AUMA SGR 05.1 User manual

Control

Parallel

Profibus DP

→Modbus TCP/IP

Foundation Fieldbus

Part-turn actuators

SG 05.1 –SG 12.1/SGR 05.1 –SGR 12.1

Control unit: electronic (MWG)

with actuator controls

AUMATIC AC 01.2 Non-Intrusive

Assembly, operation, commissioningOperation instructions

Read operation instructions first.

●Observe safety instructions.

●These operation instructions are part of the product.

●Retain operation instructions during product life.

●Pass on instructions to any subsequent user or owner of the product.

Purpose of the document:

This document contains information for installation, commissioning, operation and maintenance staff.It is intended

to support device installation and commissioning.

Reference documents:

Reference documents can be downloaded from the Internet (www.auma.com) or ordered directly from AUMA

(refer to <Addresses>).

Table of contents Page

51. Safety instructions................................................................................................................. 51.1. Basic information on safety 51.2. Range of application 61.3. Applications in Ex zone 22 (option) 61.4. Warnings and notes 71.5. References and symbols

82. Identification........................................................................................................................... 82.1. Name plate 92.2. Short description

113. Transport, storage and packaging........................................................................................ 113.1. Transport 113.2. Storage 113.3. Packaging

124. Assembly................................................................................................................................ 124.1. Mounting position 124.2. Ball handle: fit to handwheel 124.3. Part-turn actuator to valve: mount 134.3.1. Coupling 144.4. Mounting positions of local controls 144.4.1. Mounting positions: modify

165. Electrical connection............................................................................................................. 165.1. Basic information 175.2. Connection with AUMA plug/socket connector 175.2.1. Terminal compartment: open 185.2.2. Cable connection 205.2.3. Terminal compartment: close 205.2.4. Bus terminal compartment: open 215.2.5. Industrial Ethernet cable:connect 225.2.6. Bus terminal compartment: close 225.3. Accessories for electrical connection 225.3.1. Controls mounted on wall bracket 235.3.2. Parking frame

2

SG 05.1 –SG 12.1/SGR 05.1 –SGR 12.1 Control unit: electronic (MWG)

Table of contents AC 01.2 Non-Intrusive ModbusTCP/IP

235.3.3. Protection cover 235.3.4. Double sealed intermediate frame

256. Operation................................................................................................................................ 256.1. Manual operation 256.1.1. Manual operation: engage 256.1.2. Manual operation: disengage 256.2. Motor operation 256.2.1. Local actuator operation 266.2.2. Actuator operation from remote 266.3. Menu navigation via push buttons (for settings and indications) 276.3.1. Menu layout and navigation 286.4. User level, password 296.4.1. Password entry 296.4.2. Password change 306.5. Language in the display 306.5.1. Language change

327. Indications.............................................................................................................................. 327.1. Indications during commissioning 327.2. Indications in the display 337.2.1. Feedback indications from actuator and valve 367.2.2. Status indications according to AUMA classification 377.2.3. Status indications according to NAMUR recommendation 387.3. Mechanical position indicator/running indication 397.4. Indication lights

408. Signals..................................................................................................................................... 408.1. Status signals via output contacts (digital outputs) 408.1.1. Assignment of outputs 408.1.2. Coding the outputs 408.2. Analogue signals

419. Commissioning (basic settings)........................................................................................... 419.1. End stops in part-turn actuator 419.1.1. End stop CLOSED: set 429.1.2. End stop OPEN: set 429.2. Swing angle 439.2.1. Swing angle: modify 449.3. Type of seating: set 459.4. Torque switching: set 469.5. Limit switching: set 489.6. Bus address (slave address), baud rate, parity and monitoring time: set 489.6.1. Modbus TCP/IP Gateway: set 499.7. Test run 499.7.1. Direction of rotation: check 499.7.2. Limit switching: check 509.8. Switch compartment: open 509.9. Mechanical position indicator: set 509.10. Switch compartment: close 519.11. Operating time: set

3

SG 05.1 –SG 12.1/SGR 05.1 –SGR 12.1 Control unit: electronic (MWG)

AC 01.2 Non-Intrusive ModbusTCP/IP Table of contents

5310. Corrective action.................................................................................................................... 5310.1. Faults during commissioning 5310.2. Fault indications and warning indications 5610.3. Fuses 5610.3.1. Fuses within the actuator controls 5810.3.2. Motor protection (thermal monitoring)

