www.atestgaz.pl

Table of contents

1 General information................................................................................................................................5

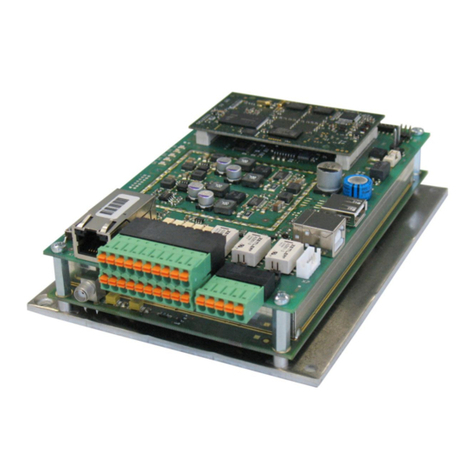

1.1 Brief description of the device...............................................................................................................5

1.2 Purpose..................................................................................................................................................5

2 Safety......................................................................................................................................................6

3 Description of the construction...............................................................................................................6

3.1 Dimension..............................................................................................................................................6

4 Input-output interfaces...........................................................................................................................7

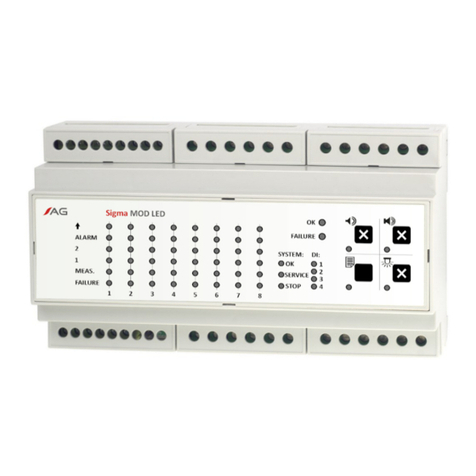

4.1 Indication of the module status.............................................................................................................7

4.2 Current outputs 4..20 mA.......................................................................................................................7

4.3 Electric interfaces...................................................................................................................................8

5 System architectures...............................................................................................................................9

6 Life cycle................................................................................................................................................10

6.1 Transport..............................................................................................................................................10

6.2 Installation............................................................................................................................................10

6.3 Start-up................................................................................................................................................10

6.4 Configuration of the module /system...................................................................................................10

6.5 Diagnostics...........................................................................................................................................11

6.6 Periodical operations............................................................................................................................11

6.7 Utilization.............................................................................................................................................11

7 Technical specification...........................................................................................................................11

8 Product marking....................................................................................................................................12

9 Appendices............................................................................................................................................12

List of Tables

Table 1: Optical indicators status notation...................................................................................................3

Table 2: Output current in arious modes of the module operation............................................................8

Table 3: Electric interface description..........................................................................................................9

Table 4: Technical specification..................................................................................................................12

Table 5: Method of product's marking.......................................................................................................12

