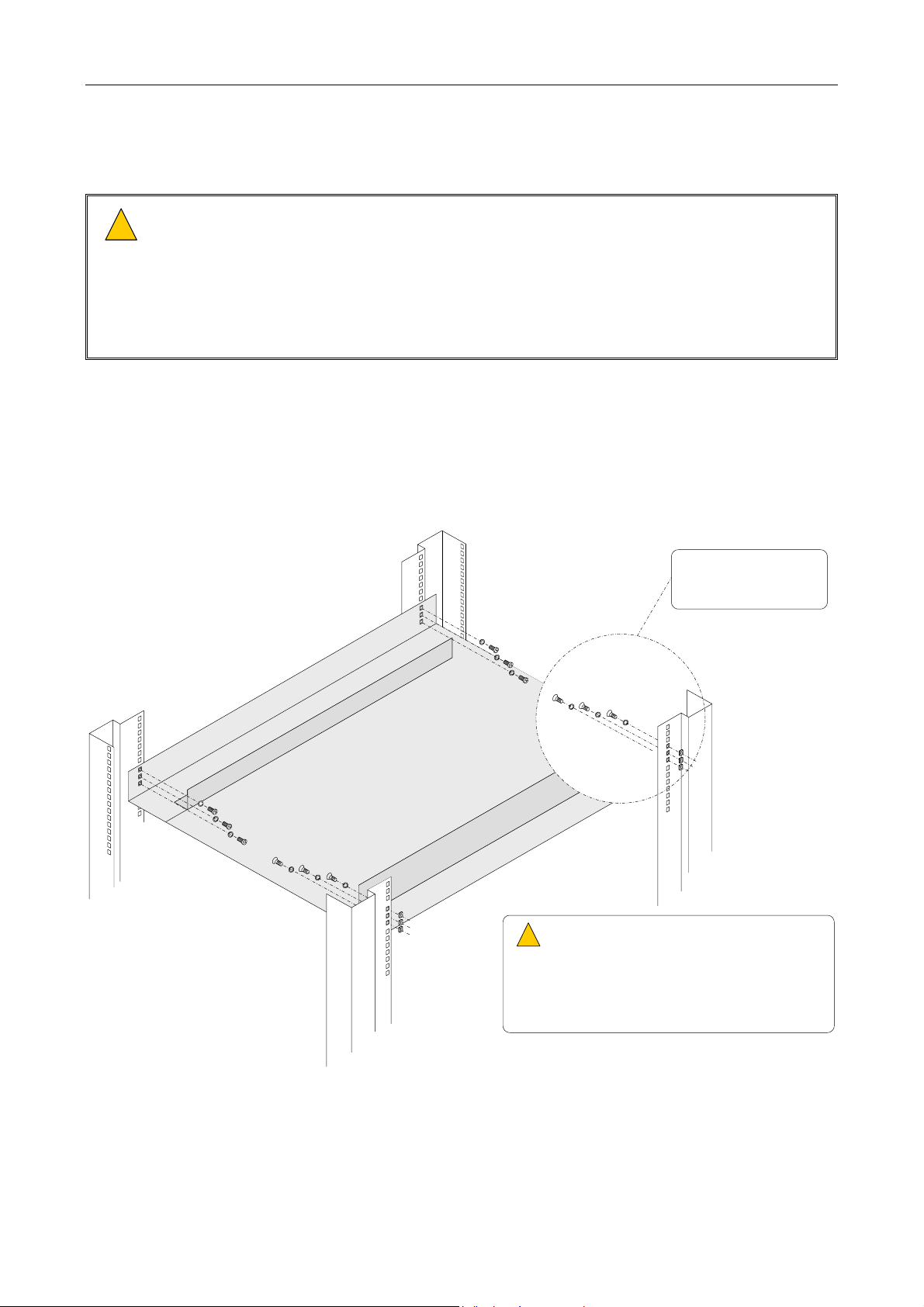

3.4.1 Battery Backup System Installation....................................................................................8