5911. Servicing and maintenance................................................................................................... 5911.1. Preventive measures for servicing and safe operation 5911.2. Maintenance 5911.3. Disposal and recycling

6012. Technical data......................................................................................................................... 6012.1. Technical data Part-turn actuator 6212.2. Technical data Actuator controls

6813. Spare parts............................................................................................................................. 6813.1. Part-turn actuators SG 05.1 –SG 12.1/SGR 05.1 –SGR 12.1 7013.2. AUMATIC AC 01.2 actuator controls with AUMA plug/socket connector (SFH)

7214. Certificates.............................................................................................................................. 7214.1. Declaration of Incorporation and EC Declaration of Conformity

75Index........................................................................................................................................

77Addresses...............................................................................................................................

4

SG 05.1 –SG 12.1/SGR 05.1 –SGR 12.1 Control unit: electronic (MWG)

Table of contents AC 01.2 Non-Intrusive ModbusTCP/IP

1. Safety instructions

1.1. Basic information on safety

Standards/directives AUMA products are designed and manufactured in compliance with recognised

standards and directives.This is certified in a Declaration of Incorporation and an

EC Declaration of Conformity.

The end user or the contractor must ensure that all legal requirements, directives,

guidelines, national regulations and recommendations with respect to assembly,

electrical connection, commissioning and operation are met at the place of installation.

Safetyinstructions/warn-

ings All personnel working with this device must be familiar with the safety and warning

instructions in this manual and observe the instructions given. Safety instructions

and warning signs on the device must be observed to avoid personal injury or property

damage.

Qualification of staff Assembly, electrical connection, commissioning, operation, and maintenance must

be carried out exclusively by suitably qualified personnel having been authorised by

the end user or contractor of the plant only.

Prior to working on this product, the staff must have thoroughly read and understood

these instructions and, furthermore, know and observe officially recognised rules

regarding occupational health and safety.

Commissioning Prior to commissioning, it is important to check that all settings meet the requirements

of the application. Incorrect settings might present a danger to the application, e.g.

cause damage to the valve or the installation.The manufacturer will not be held

liable for any consequential damage. Such risk lies entirely with the user.

Operation Prerequisites for safe and smooth operation:

●Correct transport, proper storage, mounting and installation, as well as careful

commissioning.

●Only operate the device if it is in perfect condition while observing these instruc-

tions.

●Immediately report any faults and damage and allow for corrective measures.

●Observe recognised rules for occupational health and safety.

●Observe the national regulations.

●During operation,thehousingwarms upandsurface temperatures>60°Cmay

occur.To prevent possible burns, we recommend checking the surface temper-

ature using an appropriate thermometer and wearing protective gloves, if re-

quired, prior to working on the device.

Protective measures The end user or the contractor are responsible for implementing required protective

measures on site, such as enclosures, barriers, or personal protective equipment

for the staff.

Maintenance To ensure safe device operation, the maintenance instructions included in this manual

must be observed.

Any device modification requires prior consent of the manufacturer.

1.2. Range of application

AUMA part-turn actuators are designed for the operation of industrial valves, e.g.

butterfly valves and ball valves.

Other applications require explicit (written) confirmation by the manufacturer.

The following applications are not permitted, e.g.:

●Industrial trucks according to EN ISO 3691

●Lifting appliances according to EN 14502

●Passenger lifts according to DIN 15306 and 15309

●Service lifts according to EN 81-1/A1

5

SG 05.1 –SG 12.1/SGR 05.1 –SGR 12.1 Control unit: electronic (MWG)

AC 01.2 Non-Intrusive ModbusTCP/IP Safety instructions

●Escalators

●Continuous duty

●Buried service

●Continuous submersion (observe enclosure protection)

●Potentially explosive areas, with the exception of zone 22

●Radiation exposed areas in nuclear power plants

No liability can be assumed for inappropriate or unintended use.

Observance of these operation instructions is considered as part of the device's

designated use.

Information These operation instructions are only valid for the "clockwise closing" standard

version, i.e. driven shaft turns clockwise to close the valve.

1.3. Applications in Ex zone 22 (option)

Actuators of the indicated series basically meet the requirements for applications in

dust hazardous locations of ZONE 22 in compliance with the ATEX directive 94/9/EC.

The actuators are designed to meet enclosure protection IP67 or IP68 and fulfil the

requirements of EN 50281-1-1:1998 section 6 - Electrical apparatus for use in

presence of combustible dust, requirements for category 3 electrical equipment -

protected by enclosures.

