AUMA AUMATIC ACExC User manual

Table of contents

Other AUMA Controllers manuals

AUMA

AUMA SAI 6 User manual

AUMA

AUMA TIGRON TR-M30X User manual

AUMA

AUMA SAM Ex 07.1 User manual

AUMA

AUMA SQVEx 05.2 User manual

AUMA

AUMA SAEx 07.2-UW User manual

AUMA

AUMA SAEx 07.2 User manual

AUMA

AUMA SAEx 07.2 User manual

AUMA

AUMA SQ 14.2 User manual

AUMA

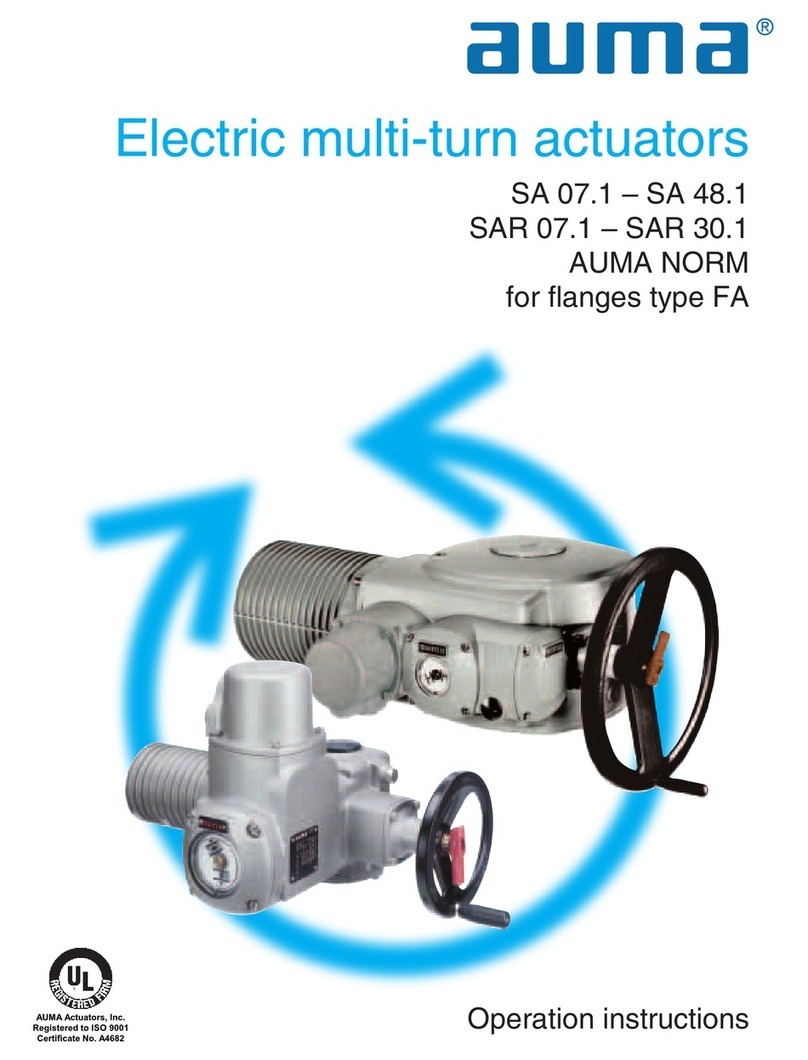

AUMA SA 25.1 User manual

AUMA

AUMA AUMATIC AC 01.2 User manual

AUMA

AUMA SA 07.2 User manual

AUMA

AUMA SQEx 05.2 User manual

AUMA

AUMA FQM 05.1 User manual

AUMA

AUMA PROFOX PF-M100X User manual

AUMA

AUMA MEC 03.1 User manual

