TABLE OF CONTENTS

Important Notices......................................................................................................................................................6

Important Safety Instructions....................................................................................................................................7

Restrictions and Warnings........................................................................................................................................8

Entrapment Prevention.............................................................................................................................................9

Glossary ..................................................................................................................................................................10

Section 1 – Installation

1.1 Specifications ...........................................................................................................................................11

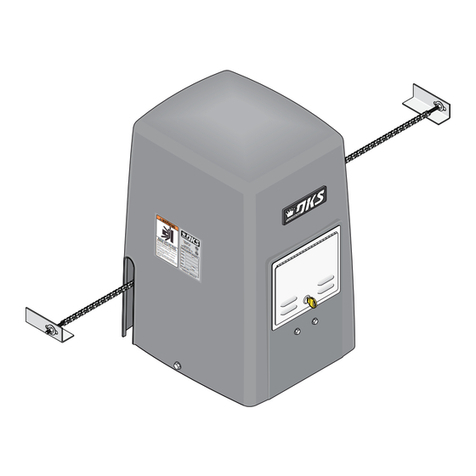

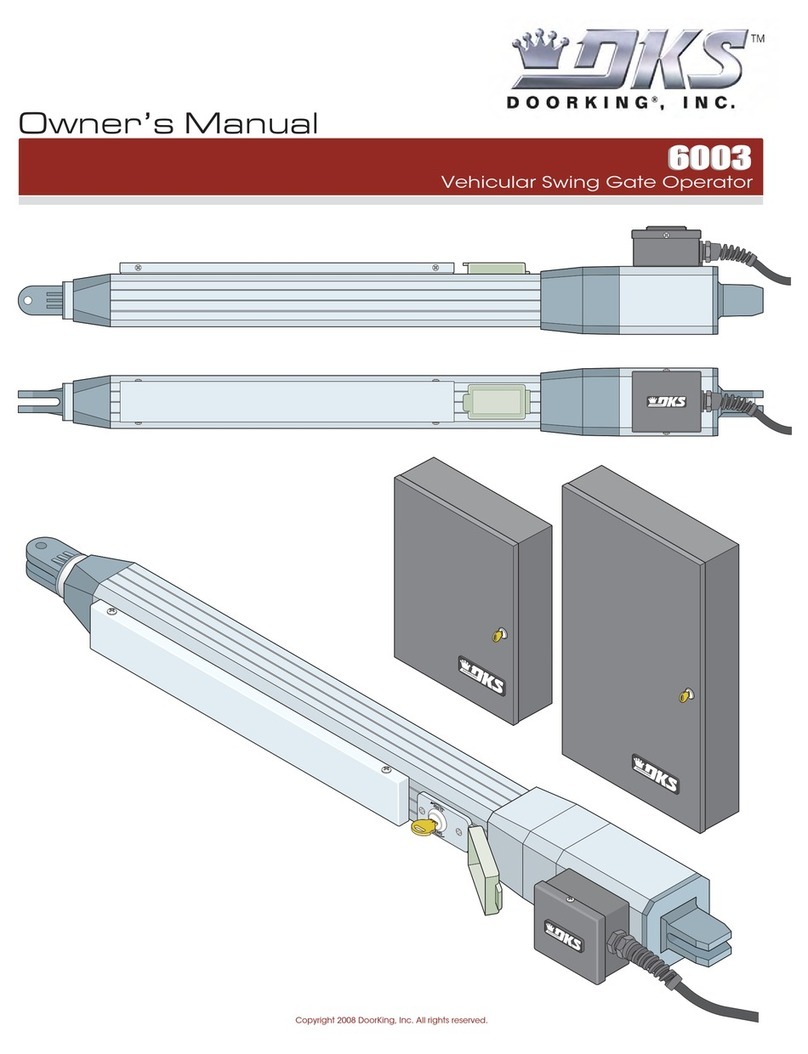

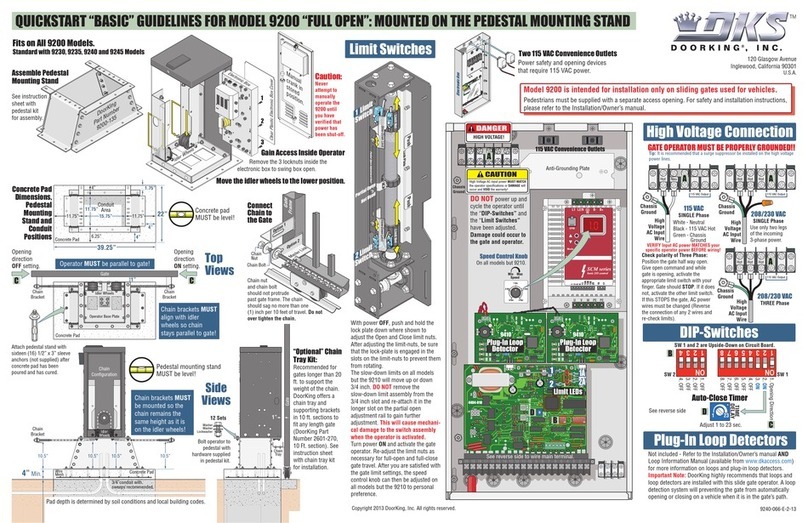

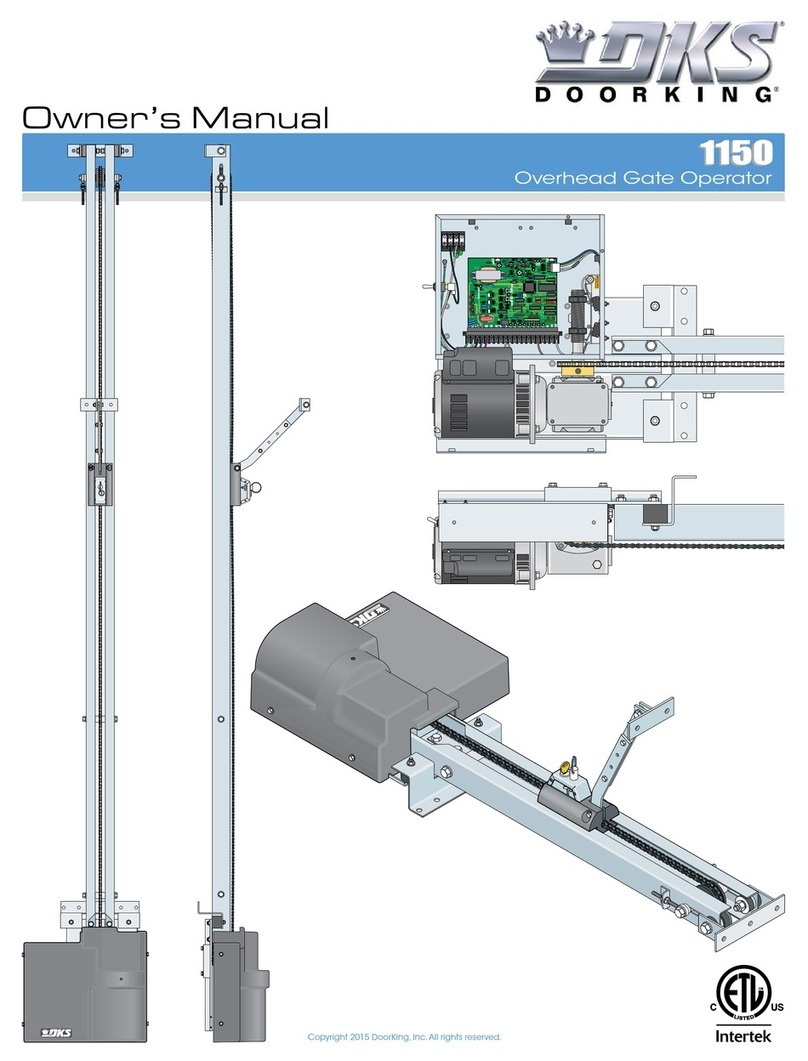

1.2 Mounting Options .....................................................................................................................................12

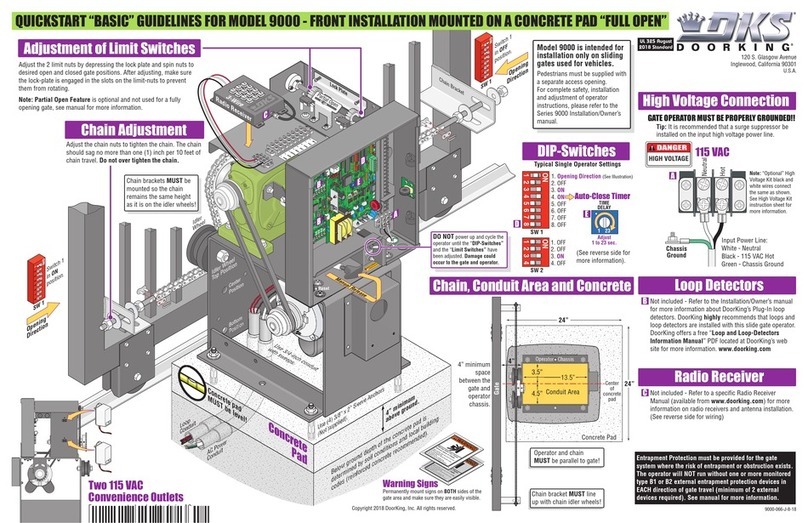

1.3 Chain Guide Adjustment...........................................................................................................................13

1.4 Pad Mount Installation..............................................................................................................................14

1.5 Mounting Stand Installation......................................................................................................................16

1.6 Chain Installation......................................................................................................................................18

1.7 Warning Sign Installation..........................................................................................................................20

Section 2 – Wiring

Conduits ...................................................................................................................................................21

2.1 High Voltage Connections........................................................................................................................22

2.2 Control Wiring...........................................................................................................................................23

2.3 Secondary Entrapment Protection Device Wiring