To comply with all requirements of EN 50281-1-1:1998, it is imperative that the

following points are observed:

●Incompliancewith the ATEXdirective 94/9/EC,theactuatorsmustbe equipped

with an additional identification –II3D IP6X T150 °C.

●The maximum surface temperature of the actuators, based on an ambient

temperature of +40 °C in accordance with EN 50281-1-1 section 10.4, is +150

°C.In accordance with section 10.4, an increased dust deposit on the equipment

was not considered for the determination of the maximum surface temperature.

●The correct connection of the thermoswitches or the PTC thermistors as well

as fulfilling the requirements of the duty type and the technical data are pre-

requisites for compliance with the maximum surface temperature of devices.

●The connection plug may only be plugged in or pulled out when device is dis-

connected from the mains.

●The cable glands used also have to meet the requirements of category II3 D

and must at least comply with enclosure protection IP67.

●The actuators must be connected by means of an external ground connection

(accessory part) to the potential compensation or integrated into an earthed

piping system.

●As a general rule, the requirements of EN 50281-1-1 must be respected in dust

hazardous locations.During commissioning, service, and maintenance, special

care as well as qualified and trained personnel are required for the safe operation

of actuators.

1.4. Warnings and notes

The following warnings draw special attention to safety-relevant procedures in these

operation instructions, each marked by the appropriate signal word (DANGER,

WARNING, CAUTION, NOTICE).

Indicates an imminently hazardous situation with a high level of risk. Failure

to observe this warning could result in death or serious injury.

Indicates a potentially hazardous situation with a medium level of risk.Failure

to observe this warning could result in death or serious injury.

6

SG 05.1 –SG 12.1/SGR 05.1 –SGR 12.1 Control unit: electronic (MWG)

Safety instructions AC 01.2 Non-Intrusive Modbus TCP/IP

Indicates a potentially hazardous situation with a low level of risk. Failure to

observe this warning may result in minor or moderate injury.May also be used

with property damage.

Potentially hazardous situation. Failure to observe this warning may result in

property damage. Is not used for personal injury.

Arrangement and typographic structure of the warnings

Type of hazard and respective source!

Potential consequence(s) in case of non-observance (option)

→Measures to avoid the danger

→Further measure(s)

Safety alert symbol warns of a potential personal injury hazard.

The signal word (here: DANGER) indicates the level of hazard.

1.5. References and symbols

The following references and symbols are used in these instructions:

Information The term Information preceding the text indicates important notes and information.

Symbol for CLOSED (valve closed)

Symbol for OPEN (valve open)

Important information before the next step.This symbol indicates what is required

for the next step or what has to be prepared or observed.

Via the menu to parameter

Describes the path within the menu to the parameter. By using the push buttons of

the local controls you may quickly find the desired parameter in the display.

< > Reference to other sections

Terms in brackets shown above refer to other sections of the document which provide

further information on this topic.These terms are either listed in the index, a heading

or in the table of contents and may quickly be found.

7

SG 05.1 –SG 12.1/SGR 05.1 –SGR 12.1 Control unit: electronic (MWG)

AC 01.2 Non-Intrusive ModbusTCP/IP Safety instructions

2. Identification

2.1. Name plate

Each device component (actuator, controls, motor) is equipped with a name plate.

Actuator name plate

Figure 1: Actuator name plate (example)

[1] Name of manufacturer

[2] Address of manufacturer

[3] Type designation

[4] Order number

[5] Actuator serial number

[6] Operating time

[7] Torque range in direction CLOSE

[8] Torque range in direction OPEN

[9] Type of lubricant

[10] Enclosure protection

[11] Permissible ambient temperature

[12] Can be assigned as an option upon customer request

[13] Can be assigned as an option upon customer request

[14] Data Matrix code

Actuator controls name plate

Descriptions

Type designation Figure 2:Type designation (example)

1. Type and size of actuator

2. Flange size

Type and size These instructions apply to the following devices types and sizes:

SG 05.1, 07.1, 10.1, 12.1 = Part-turn actuators for open-close duty

SGR05.1, 07.1, 10.1, 12.1 = Part-turn actuators for modulating duty

AC 01.2 = AUMATIC actuator controls

Order number The product can be identified using this number and the technical data as well as

order-related data pertaining to the device can be compiled.