List of Figures

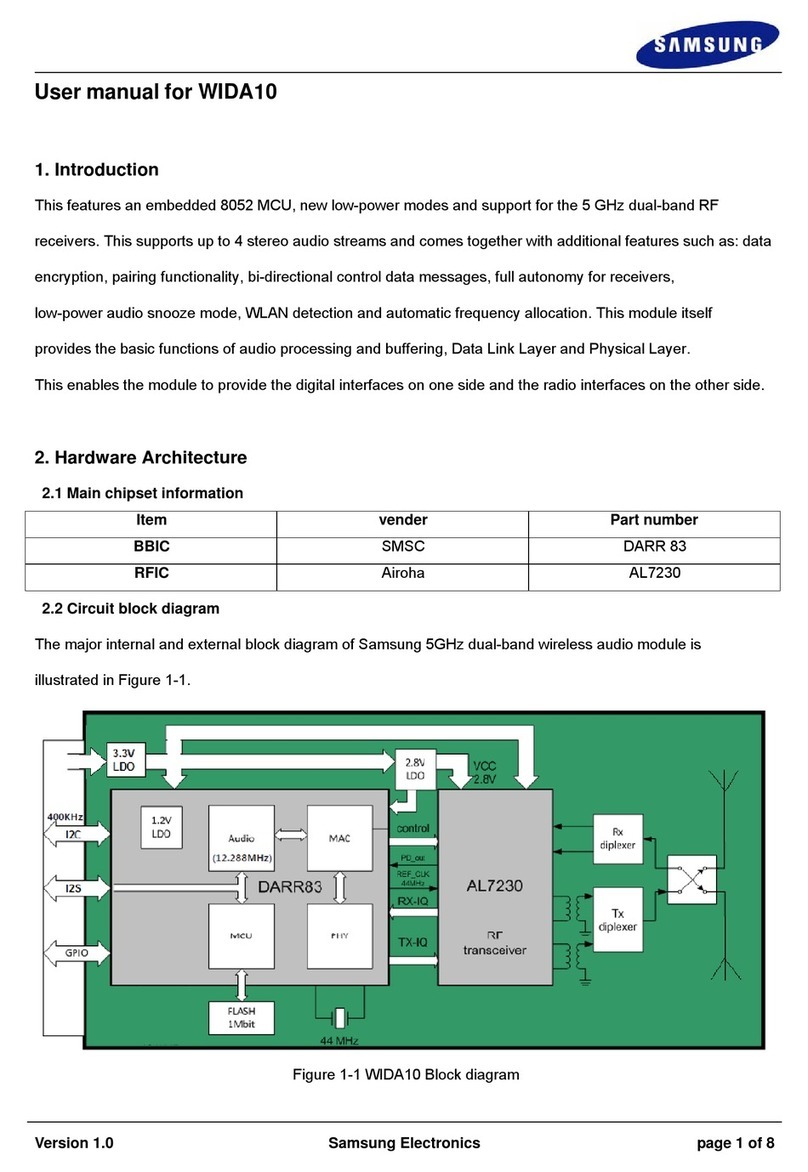

Figure 1: Structure of the Sigma MOD AO module – separation between input and output circuits............5

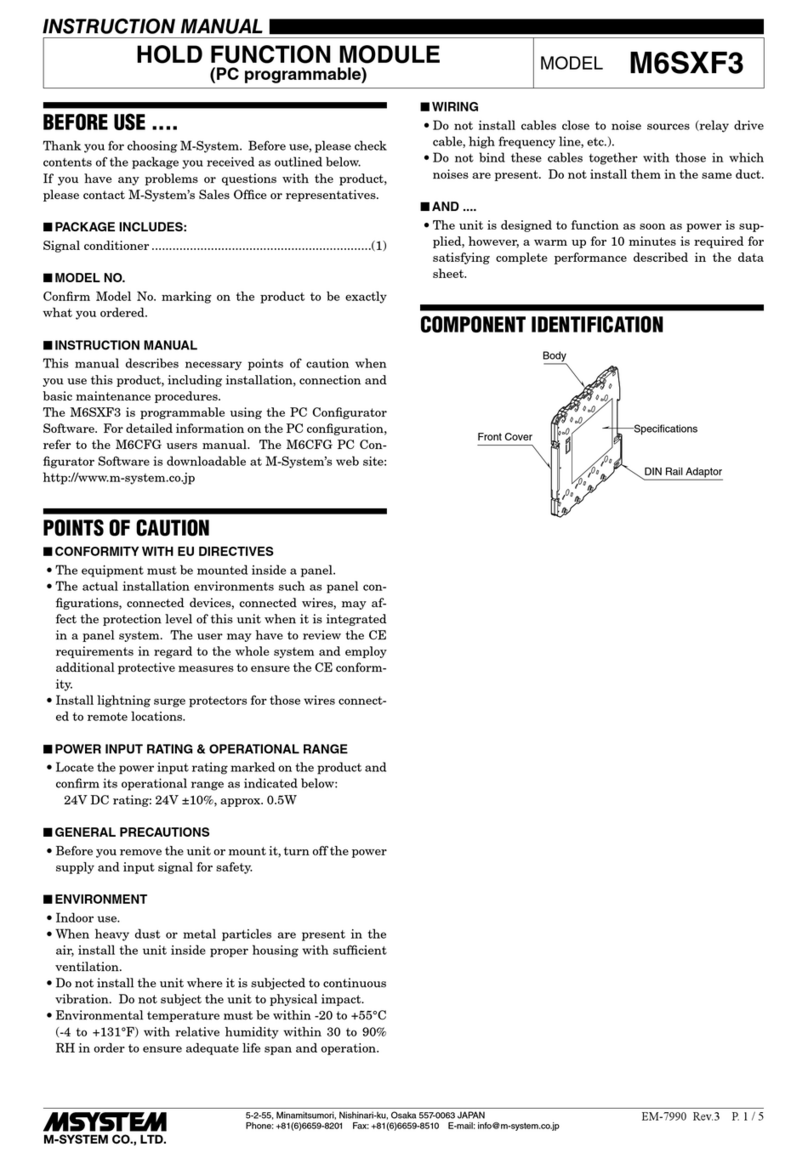

Figure 2: Dimension of de ice.....................................................................................................................6