AUMA

AUMA SQEx 05.2 User manual

AUMA

AUMA PROFOX PF-M25X User manual

AUMA

AUMA PROFOX PF-M25X User manual

AUMA

AUMA PROFOX PF-M25 User manual

AUMA

AUMA SA 16.2 User manual

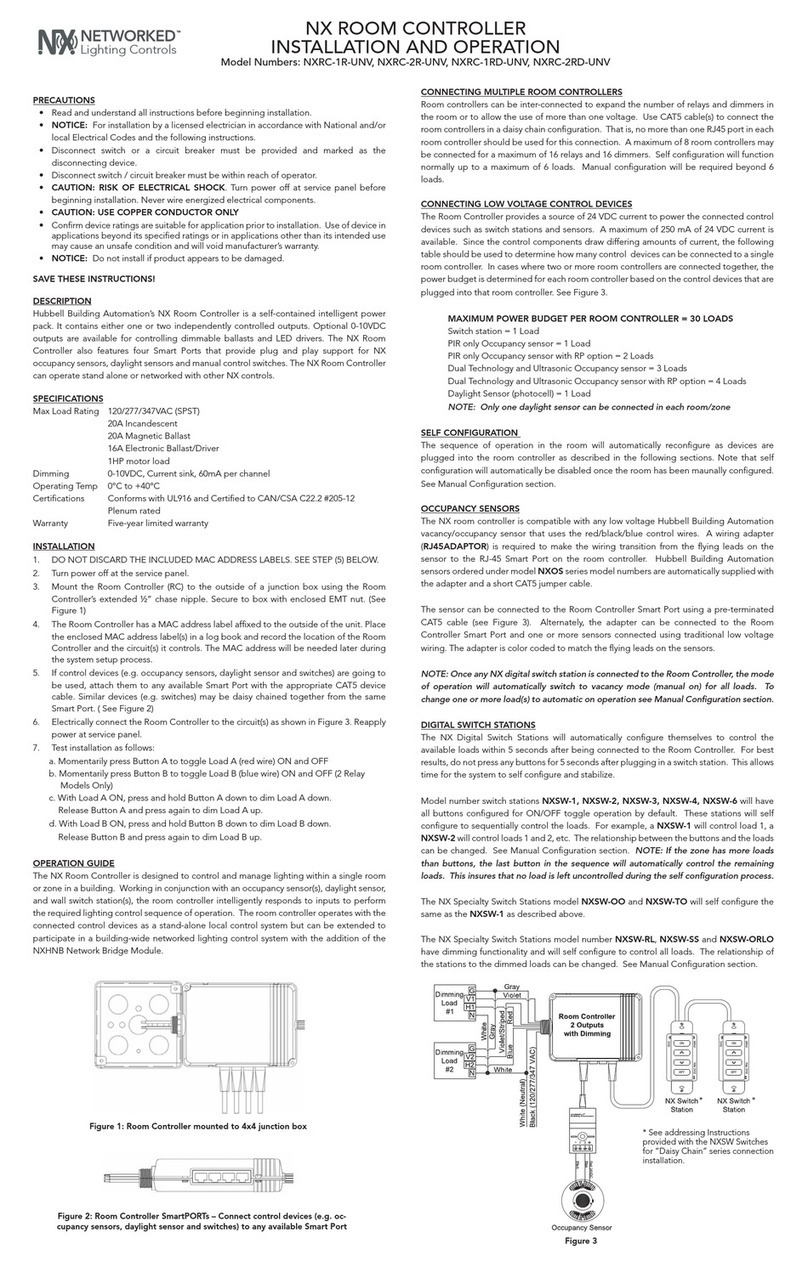

Popular Controllers manuals by other brands

Chip-Rail

Chip-Rail CR6853 manual

Alpha Technologies

Alpha Technologies Cordex CXC Series Removal Procedure

oventrop

oventrop Aktor M ST L Modbus operating instructions

EUROSTER

EUROSTER 1100K user manual

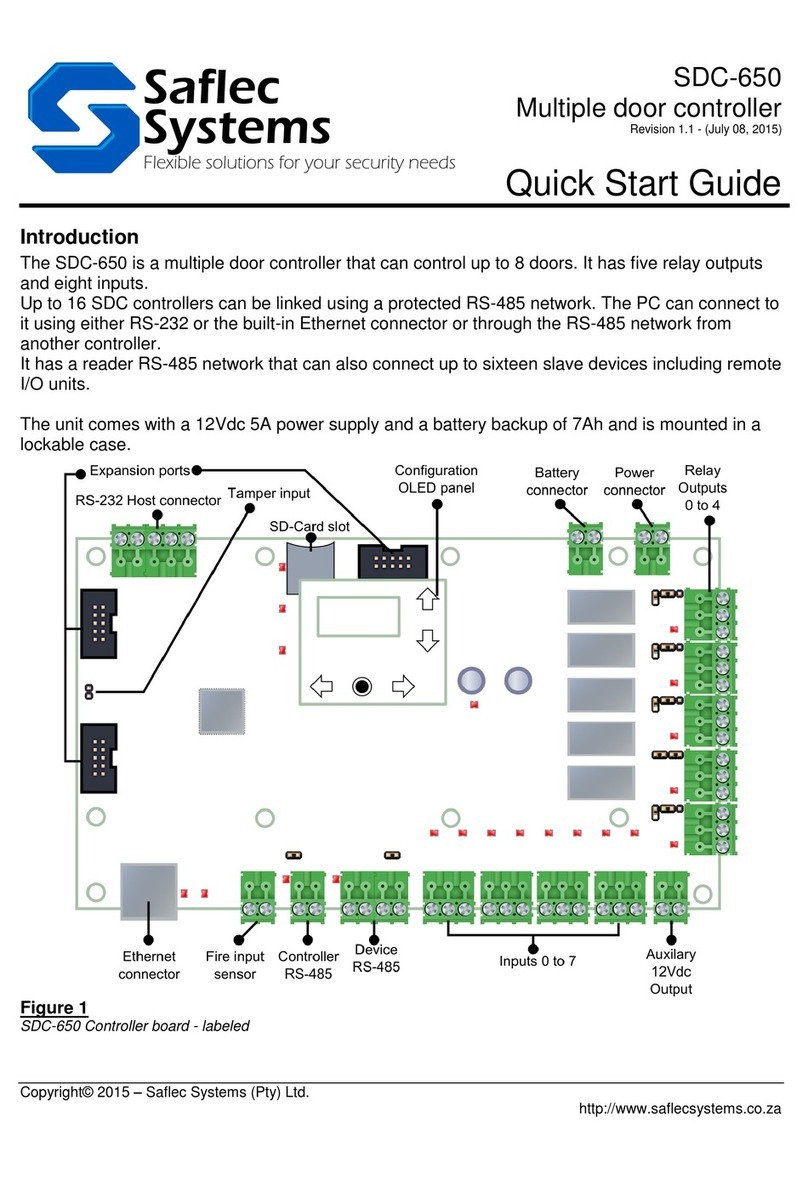

Saflec Systems

Saflec Systems SDC-650 quick start guide

Avigilon

Avigilon AC-HID-LSP-ACMEC-KIT8 installation guide