Please always state this number for any product inquiries.

On the Internet at http://www.auma.com, we offer a service allowing authorised

users to download order-related documents such as wiring diagrams and technical

8

SG 05.1 –SG 12.1/SGR 05.1 –SGR 12.1 Control unit: electronic (MWG)

Identification AC 01.2 Non-Intrusive ModbusTCP/IP

data (both in German and English), inspection certificates and the operation

instructions when entering the order number.

Actuator serial number Table 1: Description of serial number (with example)

NS123451405

1st + 2nd position: Assembly in week

Week 0505

3rd + 4th position:Year of manufacture

Year of manufacture:201414

All other positions Internal number for unambiguous product identificationNS12345

Actuator terminal plan 9 thposition after TPA: Position transmitter version

I, Q = MWG (magnetic limit and torque transmitter)

AUMA power class for

switchgear The switchgear used in the actuator controls (reversing contactors/thyristors) are

classified according to AUMA power classes (e.g.A1, B1, ....).The power class

defines the max. permissible rated power (of the motor) the switchgear has been

designed for.The rated power (nominal power) of the actuator motor is indicated in

kW on the motor name plate.For the assignment of the AUMA power classes to the

nominal power of the motor types, refer to the separate electrical data sheets.

For switchgear without assignment to any power classes, the actuator controls name

plate does not indicate the power class but the max. rated power in kW.

Data Matrix code When registered as authorised user, you may use the AUMA Support App to scan

the Data Matrix code and directly access the order-related product documents without

having to enter order number of serial number.

Figure 3: Link to the App store:

Control Table 2: Control examples (indications on controls name plate)

DescriptionInput signal Control via ModbusTCP/IP interfaceModbusTCP/IP

2.2. Short description

Part-turn actuator Definition in compliance with EN ISO 5211:

A part-turn actuator is an actuator which transmits a torque to the valve for less than

one full revolution.It need not be capable of withstanding thrust.

AUMA part-turn actuators are driven by an electric motor. A handwheel is provided

for manual operation.Switching off in end positions may be either by limit or torque

seating. Controls are required to operate or process the actuator signals.

Actuator controls TheAUMATICactuatorcontrolsare used to operateAUMAactuatorsandaresupplied

ready for use.The controls may be mounted directly to the actuator or separately

on a wall bracket.

Local con-

trols/AUMA CDT When set to local control, it is possible to

●operate the actuator via the local controls (push buttons and display) and perform

settings (contents of these instructions).

●read in or out data or modify and save settings via the AUMA CDT software

(accessories), using a computer (laptop or PC).The connection between com-

puter and AUMATIC is wireless via Bluetooth interface (not included in these

instructions).

9

SG 05.1 –SG 12.1/SGR 05.1 –SGR 12.1 Control unit: electronic (MWG)

AC 01.2 Non-Intrusive ModbusTCP/IP Identification

Intrusive - Non-Intrusive ●Intrusive version (control unit: electromechanical):

Limit and torque setting is performed via switches in the actuator.

●Non-Intrusive version (control unit: electronic):

Limit and torque setting is performed via the controls, actuator and controls

housings do not have to be opened.For this purpose, the actuator is equipped

with an MWG (magnetic limit and torque transmitter), also supplying analogue

torque feedback signals/torque indication and analogue position feedback sig-

nals/position indication.

10

SG 05.1 –SG 12.1/SGR 05.1 –SGR 12.1 Control unit: electronic (MWG)

Identification AC 01.2 Non-Intrusive ModbusTCP/IP

3. Transport, storage and packaging

3.1. Transport

For transport to place of installation, use sturdy packaging.

Hovering load!

Risk of death or serious injury.

→Do NOT stand below hovering load.

→Attach ropes or hooks for the purpose of lifting by hoist only to housing and NOT

to handwheel.

→Actuators mounted on valves: Attach ropes or hooks for the purpose of lifting

by hoist to valve and NOT to actuator.

→Actuatorsmountedtogearboxes:Attachropesorhooksforthepurposeoflifting

by hoist only to the gearbox using eyebolts and NOT to the actuator.

→Actuators mounted to controls: Attach ropes or hooks for the purpose of lifting

by hoist only to the actuator and NOT to the controls.

3.2. Storage

Danger of corrosion due to inappropriate storage!

→Store in a well-ventilated, dry room.

→Protect against floor dampness by storage on a shelf or on a wooden pallet.