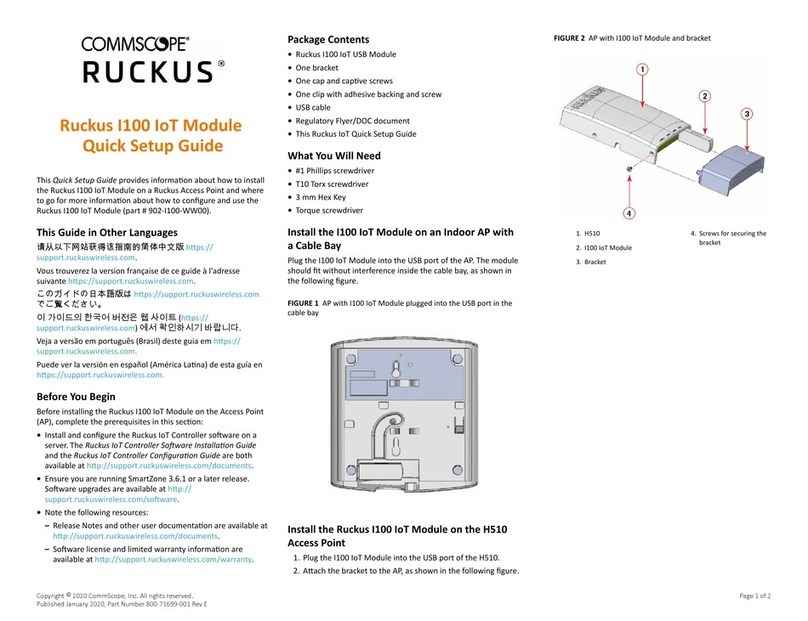

Figure 3: Sigma MOD AO front panel...........................................................................................................7

Figure 4: An acti e output...........................................................................................................................7

Figure 5: A passi e output...........................................................................................................................8

Figure 6: Electric connections......................................................................................................................8

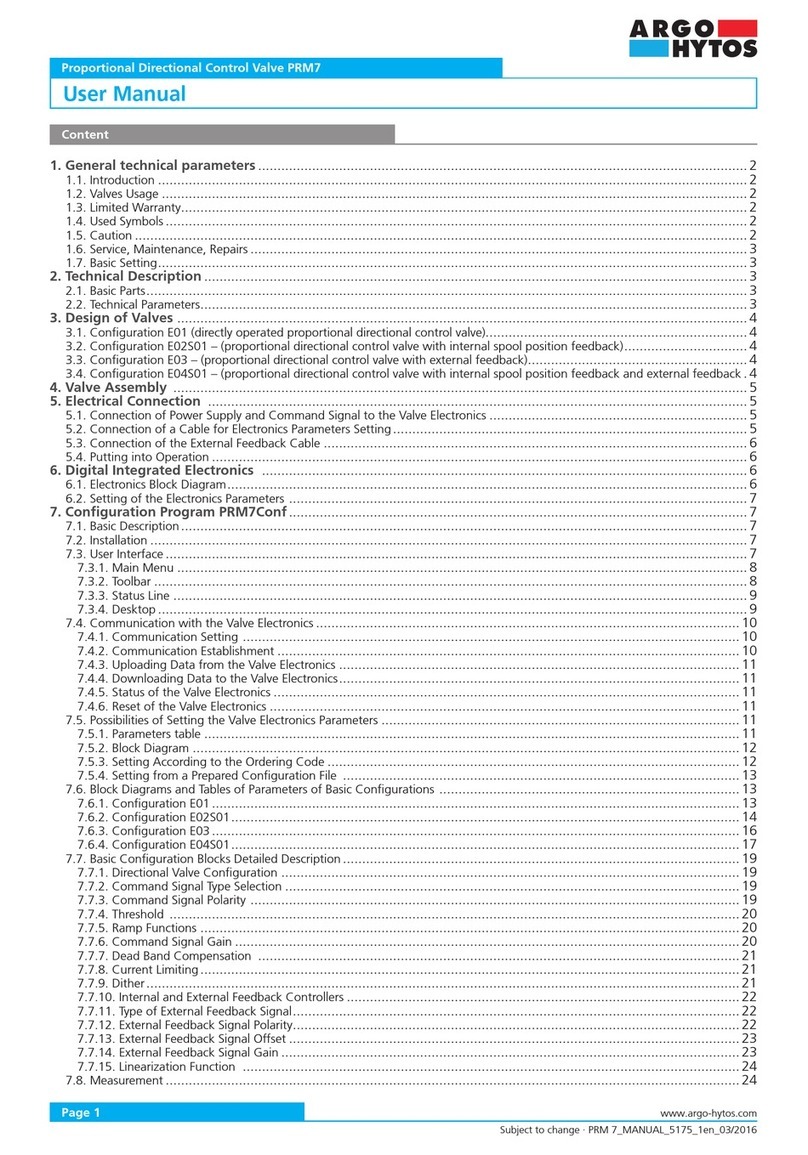

Figure 7: Example of Sigma Gas system architecture with Sigma MOD AO module.....................................9

Figure 8: Current output configuration......................................................................................................10

s. 4|12 User Manual: POD-004-ENG R01