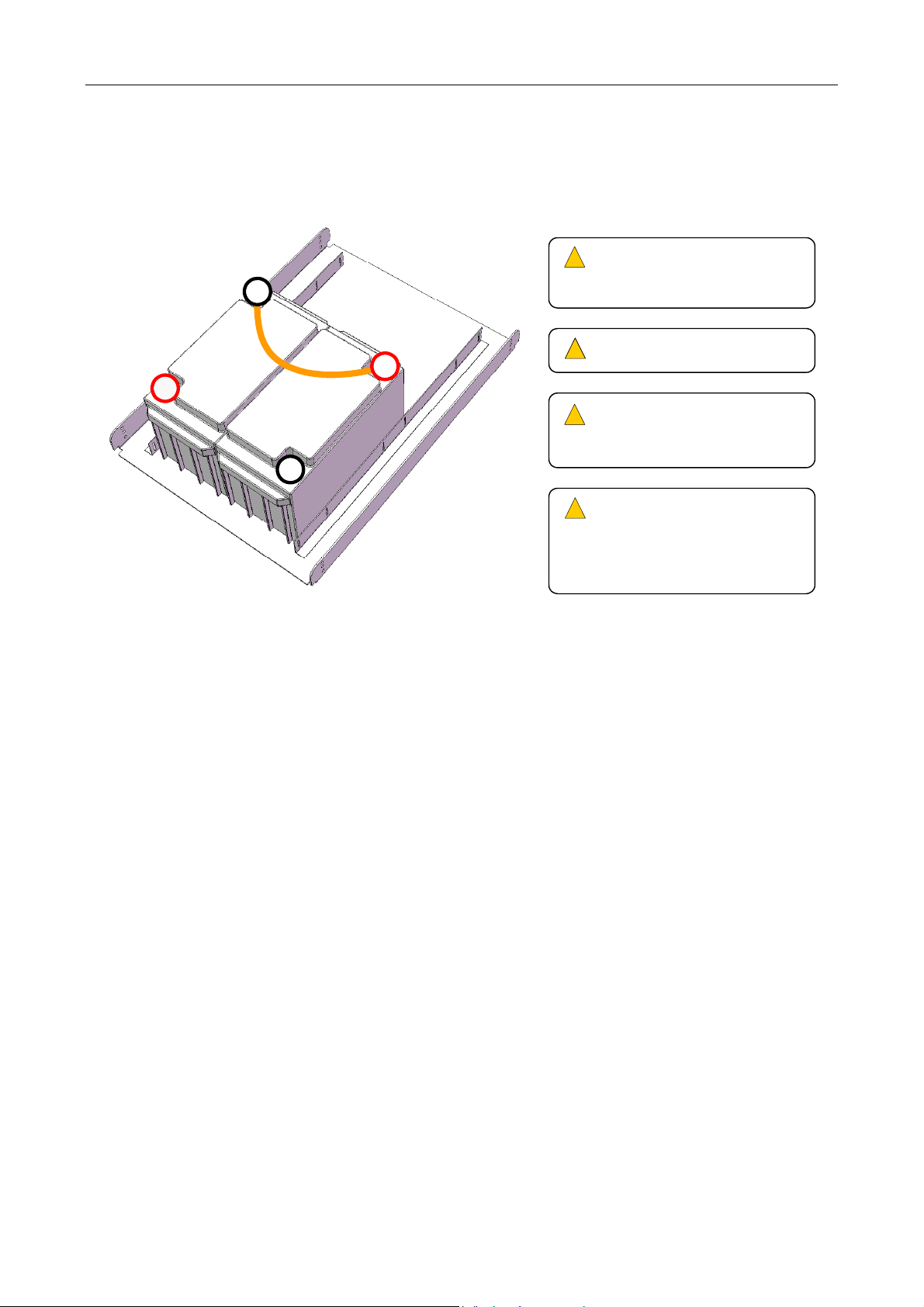

3.4.1.1 Installing the Battery Tray and Batteries..................................................................8

3.4.1.2 Installing the Charger Tray and Charger ................................................................10

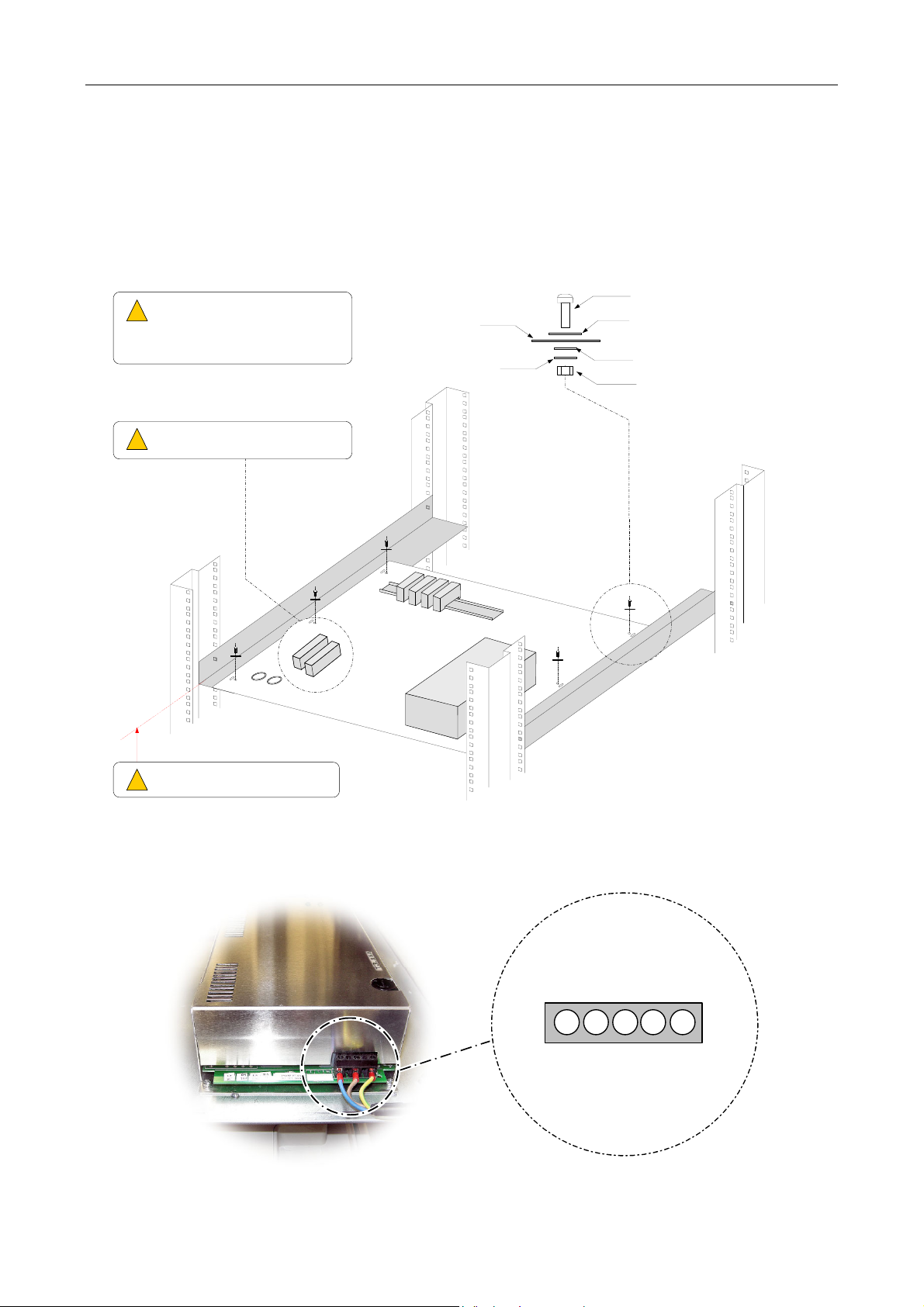

3.4.1.3 Connecting the Power Distribution (BDIST)............................................................12

3.4.1.4 Connecting the Batteries.........................................................................................13

3.4.1.5 Fitting the Front Panel ............................................................................................13

3.4.1.6 Powering the System Up .........................................................................................14

3.4.1.7 Commissioning the Battery Backup System at the Router.....................................14

3.4.2 MDIST Installation .............................................................................................................14

4Connection Diagram .................................................................................................................................15

5Commissioning .........................................................................................................................................16

5.1 Obtaining the Router’s Contact .................................................................................................16

5.2 Configuring the Router Contact for Fault Reporting ................................................................16

5.3 Configuring the Fault Text ........................................................................................................18

5.4 Configuring the Fault Type........................................................................................................18

6Fault Finding.............................................................................................................................................19

7Maintenance .............................................................................................................................................21

7.1 Visual Inspection .......................................................................................................................21

7.2 Resistance Measurement..........................................................................................................21

7.3 Battery Replacement ................................................................................................................22

8Product Specification................................................................................................................................23

9Mechanical Dimensions............................................................................................................................25

10 Safety and Precautions.............................................................................................................................28

10.1 Handling ....................................................................................................................................28

10.2 Installation ................................................................................................................................28

10.3 Weight Safety.............................................................................................................................28

10.4 Environmental...........................................................................................................................28

10.5 Electrical Safety ........................................................................................................................28

10.6 Fire / Burn Safety ......................................................................................................................29

10.7 Battery Disposal ........................................................................................................................29

10.8 Unpacking and Handling ...........................................................................................................29

10.9 Packing for Return for Repair...................................................................................................29

11 Reference Documents ..............................................................................................................................30