→Cover to protect against dust and dirt.

→Apply suitable corrosion protection agent to uncoated surfaces.

Damage on display caused by temperatures below permissible level!

→The AUMATIC actuator controls must NOT be stored below –30 °C.

Long-term storage If the device must be stored for a long period (more than 6 months) the following

points must be observed in addition:

1. Prior to storage:

Protect uncoated surfaces, in particular the output drive parts and mounting

surface, with long-term corrosion protection agent.

2. At an interval of approx.6 months:

Check for corrosion.If first signs of corrosion show, apply new corrosion protec-

tion.

3.3. Packaging

Our products are protected by special packaging for transport when leaving the

factory.The packaging consists of environmentally friendly materials which can easily

be separated and recycled.We use the following packaging materials: wood,

cardboard, paper, and PE foil. For the disposal of the packaging material, we

recommend recycling and collection centres.

11

SG 05.1 –SG 12.1/SGR 05.1 –SGR 12.1 Control unit: electronic (MWG)

AC 01.2 Non-Intrusive ModbusTCP/IP Transport, storage and packaging

4. Assembly

4.1. Mounting position

AUMA actuators and actuator controls can be operated without restriction in any

mounting position.

4.2. Ball handle: fit to handwheel

To avoid damage during transport, the ball handle is fitted at the rear of the

handwheel.

Prior to commissioning, mount the ball handle into correct position:

1. Remove cap nut [1] and pull out ball handle [2].

2. Insert ball handle [2] in correct position and fasten with cap nut [1].

3. After ball handle fitting, remove label from handwheel.

4.3. Part-turn actuator to valve: mount

Danger of corrosion due to damage to paint finish and condensation!

→Touch up damage to paint finish after work on the device.

→After mounting, connect the device immediately to electrical mains to ensure

that heater prevents condensation.

12

SG 05.1 –SG 12.1/SGR 05.1 –SGR 12.1 Control unit: electronic (MWG)

Assembly AC 01.2 Non-Intrusive Modbus TCP/IP

4.3.1. Coupling

Figure 4: Coupling fitting dimensions

[1] Coupling

[2] Valve shaft

[3] Grub screw

[4] Screw

Table 3: Coupling fitting dimensions

Z max [mm]Y max [mm]X max [mm]Type,size - output mounting flange 60–9SG/SGR 05.1-F05 60–9SG/SGR 05.1-F07 60–9SG/SGR 07.1-F07 75–24SG/SGR 07.1-F10 77915SG/SGR 10.1-F10 97–32SG/SGR 10.1-F12 100–25SG/SGR 12.1-F12 120–45SG/SGR 12.1-F14 132–57SG/SGR 12.1-F16

1. Use handwheel to drive actuator to mechanical end stop.

Information: Mount valve and actuator in the same end position.

- With butterfly valves: recommended mounting position is end position

CLOSED.

- With ball valves: recommended mounting position is end position OPEN.

2. Thoroughly degrease mounting faces of the output mounting flanges.

3. Apply a small quantity of grease to the valve shaft [2].

4. Place coupling [1] onto valve shaft [2] and secure against axial slipping by using

a grub screw, a circlip or a screw.Thereby, ensure that dimensions X,Y or Z

are observed (refer to figure and table <Coupling fitting dimensions>).

5. Apply non-acidic grease at splines of coupling.

6. Fit actuator.

Information: Ensure that the spigot (if provided) fits uniformly in the recess

and that the flanges are in complete contact.

7. If flange bores do not match thread:

7.1 Slightly rotate handwheel until bores line up.

7.2 If required, shift actuator position by one tooth on the coupling.

13

SG 05.1 –SG 12.1/SGR 05.1 –SGR 12.1 Control unit: electronic (MWG)

AC 01.2 Non-Intrusive ModbusTCP/IP Assembly

8. Fasten actuator with screws [4].

Information:We recommend glueing the screws using sealing material to avoid

contact corrosion.

→Fasten screws [4] crosswise with a torque according to table:

Table 4: Tightening torques for screws

Tightening torqueTA[Nm]Screws

Thread Strength class 8.8

11M6 25M8 51M10 87M12

4.4. Mounting positions of local controls

The mounting position of the local controls is selected according to the order.If, after

mounting the actuator to the valve or the gearbox on site, the local controls are in

an unfavourable position, the mounting position can be changed at a later date.Four

mounting positions are possible.