2.3.1 Non-Contact Sensors...............................................................................................................24

2.3.2 Contact Sensors.......................................................................................................................25

2.4 Loop Detector Wiring................................................................................................................................26

2.5 Gate Tracker™ Connections....................................................................................................................27

2.6 Auxiliary Devices

2.6.1 Alarm Reset Switch..................................................................................................................28

2.6.2 Auxiliary Stop Switch................................................................................................................28

2.7 Master / Slave Wiring

2.7.1 Operator Interface....................................................................................................................29

2.7.2 Secondary Entrapment Protection Device Wiring....................................................................30

2.8 Terminal Identification and Description

2.8.1 Main Terminals.........................................................................................................................31

2.8.2 Limit Switch Connector.............................................................................................................32

2.8.3 Reversing Device Connector....................................................................................................32

Section 3 – Adjustments

3.1 Circuit Board Adjustments........................................................................................................................33

3.2 Switch Settings.........................................................................................................................................34

3.2.1 SW 1 (Right Switch) Description and Function ........................................................................35

3.2.2 SW 2 (Left Switch) Description and Function...........................................................................35

3.3 Limit Switch Adjustment ...........................................................................................................................36

3.4 Inherent Reverse Adjustment...................................................................................................................37

3.5 Current Sensor Wire Loops......................................................................................................................38

4