Figure 5: Mounting positions A-2 and B-2

Figure 6: Mounting positions C-2 and D-2

4.4.1. Mounting positions: modify

Hazardous voltage!

Risk of electric shock.

→Disconnect device from the mains before opening.

14

SG 05.1 –SG 12.1/SGR 05.1 –SGR 12.1 Control unit: electronic (MWG)

Assembly AC 01.2 Non-Intrusive Modbus TCP/IP

Electrostatic discharge ESD!

Risk of damage to electronic components.

→Earth both operators and devices.

1. Loosen screws and remove the local controls.

2. Check whether O-ring is in good condition, correctly insert O-ring.

3. Turn local controls into new position and re-place.

Cable damage due to twisting or pinching!

Risk of functional failures.

→Turn local controls by a maximum of 180°.

→Carefully assemble local controls to avoid pinching the cables.

4. Fasten screws evenly crosswise.

15

SG 05.1 –SG 12.1/SGR 05.1 –SGR 12.1 Control unit: electronic (MWG)

AC 01.2 Non-Intrusive ModbusTCP/IP Assembly

5. Electrical connection

5.1. Basic information

Danger due to incorrect electrical connection

Failure to observe this warning can result in death, serious injury, or property damage.

→The electrical connection must be carried out exclusively by suitably qualified

personnel.

→Prior to connection, observe basic information contained in this chapter.

→After connection but prior to applying the voltage, observe the <Commissioning>

and <Test run> chapters.

Wiring diagram/terminal

plan The pertaining wiring diagram/terminal plan (both in German and English) is attached

to the device in a weather-proof bag, together with these operation instructions.It

can also be requested from AUMA (state order number, refer to name plate) or

downloaded directly from the Internet (http://www.auma.com).

Permissible networks

(supply networks) The controls (actuators) are suitable for for use in TN and TT networks with directly

earthed star point and a maximum voltage of 690 V AC. Use in IT networks is

permitted while observing the respective <Protection on site> for for maiximum supply

voltages of 600V AC.

Protection on site For short-circuit protection and for disconnecting the actuator from the mains, fuses

and disconnect switches have to be provided by the customer.

The current values for respective sizing is derived from the current consumption of

themotor (referto electrical data sheet) plus thecurrent consumption of the controls.

Table 5: Current consumption controls

Max. current consumptionMains voltage –30 %±10 %Permissible variation of the mains voltage 1,200 mA750 mA100 to 120 V AC 750 mA400 mA208 to 240 V AC 400 mA250 mA380 to 500 V AC 400 mA200 mA515 to 690 V AC

Table 6: Maximum permissible protection

Max. protectionRated powerSwitchgear 16 A (gL/gG)up to 1.5 kWReversing contactor A1 16 A (g/R) I²t<1,500A²sup to 1.5 kWThyristor B1

If controls are mounted separately from actuator (controls on wall bracket):Consider

length and cross section of connecting cable when defining the protection required.

Use appropriate insulation monitors when working in power installations, for example

an insulation monitor measuring the pulse code.

Power supply for the

controls (electronics) In case of external supply of the controls (electronics):The external power supply

must have a reinforced insulation against the mains voltage in accordance with IEC

61010-1 and may only be supplied by a circuit limited to 150 VA in accordance with

IEC 61010-1.

Safety standards All externally connected devices shall comply with the relevant safety standards.

Cable installation in ac-

cordance with EMC Signal and bus cables are susceptible to interference.

Motor cables are interference sources.

●Lay cables being susceptible to interference or sources of interference at the

highest possible distance from each other.

16

SG 05.1 –SG 12.1/SGR 05.1 –SGR 12.1 Control unit: electronic (MWG)

Electrical connection AC 01.2 Non-Intrusive ModbusTCP/IP

●The interference immunity of signal and bus cables increases if the cables are

laid close to the earth potential.

●If possible, avoid laying long cables and make sure that they are installed in

areas being subject to low interference.

●Avoid long parallel paths with cables being either susceptible to interference or

interference sources.

●For the connection of remote position transmitters, screened cables must be

used.

Type of current, mains

voltage and mains fre-

quency

Type of current, mains voltage and mains frequency must match the data on the

motor name plate.

Figure 7: Motor name plate (example)

[1] Type of current

[2] Mains voltage

[3] Mains frequency (for 3-ph and 1-ph AC motors)

Connecting cables ●For device insulation, appropriate (voltage-proof) cables must be used.Specify

cables for the highest occurring rated voltage.

●Use connecting cable with appropriate minimum rated temperature.

●For connecting cables exposed to UV radiation (outdoor installation), use UV

resistant cables.

Bus cables Only use cables for Modbus TCP/IP connection complying with category 5 (Cat. 5)

or category 6 (Cat.6).

Recommendation: Use of Cat. 6AEthernet cables (RJ45 connector supplied within

the electrical connection for field assembly is suitable for Cat. 6Acables).

Prior to installation, please note:

●Maximum cable length: 100 m.

●Install data cables at a distance of minimum 20 cm to other cables.

●If possible, data cables should be laid in a separate, conductive, and earthed

cable tray.

●Make sure to avoid potential differences between the individual devices on the

bus (perform an equipotential earth bonding).

5.2. Connection with AUMA plug/socket connector

Cross sections AUMA plug/socket connector:

●Power terminals (U1, V1, W1, U2, V2, W2): max. 6 mm² flexible/10 mm² solid

●PE connection : max. 6 mm² flexible/10 mm² solid

●Control contacts (1 to 50): max. 2.5 mm²

5.2.1. Terminal compartment: open

Information The bus connection can be separately accessed from the mains connection (refer

to <Bus terminal compartment: open>.

17

SG 05.1 –SG 12.1/SGR 05.1 –SGR 12.1 Control unit: electronic (MWG)

AC 01.2 Non-Intrusive ModbusTCP/IP Electrical connection

Figure 8: Mains connection AUMA plug/socket connector SFH

[1] Connection housing

[2] Screws for frame

[3] O-ring

[4] Screws for socket carrier

[5] Socket carrier

[6] Cable entry for mains

[7] Blanking plugs

[8] Cable gland (not included in delivery)

Hazardous voltage!

Risk of electric shock.

→Disconnect device from the mains before opening.

1. Loosen screws [2] and remove connection housing [1].

2. Loosen screws [4] and remove socket carrier [5] from connection housing [1].

3. Insert cable glands [8] suitable for connecting cables.

➥The enclosure protection IP…stated on the name plate is only ensured if suit-

able cable glands are used.

Figure 9: Example: Name plate for enclosure protection IP68

4. Seal unused cable entries [6] with suitable blanking plugs [7].

5. Insert the cables into the cable glands [8].

5.2.2. Cable connection

✔Observe permissible cross sections.

Danger of corrosion: Damage due to condensation!

→After mounting, commission the device immediately to ensure that heater min-

imises condensation.

1. Remove cable sheathing.

2. Strip wires.

3. For flexible cables: Use end sleeves according to DIN 46228.

18

SG 05.1 –SG 12.1/SGR 05.1 –SGR 12.1 Control unit: electronic (MWG)

Electrical connection AC 01.2 Non-Intrusive ModbusTCP/IP

4. Connect cables according to order-related wiring diagram.

In case of a fault: Hazardous voltage while protective earth conductor is NOT

connected!

Risk of electric shock.

→Connect all protective earth conductors.

→Connect PE connection to external protective earth conductor of connecting

cables.

→Start running the device only after having connected the protective earth con-

ductor.

5. Tighten PE conductors firmly to PE connection using ring lugs (flexible cables)

or loops (rigid cables).

Figure 10: PE connection

[1] Socket carrier

[2] Screw

[3] Washer

[4] Lock washer

[5] Protective earth with ring lugs/loops

[6] PE connection, symbol:

Information Some actuators are equipped with an additional motor heater.The motor heater

minimises condensation within the motor.

19

SG 05.1 –SG 12.1/SGR 05.1 –SGR 12.1 Control unit: electronic (MWG)

AC 01.2 Non-Intrusive ModbusTCP/IP Electrical connection

5.2.3. Terminal compartment: close

Figure 11: AUMA plug/socket connector SFH

[1] Connection housing

[2] Screws for frame

[3] O-ring

[4] Screws for socket carrier

[5] Socket carrier

[6] Cable entry for mains

[7] Blanking plugs

[8] Cable gland (not included in delivery)

Short-circuit due to pinching of cables!

Risk of electric shock and functional failures.

→Carefully fit socket carrier to avoid pinching the cables.

1. Insert the socket carrier [5] into the connection housing [1] and fasten with

screws [4].

2. Clean sealing faces of connection housing [1] and housing.

3. Check whether O-ring [3] is in good condition, replace if damaged.

4. Apply a thin film of non-acidic grease (e.g.petroleum jelly) to the O-ring and

insert it correctly.

5. Fit connection housing [1] and fasten screws [2] evenly crosswise.

6. Fasten cable glands [8] applying the specified torque to ensure the required

enclosure protection.

5.2.4. Bus terminal compartment: open

For connecting Industrial Ethernet cables, the AUMA plug/socket connector is used

as field-assembly Ethernet connector.When removing the cover [1], the connection

board is easily accessible.

20

SG 05.1 –SG 12.1/SGR 05.1 –SGR 12.1 Control unit: electronic (MWG)

Electrical connection AC 01.2 Non-Intrusive ModbusTCP/IP

This manual suits for next models

3

Table of contents

Other AUMA Controllers manuals

AUMA

AUMA SVCR 05.1 User manual

AUMA

AUMA SAEx 25.1 User manual

AUMA

AUMA GST 10.1 Administrator Guide

AUMA

AUMA SGM 04.1 User manual

AUMA

AUMA SAEx 07.2 User manual

AUMA

AUMA SAN 07.1 User manual

AUMA

AUMA SGExC 05.1 User manual

AUMA

AUMA SAEx 07.2 User manual

AUMA

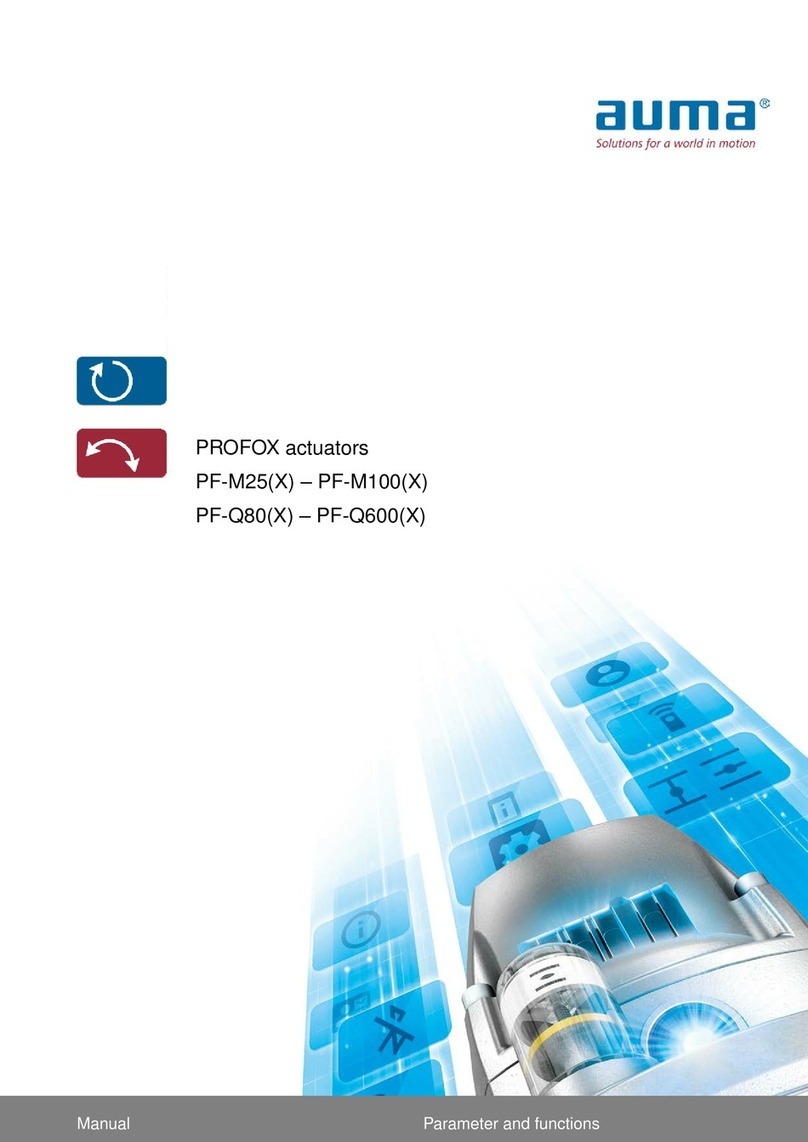

AUMA PROFOX PF-M25X User manual

AUMA

AUMA AUMATIC ACExC User manual